Search the Community

Showing results for 'server capacity'.

-

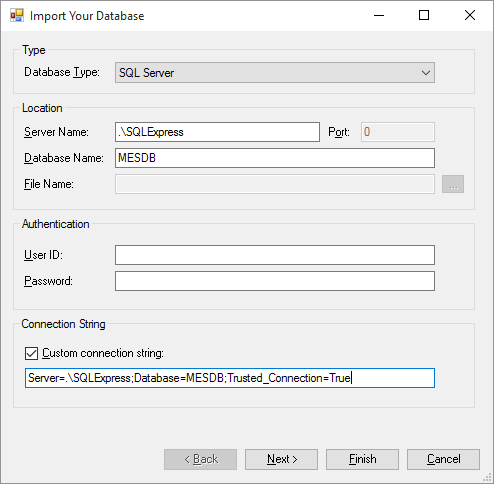

If you are binding a table to SQL Server Express, use the following connection properties If using SQL Server Security, you can specify the server name, database name, user id and password in the fields that are provided. If using Windows security, use a custom connection string. In the connection string, specify the server (e.g. Server=.\SQLExpress), database (e.g. Database=MESDB) and Trusted_Connection=True

-

I am working on a simulation of a number of firms processing raw products. If I represent the firms as resources in a server -so that the server capacity represents the number of firms, how could I identify which resource/firm processed a certain batch of products? Can this be done with a server having a capacity of its own, or should I use a pool of (secondary) resources with id labels so I can use that id to label the product batch?

-

Hi All, is there a way to make the server waiting for two (or any defined number) entities to begin the processing? I would like the server to begin processing only when two entities has arrived. Then the two entities leaves the server at the same time, and other two begin being processed. Can I do it without defining a process?

-

Hi , I have a system with a combiner, that combines different variations of batches. On exiting the combiner the crane picks the combined entity up and drops up at a server. Each of the different batches will have a different load and unload time. Is there a way to do this? Basically, does batch contain product ‘A’ if so crane time is ‘X Mins’ Does batch contain product ‘B’ if so crane time is ‘Y Mins’ Thanks for any help!

-

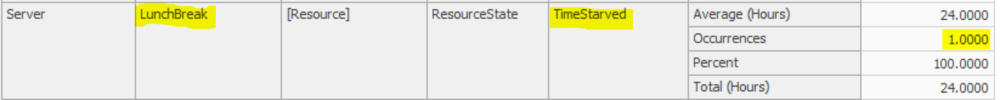

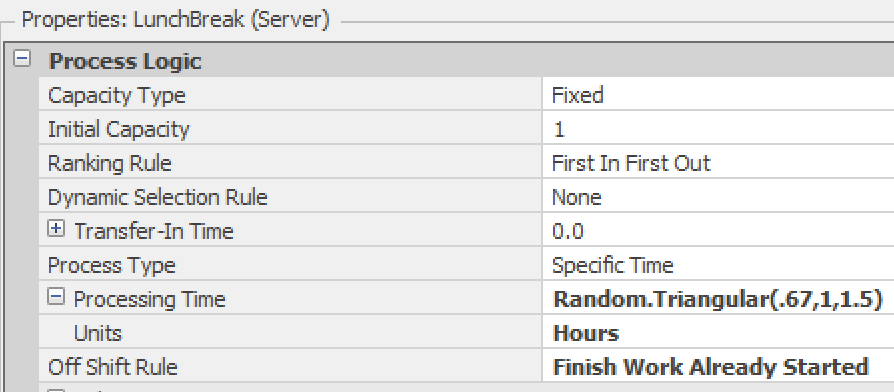

Hi - I have a vehicle that moves through several servers, one of which is 'LunchBreak;' however, when running the model, the vehicle parks at LunchBreak and the people do not get off and nothing more happens the entire run. Thoughts as to why it gets stuck here?

- 6 replies

-

- sequence table

- model trace

- (and 3 more)

-

Dear all, I have searched for quite a while in the public part of this forum, but I could not find the solution of my problem even though there were some similar issues. I have four servers and a worker who is required as secondary resource for each of them. The worker switches and is doing fine so far. However, for my optimization problem, I need to simulate the amount of workers that are necessary to ensure smooth operations. Therefore, I would like to change the capacity of each server to 2 for 2 workers or to 3 to simulate 3 workers, etc. Sadly, the capacity of the server is not changing in the simulation even though the data are entered. Is there a solution to increase the capacity of servers with a worker as secondary resource so that always several entities are processed when the simulated worker arrives? Thank you very much for your support. Greetings from Hamburg, Armin

-

Just curious if there's an easier way to go about doing this... Long story short if I am representing multiple physical positions within capacity of a server and I create my own Gantt outside Simio, it's important for me to know WHICH resource (in this case which one of the servers) is utilized by each entity. I was trying to utilize Entity.Location.Parent.Server.Processing.Contents.IndexOfItem( Entity ) and assigning it to a state on the entity and then ultimately writing to an output table. However, this doesn't seem to be working accurately. It may be a timing issue on when this step is called, but is there a default function I'm just not aware of that could be of assistance?

-

To keep things simple, let's just say I have two servers. At these two servers are 3 resources each: Server A has Resource 1, 2, and 3, and Server B has Resource 4, 5, and 6. I have a pre-determined list of Resources that needs to be selected. For example, the Entity would need to go to Server A to select Resource 2 and then Server B to select Resource 4 and then exit. I need help with the logic to help make this work. But then, once the order is finished, the resources to capture changes so the entity might have to go to Server B to get Resource 6 and then Server A to get Resource 1, then to the sink. In the big scheme of things, I'm going to have many Servers and each Server is going to have at least 4 Resources. I'm trying to figure out how to do this in the most efficient way whether it be through lists or built in properties. Thanks in advance!

-

How to increase the distence between entity to entity ?

ViniciusF replied to River's topic in SI General Discussions

To make an entity wait until the runway is free what you could do is set the Initial Traveler Capacity of the Runway path to 1. This way entities will wait at the node before entering the path. I did not understand the first question, but if you need entities to visually appear behind one another, set Allow Passing to False on the path. Alternatively, you could use conveyor instead of path to make entities allign and respect some distance. Hope it helps. -

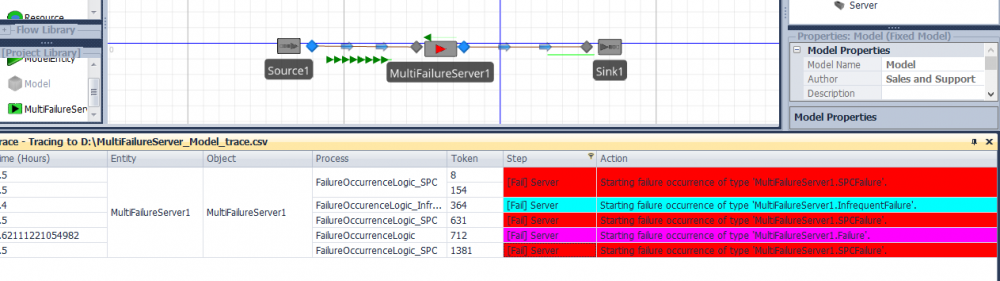

MultiFailureServer.spfx [/img] in response to the above thread: http://www.simio.com/forums/viewtopic.php?f=1&p=9187#p9187

- 1 reply

-

- 1

-

-

Hi all, I made a model of a production line (starting with 2 servers) and I am wondering whether it is possible to change the processing time of the second server based on the actual output of the first server. Theoretically seen the processing time of the server 2 = Speed of server 1 * E , in which E is a fixed formula (connected to server 2) to correct the speed. So if the first server performs according to expectation (without failures) for example 40 the processing speed of the second server is equal to 40*E with a delay of the conveyor time between server 1 and server 2. If the server has failure and thus have a lower output (for example, 30), I want to change the processing time of the second server accordingly to 30*E with a delay of the conveyor time between server 1 and server 2. Does anybody have an idea of how to do the following: How can you monitor the actual output of the first server at each timestep? Is it possible to fix the proposed formula and use it in an add-on process? How can you take the conveyor time delay into account (using a delay step in the add-on process?)? I am quite new to the software so I am not sure whether it is possible to model this in Simio. Thank you in advance!

-

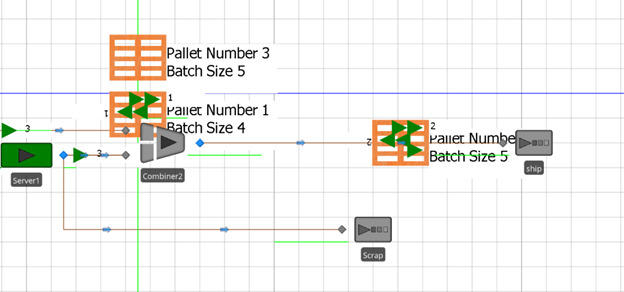

Got issues with a combiner. i have a server that processes the member parts but has a 0.1 probability of going to scrap, this means the batch size has changed. the parent part has a integer state that gets updated when this happens but doesn't update the combiner batch quantity property. I have attached an image showing this issue. you can see the pallet number displayed which is the way i match the parts with the correct pallet. the pallet(parent) also displays the batch size using the same integer state which i use in the combiner logic. Theres a pallet with 4 items on it and it shows the batch is 4 so why wont that process it? Also attached the whole model so you can look at it all Batch and Scrap.spfx

-

Hi All, I want to do some calculations just before the simulation ends. I did it previous versions without problem but now on version 15.247, "on run ending" add-on process is not being executed.I tested it even on a new simple model file with source server sink. There is just two assign steps with breakpoints on the add-on process. But in model trace it doesnt show the add-process name, the state variable value is not assigned, and breakpoint is not reached. Anyone experiencing the same problem in this version? Is there a quick solution to this? Or do I have to install older version? Kind regards, Tolgahan

-

Hello, Worker has a state variable to set ride capacity on run time (Worker.RideStation.Capacity). What you could do is save the number created on a modelentity variable, and set up a addon process trigger on Entered of the node MemberOuput@Separator to first verify if it is a worker (Decide Step with Is.Worker), and if true, you would use a Search step to search through QueueState -> Separator1.MemberOutputBuffer.Contents and assign the Worker.RideStation.Capacity to the value of the modelentity variable found.

-

Hello, I am simulating a restaurant queue with two servers. The queue is lineal and the entity order is FIFO. The 85% of the entities goes to Server 1 and 15% to Server 2. But I need that all the entities do the same path. So, those entities that have to go to Server 2, wait till Server 1 (capacity==2) is empty, and then go to Server 2 (capacity==2) without processing in S1, and those entities that go to Server 1, then, wait till Server 2 is empty, to move on without process in Server 2. The real example is a lineal queue where you have to choose between two foods, but independently which one you choose, you do the same line, taking the food in the server you choose and waiting for the people that is in the other server to finish in order to move on and pay. How can I do it? Thank you so much.

-

Hi, It is possible to add a tear-down time in a server? I have a server with a capacity over 1, so I would like to add a tear-down time to simulate the cleaning of a bed in a hospital after it was used. Thanks!

-

Hey Simio insiders, I have been working on a model with workers. The workers transport goods over a facility, from one server to another. They seem to work perfectly until about 2 hours into the simulation. I have been looking into the the 'watch' properties, and it appears that the worker is waiting for something. This happens eventough i do not have a wait process in place. It waits at a server which it is about to drop an entity. The server input buffer is infinity, since i thought it might have caused the problem. Do any of you know why my worker is waiting?

-

My model assigns capacity of 8 to a server. Two types of Entities arrive...A and C. Before each entity is processed, I am assigning the server's process time using two different random distributions, one for A types and another for C types. My question is whether or not the processing times for any 8 entities in the server at a given time will process to different process times? Or, will the process time of the last entering entity reset the process time for the others that are already in the server?

-

New to Simio and learning as I go. The attached model includes a CombinerNode1 that batches entities in groups of 2 & 5 (random.discrete). I would like Server1 to use different processing times for the different batch sizes. For example, a batch of 2 entities should be processed in 5 seconds; Batches of 5 entities in 7 seconds, etc.. Eventually I will create batches of up to 6 entities. I have tried using Server1.Processing.Contents for Processing Time, but seems to return the value of 1 all times. Any help is appreciated! Thanks! Processing time based on BatchSize.spfx

-

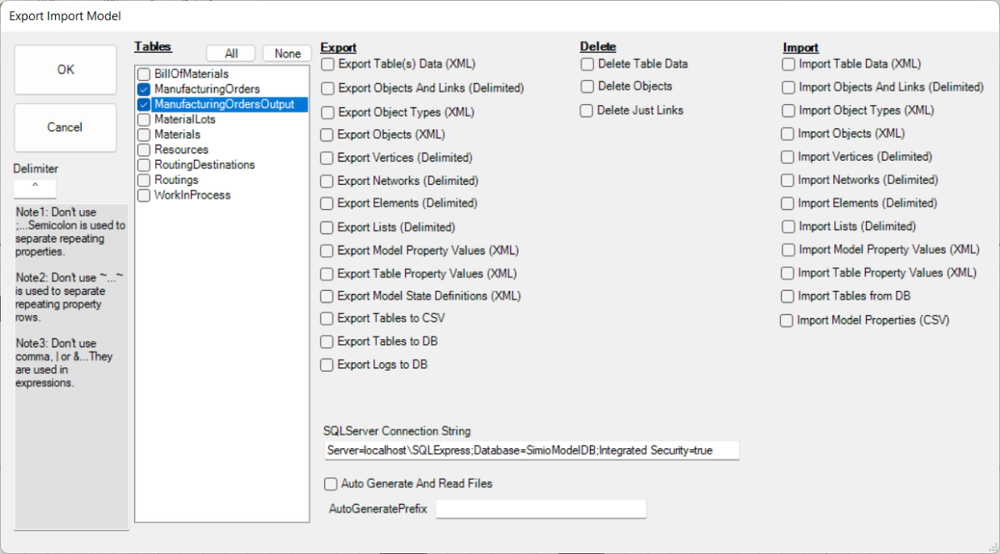

Here is a simple utility that will export, import and delete artifacts of your model. Here is a screen shot of the available capabilities. The code and DLL have can be found on SImio GitHub. Please find at this link: https://github.com/SimioLLC/ExportImportModelAddIn You will also find install instructions in the ReadMe. Here are the changes that have happend over time: Updated 2023-01-31....Added the ability to select multiple tables for export and delete table data functions. Updated 2022-10-05....Updated the exports to sort the data first my name and then export. This ensures that the data exported is in a consistent order. Updated 2021-12-07....Added the ability to select a table and then remove the data from the selected table. If a table name is not selected, all the tables in the model will have their data removed. Updated 2021-09-20....Added Update Model Properties (CSV). With this new method, you can import model properties into your model. If the file contains 3 fields...First is name, then type and last is default value. The only valid types are real, datetime, Boolean and everything else is string. If the model property already exists, it will only update the default value on the property. Note: The example assumes the field separator is a caret '^'. To change this, you need to change the delimiter field. Updated 2021-09-08....Updated the sequence of the exports, deletes and imports happen. When OK is pressed, first the exports are run, then deletes and finally the imports. With this change, I am able to Export Table to DB, Delete Table Data and Import Table from DB from in a single run. I typically do this when re-mapping auto creates elements. Since the table data need to be removed and recreated before mapping of the elements are correctly mapped. Updated 2021-09-06....Upgraded to .NET 4.7.2. Also, fixed the windows form so it displays correctly. When opened, the form should no longer need to be expanded to see all the options. Updated 2018-11-08....Added Export To CSV, Export To DB and Import From DB. Export To DB will create a table in the SQL Server database with the same table name as the table in Simio. The data columns will be of type nvarchar(max) and the default value will be the same as the default value in the Simio table. It is assumed that Simio desktop will still do the data validation, not the database. This feature is used to save the Simio data into a database so it is backed up and can be shared across users. Each time the Export To DB, if the table already exists, it is dropped, and a new table is created. This ensures that the data schemas match between the Simio model and the SQL Server database. Updated 2017-12-05....Fixed index issue with links import. Updated 2017-09-25....Fixed the import of lists. Updated 2017-07-14....Added the ability to auto generate and auto read files. Previously, the files needed to be created prior to running the add-in. Now, they will create by the export. Also, the import will retrieve the same file generated by the export. These options are available when the "Auto Generate and Read Files" option is selected. Updated 2017-07-13....Added the ability to multi-select options. Now, more than one option can be initiated when the OK button is selected. This will streamline the process of exporting, deleting and importing. This tool is very helpful for testing out your model with various configurations to ensure that runs properly under various object and/or data configuration. Updated 2017-07-11....Now supports exporting and importing of model properties, exporting and importing of table properties and delete table data. Updated 2017-06-22....Now supports exporting and importing of data tables using XML. This is simple way to export all the table data from one model and import the same data into a new model (assuming that the same tables schema exists in the new model). Updated 2017-01-27....Now supports exporting of object types using XML. This can be used with the new Configure Scheduling Resources in Simio 9.150 capabilities to define your own object type properties based on an XML document. Updated 2017-01-23....Now supports exporting and importing objects using XML. When using XML, property units are also exported and imported back in. Updated 2016-10-24....Updated files...Added support for repeating properties.

-

Hi, I have different type of entities queue up at an server output content waiting for a worker comes to pick them up for further process. After picking up, each entity will be sent to the corresponding location for further process. Ex: Product A goes to Server A, Product B goes to Server B ...etc. Can I pick up the entity based on the condition of capacity remaininig of the destination? Ex: Suppose we have 4 products A, B, A, C queue up. When the worker comes to pick up the first product A, he will check the capacity remainig of the destination Server A. If there is still capacity in the Server A, then go. If there is no capacity in the Server A, the worker go check the second product B and see if there is capacity in the Server B... etc. Can someone give me some idea how I can do this? Thanks for the help!

-

I'm making a simple simulation model of a hospital and I'm having trouble with the routing of my model. For instance, a patient first goes through ED and then to OR. if there is no room in the OR, then the patient must stay in ED. How can I model this? I don't want the patient to wait at any input or output buffer, because then it assumes that the ED bed that the patient used to stay in is now free but it actually isn't. Each bed is modeled as a server and there are more ED beds than there are OR beds. Naturally, all ED beds connect to a single transfer node, which then connect to all OR beds.

-

Hi all, I met some questions in building the model. It seems a very general quesiton but I didn't find any solution from internet... I'm building a general workflow model. I want to decide the quantity of a server to optimize the workflow. I want to use experiments or optquest to get the 'best' number for each server. If I set the capacity type as Fixed, then I can set the initial capacity as ''referenced property'', then I can use this as control in experiments/optquest. However, I have a work schedule for each server now which means I couldn't set the capacity type as Fixed. And then I couldn't set capacity as ''referenced property''. I don't know how to control this capacity in my experiments/optquest. I know I can change the 'value'(which means the capacity) in workschedule table. But I can not change this number flexible in experiments... Or I don't know how to set this value as ''referenced property'' . Is there anyone who could help me with this? Thanks a lot!

- 5 replies

-

- 2

-

-

- server quantity

- work schedule

-

(and 2 more)

Tagged with:

-

Hi All, It's been a while since I have last used Simio and I have an issue that I think should be simple. I have two entities running on a production line, one gets processed by a server and the second entity type moves through the same server almost like a conveyor with no processing. I can work around this by adding another conveyor around the server, but in real life the product does flow through this server and eats at it's capacity. Is there anyway to set up different processing times for multiple entity types on a server? Thanks, Brendan