Search the Community

Showing results for 'change units on status label'.

-

seems the variable 'i' never changed~~~ you can use a status label to check that.~~~

-

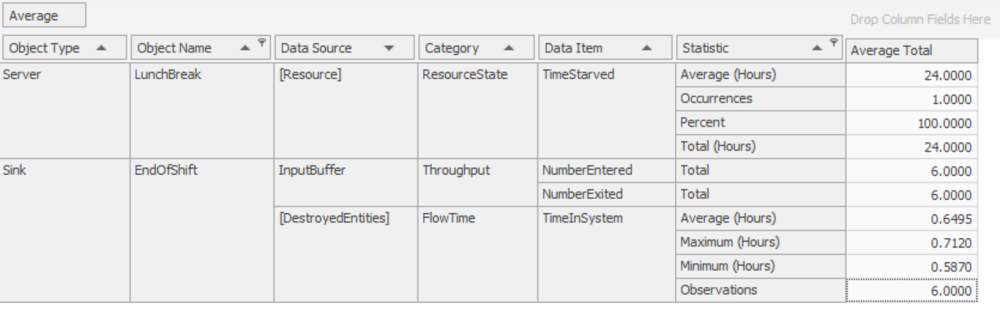

Hi - 2 questions: 1. My model has people coming on shift, being transported to various locations, and then ending their shift at the sink near the source. However, I need them to get picked up and have ALL cycled through the lunch break server. Right now, out of the 35 people on shift, only 1 person got lunch, and only 6 people had their end of shift. How do I constrain the server to ensure the vehicle drops everyone at the lunch server and then the EndOfShift? 2. I would like to model 2, 12-hour shifts (each with the 35 people). I need all 35 to show up at the same time. This is my source Entity Arrival Logic. How do I change it to have two sets of 35 show 12 hours apart?

-

12-hour Shifts with Lunch Breaks and Vehicle Transport

Ryan Welch Lutttrell replied to M_A's topic in SI General Discussions

Hi M_A, 1. This is one is a bit difficult to provide direction on without seeing how the rest of the model is structured. If all your processing times are deterministic and you are using a sequence table to route your entities, then you should be able to add the lunch break into the sequence. Similarly, make sure the sink is included at the end of all your entity sequences. Also, make sure the model run time is long enough to process all employees. That may be why they aren't showing up at the sink. 2. Change your interarrival time to 12 hours, and set your Maximum arrivals to 2. Thanks, Ryan -

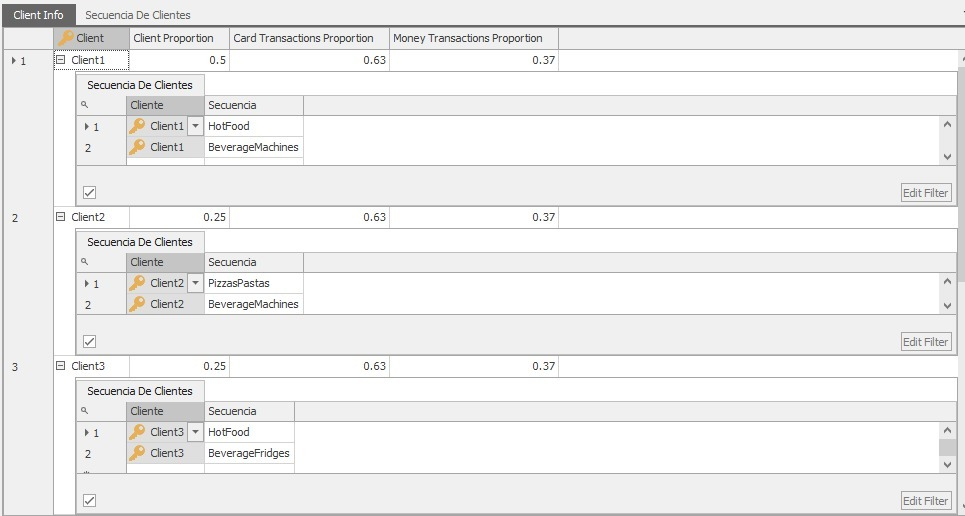

Ok. I already added the transactions proportions to each of the clientes (card 0.63/cash 0.37) in the table like you mentioned earlier. Can you help me understand how do I assign that proportions of my entities populations to the sinks (5 sinks)? Do you think if it's better if I change the sinks to servers?

-

I have attached a simple example of one approach. 1) I edited the ModelEntity object and added a state array of type MatrixFromTable. This type of array is automatically initialized from a table. Ideally I might have also added a table to the entity, but Simio doesn't work that way. Instead, I added a RepeatGroup named InitializationValues consisting of a Real property. I used this repeat group as a way to essentially add a "table" into the object, since internal to Simio there is almost no difference between a table and a repeat group. 2) Back in the model I added a table and then imported data into that table from Excel. I used 10 rows, but I could have imported 350 rows with no change to anything else. 3) Now when you place the ModelEntity object into a model, you can pass a table into the InitializationValues repeat group. Again, intead of just typing a bunch of values into the repeat group, I just say go get the whole repeat group from a specified table. This has the result of sizing that state array inside the model entity to match the current size of the table, and then initializing the state values to whatever is in the table. 4) If you run the model, you can open the Watch window on any entity and view the values of its states. I expect this won't solve all your problems, but maybe it will give you a fresh approach to consider. ImportStateValues.spfx ImportStateValues.xlsx

- 2 replies

-

- 1

-

-

- state array

- repeat group

-

(and 4 more)

Tagged with:

-

Hi all, I am working on a building evacuation project through Simio. I want to know how can I block a sink object, so entities can not exit through that sink. I also need to know if I can somehow define this situation in referenced property under Experiment and try different scenarios. For example in each scenario I block one of the exits and monitor the number exited (survivors) or evacuation time. My other problem is simulating fire with different rates and interaction of it with the entities, as when they see fire they avoid running toward that direction and change the route. Thank you for your help,

-

Dear Judy, First of all thanks for your reply. Secondly, I attached to you another version of the model after I made some modifications. It can be seen in the model, I named a new server as Section 1 and added into it two tasks (Unloading and Leveling, they were servers in previous model) each has its resource (vehicle). I used only one entity for the two tasks. Section 1 will have total Quantity by 2031.25m3 (Which means the total amount of material, since a truck will unload this material and a grader will level it on the surface). The total length of this server (Section 1) is 200 meters as in real life. For the first resource "Aggregate Tipper Truck", its total number is NumAggTr = 20, its rate per hour is named as QSTTRate (has random value), its total number of trips to finish works is TTS = 113 and quantity in each trip is named as QSTT (has also random value). While for the other resource "Grader", its total number is NumGr = 2, its rate per hour is named as QSTGRate (has random value), its total number of trips to finish works is GTS = 32 and quantity in each trip is named as QSTG (has also random value). Since the previous expressions will increase with acceleration, so I inserted Level With Acceleration for each of them to be used as state variable into Finish (Sink). Finally, PPCQSTT and PPCQSTG are the productivity of each task. I have 5 inquiries and they are: 1- Why the resources did not make the appropriate distance travelling? For example, the number of "Aggregate Tipper Truck" is 20 and total number of trips are 113 so each should make about 6 trips (113/20), since the length of Section 1 is 200 meters, then each should make 1200 meters (200*6). 2- In table which named "Sub-Activity Schedule", if I change the value under "Scheduled Finish Date" column the value under Actual Finish Date will change. Why this occurred and why "Status" never be "Ahead" or "On Time"? 3- How can I calculate the values of PPCQSTT and PPCQSTG Daily or Weekly? 4- If I want to identify constraints into each task, how can I do that? 5- How can I apply the concept of Look-Ahead Planning (Daily or Weekly), to remove the added constraints? Thank you again Best regards, Ahmed Elkherbawy Model 1.spfx

-

I have been working on this problem with Caleb @Simio who has been very helpful and we have come up with a work around. Use the Changeover step in Add-on Process, choose to 'Save Setup Time' within it. This only saves the time though, it doesn't stop the delay, so you need to change the Delay Multiplication factor from 1 to a tiny number, for example 0.01, to make the Changeover calculated delay negligible. Then, use the Assign step to multiply the saved Time back to its correct value. This variable can then be used in a Task Sequence or Add on-process as desired.

-

Hi Jeff, I am studying your model right now and I would like to kindly ask you If you could explain to me some aspects of it. 1. when you add the InfrequentFailureType property inside the multifailureserver model, why is this property a list? I do not understand this. 2. If I want, in this case, my FILLERS, to have 2 types of failures, both triggered by amounts of weight filled to container entities (this is the ideal, but it could also be by number of times that filler fills the container entity), what should I have to change from your model? Thank you so much! Tere

-

Multiple Entity with multiple sequence tables

GFurtado replied to JanainaF's topic in SI General Discussions

Check a SimBit named Choose Alternate Sequence. It creates a process containing the Set Row step to change the current sequence table. -

Try using a similar logic to the model I attached. I created a chain of states where one updates the next one, and you can easily access their values. Change to the state you want to memorize and when/where you want to trigger it. Passing TimeStamps.spfx

-

Hi Tere, We still largely used the manual approach, however we used a lot of subclassed object to make sure a change gets applied to all 8 models. We also made use of the table based autocreate to create the different layouts. We do have 8 separate models and we just copy paste the processes. Essentially we could have had one model but with 8 different sets of bindings, this was also not ideal as we have multiple table and even just selecting all of the different bindings while testing would have been cumbersome. If you find a better way please let us know. Regards, Willem

-

********************* FOR VERSION 191 AND LATER ******************************* In Sprint 191, a change was made to the Seize step's On Seized Process and the Release step's On Released Process which impacted the Token Associated and Context Objects. This change effects the logic in VehicleX. For use in Simio versions 190 and earlier, please use the files at the top of this thread. Attached is an updated VehicleX (now VehicleX3) for use in Simio 191 and later, as well as the updated examples using VehicleX3. VehicleX3 now will reject an Entity's Transport Request if an operator is not available for that vehicle. This prevents entities from seizing and waiting for an unmanned vehicle. *************************************************************************************** VehicleX3.spfx VehicleWithDriver_VehicleX3_Examples.spfx

-

I am working on a simulation of a number of firms processing raw products. If I represent the firms as resources in a server -so that the server capacity represents the number of firms, how could I identify which resource/firm processed a certain batch of products? Can this be done with a server having a capacity of its own, or should I use a pool of (secondary) resources with id labels so I can use that id to label the product batch?

-

Thank you for the answers. Since I wanted to be able to change the number of firms at will (through a model property), creating separate servers was not my preferable option. Since the products processed by firms would then be matched with the orders received by thr firms, I had to identify each firm somehow. I will try using a pool of secondary resources.

-

Within the table, highlight the column that includes the server names. Within the properties for that column shown on the right, go to the Advanced Options section, and change the Auto-set Table Row Reference from 'False' to 'True'. This will then associate the corresponding rows with the Servers that are listed and allow you to reference other columns for data associated with those Servers. Note also that for time related columns (delays, etc.), change the Unit Type property to 'Time' and specify the Default Units appropriately.

-

I want to set a timer that represents "time of failure" where if the entity is not processed within this time, it will be deemed a failure and be destroyed. This time needs to be dependent on a random draw (one for entity type, and one for a distribution based on entity type). I also need to be able to change this time due to interventions that happen. Is it possible to do this?

-

Hello, I'm wondering if anyone has a good idea for how to view a resource's utilization according to the day of the week in the pivot grid of an experiment? Currently, my best idea is to just have a status plot in the facility window to illustrate this but I'd prefer to have an average utilization by day of resources in the pivot table. The scenario I'm working with is having "technician" resources that are being seized by server objects to do "maintenance" on the truck entities coming into the maintenance shop. I'd like to see which days of the week are the busiest so I could determine where to schedule new technicians. Any help is greatly appreciated. Thanks! Pit-To-Bay Off-Shift Rule Fixed.spfx

-

Hey, I am modeling a system that has a large number of stations (e.g. 50). I created a Data Table with as Element column related to my Stations. I am transferring entities from a Source (and later from a Node) to the Stations and therefore I need to End Transfer. I would like to do this "automatically". That is, I don't want to create 50 processes where the triggering event is StationName.Entered I was trying to use the information from my Data Table: TableName[RowNumberRelatedToStation].ColumnNameOfStationElement.Entered I had a status label for: TableName[RowNumberRelatedToStation].ColumnNameOfTheStation. And this is actually showing the name of my Stations correctly. However, TableName[RowNumberRelatedToStation].ColumnNameOfTheStation.Entered is not working to trigger my Process to End Transfer. My guess is that Simio is converting the information into String and not Element and, hence, it does not recognize that Station.Entered happened. Any ideas if this should work or how can I make it work? Also, any other idea about how to End Transfer automatically are welcome. I have a solution that work, but I think it is an "ugly" one. So, I thought about asking if you may have a better solution.

-

Hi everybody! I want to know if it is possible that an entity can change from one server to another if the another server is available and the entity isn't still processing. It means if it is possible that an entity can exit from the input buffer of the first server. Thanks for your help. Best, Albert.

-

Only dynamic objects (Entities, Workers, and Vehicles) can be created during a run. Fixed objects cannot be dynamically created. But you can add capacity to a fixed object. Let's say you need up to 10 units of Server available, but you want to enable them only as needed. --The easiest approach might be to design your model with a single Server with capacity 0 (off-shift), then assign it's capacity (increment by one) every time you need more. This is appropriate for something like a ticket agent station where you bring agents on and off staff as needed. --If you need your servers to be independent, then place 10 different Servers, each with a capacity of 0 (off-shift). Then, when you need to add another server, find one that is still at capacity 0 and change it to capacity 1 (on-shift). You don't say what prompts the dynamic creation, but perhaps you can use schedules to implement either of the above. Sometimes it is possible to use an entity like a server. You can dynamically create an entity and put it somewhere, like a Storage. Then you can seize and release that entity. But you can't flow through a dynamic object.

-

Within a Server, Combiner or Separator object, you can specify the Process Type as 'Task Sequence' allowing you then to define any number of Processing Tasks for that Server, Combiner or Separator. The processing tasks can be serial or parallel tasks. By using parallel tasks, for example, with a different worker (nurse, PA, Doctor) required for each parallel task, the tasks are done independently, but can be done at the same time. Parallel tasks can be specified using the same Sequence Number (see Task Sequence and Task Sequence - Processing Tasks sections of Simio help). So, for example, you can have the processing tasks within a Server all have a sequence number of 10 (meaning parallel). One of them requires a Nurse for X time units, another requires a PA for Y time units and the other a Doctor for Z time units). The patient doesn't leave the Server until all 3 tasks are completed. However, if the Nurse is available to do his/her task, they will start. Likewise for the others. And the workers can move on to other tasks at other Servers (patient areas) as well when they are done.

-

search entities in the queue

IreneMarchiori replied to IreneMarchiori's topic in SI General Discussions

thank you .. I create a status label with the expression "CombinerName.MemberInputBuffer.Contents" and it shows me the right number of entities in the queue, but in the trace i see that search step finds 0 item and the process doesn't work:( -

Thanks for the reply! For additional context on item 1), I am hoping to have one Conveyor_Custom object subclass that has properties that allow me to configure zone lengths and overall length for each instance that I add to the model. So for example, I'm imagining dropping in a Conveyor_Custom object to the model and then setting Conveyor_Custom.ZoneLength to 12" and Conveyor_Custom.OverallLength to 6', and then having the Conveyor_Custom.InitialTravelerCapacity self-populate from the calculation that is performed by the CapacityCalculation expression (6'/12" = 12 travelers) internal to the object. The reason the expression is created in the object subclass and not the model is because the formula references the properties of the object subclass itself (ie. the formula is this: Math.Round(((OverallLength * 12) - (Math.Remainder(OverallLength * 12, ZoneLength))) / ZoneLength), with OverallLength being in feet and ZoneLength being in inches), so that for each instance it will be using different values for the calculation as these properties are changed from their default values. I essentially want to do the same for the Conveyor_Custom.NumberOfCells property, which is an inherited property from the standard library conveyor. I have it set so that the default EntityAlignment property is set to CellLocation, and the default CellSpacingType is FixedNumberCells. It's just the NumberOfCells property that I am hoping to have reference a calculated value. I can't seem to set that property to anything other than a plain integer (it doesn't seem to want to accept variables that have integer values, it just wants the values themselves). Perhaps there is another property that I can change to have it accept the variable rather than a plain integer, but I have not found it yet. Thanks!

- 2 replies

-

- properties

- subclass

- (and 16 more)

-

Right click on conveyor click "change ending note" and left click on whichever node you want.