-

Posts

28 -

Joined

-

Last visited

-

Days Won

3

ttarkan last won the day on March 7 2023

ttarkan had the most liked content!

About ttarkan

Personal Information

-

First Name

Tolgahan

-

Last Name

Tarkan

-

Company/University Name

Simulation Helpdesk OÜ

Converted

-

OCCUPATION

CEO at www.simulationhelpdesk.com

- WEBSITE

Recent Profile Visitors

1,955 profile views

ttarkan's Achievements

-

So lets say task B is dependent on Task A, hence Task A has sequence value 10 and Task B has sequence value 20 (Task A preceeds TaskB). Task A branch type should be conditional and for the condition formula should be written in to the "condition or probability" fieldç For Task B enter the processing time and other data as usual. If the auto-cancel trigger is set to "All immediate predecessors cancelled" (as it is by default), Task B will be cancelled if the condition for Task A didnt return true value. Hope this helps

- 1 reply

-

- 1

-

-

Is it possible to use neural networks with continious flow library? I have a microgrid simulation model with solar panels which charges a battery and grid are energy sources for a house. Grid charges at different rates based on time of use (TOU, i.e time of day and winter summer holiday etc) and solar company charges at fixed rate as energy is filled into battery. I would like to optimize the system using machine learning so that the house minimizes their bill by deciding when to chose grid and solar.

-

You can also use produce consume material method to add requirements to a process or processing step. You can see it when you change the process type to Task Sequence from Specific time. You can add more than one material requirement by adding tasks in parallel with same sequence number and specificying the material name and quantitiy that will be consumed for each parallel task. In that way you dont need to create and destroy uncessary entitites.

-

ttarkan started following Rate tables not working

-

Just want to remind you that the values in the rate table shows the offset from the simulation start time. Not actual day time. So if your simulation start time is 7 am your first row shows 7 am to 8am time frame and so on. Hope this helps Regards

-

Try adding the value zero for the last three lines of the rate table. Set the interval size to 1hr. That should fix your problem.

-

Hi All, I want to do some calculations just before the simulation ends. I did it previous versions without problem but now on version 15.247, "on run ending" add-on process is not being executed.I tested it even on a new simple model file with source server sink. There is just two assign steps with breakpoints on the add-on process. But in model trace it doesnt show the add-process name, the state variable value is not assigned, and breakpoint is not reached. Anyone experiencing the same problem in this version? Is there a quick solution to this? Or do I have to install older version? Kind regards, Tolgahan

-

ttarkan started following Simio-Related Positions Desired or Positions Available

-

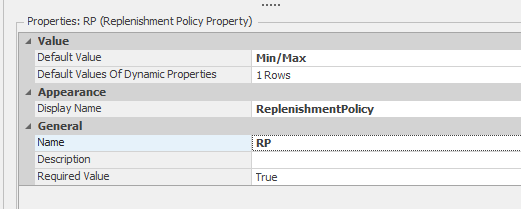

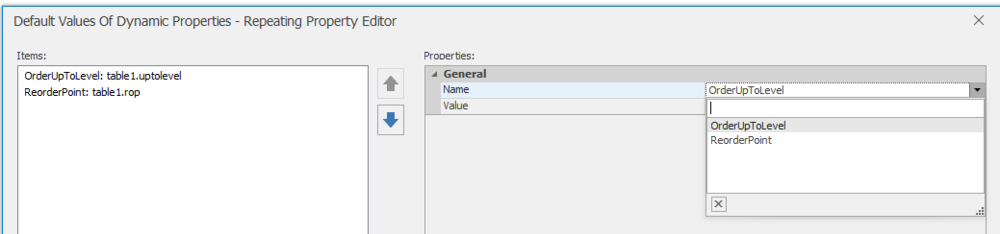

I found the answer again. For those who want to know: step 1) Add replenishment policy property to data table step 2) Chose a default value for replenishment policy step 3) Click default values of dynamic properties According to selection made in step2, the list of properties now appear at step 3. (If min/max is selected OrderUptoLevel and Reorder Point will appear)

- 1 reply

-

- materials

- data tables

- (and 6 more)

-

I want to create a list of materials from data table. I can refer to inventory replenishment policy from table by adding by adding "replenishment policy" property from data tables. But how do I define the default values of Re order point and Up to Level parameters for these auto-created materials? I cannot see such option even in the built in Material Table Scheme. Any help is really appreciated. Kind regards

- 1 reply

-

- materials

- data tables

- (and 6 more)

-

Yes it is possible. There are very good simbits about this also with loopback rules and predecessor method. Write task sequence in simbits you will see it. Hope it helps.

-

Zan, I think we were facing the same problem. I found the solution. You can check here. Hope it helps.

-

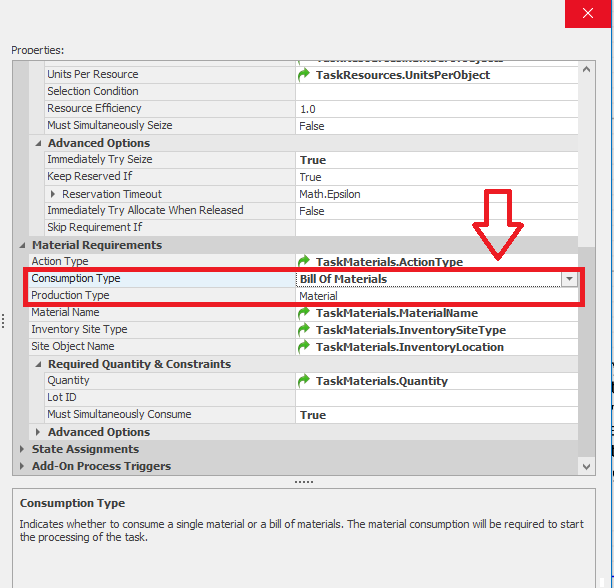

Hi all, I want to create a list of tasks from data table which I will use in the server objects tasks sequence. When I want to refer to all of the properties of material requirements to data tables, I am facing a restriction as follows: a) I can refer the material "Action Type" (Consume\Produce) property from server object to data table by adding an "MaterialActionType" enumeration property to data table. b) If referencing in a) was NOT done, for the selected action type (lets say produce was selected), I can refer the "production type" (Material/Bill of Materials) property by adding a "MaterialOptions" enumeration property to data table. However, when I do the task in a) an additional row appears in server object, now showing both consumption type and production type in properties. Then I am unable to set reference to data table as in b) any more. Is it possible to refer BOTH "Action Type" (Consume/Produce) and "Material Options" (Material/BOM) simulatenously? If yes how? Could you please guide? Kind regards, Tolgahan

-

ttarkan started following SI Sprint Releases

-

Crane Library - Bridge and Underhung bridge cranes

ttarkan replied to dsturrock's topic in SI Shared Items

How can we add a secondary resource requirement to the Crane such as Operator? -

Entity Distance travelled on Transporter

ttarkan replied to ttarkan's topic in SI General Discussions

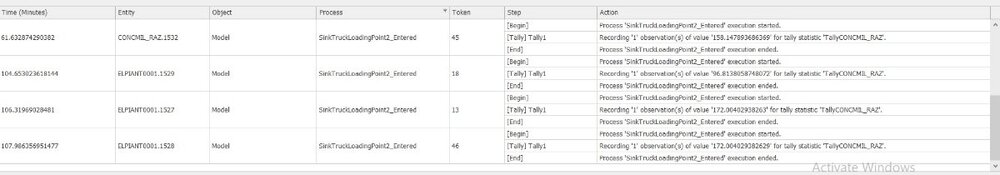

Hi again Liz. I found the problem but it wasn't easy to figure out with the RowForKey formula. I used the search function with tablerows as collection type. When I filtered the trace on the search and tally process, I found that the the table index of the found item and index of the search function was not the same in some cases especially for "small" type products. Further even the available row count of the products table was not returning the correct number rows in the table. The products table has 810 rows but it was finding 197 rows only in the search function. I had a separate "productsize" table which consists of "size" key string property and some other real type properties such as forklift capacity for each product size. I had used this productsize.size as foreign key in my main products table. I figured that the search function automatically filters to the products those matches the size of the product eventhough in search function match condition I only write ModelEntity.EntityType==Products.ProductName. When I removed the foreign key from the products table the problem was solved. Thanks for your help anyway. It was very useful and saved a ton of time from me. -

Entity Distance travelled on Transporter

ttarkan replied to ttarkan's topic in SI General Discussions

Thanks you so much for you help Liz. That's such an advanced modeling techinique I had never heard of before. I would never be able to figure it out myself. It has almost worked but correctly. It has recorded the results for some tallies correctly but recorded some tallies on the wrong tally. I think there is a problem with the set row feature somewhere. I have no problem with setting rows elsewhere in the model such as arrivals from production and arrivals from truck tables create entities correctly with all their state variables. The product list table also has unique "productnames" (entity instances), set as key and auto set-row property is set to true. I have added another coloumn with element tally statistics reference (DistanceOnForklift) to products table. I have auto created it as you suggested and turned on the auto-set row feature to true. Both my product names and tally statistics coloumn are set as key in same "products" table. But the tally step still doesnt record them to the correct tally statistics. Where am I doing wrong? Would you still be able to help me? Shall I send you the model in private message? Here is the formula I have inputted 'Products[Products.ProductName.RowForKey(ModelEntity.EntityType.Name)].DistanceOnForklift' and in the picture below you can see that tally step records into wrong tally element on last three entries. I would be glad if you could help me.