Search the Community

Showing results for 'wait in transfer node'.

-

tyr other options from the dropdown list of "From" property of transfer step.

-

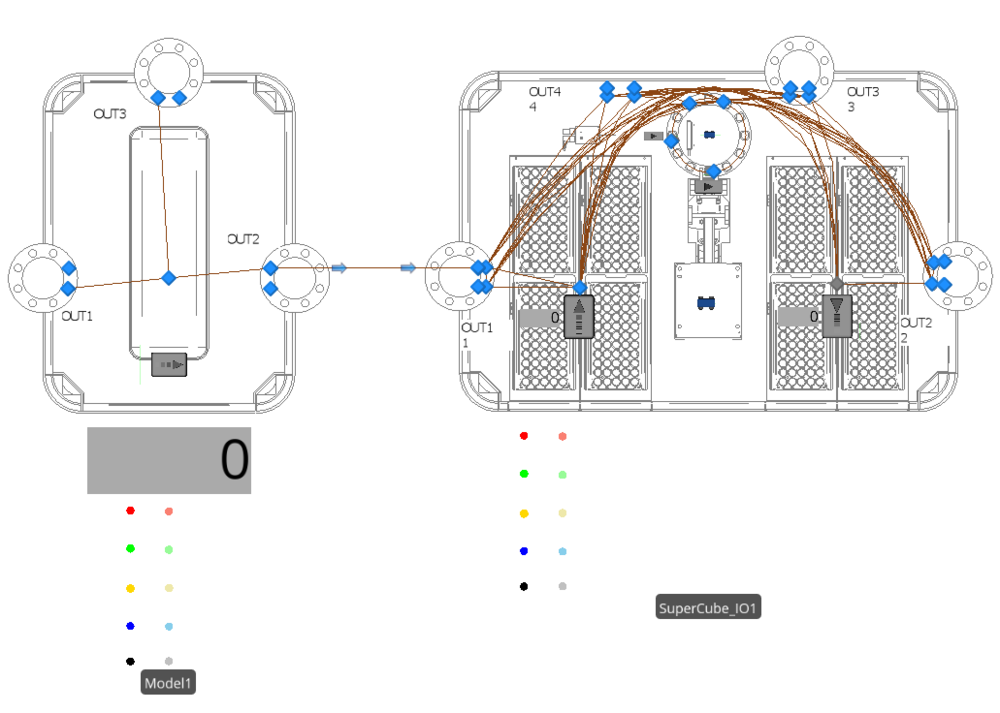

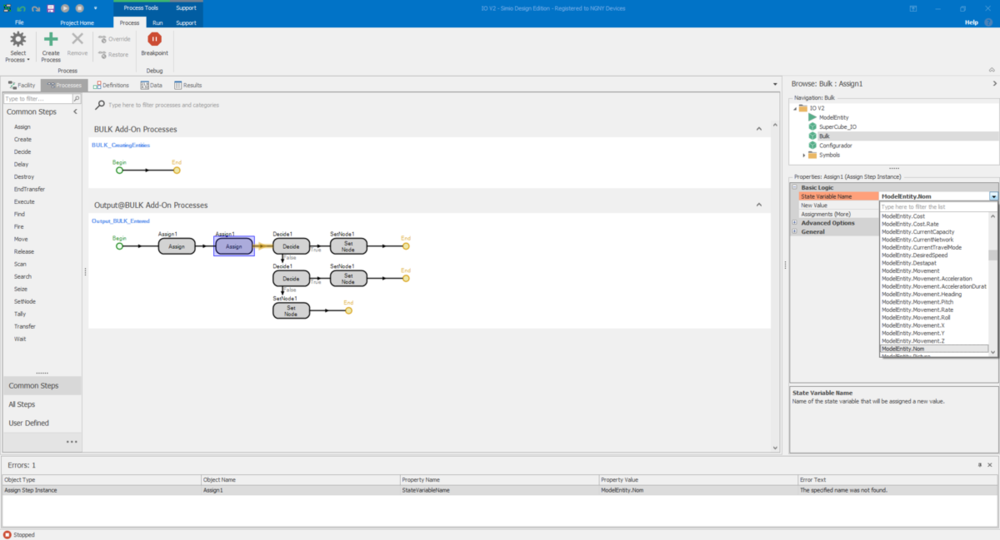

Hello everyone, First time here! I'm trying to combine 2 different models in the same file, the model on the left will create the model entities (colored dots below the model) and send them to the model on the right through the node OUT2, then, on the right model, the vehicle will pick the entity and decide its destination depending on the type of entity, the issue here is that the right model can't identify the entity as it's created on another model and will be called "Model1.Entity" instead of "Entity", i don't know how to ignore the "Model1."part. I've tried to use model entity's state variables, hoping to be able to read them with the expression "ModelEntity.NameOfVariable", but i can't seem to assign values as it says that "Specified name was not found". Fusing both models in the same model it's not an option as i want to be able to make different configurations. Thanks! CONFIGURADOR.spfx

-

Right click on conveyor click "change ending note" and left click on whichever node you want.

-

Hi All, I am attempting to model a triage logic where I want to periodically, sequentially search the contents of a storage queue associated with a station and test the availability of resources to handle processing it. If the resources are not available in the system, I would like to move to the next entity in the queue and test it until all the current queue has been examined. The goal is to sequentially walk the queue organized by priority using the lowest value first of a state variable on the entities. Is there a suggested "best" way to approach this sort of problem? Essentially I want to do a loop to examine entities in a storage queue and transfer the best one with a match to available resources. I tried using a search based on index but ran into an error getting the state values of the entity and also seem to have challenges sorting the storage queue correctly. I would be grateful if someone has a basic example of such a sequential search. Thanks Very Much, Jim

-

State Variable, Depending Routing Logic

GFurtado replied to anmanzano's topic in SI General Discussions

Set Output Link Rule property of your node to By Link Weight. Then set Selection Weight property of your links to Entity.State and 1-Entity.State. This means that when Entity.State = 1 (True), one link weight will be 1 and the other 0, and vice-versa when Entity.State = 0 (False). Check the attached model for reference. ByLinkWeight.spfx- 1 reply

-

- routing

- state variable

-

(and 1 more)

Tagged with:

-

Hello, I ran into a similar problem and am finding it difficult to construct a match expression for the combiner. I want to model a gear assembly GA(parent node) with gear g1, g2, and g3 (all connected to member node). But, there is some upstream variation affecting mating of gears. So, business process is binning them say g1-bin1 through g1-bin5. Similarly g2-bin1 through g2-bin5 and g3-bin1 through g3-bin5. I am currently using matching bin expression but stuck with the combiner is giving me GA1 = g1-bin2, g1-bin2, g2-bin2 which is wrong. How can I tweak so that I can get GA1 = g1-bin2, g2-bin2, g3-bin2. To be clear - There are thousands of g1, g2 and g3 (outsourced parts). I do not want to match some 'source entity counter' because that would assign a unique number to each gear and over-constrain the matching process. Again this might be a rather simple problem but as a beginner modeller I would appreciate a quick hint. Thanks, Hrushi

-

Hello, I am trying to combine different types of entities (coming from different sources) using a combiner. Layout: 1. One source connected to the parent node of a standard library combiner. 2. Two sources (each with a different entity) connected to the MemberInput of the combiner. I saw the Simbit but I am struggling with the matching logic for this configuration. I tried: - Matching Rule: 'Match Members' - Member Match Expression: ModelEntity.BatchMembers.IndexOfItem( Entity2) && ModelEntity.BatchMembers.IndexOfItem( Entity3) This is a rather simple problem but I would appreciate a quick hint. Larger picture: Assembly of many parts into a product with each part represented as an entity. Thanks, Michael

-

Hello, I was wondering if it is possible to change the vehicle initial home node during the simulation. In my model , I want to vehicle to park at home after his work, but in the middle of the simulation I want him to go wait in another place. Is it possible ?

-

Conditional Routing (by link weight) is not working

ATSProThiede replied to AlexDCave's topic in SI General Discussions

*If you need a custom logic, because you have a lot of batch members, you can add a entered process in the node. Then you can use a search step and search your right member. Then you can use a Decide-Step or what else and use the "SetNode-Step" and not the link weight logic. So you can set the taget destionation with the SetNode-Step :-). Or, you write the state in the Parent-Entity after these Entitiy left the Combiner. They are different options to solve this problem. -

Conditional Routing (by link weight) is not working

ATSProThiede replied to AlexDCave's topic in SI General Discussions

Hello AlexDCave, welcome in the Simio Forum! I looked in your model and saw you use "ModelEntity.InitialPriority". This value is every time 0. So the link weight expression in your links are false every time. I attached you the model "APS Design 2 - ATS 1.spfx". I added only one little Notify-Step. So you can debug your model and check the logic. Maybe this will help you in the future by the debugging of your model. In my opinion you can use the "ModelEntity.Priority" or make a own little state in your ModelEntity. Then you have to set the values to "11", "12" or "13" or what else. I made you an example for a working solution and upload it with the name "APS Design 2 - ATS 1.spfx". What I did: 1) I create a ModelEntity state "MyOwnIntegerState". 2) I changed your link weight logic on on the links by the node "PackFeed2". 3) I added the process "Output_WasherEntrance_Entered" to set the own ModelEntity state. I hope this will help you! Feel you free to ask, if you have another question. Best regards Pascal APS Design 2 - ATS 1.spfx APS Design 2 - ATS 2.spfx -

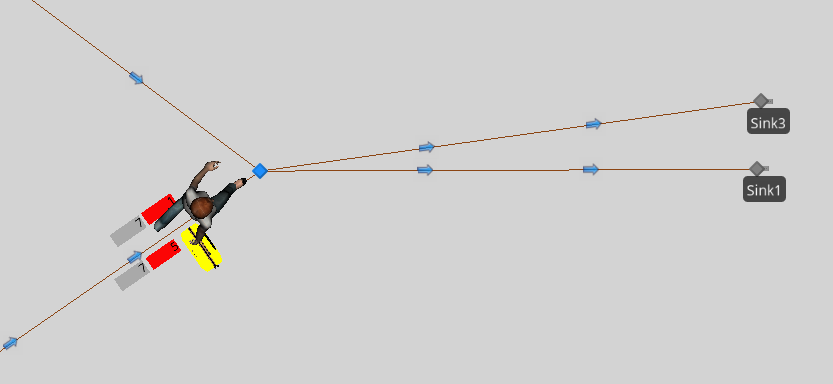

Hello, I have recently encountered an issue while simulating an airport checkpoint and thus leading to the following question: Is it possible to match member and parent priorities under certain conditions? I am trying to differentiate between those travelers (parent entity) and baggage (member entity) going though an additional screening process prior to exiting the model. Take the following image as an example. I managed to provide a priority (red status label) to those entities going through the additional screening while also providing a rule for those with a priority of 5 to exit though Sink 3 (Those with a priority of 1 should exit through Sink1 ). However, the rule seems to only apply to the parent for a reason I assume to be that the baggage is an entity initiated by a "create" step in the processes window, rather than at its own source as the parent. The current rule I have is to decide the following ModelEntity.Priority==5.0, then assigning the desired node (Input@Sink3). In the picture, although the baggage (member) has a priority of 5, the traveler (parent) has a priority of 1 and the rule only applies to the parent. How could I match the priority of the parent, only under the case in which the parent has a higher priority? (Perhaps match the greatest priority of the member and the parent to generalize) I have tried everything possible and I cannot figure it out. Any help is greatly appreciated!

-

Hello, In my model, I have two vehicle types. The first type, MyVehicle, is a subclassed vehicle similar to the vehicles in the SimBit Electric Vehicle, except they use Free Space Only. The other type of vehicles are standard vehicles. My problem is when entities seize a vehicle for transport from one server, I want them to seize the closest MyVehicle and only seize a standard vehicle if no MyVehicles are available. The output node at each server is set to select from the transport list which includes both vehicle types. If I set the reservation method to "Reserve Closest" the closest vehicle of either type is reserved and if I set the reservation method to "Reserve Best", MyVehicle[1] will be attempted to be seized even if it is not the closest MyVehicle. I assume there is a way to use an add-on process to control which vehicle is seized, but I am unsure. Just FYI, I have MyVehicles starting at two different HomeNodes, 5 per node. Any thoughts would be greatly appreciated!! Thank you! Please let me know if this description is not clear.

-

Thanks for the reply! I think I have implemented this the way you are describing, but the closest of the two vehicle types, either MyVehicle or standard vehicle, is still being selected. If you have any other ideas, they would be greatly appreciated!! Now, I'm trying to play around with "Reserve Best" and a selection condition that might choose the closest of all possible candidate types. I've tried Candidate.Transporter.NetworkDistanceTo.Node(Output@Server) with selection goal of smallest value and this still just picks the closest of the two vehicle types.

-

First rank the vehicles accoding to your preference in your node list (My vehicle first then the standard vehicles). Then, setting "reservation method" as "reserve closest" and "selection goal" as "preffered order" and "selection condition" as "Candidate.Vehicle.ResourceState!=1" will work for you.

-

Dynamic destination based on multiple conditions

craigw replied to craigw's topic in SI General Discussions

As an update to this, I think I have (at least so far) found something which provides the desired behaviour and will detail below for others. I used the SimBit 'SelectServerWithShortestLine' as a reference. I created a Node list with the inputs nodes at each Sink listed. I created an integer Property to hold the variable which represents the maximum number entities that can go to a sink (e.g. MaxContainerCapacity). On the feeding TransferNode I changed the 'Entity Destination Type' to 'Select from List' and selected the list created in Step 1. Change 'Selection Goal' to 'Smallest Value' and set the 'Selection Expression' to Candidate.Node.AssociatedStationLoad, which accounts for everything en route, in the queue and processing at a node. Therefore, the select goal is to minimise this station load. I set the selection condition to (Candidate.Node.AssociatedStationLoad + Candidate.Sink.InputBuffer.NumberExited) < MaxContainerCapacity. Which is saying only select the Node found in Step 4 if the sum of the station load and the number of entities that have 'exited' the Sink are less than the MaxContainerCapacity. -

The current implementation of consumption based on a bill of materials is interesting but somewhat limiting. I'm not an expert in SIMIO and perhaps I'm failing to find a way to do this: I create a FG from source and want to consume the respective amount of each component on its BOM. As it is, all the components will be instantly consumed when I use the consume block. However, what I want is to transfer them to a node at a given rate (and not all at once). Imagine I have a product C that requires 1 Product A, 2 Product B and 5 Product E. If I want to retrieve 1 of each (until required amount) each 30 seconds, how can this be done? I thought about a logic as follows: //Get total number of retrievals For each Material in C_BOM: Total_Required_Amount = Total_Required_Amount + required_Amount[Material] //Retrieve one of each until required amount every 30 seconds while(Total_Transfered_Amount for each Material in C_BOM: if(transfered_Amount[Material] transfer_Material_to_Node(); transfered_Amount[Material]++; Total_Transfered_Amount++; delay(30 seconds); Has anyone ever came across a similar situation where you would have to iterate over a collection (in this case a BOM)? I believe my explanation might be confused and if something is not understood, please ask. Thank you for your attention.

-

Request a transport before entiy arrives to a node

dsturrock replied to semihalkan's topic in SI General Discussions

The second problem is easy. Simply change the Execute step option highlighted above to its default "WaitUntilProcessCompleted". For the first problem, what I said is still accurate. You can easily enable homing when idle, or you can tell it to wait somewhere when idle, but you can't automatically do both. To allow you will need to provide a path so the vehicle can actually get back to transfer node 1. And you will have to add some similar logic to send the vehicle there when it is appropriate for it to go there. All of this discussion is to allow you to model exactly the behavior you have described. But as you share more details of your objective, it looks more and more like this could be easily approximated just using automatic library behavior without all this complexity. For example, the time to "pull up the man from the deep well" might just be modeled as a loading time. Every model is an approximation and a big part of effective modeling is know the correct level at which to approximate. If you would like some advice on how I would model this, please post or email me the full details of the situation you want to model and your objectives (e.g. why are you modeling it and what do you want to learn). -

Request a transport before entiy arrives to a node

semihalkan replied to semihalkan's topic in SI General Discussions

Unfortunately, two things that you considered problems are the things that are crucial to the model. First, the vehicle needs to move to transfer node 1 once it drops off entities at transfer node 2. That is a must. It needs to wait there until entities leave the server. Second, your assumption to have the entity and the vehicle to move concurrently is wrong. The problem would have been way easier if that was the case. The entity needs to start moving to transfer node 3 only when the transport arrives there. Think of it as a vehicle with a crane, pulling up a man from a deep well, where there is no ladder. Hence, the entity can only move up (in this case move to transfer node 3), after the vehicle gets there. -

My company is developing a big model that simulates the arrival of passengers to an airport. It is important to us to control the randomness of the model for two reasons: - We want to be able to replicate the outputs of an experiment if the changes had not been significant. - When running different scenarios where only part of the configuration has changed, the part of the model that has not changed should remain the same. It is possible to control the random generated number of the distributions that Simio offers, but we hadn’t been able to fix the randomness in the next cases: - When using the function RandomRow. Any change in the model that modifies the running time when the function is called changes the row selected. - When selecting a path from its weight. As well as with the RandomRow function, we have seen that only moving one meter the node that is connected to more than one path, the randomness of the path selected varies. Furthermore, because of the dimensions of the simulation, some processes take time to end. That means that in some cases when we add more data to the input tables, data that is independent to a previous part of the simulation, everything changes because the process takes a little more time to end and that changes the result of the random decisions. We would like to know if it is possible to control the randomness on this events, or what other alternative can we use. There is a mini model attached that shows the described behavior. It consist on a source that generates 100 entities, and two possible paths with the same weight. If the node that connects to both path is in the center of the facility, 45 entities go up and 55 down, like in the next picture. If the node is moved to another location, the number of entities that go up changes to 48. Finally, adding a process (with a loop that doesn’t do anything) before selecting the path, the number of entities varies again to 47. Randomness_example.spfx

-

Hi, I believe you approach is correct. I would suggest you look at the CombineMultipleEntityTypesOntoPallets Simbit for help on how to have the shirts be combined with the totes (this may help alleviate your confusion about the worker fetching totes instead of shirts). Another suggestion would be the think of the combiner in a slightly different way than the real system (parent object, like the pallets in the above node) and the shirts are then feed into the member input and combined when there are 5 shirts. Meaning the shirts are combined with the tote, then once 3 totes are filled the ARM can move them out (utilizing an evaluating seize request add-on process for the ARM transporter). Hope this helps. Jason

-

The New York City Health Department's Division of Disease Control is responsible for the identification, surveillance, treatment, control and prevention of infectious diseases in NYC. The Division is composed of seven bureaus and operates clinics across the city to provider sixual health services, tuberculosis diagnosis and treatment, and immunization. The Division is seeking one intern to assist us with a project at our clinics, with the goal on identifying new workflows to increase patient throughput and optimize resources. Duties and Responsibilities: Under supervision, the intern will perform a variety duties, including but not be limited to: Analyzing existing data that was used to measure cycle time/wait time Conducting time-motion studies to collect cycle/wait time data across clinics Analyzing clinical cycle/wait time data to identify efficiency and inefficiency Running simulations to identify changes to reduce visit cycle time Qualifications: Matriculation at an accredited college or graduate school. Employment is conditioned upon continuance as a student in a college or graduate school; Knowledge and experiences of discrete-event simulation method is highly preferred; Experiences of data collection, data entry and data analysis; An understanding of health equity issues within the context of infectious disease public health is also encouraged. Hours and Rate: 30-35 hours/week during the summer, or approximately 20 hours/week during the school year, flexible daytime and evening hours from 9am-5pm. The proposed salary range is $15.50 - $19.90 per hour. Residency Requirement: New York City residency is generally required within 90 days of appointment. However, City Employees in certain titles who have worked for the City for 2 continuous years may also be eligible to reside in Nassau, Suffolk, Putnam, Westchester, Rockland, or Orange County. To determine if the residency requirement applies to you, please discuss with the agency representative at the time of interview. Application: Please send your resume and personal statement to Dogan Kizilirmak @ <dkizilirmak@health.nyc.gov>, and feel free to reach out if you have any questions.

-

- internship

- operation research

-

(and 2 more)

Tagged with:

-

I am using transfer step for the entities to the sink but there are different links and path between the source and sink. So, if I use transfer step in add on process, the entity transfer from source to sink directly. Then, the time in system cannot be computed. I want to determine the destination (sink) by using add on process after checking some criteria. Could you please help me about this problem? My goal is to choose the sink after checking some criteria and then send entities from source to that destination(sink) by using some path randomly. Thanks, Nadere

-

No, it seems your add-on process is working correctly. How do you transfer the entities to the sink? It seems there is not time advancement between creation and disposing the entities.

-

I have made some progress, but could still use some help. Using sequence tables and 6 different entities, I now have passengers going to their correct destination. Here is my main issue: Let's say there are 2 passengers at station A, one needs to go to Station B and one to station C. There is also a passenger at station B that needs to go to station C. My transport will take the 2 from station A directly to a sink at station B. The Passenger bound for station C will not get off the transport, but the passenger bound for Station B does. The vehicle then follows a connecter to the transfer node that is "Station B". The 3rd passenger that needs to get from B to C does not get on the transport, and the transport continues along to station C. I have also noticed that after the second passenger gets off, usually the vehicle travels another route without any passengers before loading more. How can I ensure my vehicle will allow passengers to board at any station when it has excess capacity? Right now it's only loading if there are 0 passengers on board.

-

First of all, you will need a Sequence Table (Definitions tab / Tables window) - select Add Sequence Table. In the Sequence column, you would list the order of servers/locations the entities will travel - for example, Input@Server1, Input@Server2, Input@Server1, Input@Sink would cause the entity to visit Server1 twice. Next, in the same table, add an Expression type of column where you will store the processing time information at each corresponding step. This way, the processing time at Input@Server1 may be different with each step (and visit to the same server). Within the ModelEntity, set the Initial Sequence property to the sequence table name. Within each transfer node (exit of the Source and Servers), change the Entity Destination Type to 'By Sequence'. Processing Time at each Server should then reference the 'SequenceTable.ProcessingTimeColumn'. See several of the SimBits that contain sequences, including EntityFollowsSeqeunceWithTable.spfx.