Search the Community

Showing results for 'source objects disappear'.

-

Sry i said it should be 100 each day, that was just a mean which i dont want to use. I would like the rate table to make 100 day one, 98 day two and 102 day tree, and a mean cant be used, cause i need to model the reality in the process. And as mentioned before, should the source make all the entities from the table at ones (when the workday starts).

-

There are several ways of doing this. One way would be to write out (to a external spreadsheet OR an output table in Simio, depending on your Simio licensing) the exit time for each entity (and perhaps other entity specific property information, such as priority, etc. Then, you could use that same file (or copy of the output table results) as an input file for your second model. Alternatively, you could place each of these 'models' into a third 'model' in the project and connect them. This would require several changes - the first model (with the Sink output) would require the model to simply have a Transfer Node output - and then right-click the Transfer Node and select 'Bind to New External Output Node'. This will allow that model to then become an object in another model. The second model would also need to be revised to include a Basic Node input (instead of the Source input) where you would right-click on the Basic Node and select 'Bind to New External Input Node'. Finally, you would select New Model from the Project Home ribbon to start building your 'combined' model. On the left side of Simio, instead of selecting from the Standard Library of objects, you would select your Model1 and Model2 objects from the Project Library at the bottom. The TransferNode of Model1 can then be connected to the BasicNode of Model2 with a path. That is the basic concept - you may wish to look at SimBits under the category 'Building New Objects / Hierarchy' for more information.

-

Hello everyone, I am a master's student in operations management trying my hand at Simio for the first time. I want to develop a model that simulates the delays incurred by variable supply lead times which may lead to stock-outs at a manufacturing plant. I would like to model demand so that each entity generated by a single source module corresponds to a sales order. Each order should have a probability to include orders for several specific product types (since sales orders may contain orders for different product types). As such, entities should have an arrival rate which corresponds to the arrival rate of orders at the company, and the product mix of each order should reference the probability of a given product type being included in that order (i.e. product A has 25% probability to be included, product B has 50%, etc.). Is it possible to do this? I would also like for each product type to be associated with a specific BOM. I.e., a server module should reference each entity instance to consume material as defined by the BOM’s of the products stated by the entity instance. I have defined each component as material elements and defined a BOM for each finished product that references the materials needed. However, in the server module I am only able to input a specific type of finished product as material requirements... Your help is greatly appreciated!

-

Hello, In my simulation model, I have an object which contains a source and 3 transporters (Vehicles). I added 3 such objects in my main model. How should I specify transporter name in the output node of the object in the main model for the model to run well? I tried setting up a table and searching the row for the vehicle name, seems to give errors. Thank You.

-

Visualize Utilization in Facility Window or Dashboard Reports I have a source – several servers – sink model. It’s a model of an assembly line production meaning that the entity cannot continue to Server 2 if Server 2 is occupied. The servers have different production times and I want to compare the different utilizations of the servers. I did this over the experiment window and the expression Server1.ResourceState.PercentTime(1) . In a next step I want to visualize these utilizations next each other with something like a bar chart. I came up with two possible ways of doing so but both didn’t work. In the facility window with the animation tools like the linear gauge. The problem here is probably that the expression “PercentTime” has no reference to what the overall time is, while the model is running, and therefore the gauge shows constant 100% the whole time. Or in the experiment window in the dashboard reports which doesn’t have percent time as a response. Is there any other way of visualizing the utilization?

-

Hi Not sure if this post is in the appropriate place, but let me ask my question. I got Simio 9 - Academic license. I made a simple Source-Server-Sink model connected with the Path objects. However - in the Navigation window I don't see these objects. I see only the ModelEntity, the Model and the Experiment folder with the experiment I created. Reading through the book "Simio and Simulation: modelling, analysis, applications" it says the if I need to add properties to an object, I need to select that object in the Navigation window (pp.132-133)...but as I said - I dont see my objects... Am I doing something wrong?

-

Hi - Let's say I have two objects Object1 and Object2 in my project. In a model I have one instance of Object1 as Object1_01 and another instance of Object2 as Object2_01. Is there any way I can access the variables values of Object1_01 from Object2_01. I tried to define an ObjectInstanceProperty in Object2 and set it to Object1_01 for Object2_01 instance but its not working. Any ideas that can solve this issue? Thanks Zaki

-

Check my attached model. I'm not sure if this was the best approach, but it works. I created two events: One is triggered 100 times to executes another process 100 times. Each process will run its own Delay step and fire the second event to trigger the source. Let me know if this isn't what you need. 100 entities.spfx

-

I'd recommend you read the Create help documentation. It provides some detailed info on how the step functions. It also mentions the CONWIP and DynamicallyCreatingVehicles SimBits for examples using the Create step. For my second suggestion, yes this can be done with variables. What I would do is create a new Source and Sink that create entities that just tells the model to perform logic. And since this is just a regular sink, you can specify when to create those entities however you desire (by arrival table, randomly.....).

-

Hello, everyone! is it possible to use a Look Up Table and Rate Table to the same time in the source in SIMIO? Let me know if you know a way to do that, please. Thanks for your help!

-

Hi Alb, What I would suggest is for you to use process logic to create your order entities rather than a source. The Create process step can be used to create entities just like a source, and you can put in logic that looks up the percentages. I would also suggest you use timers or perhaps a source to just create trigger entities that tells your model when to fire events (perform logic). For example, in your above case, perhaps have a source that creates an entity at 7pm, 7:30pm, and 8pm. These entities then trigger the process to be executed that decides the percentage of entities to be created at each time.

-

Thanks, Jason for your answer and your interest. The situation is the following: I have to receive an order with set amount of entities that must be completed in a specific date and hour, but I need to distribute that order in some intervals before the deadline. It means, If I have an order with 15 entities for November 3 at 8 pm, I could receive 10% of the entities at 7 pm, 50% at 7:30 pm and 40% at 8 pm. So, I have the idea to do an arrival table for the schedule of the order and a rate table for the percentages that I need. And I want to know that is possible in SIMIO to put both in the source? Thanks for your help!

-

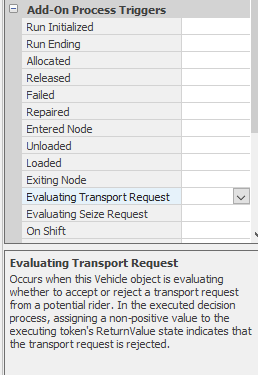

Hello, I would suggest you look into creating a ForkLift EvaluatingTransportRequest add on process. This will allow you to control what requests the Forklift is accepting or rejecting. Additionally, it may be wise to use two separate Forklift objects (rather 2 instances of the same forklift). This may be easier as you could designate one Forklift to be the secondary that moves to Dock 2 first when a truck arrives. Jason

-

I just want to make a label that outputs a list string, given a list state number. Similar to the Busy, Transporting, Failed list state types objects have. E.G. Have a label over a vehicle, that says "Transporting" while it is moving, "Failed" when it has failed... etc. The only way I can see how to do it, would be to make my own table, and do a search in it using the resource state number. Will post back if I find it before someone else posts.

-

Petr, I tried out your updated version, as I had used Glen's original in the past. There is definitely a speed boost with this version. My "test" import file is the 25 X 25 grid attached (625 BasicNode and 1200 Path Objects.) On my old laptop this imports in about 60 seconds. I noticed that the progress bar works great for the Objects sheet, however it does not appear to update when the Links are imported. The progress remains at 0 while the links are imported, though the routine works and I see the dialogue at the end with no errors. The nodes only take about 10 seconds to import and the links constitute the remaining ~ 50 seconds. I tried turning off visibility of the links/arrows, but this made no difference. I haven’t tried vertices yet. Also, note that I had to re-build the add-in in Visual Studio, as I seem to have an issue with adding add-in .dll's from an outside source to my ..\SimioUserExtensions directory. Hopefully I did not break the application in the process. Thank you very much - this is very useful! 25 X 25 Grid Import.xlsx

-

Hello, I ran into a similar problem and am finding it difficult to construct a match expression for the combiner. I want to model a gear assembly GA(parent node) with gear g1, g2, and g3 (all connected to member node). But, there is some upstream variation affecting mating of gears. So, business process is binning them say g1-bin1 through g1-bin5. Similarly g2-bin1 through g2-bin5 and g3-bin1 through g3-bin5. I am currently using matching bin expression but stuck with the combiner is giving me GA1 = g1-bin2, g1-bin2, g2-bin2 which is wrong. How can I tweak so that I can get GA1 = g1-bin2, g2-bin2, g3-bin2. To be clear - There are thousands of g1, g2 and g3 (outsourced parts). I do not want to match some 'source entity counter' because that would assign a unique number to each gear and over-constrain the matching process. Again this might be a rather simple problem but as a beginner modeller I would appreciate a quick hint. Thanks, Hrushi

-

Hello, I am trying to combine different types of entities (coming from different sources) using a combiner. Layout: 1. One source connected to the parent node of a standard library combiner. 2. Two sources (each with a different entity) connected to the MemberInput of the combiner. I saw the Simbit but I am struggling with the matching logic for this configuration. I tried: - Matching Rule: 'Match Members' - Member Match Expression: ModelEntity.BatchMembers.IndexOfItem( Entity2) && ModelEntity.BatchMembers.IndexOfItem( Entity3) This is a rather simple problem but I would appreciate a quick hint. Larger picture: Assembly of many parts into a product with each part represented as an entity. Thanks, Michael

-

Varying Path Length and Moving Servers

gocken replied to DavidMann's topic in SI General Discussions

You can place some enough transfer nodes at different distances and directions (In freespace it will be hard to stop modelentity object and seize the server object. This can be quite challenging task). Then you can randomly send the modelentities to one of these transfer nodes (This is for sending entities some vector away from the source). Then, define an entered add-on process trigger for each transfer nodes and place a move step onto this add-on process. In resource movement request of this step define object type specific (or from list), object name any server (or from list you set), and destination node as the transfer node itself. Then, you can try seize step to or transfer step to send the entity onto server object. You have to try some options. -

I'm trying to model a towing company. A call comes either jump start or tow (entity 1 and 2) from two different sources. They go through a dispatch (server1) and get delivered to a specific driver (servers 2,3,4 or 5) . Each call coming in will have some exponentially distributed distance from origin associated with it (and direction component?) My challenges are: Is there a way to take and entity from a source and move it into free space some vector away from the source (distance and direction). Then, if that is possible, can I move a server to that location to process it (and if a tow then move some other vector distance after process). Finally, the ultimate goal of the model is to create a conditional routing logic for the dispatch server to compare distance from call and availability of drivers. Such that if a driver is finishing up near the next call, that server will take priority over the one with an empty queue if further away. TLDR: Can servers move? Is there a way I can change how long a path is based on variable input?

-

Conditional Routing (by link weight) is not working

AlexDCave replied to AlexDCave's topic in SI General Discussions

Hello, In response to JBeltran: I can figure out how to grab the variable member.priority. If I was able to do that, the rest would be easy I think. I played around with the search function and it didn't seem to work (maybe I am using it wrong?) In response to ATSProThiede: The instance I uploaded was only using the InitialPriority because that was my latest attempt. I had attempted other options that I noted in the OP. Also, you can change the InitialPriority away from 0 in the entity's options. My problem is that only the parent's values are able to be seen. I have no criteria to change the ModelEntity.Priority because the decision needs to be based off of the entity type of the member. The file you attached does not work properly. I turned off the H1BUnits source, so everything should go to packlane1, yet some go to packlane2 or even bypass both to the sink. I have done quite a bit of digging and have found probably 3-4 other feeds that were never answered as member data seems to be difficult to access. Thank you both for the feedback. Please let me know if you have other ideas or I didn't properly test your reply. Best regards, Alex -

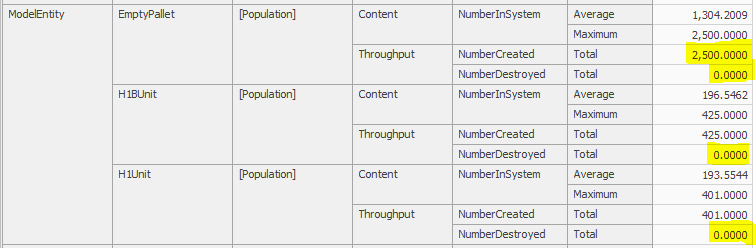

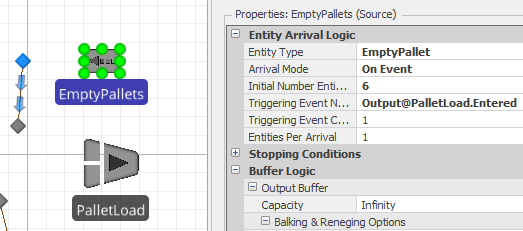

I ran your model until the warning occurs and then examined the Content and Throughput categories in your Results Pivot Grid. I didn't notice any alarming buildups in any of the Combiners, Conveyors, or Servers, but the Entity statistics appear unusual: None of your 3 entity types ever exit the system. Your problem is with creation of too many empty pallets. Another thing I noticed that could be the main problem is that your Empty Pallet source creates 6 empty pallets every .25 minutes, with no limit. When I converted this to a just-in-time (Event Based) creation the entity limit problem went away for that entity type: To answer your specific question, on the Project Home ribbon there is a place to open a Breakpoints window that allows a lot of flexibility to trigger a model break (pause) when a specific condition occurs. I hope this helps.

-

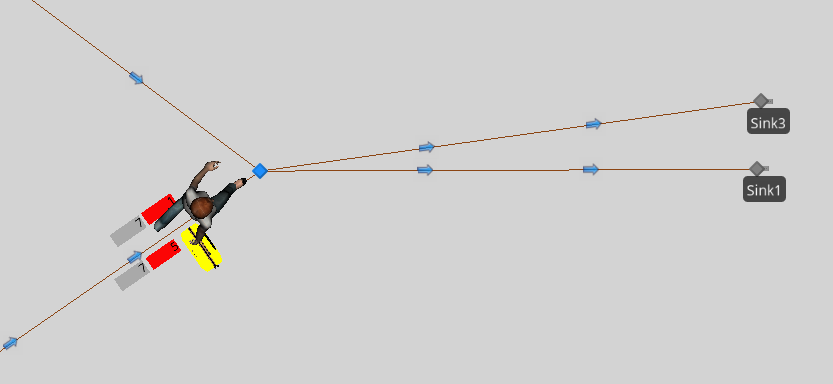

Hello, I have recently encountered an issue while simulating an airport checkpoint and thus leading to the following question: Is it possible to match member and parent priorities under certain conditions? I am trying to differentiate between those travelers (parent entity) and baggage (member entity) going though an additional screening process prior to exiting the model. Take the following image as an example. I managed to provide a priority (red status label) to those entities going through the additional screening while also providing a rule for those with a priority of 5 to exit though Sink 3 (Those with a priority of 1 should exit through Sink1 ). However, the rule seems to only apply to the parent for a reason I assume to be that the baggage is an entity initiated by a "create" step in the processes window, rather than at its own source as the parent. The current rule I have is to decide the following ModelEntity.Priority==5.0, then assigning the desired node (Input@Sink3). In the picture, although the baggage (member) has a priority of 5, the traveler (parent) has a priority of 1 and the rule only applies to the parent. How could I match the priority of the parent, only under the case in which the parent has a higher priority? (Perhaps match the greatest priority of the member and the parent to generalize) I have tried everything possible and I cannot figure it out. Any help is greatly appreciated!

-

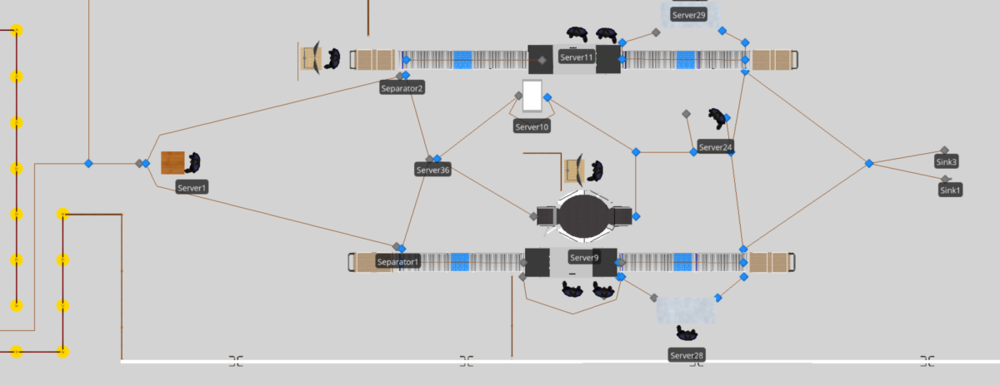

Hello, I have been utilizing SIMIO for a couple of months, however I am relatively unfamiliarized with some of the features. I have recently encountered a difficulty while simulating an airport screening checkpoint. Take the attached picture as a reference. I have entities arriving from a single Source, processed initially at Server 1, and then following a series of separators and additional servers along the way. At Separator 1, the member (luggage) is separated from the parent (passenger). (Luggage is created by a "create" step in an add on process, rather than at its own Source). However, I would like to distinguish statistics between those travelers and luggage going twice through a server. For example in Server 10, I have a loop going from the output node to the input node for the re-scanning of passengers. I managed to provide a priority value to the passengers going though that created loop, and an add on process rule to send those with that priority value to Sink 3, while those without the priority value to Sink 1. I tried applying the same concept to the loop seen in Server 9. However, when the passenger picks up the luggage at the transfer node located at end of the conveyor belt, both the member and the parent exit through Sink 1, rather than Sink 3. It appears that only the member obtains the priority, but not the parent. Although I tried, I did not manage to match the priorities and thus have the combined entities exit the model as anticipated. Any thoughts on how I could match the priorities, or perhaps, any suggestions to make this possible? Any help is greatly appreciated!

-

Hi George, I know the normal ways, to create an entity from a table are: 1) Use a timer with the date/time table for a trigger for a own process or 2) A source with the arrival table option. If you want to create entities, maybe you can make a loop process like GFurtado with an Read-Step/Excel-Step and then you can use the Create-Step of Simio. Then you can check with an Decide-Step "TimeNow >= value" for example and create your Entity. With this option you can use FastForward too. With an lower delay time it is near the real time. Maybe this could be a solution for your problem. Because, then you dont need a third party tool to click on import. I checked the Simio API and I dont find something about a trigger for the Simio buttons or a button click event, what we can use for the problem. It would be nice, if there is an API to "use" the button click processes. For example, to import one or all tables again. Maybe a professional Simio API developer know more and can write here. Have a nice day! Best regards Pascal

-

My company is developing a big model that simulates the arrival of passengers to an airport. It is important to us to control the randomness of the model for two reasons: - We want to be able to replicate the outputs of an experiment if the changes had not been significant. - When running different scenarios where only part of the configuration has changed, the part of the model that has not changed should remain the same. It is possible to control the random generated number of the distributions that Simio offers, but we hadn’t been able to fix the randomness in the next cases: - When using the function RandomRow. Any change in the model that modifies the running time when the function is called changes the row selected. - When selecting a path from its weight. As well as with the RandomRow function, we have seen that only moving one meter the node that is connected to more than one path, the randomness of the path selected varies. Furthermore, because of the dimensions of the simulation, some processes take time to end. That means that in some cases when we add more data to the input tables, data that is independent to a previous part of the simulation, everything changes because the process takes a little more time to end and that changes the result of the random decisions. We would like to know if it is possible to control the randomness on this events, or what other alternative can we use. There is a mini model attached that shows the described behavior. It consist on a source that generates 100 entities, and two possible paths with the same weight. If the node that connects to both path is in the center of the facility, 45 entities go up and 55 down, like in the next picture. If the node is moved to another location, the number of entities that go up changes to 48. Finally, adding a process (with a loop that doesn’t do anything) before selecting the path, the number of entities varies again to 47. Randomness_example.spfx