Search the Community

Showing results for 'simio versions'.

-

Hi all, I am working on a building evacuation project through Simio. I want to know how can I block a sink object, so entities can not exit through that sink. I also need to know if I can somehow define this situation in referenced property under Experiment and try different scenarios. For example in each scenario I block one of the exits and monitor the number exited (survivors) or evacuation time. My other problem is simulating fire with different rates and interaction of it with the entities, as when they see fire they avoid running toward that direction and change the route. Thank you for your help,

-

Hello every body. I am a beginner on SImio and this software is very powerfull. I have a problem I want to modify Fixed route vehicle's destination. I don't want a vehicle on demand.I need a fixed route vehicle. But I need to modify the vehicle's destination. Because I want the first vehicle Go to the first source and i want the second vehicle go to the second sources. And I have 80 vehicle and i want this loop destination for all vehicle. It's works very well for the First 5 vehicles ( For Source_Aub_Char in my model) and it's doesn't work for the sixth and after it's works. But my method doesn't work for all vehicle. I don't understand why. My method is : - I select the current vehicle with "Path1.Contents.FirstItem" - And After with "set Row" i selected différent sequences table for the current vehicle - I do a count for the number vehicle entrance and the model choice the good sequence table with this counter. There is my simplify model in attachement. Some body can help me to see what's wrong or to give me a better method ? Thank you very much. And sorry for my english i'm french. Question FOrum.spfx

-

I have been working on this problem with Caleb @Simio who has been very helpful and we have come up with a work around. Use the Changeover step in Add-on Process, choose to 'Save Setup Time' within it. This only saves the time though, it doesn't stop the delay, so you need to change the Delay Multiplication factor from 1 to a tiny number, for example 0.01, to make the Changeover calculated delay negligible. Then, use the Assign step to multiply the saved Time back to its correct value. This variable can then be used in a Task Sequence or Add on-process as desired.

-

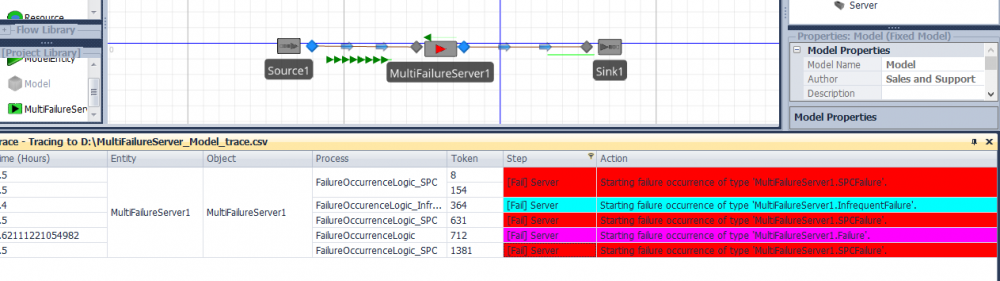

MultiFailureServer.spfx [/img] in response to the above thread: http://www.simio.com/forums/viewtopic.php?f=1&p=9187#p9187

- 1 reply

-

- 1

-

-

Hi all, I made a model of a production line (starting with 2 servers) and I am wondering whether it is possible to change the processing time of the second server based on the actual output of the first server. Theoretically seen the processing time of the server 2 = Speed of server 1 * E , in which E is a fixed formula (connected to server 2) to correct the speed. So if the first server performs according to expectation (without failures) for example 40 the processing speed of the second server is equal to 40*E with a delay of the conveyor time between server 1 and server 2. If the server has failure and thus have a lower output (for example, 30), I want to change the processing time of the second server accordingly to 30*E with a delay of the conveyor time between server 1 and server 2. Does anybody have an idea of how to do the following: How can you monitor the actual output of the first server at each timestep? Is it possible to fix the proposed formula and use it in an add-on process? How can you take the conveyor time delay into account (using a delay step in the add-on process?)? I am quite new to the software so I am not sure whether it is possible to model this in Simio. Thank you in advance!

-

Is there a way to create a column of Time property without date using Simio Table, just like the start time and end time of day pattern of the work schedules? The work schedule doesn't suit my needs.

-

Hello! I want to make the simulation model which illustrates about the interference time about three kinds of truck. And such trucks enter the warehouse and head to the specific loading spot to do forwarding operation with one goods among four kinds. That is why interference time occur, by which I mean that I have to make model to find the most suitable spot for each goods forwarding activity by switching each spot. However I can not find the accurate properties avoiding each other objects at path, or even allocating several time delay on the situation that they encounter. Anyway, I want to see object avoid each other by decelerating its speed and calculate overall time delay at the result tab. (20 seconds per each interference) If I can apply the time delay, the kind of the object does not matter. I already tried to make the entities play a role as the truck that works mentioned above, but that trial was failed because there are no property to decelerate, or avoid at least.. I sincerely want my dear SIMIO to achieve a success in this modeling.. Thank you!

-

Getting Started - Engineering Office

jzhou replied to Shane Sullivan's topic in SI General Discussions

simio is capable for this purpose. -

Getting Started - Engineering Office

willem replied to Shane Sullivan's topic in SI General Discussions

Hi Shane, With the process you described it is very possible, I would suggest the engineers as servers and the orders as entities. The scale of your project might however not justify the means, Simio is more than capable, however I would not purchase it just for this application (if you already have it it would be a great project). Regards, Willem -

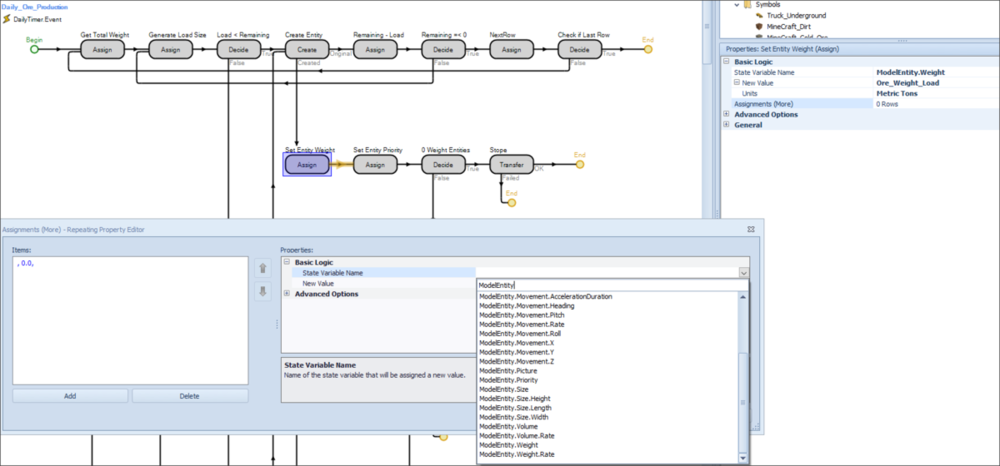

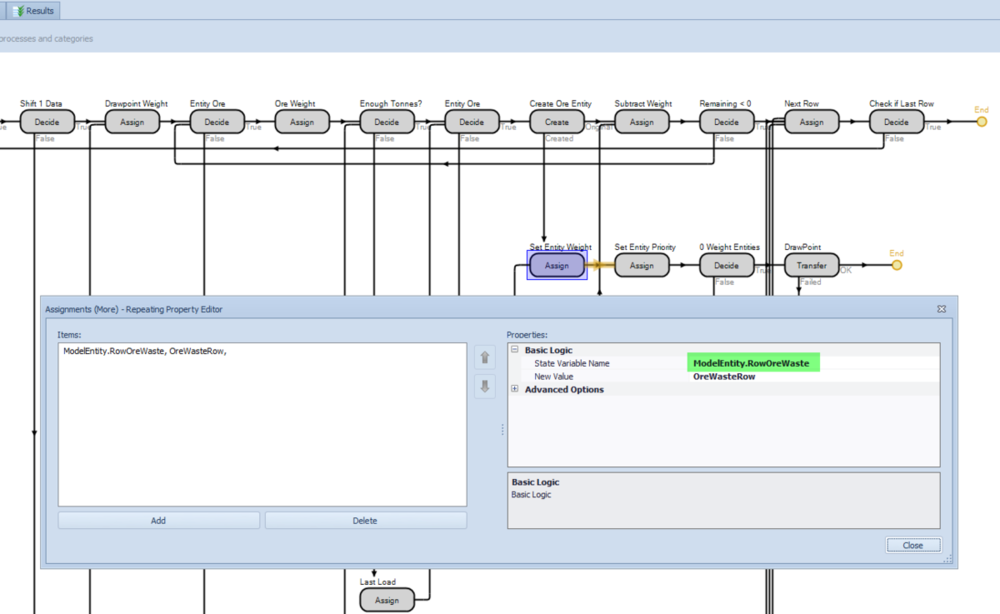

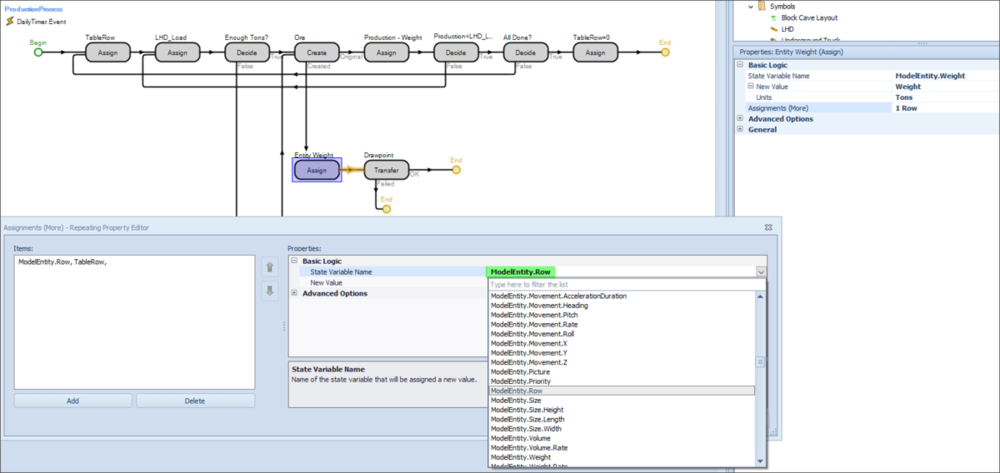

Hello, I am fairly new to Simio and having a bit of an issue trying to understand how I can create the pull down option for "ModelEntity.Row", when trying using an "Assign" step to set the Entity Weight. I hope this makes sense and I have attached a few pictures. The first is a screenshot of my process in the simulation I am working, and as can be seen I do not get an option that reads "ModelEntity.Row" and/or "ModelEntity.RowOreWaste". the last two pictures are from simulations I am using as reference when creating my process and simulation model. thank you

-

Hi all, I was wondering, is it possible to record the time in system of entity instances and subsequently plot the values in a histogram? Of course, I can see the average, min and max values in the results tab, but I am interested in knowing what the distribution is like for model validation purposes. If it is not possible to plot the values in Simio, is it perhaps still possible to access and export the values, i.e. to a .csv document? Hopefully my question is clear. Best regards, Michkel Mariegaard

-

Hello everyone, I am a master's student in operations management trying my hand at Simio for the first time. I want to develop a model that simulates the delays incurred by variable supply lead times which may lead to stock-outs at a manufacturing plant. I would like to model demand so that each entity generated by a single source module corresponds to a sales order. Each order should have a probability to include orders for several specific product types (since sales orders may contain orders for different product types). As such, entities should have an arrival rate which corresponds to the arrival rate of orders at the company, and the product mix of each order should reference the probability of a given product type being included in that order (i.e. product A has 25% probability to be included, product B has 50%, etc.). Is it possible to do this? I would also like for each product type to be associated with a specific BOM. I.e., a server module should reference each entity instance to consume material as defined by the BOM’s of the products stated by the entity instance. I have defined each component as material elements and defined a BOM for each finished product that references the materials needed. However, in the server module I am only able to input a specific type of finished product as material requirements... Your help is greatly appreciated!

-

John, I too believe Task Sequences could be very useful for your project. For example, for the multiple patient types coming in, you could utilize a Branch Type of 'Conditional' in your Task Sequence so to only use a certain workflow for that type of patient. There is a general description of Conditional and Probabilistic Branching in the Simio Reference Guide Help page titled "TaskSequence" along with some other helpful information on Task Sequences. Additionally, I recommend you take a look at the SimBits titled "Task Sequence and Worker In Table (from project Task Sequence And Worker)" and "Using Relational Tables to Define Task Resource Lists". If you investigate how Task Sequences are used in these examples, I believe you will find some methods that might help you in your modeling endeavors. If Task Sequences still do not help you achieve your goals, it would be helpful to have more details on what you are trying to do. I think writing your own steps should be resorted to later after other options have been exhausted. If you email in to support@simio.com we can continue our conversation.

-

you can define task sequences via simio's data tables. Then, if you feed data tables externally you do not need to enter them manually. I think there are one or more simbits related to task sequences via data tables.

-

Within a Server, Combiner or Separator object, you can specify the Process Type as 'Task Sequence' allowing you then to define any number of Processing Tasks for that Server, Combiner or Separator. The processing tasks can be serial or parallel tasks. By using parallel tasks, for example, with a different worker (nurse, PA, Doctor) required for each parallel task, the tasks are done independently, but can be done at the same time. Parallel tasks can be specified using the same Sequence Number (see Task Sequence and Task Sequence - Processing Tasks sections of Simio help). So, for example, you can have the processing tasks within a Server all have a sequence number of 10 (meaning parallel). One of them requires a Nurse for X time units, another requires a PA for Y time units and the other a Doctor for Z time units). The patient doesn't leave the Server until all 3 tasks are completed. However, if the Nurse is available to do his/her task, they will start. Likewise for the others. And the workers can move on to other tasks at other Servers (patient areas) as well when they are done.

-

Let's say I want exactly 100 entities arrive where the arrival of each one follows a normal distribution with mean 1 hour and standard deviation of 5 minutes from the start of the simulation. How can I model that within SIMIO? The interarrival time doesn't make sense because I don't know / care what the interrarrival time between each entity is. I realize that I could randomly generate 100 normal random variables outside of SIMIO and input them all as an appointment, but I am wondering if there is a better way especially if I want to do many replications with a different set of 100 random variables each time.

-

http://cdn2.simio.com/Simio-11.192.18835.zip

-

Hello, everyone! is it possible to use a Look Up Table and Rate Table to the same time in the source in SIMIO? Let me know if you know a way to do that, please. Thanks for your help!

-

Thanks, Jason for your answer and your interest. The situation is the following: I have to receive an order with set amount of entities that must be completed in a specific date and hour, but I need to distribute that order in some intervals before the deadline. It means, If I have an order with 15 entities for November 3 at 8 pm, I could receive 10% of the entities at 7 pm, 50% at 7:30 pm and 40% at 8 pm. So, I have the idea to do an arrival table for the schedule of the order and a rate table for the percentages that I need. And I want to know that is possible in SIMIO to put both in the source? Thanks for your help!

-

Just curious if there's an easier way to go about doing this... Long story short if I am representing multiple physical positions within capacity of a server and I create my own Gantt outside Simio, it's important for me to know WHICH resource (in this case which one of the servers) is utilized by each entity. I was trying to utilize Entity.Location.Parent.Server.Processing.Contents.IndexOfItem( Entity ) and assigning it to a state on the entity and then ultimately writing to an output table. However, this doesn't seem to be working accurately. It may be a timing issue on when this step is called, but is there a default function I'm just not aware of that could be of assistance?

-

I am trying to set up a custom object subclass for a conveyor that emulates an accumulating conveyor which has configurable "zone" lengths and overall lengths. Zones can be equated to "cells" in Simio. For example, if I have a 6' long conveyor with 12" zones, then I would have QTY 6 zones on the 6' long conveyor, which means a traveler capacity of 6 and a cell count of 6. For a 6' conveyor with 24" zones, I would have QTY 3 zones, traveler capacity of 3 and cell count of 3, and so on. In my custom object subclass, I have custom properties for the conveyor length and zone length. I have a function that calculates the traveler capacity based on this. The issue I am having is setting the initial traveler capacity and fixed cell count properties to reference the output of this function. The problem is two fold: 1) How do I create a default property value that references another property or function within the same object instance? For example, say my object subclass is called "Conveyor_Custom" and my capacity calculation function is called "CapacityCalculation". I am able to reference the function output by typing Conveyor_Custom1.CapacityCaculation in the property pane of the first object instance (which is Conveyor_Custom1) on the main model, but I have to type this out for each instance that I create (ie. Conveyor_Custom1, Conveyor_Custom2, etc.). I am looking for a way to set the default value for the entire object subclass to reference the calculation from it's own instance. This default would need to be set within the object definition itself, so that I could drop many instances of the object into the model without needing to type in the name of each instance into the property pane manually. For example, something like Self.CapacityCalcuation would be great, but I am not sure there exists a generic self-reference placeholder and I can't find it in the documentation. 2) Even when I type in the capacity calculation reference manually for each object instance, I still get an error for the NumberOfCells property. For example, in the main model, in the property pane for the first object instance, I can manually set the InitialTravelerCapacity to Conveyor_Custom1.CapacityCalculation and get the correct value returned with no errors. However, when I set NumberOfCells to Conveyor_Custom1.CapacityCalculation, I get the error "Invalid numeric value". The output of the function is an integer (I have some rounding in there to make it so) so I am not sure why the value is invalid. I also tried setting it to Conveyor_Custom1.InitialTravelerCapacity and this also throws the same error. It would be convenient to be able to set the traveler capacity and cell count to the same value, since on accumulation conveyors with defined zone lengths, this is the real physical situation. It doesn't make sense for me to have to manually calculate this and input the actual integer value when there is already a function set up to do this and other properties are able to reference the output of that function. If anyone has experience with this please let me know, in the meantime I am doing it manually but it is very tedious. Thanks!

- 2 replies

-

- properties

- subclass

- (and 16 more)

-

Hello Can simio use time series data (say from an excel file) as cost input for servers, that updates every hour?

-

New to Simio and learning as I go. The attached model includes a CombinerNode1 that batches entities in groups of 2 & 5 (random.discrete). I would like Server1 to use different processing times for the different batch sizes. For example, a batch of 2 entities should be processed in 5 seconds; Batches of 5 entities in 7 seconds, etc.. Eventually I will create batches of up to 6 entities. I have tried using Server1.Processing.Contents for Processing Time, but seems to return the value of 1 all times. Any help is appreciated! Thanks! Processing time based on BatchSize.spfx

-

The conditional routing by link weight (PackFeed2 - Conveyor22 or Conveyor 23; PackFeed4 - Conveyor26 or Conveyor27) is not working for me. The current file is set to make the decision by initial priority, but I have tried other methods with no success: > Assign ModelEntity.Priority with addon process, then route by link weight of ModelEntity.Priority=="X" > Assign link weight by ModelEntity.EntityType > Assign link weight by ModelEntity.BatchMembers.Contains("X") I think this may not be working because they are arriving as a parent/member batch. Is there a different link weight condition that may work. Please note I have 1 parent type and 2 member types. The decision needs to based off of the member entity. The area of concern is towards the end of the process at the top left of the simio (file attached). APS Design 2.spfx

-

Hello I need to forecast costs using an exponential model and then use it for simulation input. Basically, I want to tell simio that the price for this hour is given by this equation, and this price is used at this place and then minimized as part of response in optquest. Any ideas how this can be done? TIA!