Search the Community

Showing results for 'output table functions'.

-

I have attached a simple example of one approach. 1) I edited the ModelEntity object and added a state array of type MatrixFromTable. This type of array is automatically initialized from a table. Ideally I might have also added a table to the entity, but Simio doesn't work that way. Instead, I added a RepeatGroup named InitializationValues consisting of a Real property. I used this repeat group as a way to essentially add a "table" into the object, since internal to Simio there is almost no difference between a table and a repeat group. 2) Back in the model I added a table and then imported data into that table from Excel. I used 10 rows, but I could have imported 350 rows with no change to anything else. 3) Now when you place the ModelEntity object into a model, you can pass a table into the InitializationValues repeat group. Again, intead of just typing a bunch of values into the repeat group, I just say go get the whole repeat group from a specified table. This has the result of sizing that state array inside the model entity to match the current size of the table, and then initializing the state values to whatever is in the table. 4) If you run the model, you can open the Watch window on any entity and view the values of its states. I expect this won't solve all your problems, but maybe it will give you a fresh approach to consider. ImportStateValues.spfx ImportStateValues.xlsx

- 2 replies

-

- 1

-

-

- state array

- repeat group

-

(and 4 more)

Tagged with:

-

I think this will be very useful as well. I am looking at production output statistics and would like to see periodic statistics. I am going to try this out. Hope it works. Thank you so much

-

Hello, I don't think you attached a file to your post. I would recommend looking at the Output Tables help topic. Instead of using the Server's built-in State Assignments, you may need to use an Add-On process with an Add Row step followed by an Assign step to update the Output Table. Happy modeling! Adam

- 1 reply

-

- output table

- assign table state

-

(and 1 more)

Tagged with:

-

Hello every body. I am a beginner on SImio and this software is very powerfull. I have a problem I want to modify Fixed route vehicle's destination. I don't want a vehicle on demand.I need a fixed route vehicle. But I need to modify the vehicle's destination. Because I want the first vehicle Go to the first source and i want the second vehicle go to the second sources. And I have 80 vehicle and i want this loop destination for all vehicle. It's works very well for the First 5 vehicles ( For Source_Aub_Char in my model) and it's doesn't work for the sixth and after it's works. But my method doesn't work for all vehicle. I don't understand why. My method is : - I select the current vehicle with "Path1.Contents.FirstItem" - And After with "set Row" i selected différent sequences table for the current vehicle - I do a count for the number vehicle entrance and the model choice the good sequence table with this counter. There is my simplify model in attachement. Some body can help me to see what's wrong or to give me a better method ? Thank you very much. And sorry for my english i'm french. Question FOrum.spfx

-

Hi everybody! I have a problem at the moment that defines a state variable in an output table. In my example, I defined an integer state variable which tried to give a reference for the row in the output table. Then, I assign on server state assignments the time in process and tried to write it on the output table. I attach the file so it can be better understood. thanks for helping me!

- 1 reply

-

- output table

- assign table state

-

(and 1 more)

Tagged with:

-

Multiple Entity with multiple sequence tables

GFurtado replied to JanainaF's topic in SI General Discussions

Check a SimBit named Choose Alternate Sequence. It creates a process containing the Set Row step to change the current sequence table. -

Maybe my formulation was not clear enough: I am asking whether it is possible to memorise a state value for each minute (in a table or array) and read the values of this on a later timestep?

-

I have a question regarding the use of a model state value at a specific timestep. I used a Tallystatistic and processes to calculate the output of a server for a specified interval, based on the Simbit Hourly Statistics. This works, however I dont want the value of the same timestep, but I want to use it two timesteps later. So for example if a server A output variable equals 10 at timestep t=1, I want to save this value as part of the input for server B for timestep t=3. So the value should be 'memorised' for two timesteps. I was wondering whether there are any suggestions on how to model this?

-

Hi Tere, We still largely used the manual approach, however we used a lot of subclassed object to make sure a change gets applied to all 8 models. We also made use of the table based autocreate to create the different layouts. We do have 8 separate models and we just copy paste the processes. Essentially we could have had one model but with 8 different sets of bindings, this was also not ideal as we have multiple table and even just selecting all of the different bindings while testing would have been cumbersome. If you find a better way please let us know. Regards, Willem

-

Hi all, I made a model of a production line (starting with 2 servers) and I am wondering whether it is possible to change the processing time of the second server based on the actual output of the first server. Theoretically seen the processing time of the server 2 = Speed of server 1 * E , in which E is a fixed formula (connected to server 2) to correct the speed. So if the first server performs according to expectation (without failures) for example 40 the processing speed of the second server is equal to 40*E with a delay of the conveyor time between server 1 and server 2. If the server has failure and thus have a lower output (for example, 30), I want to change the processing time of the second server accordingly to 30*E with a delay of the conveyor time between server 1 and server 2. Does anybody have an idea of how to do the following: How can you monitor the actual output of the first server at each timestep? Is it possible to fix the proposed formula and use it in an add-on process? How can you take the conveyor time delay into account (using a delay step in the add-on process?)? I am quite new to the software so I am not sure whether it is possible to model this in Simio. Thank you in advance!

-

Is there a way to create a column of Time property without date using Simio Table, just like the start time and end time of day pattern of the work schedules? The work schedule doesn't suit my needs.

-

Waiting on the path if there is no seat in input buffer

asneath replied to Sea Jung's topic in SI General Discussions

I noticed that the Source is not making just two entities, as you stated, it is actually making several as governed by your Interarrival Time. But since you have Output@Source1 (TransferNode) Blocked Destination Rule set to 'Select Available Only', all entities created after the first two are waiting until one of the Servers has finished processing. You will notice that once Server1 has finished processing, an entity is released from the Source (since its destination has been assigned). I would recommend exploring this further by enabling 'Model Trace', from the Run Ribbon, to see what is happening behind the scenes. Happy modeling! -

You can use seperate servers (each has 1 capacity) each represents individual firms. Create entities (raw products) via a data table where you should also include one column (a node property from object reference property) to represent where the created entity will be processed (as its destination). Then at the output node of the source object set entity destination type property to specific. Then set node name to Table1.NodeInstanceProperty1. The entities will be routed appropriately.

-

Referencing List State Variable in Expression

gocken replied to james.waller's topic in SI General Discussions

It seems defining a list state variable within a data table will work? -

Hello together, would be very thankful for any advice: I have a sequence table with sequences according to their workstations: A - B - C - D If I only have one operator, they can just be done one after another. If I have 2 Operators A and B can be done simultaneously to C. How can I model this? The problem is probably, that the entity (batch) has to be splitted to let workstation A and C run at the same time. I tried it with process-add-ons like creating a second entity and transfer it to Station C. There might be a much easier solution?! Thank you in advance!

-

Hello, I'm wondering if anyone has a good idea for how to view a resource's utilization according to the day of the week in the pivot grid of an experiment? Currently, my best idea is to just have a status plot in the facility window to illustrate this but I'd prefer to have an average utilization by day of resources in the pivot table. The scenario I'm working with is having "technician" resources that are being seized by server objects to do "maintenance" on the truck entities coming into the maintenance shop. I'd like to see which days of the week are the busiest so I could determine where to schedule new technicians. Any help is greatly appreciated. Thanks! Pit-To-Bay Off-Shift Rule Fixed.spfx

-

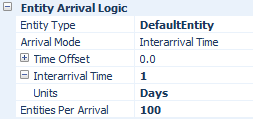

Ok, in this case, I tried to solve it using a regular Data Table. Maybe not the prettiest solution, but check the attached model. I used the TimeNow expression to check what day is it and assigned the Entities per Arrival property to that day's row of the data table. Arrival.spfx

-

Sry i said it should be 100 each day, that was just a mean which i dont want to use. I would like the rate table to make 100 day one, 98 day two and 102 day tree, and a mean cant be used, cause i need to model the reality in the process. And as mentioned before, should the source make all the entities from the table at ones (when the workday starts).

-

-

Hi, I have a source with a rate table, it is set to make an output of 100 entities every day. The problem is that the entities comes out one at a time trough that day, but they should all arrive together at the start of the day, so that the servers has the whole day to process them.

-

Two entities, where one always will be processed first

GFurtado replied to svend2000's topic in SI General Discussions

I set ModelEntity.Priority = X at Output@SourceX State Assignments property, but it could be assigned anywhere before the server. -

John, I too believe Task Sequences could be very useful for your project. For example, for the multiple patient types coming in, you could utilize a Branch Type of 'Conditional' in your Task Sequence so to only use a certain workflow for that type of patient. There is a general description of Conditional and Probabilistic Branching in the Simio Reference Guide Help page titled "TaskSequence" along with some other helpful information on Task Sequences. Additionally, I recommend you take a look at the SimBits titled "Task Sequence and Worker In Table (from project Task Sequence And Worker)" and "Using Relational Tables to Define Task Resource Lists". If you investigate how Task Sequences are used in these examples, I believe you will find some methods that might help you in your modeling endeavors. If Task Sequences still do not help you achieve your goals, it would be helpful to have more details on what you are trying to do. I think writing your own steps should be resorted to later after other options have been exhausted. If you email in to support@simio.com we can continue our conversation.

-

I want to be able to schedule events for the future without having to define a separate timer for each possible time this will happen. Ideally i'd like to be able to index into a vector of timers to start one, so it can be dependent on a state variable. One use of these would be recurring tasks, for instance, while a patient is in post-surgery, they will be administered medicine every r hours. This is dependent on them exiting surgery (it doesn't begin at a specific time), so a rate table doesn't really work, and that would run into a similar problem of having to define different rate tables for each patient type and recurring tasks (potentially hundreds). Any ideas?

-

I'd recommend you read the Create help documentation. It provides some detailed info on how the step functions. It also mentions the CONWIP and DynamicallyCreatingVehicles SimBits for examples using the Create step. For my second suggestion, yes this can be done with variables. What I would do is create a new Source and Sink that create entities that just tells the model to perform logic. And since this is just a regular sink, you can specify when to create those entities however you desire (by arrival table, randomly.....).

-

I have a system with 3 steps. At each step a certain amount of product is process and batched (using a combiner) on to a pallet. I have to assign a sequence table to the member entities and the parent (pallet) entities. However this is resulting in some batches sitting at a combiner because the pallet follows the sequence instead of going to the next batch ready if the pallet is empty. Any thoughts on how to handle this? If there is no call for an empty pallet the pallets could stay where they are or go to a specific location.