Search the Community

Showing results for 'combiner parent'.

-

Referencing tables/properties from other models

Liz Millar replied to TweeMansLeger's topic in SI General Discussions

Hi Jason, I recommend checking out the SimBit, found in the Support ribbon in Simio, titled "Hierachy with Tables". This could show you an idea of how you might use a Repeat Group Property to read in a Data Table at the parent model in to the sub model. Liz -

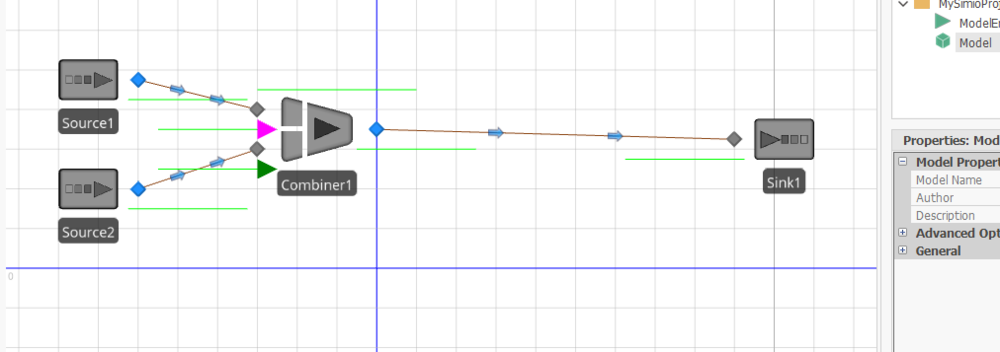

Just use combiner object. There is a very close simbit in simbit library, just check it out.

-

Process two entities in a server at the same time

dsturrock replied to ALE's topic in SI General Discussions

People often miss the fact that a Combiner is basically just a Server with some extra combining logic. It sounds like that is exactly what you need here. Replace your Server with a Combiner, then immediately follow your Combiner with a Separator to restore the entities to their individual members. -

Thanks Gustavo, actually what worked for me was ContainerEntity.Location.Parent.Name! Anyway thank you very much. I have another doubt which I think is far more complicated. I have two "streets" with a container entity moving moving along each of them. This streets have both fillers and emptiers, and I wish to write in excel every time a container entity goes from a filler to an emptier and how long that took. For example if my container on street 1 goes from filler_2 to emptier_6 I would like a row in excel with those 3 columns: starting filler, ending emptier and time between. I achieved this without problem for one of the streets (adding add on process triggers to all of the fillers and another for all of the emptiers). The thing is when I add this same processes to the emptiers/fillers of street 2, my excel goes crazy and obviously because of two reasons: the time I register to calculate time between is being updated in both streets every time a container goes out of an emptier, and exactly the same happens with the row that this 3 things have to be written in the excel. I don't know hoy I can manage to construct the variables time and row_count without them getting confused and hence my excel becoming useless. Thanks, again!!!

-

you could use a Combiner object to represent the assy station. and on the combiner's After Processing Add-on trigger , you create a processes like below..

-

Within a Server, Combiner or Separator object, you can specify the Process Type as 'Task Sequence' allowing you then to define any number of Processing Tasks for that Server, Combiner or Separator. The processing tasks can be serial or parallel tasks. By using parallel tasks, for example, with a different worker (nurse, PA, Doctor) required for each parallel task, the tasks are done independently, but can be done at the same time. Parallel tasks can be specified using the same Sequence Number (see Task Sequence and Task Sequence - Processing Tasks sections of Simio help). So, for example, you can have the processing tasks within a Server all have a sequence number of 10 (meaning parallel). One of them requires a Nurse for X time units, another requires a PA for Y time units and the other a Doctor for Z time units). The patient doesn't leave the Server until all 3 tasks are completed. However, if the Nurse is available to do his/her task, they will start. Likewise for the others. And the workers can move on to other tasks at other Servers (patient areas) as well when they are done.

-

I have a system with 3 steps. At each step a certain amount of product is process and batched (using a combiner) on to a pallet. I have to assign a sequence table to the member entities and the parent (pallet) entities. However this is resulting in some batches sitting at a combiner because the pallet follows the sequence instead of going to the next batch ready if the pallet is empty. Any thoughts on how to handle this? If there is no call for an empty pallet the pallets could stay where they are or go to a specific location.

-

Hello, in general it sounds like your approach is good. You could use either an Object Reference State Variable or String State Variable (called something like 'WhichServer'), defined on ModelEntity, depending on the expression you use to make the assignment. For instance, with an Object Reference State Variable you could use 'ModelEntity.Location.Parent.Server'. With a String State Variable you would use 'ModelEntity.Location.Parent.Server.Name'. In terms of timing, you could make the assignment really anytime the ModelEntity is in the Server. You might use the Servers' On Entering State Assignments for example. Then somewhere downstream, perhaps the Entered Add-On Process at a Sink, you could use Add Row and Assign steps to populate the Output Table. Again, just be mindful to make the column types (Object Reference State Variable or String State Variable) match up with the assignments you are making. For instance you might have a String State Variable column named 'Entity' and, in the Add-On Process at the Sink, you assign 'OutputTable1.Entity' the New Value of 'ModelEntity.Name'. Then you could have an Object Reference State Variable column named 'Server' and in the same process assign 'OutputTable1.Server' the New Value 'ModelEntity.WhichServer' (since it is also an Object Reference State Variable). The result will be a list of each ModelEntity (Name) and the Server that processed it. Hope this helps! Adam

-

Just curious if there's an easier way to go about doing this... Long story short if I am representing multiple physical positions within capacity of a server and I create my own Gantt outside Simio, it's important for me to know WHICH resource (in this case which one of the servers) is utilized by each entity. I was trying to utilize Entity.Location.Parent.Server.Processing.Contents.IndexOfItem( Entity ) and assigning it to a state on the entity and then ultimately writing to an output table. However, this doesn't seem to be working accurately. It may be a timing issue on when this step is called, but is there a default function I'm just not aware of that could be of assistance?

-

Conditional Routing (by link weight) is not working

AlexDCave replied to AlexDCave's topic in SI General Discussions

Does anyone know how to utilize the memberinput@"combiner" in a process? I tried a process "UnitIdentity" with a decision step "MemberInput@PalletLoad==H1BUnit" to set a real state "UnitTypeID" and a ModelEntity.Picture so I can utilize the link weights further downstream. I placed this in the Processing Add-On for the combiner. I have attached the file. It feels so close to a resolution and any help would be appreciated! Best regards, Alex APS Design 2.spfx -

Hello, I ran into a similar problem and am finding it difficult to construct a match expression for the combiner. I want to model a gear assembly GA(parent node) with gear g1, g2, and g3 (all connected to member node). But, there is some upstream variation affecting mating of gears. So, business process is binning them say g1-bin1 through g1-bin5. Similarly g2-bin1 through g2-bin5 and g3-bin1 through g3-bin5. I am currently using matching bin expression but stuck with the combiner is giving me GA1 = g1-bin2, g1-bin2, g2-bin2 which is wrong. How can I tweak so that I can get GA1 = g1-bin2, g2-bin2, g3-bin2. To be clear - There are thousands of g1, g2 and g3 (outsourced parts). I do not want to match some 'source entity counter' because that would assign a unique number to each gear and over-constrain the matching process. Again this might be a rather simple problem but as a beginner modeller I would appreciate a quick hint. Thanks, Hrushi

-

Conditional Routing (by link weight) is not working

AlexDCave replied to AlexDCave's topic in SI General Discussions

Hello, In response to JBeltran: I can figure out how to grab the variable member.priority. If I was able to do that, the rest would be easy I think. I played around with the search function and it didn't seem to work (maybe I am using it wrong?) In response to ATSProThiede: The instance I uploaded was only using the InitialPriority because that was my latest attempt. I had attempted other options that I noted in the OP. Also, you can change the InitialPriority away from 0 in the entity's options. My problem is that only the parent's values are able to be seen. I have no criteria to change the ModelEntity.Priority because the decision needs to be based off of the entity type of the member. The file you attached does not work properly. I turned off the H1BUnits source, so everything should go to packlane1, yet some go to packlane2 or even bypass both to the sink. I have done quite a bit of digging and have found probably 3-4 other feeds that were never answered as member data seems to be difficult to access. Thank you both for the feedback. Please let me know if you have other ideas or I didn't properly test your reply. Best regards, Alex -

Conditional Routing (by link weight) is not working

ATSProThiede replied to AlexDCave's topic in SI General Discussions

*If you need a custom logic, because you have a lot of batch members, you can add a entered process in the node. Then you can use a search step and search your right member. Then you can use a Decide-Step or what else and use the "SetNode-Step" and not the link weight logic. So you can set the taget destionation with the SetNode-Step :-). Or, you write the state in the Parent-Entity after these Entitiy left the Combiner. They are different options to solve this problem. -

Conditional Routing (by link weight) is not working

JBeltran replied to AlexDCave's topic in SI General Discussions

Hello Alex, You cannot directly see the variables of a member which is inside a batch unless you use a process looking for it (with a Search and extracting the required value) An easier method is to transfering the value of the variable of interest (Member.Priority) to the holding Parent (for exemple, onto Parent.My1stMemberPriority) and run your decision logic pointing to it. Regards, -

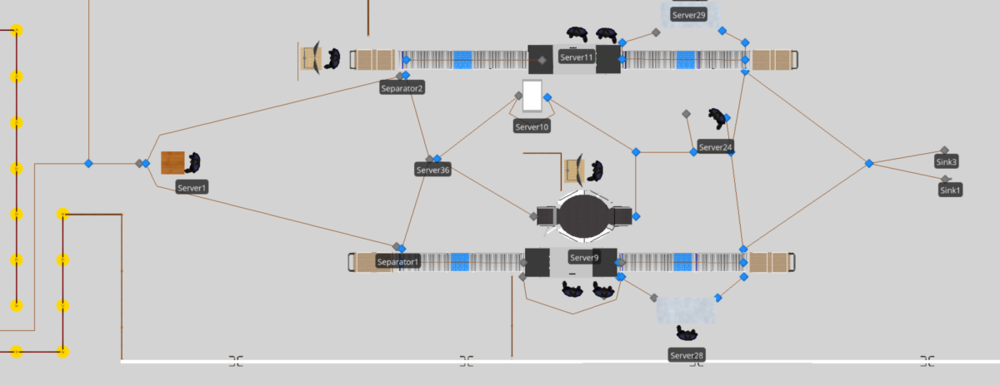

The conditional routing by link weight (PackFeed2 - Conveyor22 or Conveyor 23; PackFeed4 - Conveyor26 or Conveyor27) is not working for me. The current file is set to make the decision by initial priority, but I have tried other methods with no success: > Assign ModelEntity.Priority with addon process, then route by link weight of ModelEntity.Priority=="X" > Assign link weight by ModelEntity.EntityType > Assign link weight by ModelEntity.BatchMembers.Contains("X") I think this may not be working because they are arriving as a parent/member batch. Is there a different link weight condition that may work. Please note I have 1 parent type and 2 member types. The decision needs to based off of the member entity. The area of concern is towards the end of the process at the top left of the simio (file attached). APS Design 2.spfx

-

I have recreated a system to see theoretical capacities and it has multiple sources (1 parent and 2 different members that I combine). I have turned off balking because that interferes with my unit mix. I have also changed all buffers to a finite number and crossing logic capacities to 1. Even with all of this, I still hit the 2500 max entities and an error pops up. This system should only be able to hold a couple hundred, so I know I don't need to adjust my capacity size. I made the units stop at the 1st server so I could isolate the issue and it appears to be upon creation or in the combiner. My question is, how can I have unit production pause (not stop) when the buffers and capacities are full? I have attached the file for reference. APS Design 2.spfx

-

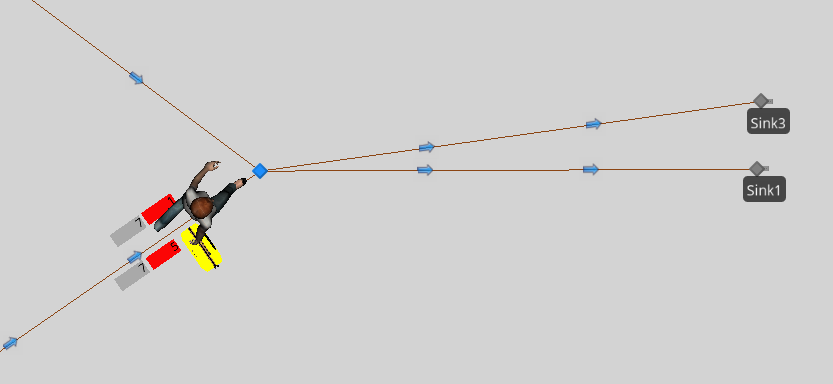

Hello, I have recently encountered an issue while simulating an airport checkpoint and thus leading to the following question: Is it possible to match member and parent priorities under certain conditions? I am trying to differentiate between those travelers (parent entity) and baggage (member entity) going though an additional screening process prior to exiting the model. Take the following image as an example. I managed to provide a priority (red status label) to those entities going through the additional screening while also providing a rule for those with a priority of 5 to exit though Sink 3 (Those with a priority of 1 should exit through Sink1 ). However, the rule seems to only apply to the parent for a reason I assume to be that the baggage is an entity initiated by a "create" step in the processes window, rather than at its own source as the parent. The current rule I have is to decide the following ModelEntity.Priority==5.0, then assigning the desired node (Input@Sink3). In the picture, although the baggage (member) has a priority of 5, the traveler (parent) has a priority of 1 and the rule only applies to the parent. How could I match the priority of the parent, only under the case in which the parent has a higher priority? (Perhaps match the greatest priority of the member and the parent to generalize) I have tried everything possible and I cannot figure it out. Any help is greatly appreciated!

-

Hi, I am trying to make it so that at the end of a process all of my combiners (say 10 or 20) collect all entities (assigned to a particular combiner when they enter the system) but wait to release to the sink until the simulation reaches a certain time (say 9:00 AM) AND all entities have been processed through the system and are in their assigned combiner. I use a combiner because they turn into a different type of entity before exiting the system. I've tried a few different things but cannot seem to get the process logic down. Any help?

-

Hello, I have been utilizing SIMIO for a couple of months, however I am relatively unfamiliarized with some of the features. I have recently encountered a difficulty while simulating an airport screening checkpoint. Take the attached picture as a reference. I have entities arriving from a single Source, processed initially at Server 1, and then following a series of separators and additional servers along the way. At Separator 1, the member (luggage) is separated from the parent (passenger). (Luggage is created by a "create" step in an add on process, rather than at its own Source). However, I would like to distinguish statistics between those travelers and luggage going twice through a server. For example in Server 10, I have a loop going from the output node to the input node for the re-scanning of passengers. I managed to provide a priority value to the passengers going though that created loop, and an add on process rule to send those with that priority value to Sink 3, while those without the priority value to Sink 1. I tried applying the same concept to the loop seen in Server 9. However, when the passenger picks up the luggage at the transfer node located at end of the conveyor belt, both the member and the parent exit through Sink 1, rather than Sink 3. It appears that only the member obtains the priority, but not the parent. Although I tried, I did not manage to match the priorities and thus have the combined entities exit the model as anticipated. Any thoughts on how I could match the priorities, or perhaps, any suggestions to make this possible? Any help is greatly appreciated!

-

Hi, I believe you approach is correct. I would suggest you look at the CombineMultipleEntityTypesOntoPallets Simbit for help on how to have the shirts be combined with the totes (this may help alleviate your confusion about the worker fetching totes instead of shirts). Another suggestion would be the think of the combiner in a slightly different way than the real system (parent object, like the pallets in the above node) and the shirts are then feed into the member input and combined when there are 5 shirts. Meaning the shirts are combined with the tote, then once 3 totes are filled the ARM can move them out (utilizing an evaluating seize request add-on process for the ARM transporter). Hope this helps. Jason

-

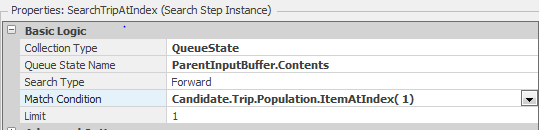

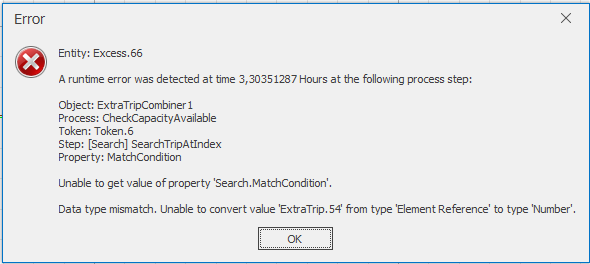

Hi, I would like to return information from an entity in a queue (parent input buffer) at a specific index. If I use the search step with following property values (see attached image) I receive an error (see attached image). What does this error exactly mean and how can I solve this problem? Thanks in advance! Christa

-

In the batch that was created, I want to search the member entity with the lowest value for state variable "NumberOfRollContainers" and change its value to: <<TotalREQ" - 0.9 * "CapacityTrip">>, where "TotalREQ" and "CapacityTrip" are state variables of the parent entity. I am struggling with how to use the search step in this situation, so help is appreciated. Thanks in advance!

-

You can sum the "NumberOfRollContainers" whenever a member entity enters the combiner object by using "on member entering" property under "state assignments" section. Then, set this total to the "TotalRollContainers" state variable of the parent objet by using "before exiting" property of combiner object.

-

Hi, Is it possible to set the state variable of the parent entity in a batch equal to the sum of state variables of all member entities in the batch? Context of the case; a truck (parent) is loaded with x number of orders (members). These orders have a specific value for the state variable 'NumberOfRollContainers'. The truck has the state variable 'TotalRollContainers', which should equal the sum of the 'NumberOfRollContainers' in that batch. Kind regards, Christa

-

A couple quick thoughts: Both from your description and from what I know about chair lifts, it seem that using a conveyor might be the best modeling approach. You might consider using a combiner instead of a server to synchronize all waiting skiers together into a lift car.