Search the Community

Showing results for 'source objects disappear'.

-

Hello! So I am using a source that is sending out 9 different entities, each with a priority 1-9. They are listed in a Data table called 'Part Data' This is the 'Table Row Referencing' call I am using in 'Before Creating Entities' in the 'Row Number' section: PartData.Priority.RandomRow I want to switch this to use a Random.Normal(mean, sd) - is that possible with discrete values in the table? Thank you for any help you can provide!

-

Simio has a number of enabling features that are not widely known. When you save a project file, most people use the .spfx extension which is a compressed binary file. But if you would like to take advantage of a version control software (VCS), you generally want the VCS to manage versioning and file compares and file compression, itself. Simio has a multi-file project format referred to with a .simproj extension, which is designed with exactly that purpose in mind. Ths format involves a single key simproj file and a related set of folders that contains the uncompressed version of all the included components. This allows VCS to recognize when a small change to your model is made that it only needs to save that small change and not the entire model. While this works with any VCS, internally at Simio we use Tortoise SVN (http://tortoisesvn.net/) which works quite well for us. Simio also has some built-in features to help track and maintain model/library versions. If you right-click on an object (a model) and select "Properties" you will see a set of model properties for that object including Version. This version number is referenced when loading this object as part of a library to help evaluate if an object has been changed and if the change should be accepted (more on this below). Some additional model properties including Description, Keywords, and Categories. These are available in your model, plus they are available externally. For example the Sample SimBit Solutions interface uses these properties to help you quickly find a SimBit of interest. Some of them are also used in the Model Documentation Report. Speaking of which, the Model Documentation Report is designed to provide a quick way of examining all non-default parameters in your project. It can be useful to instructors evaluating assignments or as a way to record or share a snapshot of your model data. If you click on your Project name in the navigation window, the click on Models and the Edit ribbon you will see various options for subclassing, cloning, and copying library objects. These options, while subtle, give you greater control over how the lineage of an object wil be handled. You will also see options on this ribbon to protect your object from viewing and editing, and also to describe changes that have been made with the latest version.

-

Hi All, I want to do some calculations just before the simulation ends. I did it previous versions without problem but now on version 15.247, "on run ending" add-on process is not being executed.I tested it even on a new simple model file with source server sink. There is just two assign steps with breakpoints on the add-on process. But in model trace it doesnt show the add-process name, the state variable value is not assigned, and breakpoint is not reached. Anyone experiencing the same problem in this version? Is there a quick solution to this? Or do I have to install older version? Kind regards, Tolgahan

-

Hi, I have a source with a rate table, it is set to make an output of 100 entities every day. The problem is that the entities comes out one at a time trough that day, but they should all arrive together at the start of the day, so that the servers has the whole day to process them.

-

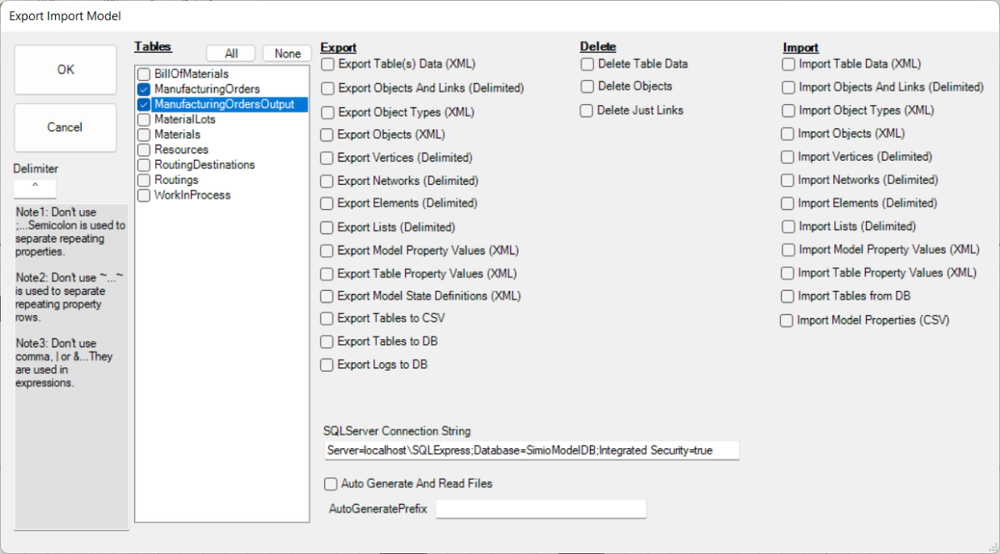

Here is a simple utility that will export, import and delete artifacts of your model. Here is a screen shot of the available capabilities. The code and DLL have can be found on SImio GitHub. Please find at this link: https://github.com/SimioLLC/ExportImportModelAddIn You will also find install instructions in the ReadMe. Here are the changes that have happend over time: Updated 2023-01-31....Added the ability to select multiple tables for export and delete table data functions. Updated 2022-10-05....Updated the exports to sort the data first my name and then export. This ensures that the data exported is in a consistent order. Updated 2021-12-07....Added the ability to select a table and then remove the data from the selected table. If a table name is not selected, all the tables in the model will have their data removed. Updated 2021-09-20....Added Update Model Properties (CSV). With this new method, you can import model properties into your model. If the file contains 3 fields...First is name, then type and last is default value. The only valid types are real, datetime, Boolean and everything else is string. If the model property already exists, it will only update the default value on the property. Note: The example assumes the field separator is a caret '^'. To change this, you need to change the delimiter field. Updated 2021-09-08....Updated the sequence of the exports, deletes and imports happen. When OK is pressed, first the exports are run, then deletes and finally the imports. With this change, I am able to Export Table to DB, Delete Table Data and Import Table from DB from in a single run. I typically do this when re-mapping auto creates elements. Since the table data need to be removed and recreated before mapping of the elements are correctly mapped. Updated 2021-09-06....Upgraded to .NET 4.7.2. Also, fixed the windows form so it displays correctly. When opened, the form should no longer need to be expanded to see all the options. Updated 2018-11-08....Added Export To CSV, Export To DB and Import From DB. Export To DB will create a table in the SQL Server database with the same table name as the table in Simio. The data columns will be of type nvarchar(max) and the default value will be the same as the default value in the Simio table. It is assumed that Simio desktop will still do the data validation, not the database. This feature is used to save the Simio data into a database so it is backed up and can be shared across users. Each time the Export To DB, if the table already exists, it is dropped, and a new table is created. This ensures that the data schemas match between the Simio model and the SQL Server database. Updated 2017-12-05....Fixed index issue with links import. Updated 2017-09-25....Fixed the import of lists. Updated 2017-07-14....Added the ability to auto generate and auto read files. Previously, the files needed to be created prior to running the add-in. Now, they will create by the export. Also, the import will retrieve the same file generated by the export. These options are available when the "Auto Generate and Read Files" option is selected. Updated 2017-07-13....Added the ability to multi-select options. Now, more than one option can be initiated when the OK button is selected. This will streamline the process of exporting, deleting and importing. This tool is very helpful for testing out your model with various configurations to ensure that runs properly under various object and/or data configuration. Updated 2017-07-11....Now supports exporting and importing of model properties, exporting and importing of table properties and delete table data. Updated 2017-06-22....Now supports exporting and importing of data tables using XML. This is simple way to export all the table data from one model and import the same data into a new model (assuming that the same tables schema exists in the new model). Updated 2017-01-27....Now supports exporting of object types using XML. This can be used with the new Configure Scheduling Resources in Simio 9.150 capabilities to define your own object type properties based on an XML document. Updated 2017-01-23....Now supports exporting and importing objects using XML. When using XML, property units are also exported and imported back in. Updated 2016-10-24....Updated files...Added support for repeating properties.

-

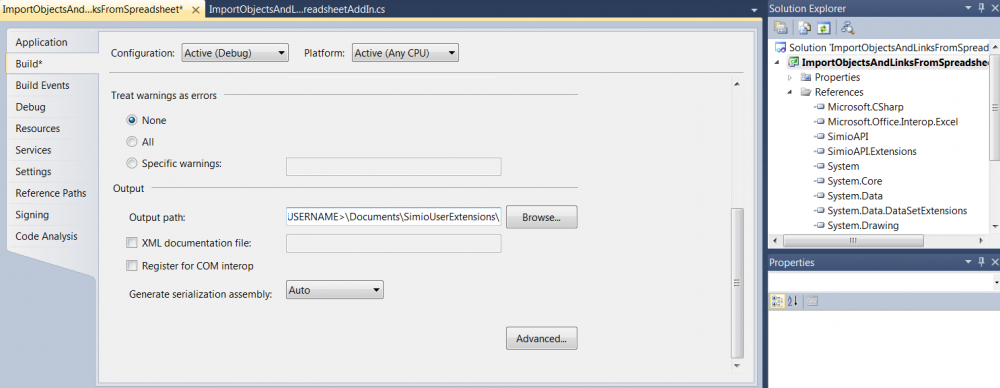

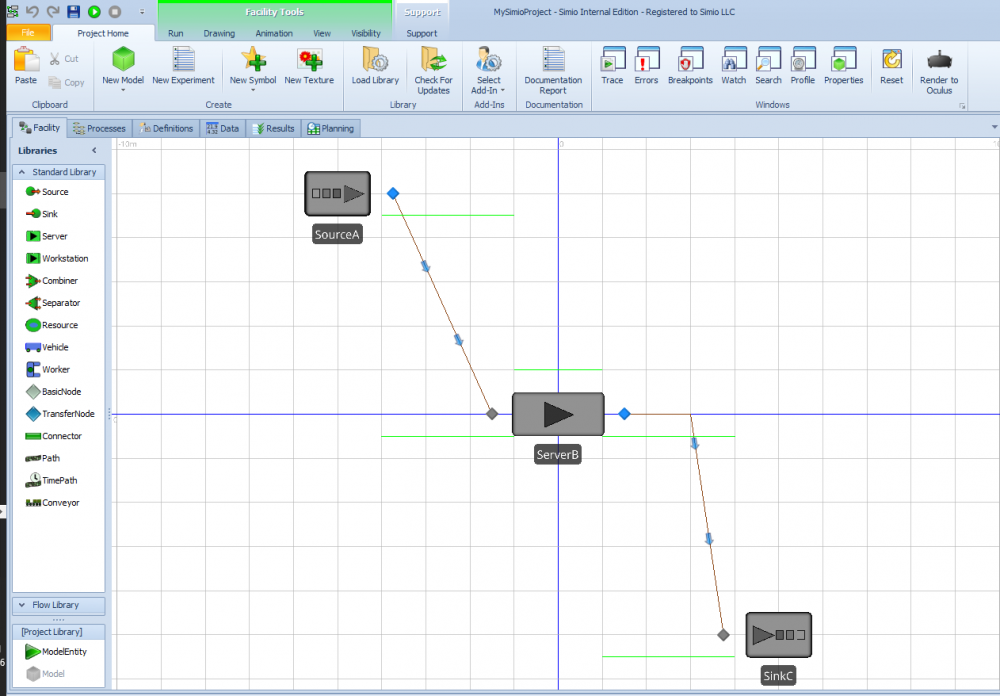

We have added a Simio add-in that will import a model (objects and links) from a spreadsheet. The most DLL, spreadsheet and code are provided in a later post.. NOTE: You do not need the code to run the add-in. All you need is the ImportObjectsAndLinksFromSpreadsheetAddInDLL_V5.zip and ImportObjectsAndLinks_v5.xlsx. The code is also provided in case you wish to make changes to the add-in. You can run the addin just using the DLL and spreadsheet. All you need to unzip the DLL into C:\Users\\Documents\SimioUserExtensions. You might need to add the SimioUserExtensions under MyDocuments (C:\Users\\Documents) in case it does not already exist. Once you run the add-in in Simio, use the attached spreadsheet. It should create a Source, Server, Sink with an Entity and a Vehicle. If you want to use the code, you will need to update the project properties..under build. The output path needs to be C:\Users\\Documents\SimioUserExtensions...See attached screen shot. Give it a try. Let us know if you have any questions. Updated 2106-10-24.....Added support for repeating properties and wrapped import using BulkUpdate method to speed up import . ImportObjectsAndLinksFromSpreadsheetAddIn_DLL.zip ImportObjectsAndLinksFromSpreadsheet_Code.zip ImportObjectsLinksVertices.xlsx

-

I'm having trouble calculating the average time between Objects. I know there's some built in function called time in system to get entity totle time in the system. But now I care the time entity spent between nodes. EG: I have entityA, entityB, entitleC, I want to find the entityA average time spent from server1 to the server6, from server1 to the very end, from the very begining to server4? How should I do these, what does the expression look like? I want to add a label to show that numbers dynamically during the run of the model.

-

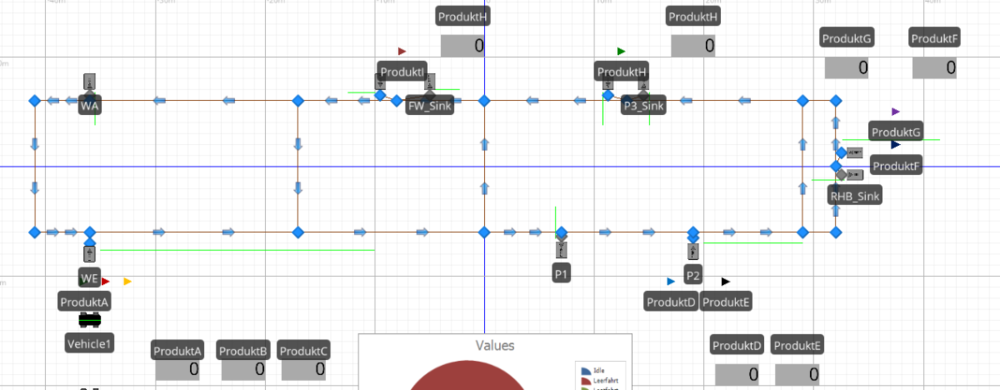

I want to build a simple repository model,as the Picture below. And there are two Funktions, that i donn't know, how to implement. The first Problem is: I hope that several products with different total amount can be generated in sequence one by one. For Example, there are 50 Product A, 40 Product B and 30 Product C at Source WE. They schould be generated in sequence. First 50 Product A,1,2,3...50 one by one generated. Then 40B, generated one by one and finally C. At present, I can only achieve one-time generation of all A, then all B and All C. The second Problem ist: there are may be 10 Vehicles in the System. I want to record the total time of the car loaded and empty travel time, and the corresponding percentage of these two items. I would be very very grateful if you could help. I'm really in a hurry and hope to get your help.

-

I'm trying to initialize a model with over a 100,000 entities of the same type. However, when I do so, I get a warning "the number of active entities in the simulation has exceeded 20,000 objects". If I continue, Simio basically crashes after a few minutes. I tried to scale everything down by a factor of 1000, but then when I try to create entities in quantities < 1, it doesn't seem any entities get created. So my question is how do I balance out the need to have 100,000+ entities and the need to be able to create new ones on a much smaller scale (10s for example). Thanks in advance for any help with this.

-

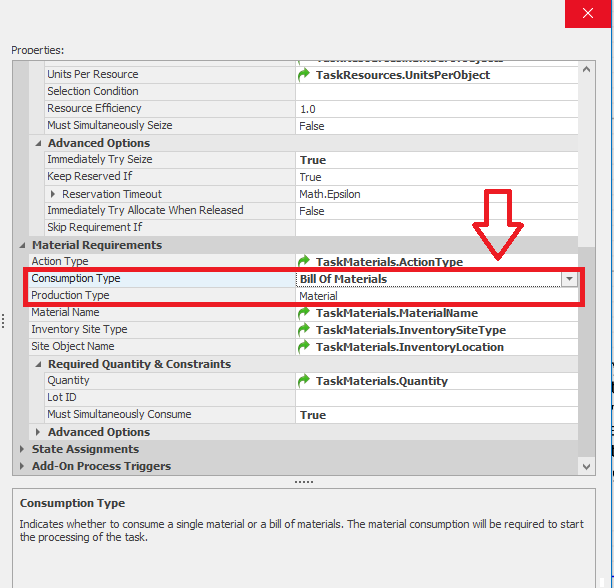

Hi all, I want to create a list of tasks from data table which I will use in the server objects tasks sequence. When I want to refer to all of the properties of material requirements to data tables, I am facing a restriction as follows: a) I can refer the material "Action Type" (Consume\Produce) property from server object to data table by adding an "MaterialActionType" enumeration property to data table. b) If referencing in a) was NOT done, for the selected action type (lets say produce was selected), I can refer the "production type" (Material/Bill of Materials) property by adding a "MaterialOptions" enumeration property to data table. However, when I do the task in a) an additional row appears in server object, now showing both consumption type and production type in properties. Then I am unable to set reference to data table as in b) any more. Is it possible to refer BOTH "Action Type" (Consume/Produce) and "Material Options" (Material/BOM) simulatenously? If yes how? Could you please guide? Kind regards, Tolgahan

-

To model shelves, I am trying to create a series of custom "Shelf" objects (subclass of servers) located in a grid pattern. I used a spreadsheet to automatically calculate the coordinate locations and generate a name (string) for each object based on its position within the grid. With just the Shelf object types in the spreadsheet, can bind the file to my object reference table no problem, import the data, and populate the facility window with my objects. That part works fine! Next, since I have an aisle running between the rows of objects, I wanted to set it up so that the objects all face "inwards", ie. the input and output nodes for the objects are facing the aisle. Originally I thought of rotating the Shelf object, but I ran into 2 issues: first, I discovered that I can't set the Shelf yaw orientation from the table, so that's not going to work. Second, I realized that even when I rotate the Shelf in the facility window, the nodes do not rotate with their parent object. I decided I would leave the Shelf in the same orientation as it is placed, but I would just re-locate the input/output nodes to the opposite edge of the Shelf objects on the far side of the aisle. For this I would need to make sure I can set locations for the input/output nodes in the same object reference table. When I added a row to the object reference table from within Simio (prior to binding to a spreadsheet), a drop down appeared, and I could select the input or output nodes for any object that already existed in the table, and then define the node's location in the cartesian coordinate columns. When creating a node this way, the node location is still relative to the object, ie. I can drag the object in the facility window and the node moves relative to the object, which is perfect. This input/output node creation and relative location definition via table is exactly what I am trying to automate, but this is where I started running into problems. In my spreadsheet I used formulas to generate names for the nodes to match the formatting of the input and output nodes in Simio (ex. "Input@..."/"Output@..."). I also added a formula to assign all input node object types to BasicNodes and all output nodes to TransferNodes and calculate the desired location coordinates for the nodes. The spreadsheet I made has the same format as the table in Simio where I tested manually creating and positioning the nodes. The issue is that when I bind the table and import the spreadsheet data to my model, the node names automatically change and are no longer formatted to reference the parent object. Because of this, these name-changed node objects are created in addition to the input and output nodes that are created for each Shelf object. However, if I remove the binding and add a new row, once again I can find the node name in the drop down list and assign the coordinates manually, and the input/output node that references the parent object will move to where I send it. My question is: how can I set the input/output node locations for the objects when creating objects from a table? There are over 500 Shelf objects in the table so I do not want to locate them manually, but the automated method is not working either. The only idea that I have is to make a new object "Shelf2" and define the external view to have the nodes on the opposite side, but that seems like a less-than-idea solution because then I would have 2 custom objects to update and maintain, that are otherwise identical. I am hoping that I don't have to do this hacky solution but I am interested to see if anyone else has dealt with this and has ideas. Thanks!

-

In the source of my model, I would like to generate arrival events by looking through row by row of a given table. However, I only want to create the 2nd arrival event when all the entities of the created by the first arrival event has moved beyond a certain point, where Globalstatevalue = 0. So in my process flow, I did something like this:When the globalstatevalue = 0, I want to go to the next row of my table and generate the 2nd arrival. I did this my fire an event The setting at my source: Arrival Mode: On event Triggering Event Name: name of event that I fired in the process flow. I managed to get the initial arrival to make sure that the Globalstatevalue = 0. condition is reached. However, the 2nd event is not triggerd at all and the CurrentRowNumber is not incremented as well. May I have some advice please? Thank you

-

Hi, is there a way to add a fixed object? For example, I added a floor in project, but sometimes I always accidentally move the floor instead of moving the object. How to set the floor to be fixed/"unmovable"? Thanks.

-

Hello all and thanks for letting me be a part of Simio Insiders I am closing in on having done my first source, server, sink simulation. It is done as a part of a University study and is due next week. Feel free to download my attempt and have a look at it. The process I want to simulate is as follows: 1. Chef recieves an order of 1-6 beef patties 2. The chef puts the patties in a grill, that has capacity of 12 patties, and a base cooking time/process time of 1 minute total (that increases with order size) 2a. If more orders come in, while the grill is preparing an existing order, they have to be put in queue, as the grill should not be interrupted. When the grill/server is free again, it will take all - or up to 12 - from the queue, depending on how many orders are in queue 3. The patties go to the sink I am using a Time Varying Arrival Rate table from real life data, on the course of 2.5 hours. The trouble I am having is as follows, and please, feel free to only answer some of them, if you don't have answers for all: _____________________________ a) Order size We want to have orders vary from 1 to 6 patties, per order, in a way that resembles this distribution: 1 (min order size) patty ; was ordered 2 times 2 patties ; was ordered 18 times 3 patties ; 9 ... 4 ; 7 5 ; 3 6 (max order size) ; 1 I have not been able to imitate this behavior. Right now, I use Entities per Arrival to be Random.Possion(2), as this looks a bit like this distribution above, but the flaw with Poisson is (I believe), is that an order-size of 0 patties is a possibility, which doesn't make sense. I have also been playing around with a lookup table, without a real clue on if that's the right thing to do. What should I do to resemble this? _____________________________ b) Server (grill) behavior The problem right now is, that the grill (server) can keep taking in patties, even if it's already processing. That doesn't make sense, if you think about it, since you can't put patties into a closed grill. I want it to start preparing an order, as soon as it gets it, and just let the queue of patties build up until the grill is free again. Then, take up to 12 patties into the grill. _____________________________ c) Process times For the grill, I want the process times to follow the amount of patties in the grill. The grill takes 60 seconds to prepare a patty, and we assume each patty takes 2 seconds to load. Therefore, we choose to simplify that: 1 patty takes 62 seconds to make 2 patties take 64 seconds 3 ; 66 sec 4 ; 68 sec 5 ; 70 sec 6 ; 72 sec 7 ; 74 sec 8 ; 76 sec 9 ; 78 sec 10 ; 80 sec 11 ; 82 sec 12 (max grill capacity) patties ; 84 sec Which is basically y = 2x + 60 In the simulation I uploaded, each patty, no matter the order size, just takes 60 seconds, which is incorrect. How do I get the grill to behave like this? _____________________________ d) Batching After getting the server behavior to work, I want to work with the utilization of the grill. My idea is, that if the server (grill) is told NOT to start preparing patties right at the moment, it receives the order, e.g. if the quantity is small, but instead waits a certain amount of seconds, to see if more orders should come in, maybe the total wait can become less. There shouldn't grow any large queues with the current arrival rates, but if we double it, it might become relevant, so customers shouldn't wait for too long. Another option would be, that it waits till a certain amount of patties are in queue, such as a minimum of 6. _____________________________ Thanks again, and I sure hope you will take a look at this! You are more than welcome to edit the file, but it is also fine, if you just type in here. Best regards, Johan Grill.spfx

-

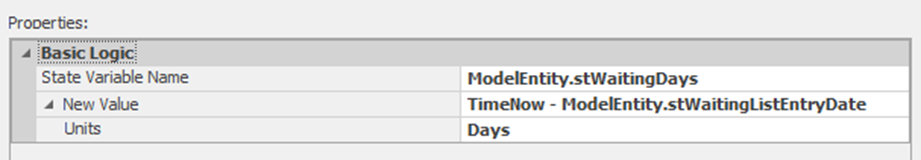

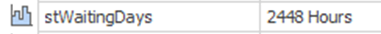

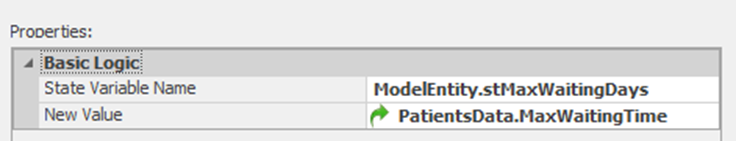

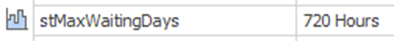

Hi, I'm having trouble with unit conversion when doing state assignments at a source. There are two different cases where this problem appears in the model: Subtracting TimeNow minus a Date Time state variable (ModelEntity.stWaitingListEntryDate) Although the specified unit for this property is 'Days', the assigned value is in hours and the unit is also 'Hours'. If I manually convert it by dividing by 24, the assigned value is in days, but the displayed unit is still ‘Hours’. Unit conversion issue when assigning a new value to a state variable from a data table Although the PatientsData.MaxWaitingTime is a real property with default unit ‘Days’, the assigned value to the state variable is converted to ‘Hours’. As in the first case, if I manually convert it by dividing by 24, the assigned value is in days, but the displayed unit is still ‘Hours’. In the attached model (time_units_conversion.spfx) you will find a simple example where you can see this in more detail. Any suggestions to solve this issue will be highly appreciated. Thank you and best regards, Nicolina

-

- state variable

- state assigments

- (and 8 more)

-

Hi, I´m looking for a solution, that a source can create different entities (Part A, B and C) in a certain order (and then repeat it, not based on random). For Example: 1st Arrival Part A, 2nd Arrival Part B, 3rd Arrival Part C, 4th Arrival Part A (and so on). Is there an opportunity to realise this? I tried to use a data table, but probably I missed a necessary step. Thank you for helping. Chris

-

Here is an add-in that will rename the objects in your model based on values in a table. The first time you run the add-in, it will create a table called "Object Name Change". The uses will add the existing object name(s) and the new object name(s). Once done, run the add-in again and the object names will be changed in the model. To install, download the "RenameObjectsDLL.zip". Extract the "RenameObject.dll". Right click DLL and select Properties and then Unblock. Then, copy DLL into "C:\Users\\Documents\SimioUserExtensions". You might need to add the SimioUserExtensions folder under MyDocuments (C:\Users\\Documents) if it does not already exist. The c# code is also provided in the RenameObjectsCode.zip RenameObjectsDLL.zip RenameObjectsCode.zip

-

Hello, and thanks for the Vehicle with Driver model; it seems quite useful. However, I've run into a problem when using two different vehicles that require the same driver; wondering if someone can help. Situation is where a Part (Entity) requires Vehicle_A with Driver_1 to go from Source to Station_1, then requires Vehicle_B with Driver_1 to go from Station_1 to Station_2 (Exit). If another Part arrives at Source (requesting Vehicle_A) while Driver_1 is busy with Vehicle_B, the request gets put into the global VehicleRequestQueue. When Driver_1 becomes free/idle, it looks at the global queue and sees the request, but for some reason Driver_1 seems to ignore it ("...failed to find and plan an eligible visit request"). Is that because the request was for Vehicle_A and not the Driver? If so, how would I get Driver_1 matched up again with Part Entity requests for Vehicle_A? Thoughts? Thanks, John

-

Hi What limitation in the number of symbols ("objects") are you referring to ? There is not such a thing, as far as I know

-

Hi, I have a production line with 2 sources. The arrival of entity A in source 1 triggers an arrival of entity B in source 2. Entity A and entity B then enter their respective servers for a processing time. Entity A is processed at table_openings between 10 and 15 minutes with probabilities whereas Entity B is processed at table_MF for 10 minutes. The process type is task sequence. Both Entity join at a combiner. Entity A is the parent and Entity B is the member. Afterwards, the combined entity continue along the production line. I have expected processing times for each task at each server. Before starting a task, a process starts where a state statistic registers the state processing time of the entity. I also put list state to verify the schedule utilization. I have verified visually and the state value for processing time is correct for every station while the simulation is running. What I have observed is that the state statistic average processing time for the servers before the combiner is the expected value, however, all the other stations are 10 minutes off. The simio output has the right processing times for all the stations after the combiner but not for the two stations before the combiner. Moreover, the list state average time busy value are ok for all the stations after the combiner but again the station before the combiner, it gives the total number of minutes it was busy. Also, if i do the average of the state log observation for each station in excel afterwards, I get all the correct processing times. I am guessing it has something to do with the combiner, but I am lost. How can the processing time for table_MF be 10,48 when the processing time is a fixed 10 minutes in the facility window? Why is the list State MF and OP different from all the other list states? Thank you for your help!

-

Hello, I got an issue that I do not know how to solve. I have 2 sources creating different entities I need them to stop creating according to a Workschedule. I can assign this schedule to the Separator but not the sources. Thank you in advance for any support.

-

Hi all, I'm trying to do an information network model, and I need to have hundreds of thousands of "nodes" in this model, each node would need a source, server, and maybe a sink. And the "nodes" need to be connected to each other as well. Is it possible do create such "node" automatically instead of manually creating them? And would the runtime efficiency be okay? or should I switch to other simulation software/language? Any suggestions would be appreciated. Thanks!

-

Hello, I would like to make a server disappear when I finish processing entities with it. Would there be a way I can do this ? Thank you, Flora

-

Hi, I have an issue related to workers going off-shift and abandoning the reserved entities in different servers, depending on when the shift change happens (picture attached is an example). The shift change is based on switching from Worker of x number of population to y number of population to meet my WorkSchedule. The Worker should always carry different entities throughout, entities cannot travel alone. The logic issue happens as a result of entities left in servers or buffers that were not picked up by workers due to the end of shifts, causing too many objects/entities in the system not destroyed. An expert suggested to build process that checks the Worker's Allocation Queue when it goes off shift to see if there are any entities in it, and if there are, turn the Worker back on shift. I tried to build that process, but I could find the right steps. Any help on identifying the right steps or a different way to model workers shifts is appreciated.

-

Hello Simio-Community, I want to simulate a vegetable garden with a source, with a maximum number of vegetables (maximum arrivals in Simio). People can take as much vegetables as they want in the garden until it is empty. Once one vegetable has been gathered it takes a few weeks to grow again. Do you have an idea of how I can handle this ? I'm quite new in Simio. Thank you in advance,