Search the Community

Showing results for 'source objects disappear'.

-

Hi everybody Not sure if opening a new topic is the best way, but I did not manage to find (even with Search) a discussion on the possibility to create fixed objects (servers, workstations or objects of fixed class) in a dynamic way. Here is what I mean: Entity enters the model if(the needed fixed object exists) -> entity is routed to that object else a new fixed object is created entity is routed to that object I tried the Create step in a process, but as far as I can go this step creates an Agent type of object. I'd appreciate any suggestions, ideas, feedback - thanks people!

-

Hello, My model has 157 control variables now and it turns out I need about 300 runs per experiment and is at over 90MB. I can leave my experiments to run over lunch or if I’m away from my desk, but what becomes cumbersome is when I have to make a change to my object class, but my computer doesn’t respond when I click on a node, path, station, etc. in the facility window to make a change. So then I have to remove all my objects from the main model and make my changes to the object. When I do this, then I lose all my experiment settings (Set Referenced Property). Also, there is the issue that when I change the physical screening line in the facility window, then if that object is still in the main model, it gets resized. So then I have to remove the object from the main model and drag a new one in, which also makes me lose all my experiment settings. I find that making changes to my model and resetting the experiments is not efficient. Is there anything I can do to avoid all this extra work or is this just part of Simio? I have 8 GB of RAM and an Intel Core processor at 3.10GHz. I'm running Simio version 7.114.1171. I’m due for an upgrade anyway, but don’t actually think I would gain anything compared to what I have with my model now. Thanks. Maryam

-

Hello everybody, I was wondering if it's possible to import/export sub-models, or if I should focus my efforts in trying to build a custom library instead? I'm building some models which could potentially be used in other projects later on if they could be imported instead of rebuilt from scratch. I'm not really familiar with how customized objects are created however. Any input is appreciated

-

I have a problem with the source arrival mode.For the source "Arrival Mode" i want to use "On Event". So for "Triggering Event" i have 3 options. Object@Entered, Object@Exited and Object@CapacityChanged. So in my model source A is delivering something to sink B. And every time the entity from source A entered sink B a new entity should be created. So i used "Input@SinkB.Exited" and "Input@SinkB.Entered", i tried both. Because i don't really know if there is a huge difference. I guess the exited will create an entity as soon as the one entity left the system through the sink and the entered as soon as the entity enters the sink. But please correct me if i am wrong. So anyhow my problem is now, that the Source is creating more entities as it should. It creates entities even if now entity entered the connected sink. Maybe you guys can help me why that doesn't work as it should be.

-

I want to create library of warehouse objects. This should have a hierarchy (one storage cell, rack composed of those cells and aisles composed of racks), I want vehicles to go through those objects for example enter aisle, than enter rack and cell, after that another cell/cells in rack, than the same in another aisle. But vehicle (or entity) have the problem, that thay cannot see through objects they don't know what is behing. So if they are ordered just to move through some objects, thay will fail to do so. Is there any good approach to solve this? Or is it better to just have cells and connect them on model level?

-

Senior Industrial Engineer - Simulation Req #: 67308BR York, Pennsylvania, United States Engineering & Technology Platforms & Services Posted on:03/29/2021 Job Summary Career Level Experienced Travel Percentage 10% Full-Time / Part-Time Full-Time Clearance Level - Must Currently Possess None Shift 1st Shift Relocation Available Yes ITAR: U.S Citizen or Green Card Required Yes Clearance Level - Must Be Able to Obtain None Job Description What motivates you? If the answer is a position where you can develop your skills and earn opportunities for advancement while being part of a forward looking team then this is what awaits you in a career at BAE Systems. Our employees work on the world’s most advanced combat vehicle systems. From the M109A7 Mobile Howitzer with its long range firepower to the Amphibious Combat Vehicle that transports America’s Marines from ship to shore, we are developing the technology of tomorrow while delivering the most cutting-edge equipment available today. Our flexible work environment provides every opportunity to positively impact the company without giving up your personal life and we welcome all those who understand the importance of improving production velocity, having big ideas, and craving innovation. We draw strength from our diversity and always put our customers first through an unwavering commitment to bring the warfighter home safe. Does this sound like a team you want to be a part of? If so, come build your career with BAE Systems. The Combat Vehicles line of business within the Platforms & Services (P&S) Sector of BAE Systems is looking for a self-motivated Senior Industrial Engineer to support the production scheduling of armored military vehicles. Working as a team member of a larger Industrial Engineering Group, this Engineer will be required to build and maintain simulations for varied fabrication, assembly, and testing processes. The candidate must also be comfortable with soliciting input through face to face interaction and, in general, must demonstrate that they possess strong analytical, problem-solving, and interpersonal skills that will support individual and team growth. A strong background in discrete event simulation, specifically with the use of SIMIO, is necessary. Specific responsibilities include: Day-to-Day · Complete simulation support activities such as time studies, production line balancing and production metric development · Evaluate complex Technical Data Packages (Drawings, Bills of Material) and be able to understand how a component or vehicle is assembled · Utilize a strong understanding of integration activities like implementation of standard work, material kitting, metric tracking, and process improvement to advance manufacturing methods. · Work on the manufacturing floor with other Engineering disciplines, production supervisors, and employees that directly interact with the components or vehicles being produced. Internal and External Customer Relationships · Engage in regular communications with production support, planning, logistics, quality, manufacturing supervisors, and direct labor workforce to assess operations performance. · Summarize and present findings to internal customers to gain buy-in for improvement efforts · Discuss the status of metrics and key performance indicators with appropriate decision makers Development · Work with Industrial Engineering leadership to understand the expectations of new Engineer within the organization and company · Share responsibility of self-development with immediate supervisor · Maintain a safe work environment and ensure compliance with safety objectives and policies. Required Education, Experience, & Skills - 4+ years of simulation experience within SIMIO - BS degree from an accredited university Preferred Education, Experience, & Skills Demonstrated capability with the use and application of SIMIO discrete event simulation software. About BAE Systems Platforms & Services BAE Systems, Inc. is the U.S. subsidiary of BAE Systems plc, an international defense, aerospace and security company which delivers a full range of products and services for air, land and naval forces, as well as advanced electronics, security, information technology solutions and customer support services. Improving the future and protecting lives is an ambitious mission, but it’s what we do at BAE Systems. Working here means using your passion and ingenuity where it counts – defending national security with breakthrough technology, superior products, and intelligence solutions. As you develop the latest technology and defend national security, you will continually hone your skills on a team—making a big impact on a global scale. At BAE Systems, you’ll find a rewarding career that truly makes a difference. The Platforms & Services (P&S) sector under BAE Systems, Inc does the big stuff: the armored combat vehicles, naval guns, missile launchers, and naval ship repair…just to name a few. Our employees take pride in the work they do and why they do it. They are on the front lines every day, building our products to protect the lives of those who serve. We may be biased, but we think P&S does some of the coolest work around, and we think you will too. At BAE Systems, we celebrate the array of skills, experiences, and perspectives our employees bring to the table. For us, differences are a source of strength. We’re laser-focused on high performance, and we work hard every day to nurture an inclusive culture where all employees can innovate and thrive. Here, you will not only build your career, but you will also enjoy work-life balance, uncover new experiences, and collaborate with passionate colleagues. https://jobs.baesystems.com/global/en/job/67308BR/Senior-Industrial-Engineer-Simulation Thanks, Jenny Ridings, PHR Principal Talent Acquisition Specialist BAE Systems My pronouns are she / her M: +1 904 570 2489 | E: jenny.ridings@baesystems.com https://jobs.baesystems.com Connect with BAE Systems: Join our talent community!

-

Multiple entities arriving at exactly 8am each day.

lstretton replied to Kameswara Sukesh's topic in SI General Discussions

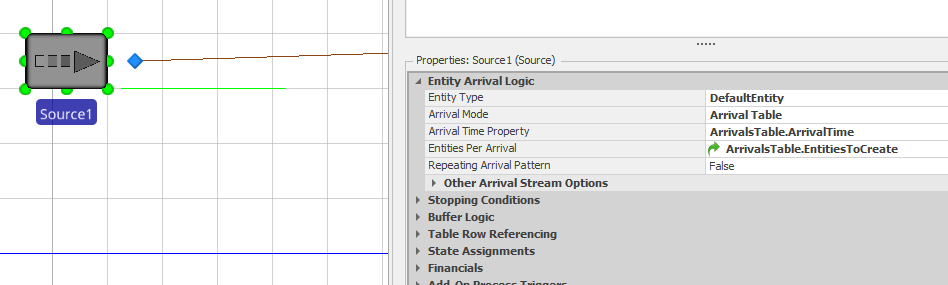

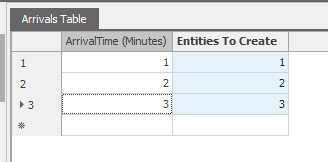

You might want to look into Arrival Tables. See the following screen grabs. Configure the source to create entities based on the arrival table as follows: Setup the arrival table to define the arrival time and the number of entities per arrival as follows: Hope this helps, Lucas. -

Hi, I have 6 entities arriving at exactly 8am each day. Each of the 6 entities will create a certain number of entities on arrival from their respective distributions. How do I model in my source? I cannot have multiple sources as each entity has its own server processing times. Please can you help? Thank you

-

Hello everybody, Is there any way to collect state statistics for each candidate from population of i.e. vehicles without sub-classing this object? I have i.e. v1ehicle with a population of 8, I want to have the number of movements for each of this 8 forklifts. Can I do it without subclassing vehicle object or making 8 seperate state statistics elements? Thanks in advance.

-

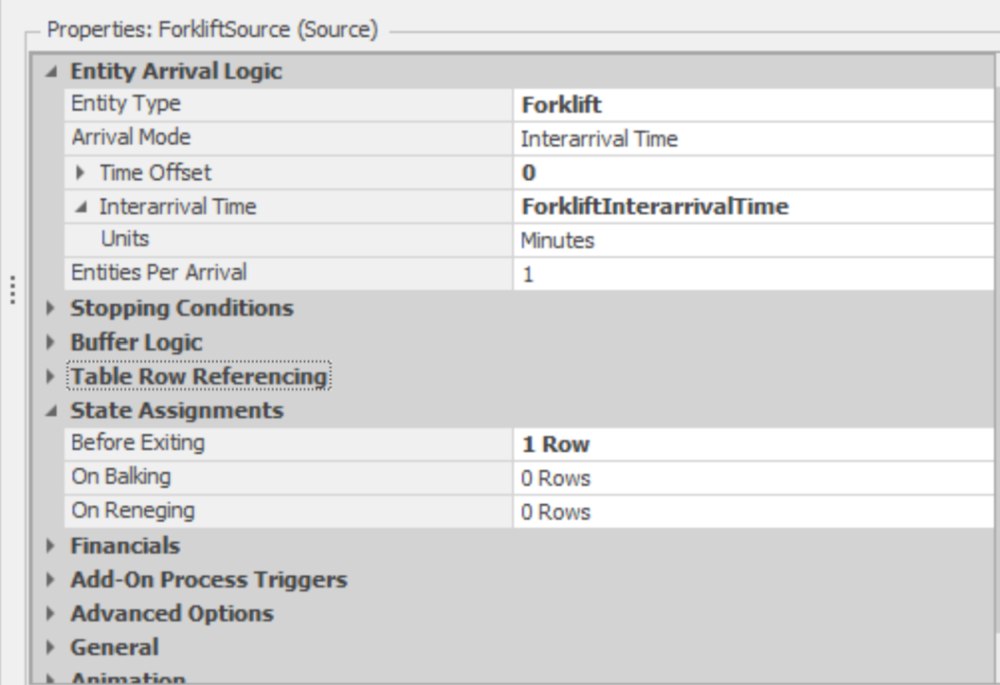

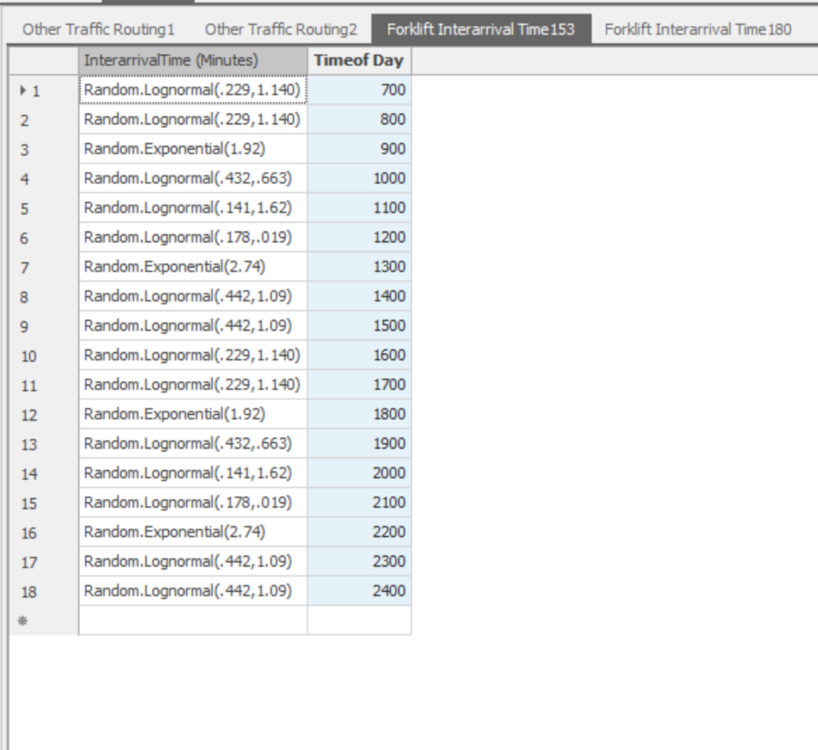

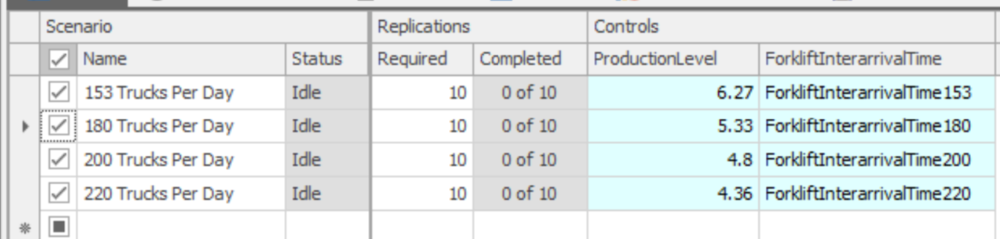

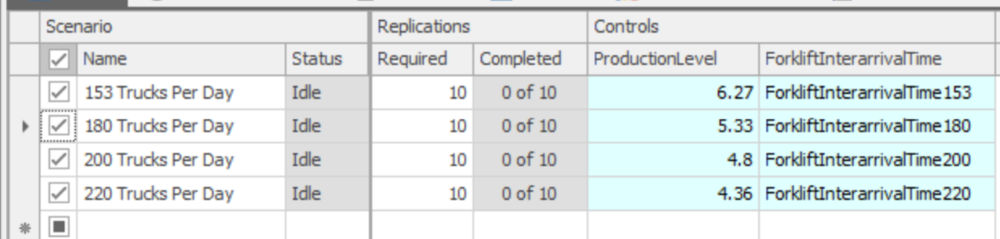

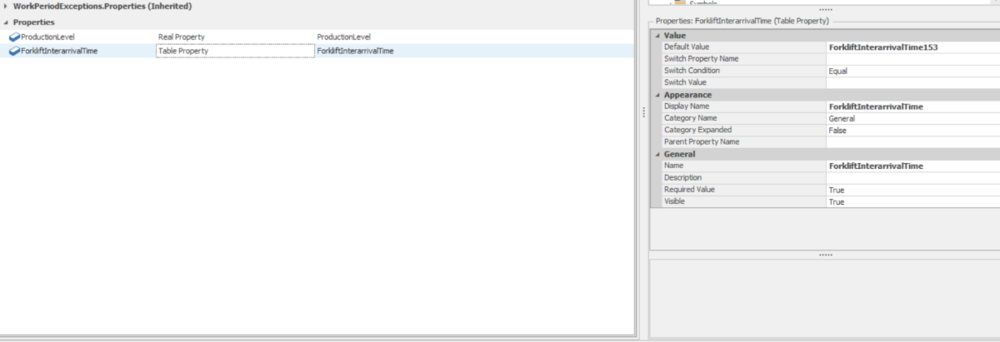

I have a source, called forklift source, that has a varying interarrival time based on the time of day. To do this, I created a time indexed table with the different interarrival times in different rows and the interval period set to one hour. This source also depends on the interarrival time of another source called Newtrucksource, but not on an hourly basis. I am trying to conduct an experiment where the interarrival time of newtrucksource changes with different experiments and a different time indexed interarrival table for source 1 is used for each of these different interarrival times. To do this, I created a real property for newtrucksource's interarrival time and a table property for forkliftsource's time indexed interarrival table. However, I can't get this to work because in the model, the interarrival time property for the forkliftsource must be a "number" and I am referencing a table which comes up as using "string". Trying to find a way to make this work.

-

Record Statistics Per Entity Throughout Simulation

Emiliano posted a topic in SI General Discussions

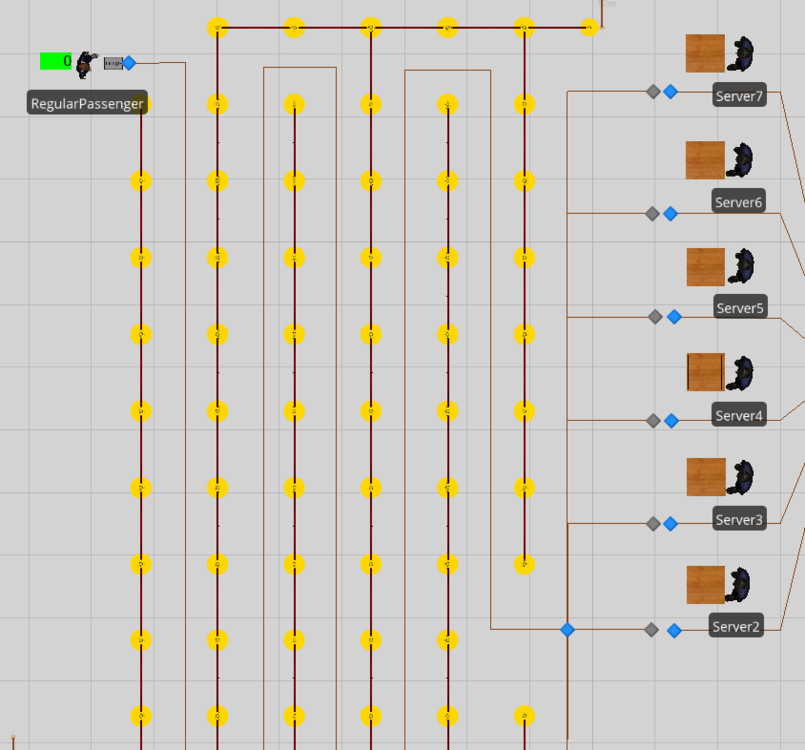

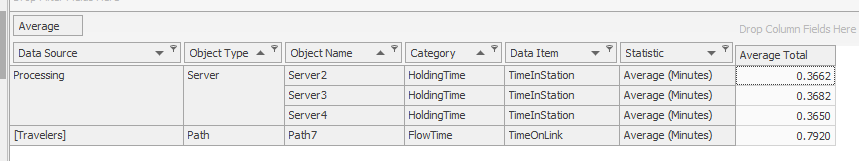

Hi! I have been using SIMIO for quite some time now, but I have barely come across this need. I need to record the time spent per entity at any given path/server in the simulation, rather than obtaining the average time for all entities at the end of the simulation. Take the image below as an example. I need to record the time spent in the link (TimeOnLink) per entity generated. The path corresponds to that connecting the source to servers 2-7. Then, I need to record the time spent per entity on servers 2-7 (TimeInStation). I can display the unique ID number for each entity by Entity.ID, now I need to match the statistics. I figure the best way to model is trough ExcelWrite, but I can't manage to make it work. Any hints? The plan is to get the following information per entity, rather than a summary of all entities.- 1 reply

-

- excelwrite

- entity

-

(and 1 more)

Tagged with:

-

Assigning Stochastic Node to Worker/Vehicle

CWatson replied to pabondaniel97's topic in SI General Discussions

Within each of the Source objects, you would specify (within the output node of the Source) that a worker is required to transport the entity(s) to the next node. The decision making of the worker is then handled by the worker itself. The worker has several decision making options - first of all, for transporting, the worker has Transport Logic properties, one of which is the Task Selection Strategy property, which can be set to First In Queue, Largest/Smallest Distance or Largest/Smallest Priority. In addition to that, under the Worker's Add-On Process Triggers properties, you have the Evaluating Transport Request process that can be used to accept or reject any transport request. You can add custom logic, a distribution, etc. within a Decide step in that called process and simply then accept (Token.ReturnValue == True) or reject (Token.ReturnValue == False) a request (which is the first in the allocation queue, as ranked as noted above). You can use the requesting entity location within the decision logic as well. -

Modeling multiple cranes on a common (shared) runway is hard to do well. Still harder when you take into account acceleration, crane blocking, and good 3D animation. If you have encountered this problem, here is a solution. For standard bridge crane movement, we recommend the simpler Crane object in the Extras library. But if you need the underhung cranes with cabs moving between bays, read on... The Simio Crane Library is a collection of objects designed for modeling multiple cranes operating simultaneously in a bay. The library is provided as an example of complex material handling using the standard features of Simio. The Crane library may be used in conjunction with the Simio Standard Library, and Crane pickups are done using the standard TransferNode (e.g. the output side of a Server). Crane drop-offs can be done at either a BasicNode or TransferNode. The Crane Library can also be used with custom libraries as long as they support rider pickups using the standard transporter ride features. The Crane Library consists of objects representing the Bay, Bridge, Cab, Lift, and Crane (the end effecter that actually picks up and drops off the item). These objects are combined together to model multiple cranes moving in a single bay. The separation of objects in this way allows you to use your own symbol for each component. A Crane movement occurs by first rising up from the pickup node to a specified travel height, traveling laterally at that height, and then lowering down to the specified drop-off node. All travel is done through free space without the need to explicitly draw a network. The Crane library also fully supports independent acceleration/deceleration and the ability for one crane to cause another blocking crane to move out of the way. The above library file is now obsolete. Instead, download the library posted closest to the bottom topics. Like all Simio-provided libraries, this library is open so you can look at how it was built, learn from it, and subclass your own objects to improve them. But unlike our built-in libraries, this is not fully supported (although we can provide some help) and we may not continue enhancing it, particularly if we decide to build this capability into the base Simio products. We are anxious to receive your feedback on this library.

-

In fact, even if I use just two simple nodes without any steps and other objects, it is not possible to create a street route on map, while it was possible until about a month ago. The features of my software are as follows: Version: 12.205.20430 (64bit) License Type: Academic RPS Expiration: 2021 - 06- 30 Best regards, Milad

-

Hi everyone, I am working on a project that has more than 2,000 different arrival distributions. The distributions are all exponential, but they all change over time. To illustrate: suppose I am modeling 30 companies around the world, each company with a group of suppliers (or clients), each supplier (or client) with a group of parts (or orders) that will be arriving in my company to be processed. Each one of these parts coming from each supplier to each company (I will call it a combination) has its own distribution that changes over time. [this is an analogy to my problem] If I had only 1 company with a few suppliers and a few parts, the natural solution would be to use Rate Tables. This would be good because I want to investigate the impact of different Rate Scale Factors (increase or decrease of arrivals) on my key performance indicators. However, as I mentioned, I have more than 2,000 different distributions. So, my main question is: does anyone have a suggestion about how to create these arrivals in an efficient manner? I am assuming creating one source and one table for each possible combination would not be efficient, as it may make the model super heavy. I have thought about two different solutions (which I am not sure if it is good and, even worse, I do not know how to implement yet). So, recommendations to any materials, SimBits or tutorials that might provide more information about my ideas are really appreciated. #1) One idea was using an object inside an object in Simio. This may reduce at least a few combinations?! However, I do not know how to model objects inside objects in Simio. #2) Letting Simio auto-create all my servers and auto-fill the information using tables. This means that I would create one source for each combination. Although this may not be computationally efficient, at least I would not have to drag and drop each one of them. But again, I am new to this auto-create object tool and I do not know how to implement it. So, I really appreciate: - any ideas on how to solve my problem in an efficient way - materials that may teach me how to solve my problem using my idea #1 or #2. Another issue is that RateTables (as far as I know) cannot be imported and binded. So, how can I input all my 2,000 columns of arrival rate data in Simio? Otherwise, my solution #2 is really bad. I have also discussed the idea of grouping the arrivals together and using TableRowReferencing and discrete distributions ("mix") to reduce the number of possible combinations. However, the team I am working with does not think this is a good idea, since each distribution change over time in a different way. So, combining them may not be very accurate. Thanks!

-

Hello, I have the following situation, I have a source followed by 3 servers in parallel. These servers are then connected to a fourth server, which finally leads to the sink. The thing is I need that the 3 first servers must hold the entity (stay blocked) until the fourth server is free. Additionally, if one of the 3 servers in parallel has capacity available, this one must stay blocked until de fourth server finishes its process. I attached the model I made, and the main problem are the three servers in parallel which are staying blocked after the first entity pass through. Thanks in advance block.spfx

- 2 replies

-

- blocked server

- queueing

-

(and 1 more)

Tagged with:

-

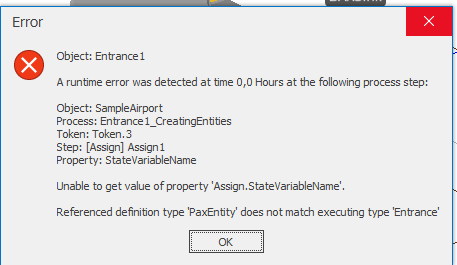

Hi, I am trying to use an assign step to assign a date/time state from a table to an entity. When I try to run the model, I get the following error: "Referenced definition type 'PaxEntity' does not match Executing type 'Entrance'. Entrance in this case is a source object. What is this executing type it is talking about? Any ideas on how to fix this are also appreciated. Kind regards, Jason Airport Library.spfx

-

Hi Jason, I recommend using a Notify step with the expression Token.AssociatedObject.Name prior to your Assign step. This will read out the associated object that is executing the process with your Assign step. It might be that the Entity is not the object executing that process. If your entity is not executing the process, you might want to find another process trigger or Search for the entity in the population. If its a process that could be triggered by an entity, or another object, say a Worker, you could start your process with a Decide step that filters out the non-ModelEntity objects. This could be as simple as checking 'Is.ModelEntity' with the Decide step. Happy modeling, Liz

-

Hi, I am trying to build an object library for an airport terminal. For this, I build the objects as separate models and place them in a 'sampleairport' model for testing them all together. The 'sampleairport' model contains all the objects, so it has no issue referencing to properties from the placed objects. However the other way around does not seem possible. For example; I want the user to import a standard format flight schedule, which will be uploaded in the 'sampleaiport' model. Now I need to reference this table from the other models, but Simio does not allow me to do this? Is there a way I can reference the table or other properties from models in my other models? Thank you Jason

-

I have a model where I have 7(seven) entities and for each entity there are many possibilities paths. Is possible an entity be programmed with multiple sequences tables? For example, the entity can go to source -> server1 -> sink, and also randomly it can go to source -> server2-> sink, something like that.

-

Hello, I am interested in doing a simulation model with a colleague. Because of this we want to reduce the workload by dividing the tasks to be done. Is it possible or is there any way to join different files (models) into a final one? Or copy objects from one model to another? Thanks in advance.

-

One Model With Differents Collaborators

TweeMansLeger replied to Marcos's topic in SI General Discussions

Your colleague can create models that will be part of an object library for your model. - You can't join different models into a final one but - You can import a custom object library made by your colleague. On the project home tab > Load library > Select your colleague's SPFX file > Import Now you can drag and drop the premade objects into your cooperative final model. This is how I collaborate on projects. -

If arrival rates at sources and processing rates at servers are all same there should not be any difference between these two systems. Check 1) Are the processing times of all server objects are same? 2) Are the interarrival times of source objects all same? the conveyor speeds does not affect the queue length. It does affect only finishing time of processing parts.

-

As far as I know the answer is "no". But, right click on one of them and select "Object property spreadsheet". Then in the panel opened below select i.e., travel logic and you will see a list of the path objects on left. Select one of them. Then, you will see it is selected in facility layout as well. I hope this feature can meet your requirements at least to a degree?

-

Process Logic Design for Data-Generated Models

oalotaik replied to oalotaik's topic in SI General Discussions

Thanks Adam for the reply. I know a fair amount about Processes; I just needed a clarification about some aspects related to large models created using tables. The example I mentioned in the original post may be simple but it could easily scale to include 100's of locations. I will give some examples of these aspects that get tricky in such large models below. Thanks Glenn for the clarification. The tip about finding where processes are being referenced in a model is great! The MultiEchelonSupplyChain example may look simple, but it has the potential to be complex. When I asked the question what I had in mind is a similar model but with 100s of locations like DistributionCenter and Retailer (Basic Nodes). Imagine you want 300+ basic nodes (like in my case) to have the same add-on process. Imagine having 300+ inventory elements that you want to write statistics for using a Write step. It's tedious to do things manually. As for referencing the same add-on process for 100s of objects (basic nodes in my case), I found a trick, which is to add the add-on process to one of the objects and then sub-class it so that the process becomes a default for the newly sub-classed object. Then change all the other objects to the new sub-classed object. As for writing statistics for 300+ inventory elements, I couldn't find a way to automate the process. To be clear, I want (for each inventory element) to write statistics at various points throughout the simulation run. The standard reported stats for inventory elements are only "Totals" or "Averages" or a function of the two. What I want is to see how a statistic changes over time, so I need to write to a CSV file using a Write step. When working with large models, there's a need for automating some modeling aspects. Creating objects and elements can be easily automated using tables. It's dealing with these created objects and elements that sometimes needs tricks and workarounds to automate.