Search the Community

Showing results for 'simio versions'.

-

Hello All, I am new to Simio and trying out a simulation of an aircraft component assembly shop. I am using Sequence table for my jobs routing and processing scenarios which is - Source -> Set A (4 servers) -> Set B (7 servers) -> Set C (5 servers) -> Set D (2 servers) -> Sink Here each Set denotes similar workbenches to any of which a job can be routed based on utilization and availability at that point of time. So for routing job based on above criteria from Source, I created sequence table with 'Node list property' (which is list of input nodes on 4 servers of Set A) instead of 'SequenceDestination Property' as required by Sequence table. I want to replicate the sequencing from Source -> Set A -> Set B and so on. But want simio to pick the server of these sets based on my criterion. Unfortunately it is not working as I assume Sequence table need to have specific node as SequenceDestination. I am not sure if I am doing it right or what is correct and way to do it. I will highly appreciate any suggestions to make this happen in Simio. Thank you. -Mohmed

-

Hello, I want to model an evacuation network design problem with Simio. My goal is to consider traffic congestion in the model. Congestion happens when road capacity is not enough for that amount of people immediately leave the source node. I was wondering if you could let me know how to consider capacity for either path or connector. I would be happy if you could share an example with me. Thanks, Nadere

-

Sequence Table - Destination as 'Node list property'

CWatson replied to mohmed Shaikh's topic in SI General Discussions

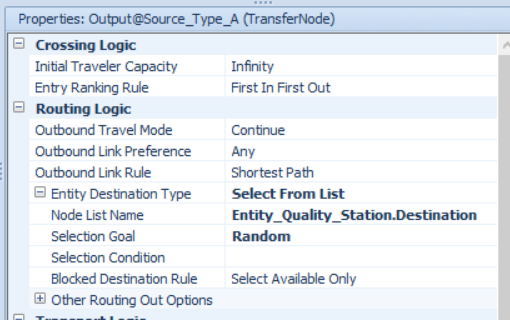

You can still use your various 'lists' of servers in SetA, SetB, etc.). You still will need a Sequence table with the Sequence Destination property column. This tells Simio within the Sequence table the destination to route. So, within your Facility window, add a TRANSFERNODE before each 'set' of areas, let's say named SetA, SetB, SetC, SetD. Then, within the TransferNode, use the 'Select From List' for Entity Destination Type property and specify the appropriate list (SetAList, etc.). Then, within the Sequence table, route to the TRANSFERNODE that uses the particular list - so in the above, you would have within your Sequence table, SetA, SetB, SetC, SetD and Input@Sink. Within each of your Server's output nodes, specify Entity Destination Type as 'By Sequence'. You may wish to look at the example named SchedulingDiscretePartProduction to see the layout of the nodes within each section and the Routings table used (this is a much larger example, but the concept of the nodes, the sequence table and in that case a RoutingDestinations table (which is like a node list in Lists) is basically the same. -

Please either attach a copy of the model you are referring to with this post or send the model with description of problem to support@simio.com. Thank you.

-

Need some direction on creating mass load of entities. Attached is my file for version 10.174. Haven’t updated yet to 187. In the file I have two models: VIR_Workflow and CVOR. I’m trying to recreate what I did in VIR_Workflow where I imported a table of all the entities. It would be daunting to creating hundreds of individual entities. I want to do the same thing with CVOR however, it did not load to create the entities itself as I thought is capable of doing. There’s over 5000 entities for this model. I have also attached the CVS files I used to import data. Please advise the best way to load in pre-sets of data to create the entities instead of doing it manually. Or if there's something simpler in doing what I want to do please share. I think I missed some kind of step. SIMIO.zip

-

Multiple servers with single shared capacity

Hristiyan Petkov replied to Hristiyan Petkov's topic in SI General Discussions

Thanks a lot for your quick reply, Dave. I will try your approach today. Meanwhile, I have acknowledged your recommendation and created a new thread in the Simio Insiders forum to allow for file attachments: Thanks again, Hristiyan -

RandomRow for only part of a table

dsturrock replied to JaimeSotomayor94's topic in SI General Discussions

To start with, Destinations in Simio are always nodes. So the table should have a column of type Object Reference Property > Node. Although its not on the pull-down list, when you specify a entity destination as Select From List, you can also specify a table column of type node list and it will automatically respect the table rows associated with that entity. Model_RandomRow_FilteredTable.spfx -

Yes, you can certainly model this in Simio, and can easily make it terminating. I would suggest reviewing any simulation textbook for verification and validation techniques. The general answer for number of replications is to run for a few (5-10?) replications and look at the half-width on your key output measures. If the HW is too wide, then run additional replications until all your key measures are at the precision you need.

- 1 reply

-

- 1

-

-

Hello, I am working on evacuation network design problem. My network has several evacuation areas (source nodes), road segment, and shelters (destination nodes). I consider congestion as people might stick in the traffic and they have to reduce their speed in the road. My goal is to send people from hazard areas to safe areas in the defined time horizon. So my first question is that, can I use SIMIO for simulating my model? Since my model has limited time for evacuation (Terminating problem), can I validate my problem with replications, if yes, how many replications I need? 2) Is there any other method to validate my model? Thanks,

-

Multiple servers with single shared capacity

dsturrock replied to Hristiyan Petkov's topic in SI General Discussions

Tricky problem. If you had posted this in a Simio Insiders forum instead of the public forum I could have replied with a model and figures. I would probably take the opposite approach - instead of adding additional "fake" machines, I would consider representing each workcell as a single server that makes use of associated resources for metrology, CNC, and airblast. I'd use Task Sequences to do the sequential processing of each part, then use the associated Loopback feature of Task Sequences to start over with the subsequent parts. There are a number of SimBits demonstrating task sequences. Unfortunately the only one demonstrating loopback (ServerUsingTaskSequencesWithDataTables_Loopback) uses data tables (which complicates things) but you might get the idea. Or you could do a similar approach with process logic steps. If you repost this in Simio Insiders you might get more help. -

To model shelves, I am trying to create a series of custom "Shelf" objects (subclass of servers) located in a grid pattern. I used a spreadsheet to automatically calculate the coordinate locations and generate a name (string) for each object based on its position within the grid. With just the Shelf object types in the spreadsheet, can bind the file to my object reference table no problem, import the data, and populate the facility window with my objects. That part works fine! Next, since I have an aisle running between the rows of objects, I wanted to set it up so that the objects all face "inwards", ie. the input and output nodes for the objects are facing the aisle. Originally I thought of rotating the Shelf object, but I ran into 2 issues: first, I discovered that I can't set the Shelf yaw orientation from the table, so that's not going to work. Second, I realized that even when I rotate the Shelf in the facility window, the nodes do not rotate with their parent object. I decided I would leave the Shelf in the same orientation as it is placed, but I would just re-locate the input/output nodes to the opposite edge of the Shelf objects on the far side of the aisle. For this I would need to make sure I can set locations for the input/output nodes in the same object reference table. When I added a row to the object reference table from within Simio (prior to binding to a spreadsheet), a drop down appeared, and I could select the input or output nodes for any object that already existed in the table, and then define the node's location in the cartesian coordinate columns. When creating a node this way, the node location is still relative to the object, ie. I can drag the object in the facility window and the node moves relative to the object, which is perfect. This input/output node creation and relative location definition via table is exactly what I am trying to automate, but this is where I started running into problems. In my spreadsheet I used formulas to generate names for the nodes to match the formatting of the input and output nodes in Simio (ex. "Input@..."/"Output@..."). I also added a formula to assign all input node object types to BasicNodes and all output nodes to TransferNodes and calculate the desired location coordinates for the nodes. The spreadsheet I made has the same format as the table in Simio where I tested manually creating and positioning the nodes. The issue is that when I bind the table and import the spreadsheet data to my model, the node names automatically change and are no longer formatted to reference the parent object. Because of this, these name-changed node objects are created in addition to the input and output nodes that are created for each Shelf object. However, if I remove the binding and add a new row, once again I can find the node name in the drop down list and assign the coordinates manually, and the input/output node that references the parent object will move to where I send it. My question is: how can I set the input/output node locations for the objects when creating objects from a table? There are over 500 Shelf objects in the table so I do not want to locate them manually, but the automated method is not working either. The only idea that I have is to make a new object "Shelf2" and define the external view to have the nodes on the opposite side, but that seems like a less-than-idea solution because then I would have 2 custom objects to update and maintain, that are otherwise identical. I am hoping that I don't have to do this hacky solution but I am interested to see if anyone else has dealt with this and has ideas. Thanks!

-

Thank you. I used another computer which doesn't have enterprise version simio to open it and it's helpful... I did't know 'Is.xxx' function...

-

Hi Sean, I would recommend exploring Time Paths. You can set a specific or random Travel Time on Time Paths. I don't know your scenario exactly, but you could have 3 different Time Paths linking ServerA and ServerB with Selection Weights referring to the specific Entity item number and each of these Time Paths could have a different Travel Time. All the best, Caleb Simio Technical Support

-

Hi Sean, Where is your Process triggered? Depending on its location, it may allow multiple Entities to Delay simultaneously. For example, if this Process is at Output@ServerA, this will allow multiple to Delay at once and the Entity that finishes the Delay step first will move along the Path to ServerB first. You can have them Delay one at a time if you change the Output Buffer Capacity to '1', however, this will cause ServerA to be in a blocked state until the Delay is complete. All the best, Caleb Simio Technical Support

-

Hi Mauricio, You can create a mock warm-up period by using an OnRunInitialized Process. An OnRunInitialized Process is executed when the model is first initialized. For example, you can use OnRunInitialized to Create and Transfer Entities into specific Servers as soon as the model is initialized, which is similar to what a warm-up period does. You can read more about OnRunInitialized in the Simio Reference Guide under the topic "Processes". While using OnRunInitialized can give you similar results to a warm-up period, it is not exactly the same as the Warm-up Period in the Experiments window. Keep in mind doing this will affect your Experiment and any other statistics collected (i.e. if you use a Warm-up Period in the Experiment it will essentially warm-up twice). A second option to explore is using a Timer to trigger a Process that contains a Clear Statistics step. This Timer should only go off once. This option is more similar to what a Warm-up Period in the Experiments window actually does. All the best, Caleb Simio Technical Support

-

Hi Sean, I would recommend exploring an Add-On Process Trigger that utilizes a Delay step. You can have the Delay Time of the Delay step set to an equation that is random (i.e. 'Random.Exponential(mean)'). All the best, Caleb Simio Technical Support

-

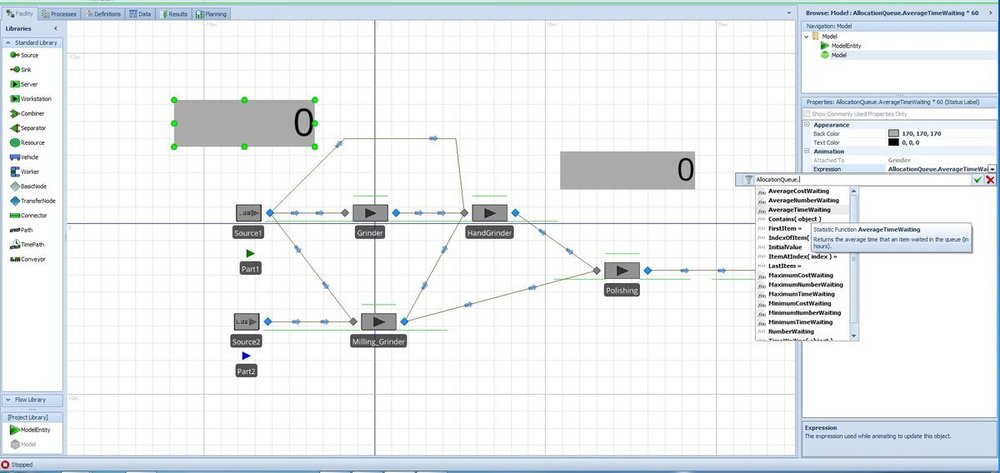

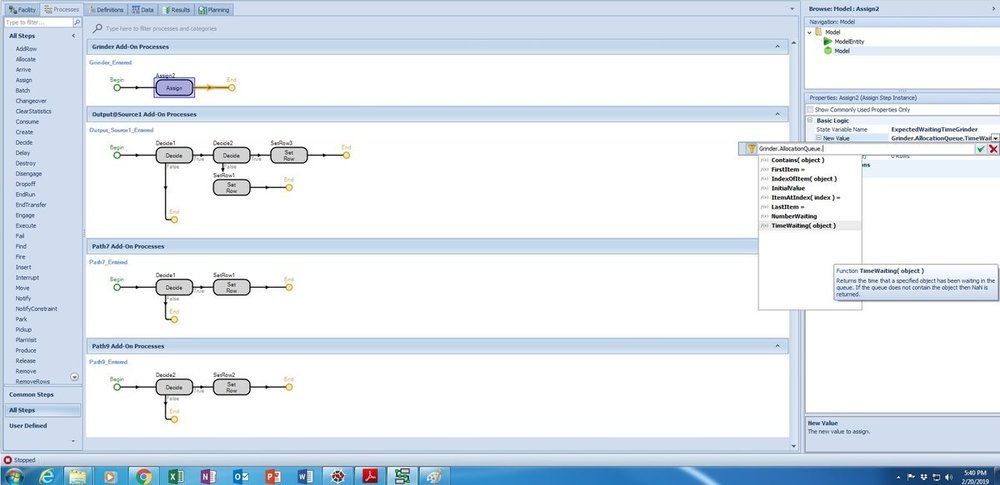

Hi, I am new to Simio. I was trying to add a routing decision in my model based on average time waiting at a server. But this function only shows up in the status label but not when I try to use it in the Processes as shown in the images. An entity reaching a node should choose the route to a server which has minimum average time waiting. What I am trying to achieve is to create a dynamic routing so that the average Time in System of the entity will be minimized. I don't know whether this is the right method or if we need to work with API or functions to achieve this. Any help would be much appreciated. Thank you in advance.

-

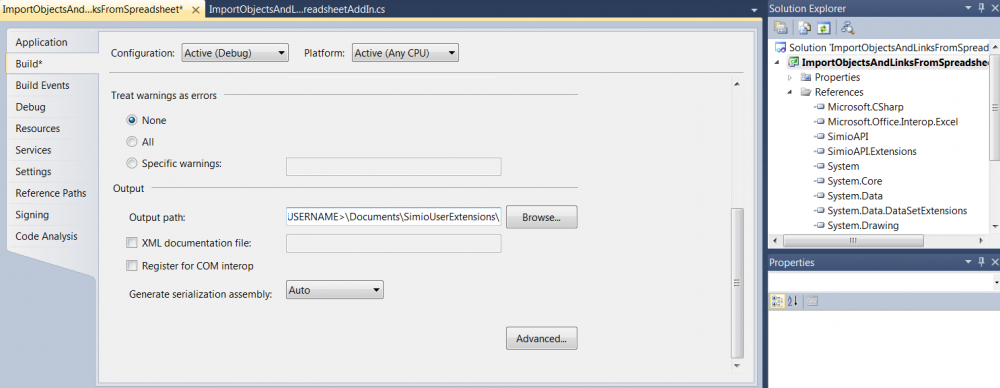

We have added a Simio add-in that will import a model (objects and links) from a spreadsheet. The most DLL, spreadsheet and code are provided in a later post.. NOTE: You do not need the code to run the add-in. All you need is the ImportObjectsAndLinksFromSpreadsheetAddInDLL_V5.zip and ImportObjectsAndLinks_v5.xlsx. The code is also provided in case you wish to make changes to the add-in. You can run the addin just using the DLL and spreadsheet. All you need to unzip the DLL into C:\Users\\Documents\SimioUserExtensions. You might need to add the SimioUserExtensions under MyDocuments (C:\Users\\Documents) in case it does not already exist. Once you run the add-in in Simio, use the attached spreadsheet. It should create a Source, Server, Sink with an Entity and a Vehicle. If you want to use the code, you will need to update the project properties..under build. The output path needs to be C:\Users\\Documents\SimioUserExtensions...See attached screen shot. Give it a try. Let us know if you have any questions. Updated 2106-10-24.....Added support for repeating properties and wrapped import using BulkUpdate method to speed up import . ImportObjectsAndLinksFromSpreadsheetAddIn_DLL.zip ImportObjectsAndLinksFromSpreadsheet_Code.zip ImportObjectsLinksVertices.xlsx

-

Hi, Thanks for the comments. Brief update, somehow I figured out I can do that by setting the transporter selection condition as "(ModelEntity.DestinationNode.AssociatedStation.CurrentCapacity - ModelEntity.DestinationNode.AssociatedObject.Server.InputBuffer.Content) > 0". Then, it will have the result as I want. However, one new issue comes up. When the worker pass a certain entity (let's say server A does not have capacity now, so the worker pass the product A, and goes to deal with other product. ), the passed entity will sit in the queue like forever. The worker will continue to move the new arrived entity, but will not touch the passed entity even the server A has the capacity later. What should I do to ask the worker go back to move the passed entity? I'm new to Simio. Thanks for the help. Best,

-

Jeff's solution is elegant and enough. Still, I liked the way you handled the problem via processes. You need not to define Stopcreatingentities event to fire. I revised your logic and attached its revised form as a png file (can not saved my changes due to having a different version of simio).

-

Dave had shared a post which, I think, can be a solution or at least a starting point to your problem. Here is the path to that solution: https://www.simio.com/forums/viewtopic.php?f=36&t=2334

-

How to set server quantity after set work schedule in experiment

gocken replied to Sean's topic in SI General Discussions

To the best of my knowledge, optquest has no capability of optimizing string or boolen type controls. In the case of automatic optimization (which you want) it does not work! (i.e., It works automatically with only numerical values.). I do not understand why it can not but this is the way it optimizes so far. If you want to optimize string type controls you have to code your optimization routines (i.e., usually via metaheuristics) and integrate them with simio. For this to happen you should be somewhat an advanced user. If not you should ask for further help.- 5 replies

-

- server quantity

- work schedule

-

(and 2 more)

Tagged with:

-

We will have 1 or more openings for an Industrial/Systems Engineering intern with our office at the National Institutes of Health (NIH) in Bethesda, MD. We are seeking a 3rd or 4th year undergrad industrial/systems engineering student with some experience with Simio and computer simulation concepts that you would have opportunity to apply in a federal government setting. Some background on what our office does at NIH: https://www.ors.od.nih.gov/OD/OQM/Pages/index.aspx The announcements will open on Monday, February, 4th and close on February 8th or when the applicant cut-off is reached – so please apply on Feb 4 if interested! Student Trainee (Administrative Support) – GS-0399-1/2/3/4/5/6/7: https://www.usajobs.gov/GetJob/ViewDetails/523190300 Student Trainee (Engineering) – GS-0899-1/2/3/4/5/6/7: https://www.usajobs.gov/GetJob/ViewDetails/522951000 If you have questions about the internship with our office, contact OQMCareers@mail.nih.gov