Search the Community

Showing results for 'worker shifts'.

-

Entity Exiting a Queue when a releasing condition changes

Alicia replied to Alicia's topic in SI General Discussions

Thank you for the response. But what I'm loking for is to storage elements in a queue indefinitely until its due date is reached. When the due date of the entity is reached on simulation time the entity will be then taken from the queue by a worker -

My main difficulty at the moment is the batching logic. How to simplify it to use the matching expressions instead of an add-on process. In real-life, the worker needs to decide which filling station to batch for - each one puts a different material in the containers. the worker stays at the filling station until the containers in the batch are full. which family of skus to create a batch for, based on pressure and volume which individual skus and how many of each to put in the batch. currently there are upwards of 30 different skus that can go in a batch. a batch is around 40 members. all the members can be from the same sku or it can be all mixed up (so long as volume and pressure of all members of the batch are the same). which skus and how many of each depends on full inventory for the sku, forecasted demand for each sku, and service level goals that can differ by sku class. This is pretty much a production scheduling problem. I'm not saying it can't be done with matching expressions, I just don't (yet) see how it could be done with single expressions. Really, though, that's ok. I have a way to do this now, even with add-on processes. it may not be most efficient, but a few days ago, nothing was working. I can't tell you how much I appreciate your help.

-

These are extra works. Note that in the last figure we seize the worker as the secondary resource before processing. This is enough for your purposes. Thus, the processes you defined are not necessary for now. Defining a worker as a secondary resource before processing means that whenever a batching process is to be done a worker is required for this to happen (The worker will be seized before the processing for executing the batching.), i.e., if the worker is not available the batching can not begin.

-

I will try to use the match expressions to determine which containers to batch. It would make things simpler. In the meantime, I discovered I could insert an extra server with 0 processing time just to store the worker and trigger the processing. Then, if a member entity is ready to batch, the worker can perform the batch. If there is no member entity yet, the worker waits in the output buffer and then when the member entity arrives at his detached queue (I needed to add that back in for this to work) it transfers the worker back to the input of this server so the worker can execute the batching logic again. Then, the parent and members arrive together at the combiner and they're ready to be combined. Again, I'll try again to use the match expressions, but if I can't figure that out, this should suffice. thank you very much for your help. using combiner.spfx

-

Thank you gocken. This is so helpful. It makes things much simpler. I created an example with an entity which uses the worker as a transporter to go to the parent node at the combiner. the batch is created and they move on together. This seems to work well. But, I need to be able to perform the batch selection in a process. This is where things keep falling apart for me. I made the combiner match on member and parent, giving the entities a state variable set to True if those items were to be batched. I want to set this in an add-on process. Further, I need to be able to trigger this process when either a parent or a member entity enter their input buffers. I have an example attached that uses the add-on process. Once the parent enters the input buffer, the parent can choose what to batch. The batched items move on to server1 and the separator. Then, the worker (entity and transport) return to parent input of combiner, but it's empty. The unbatched entity goes to server2 (just to ensure it arrives after the parent). I thought it would leave server2 and trigger an add-on process on arriving at the member input node, but the add-on process is triggered when still at the server2 output node. So, in the add-on process, I transfer the parent to the parent input node (just to get the parent to kick off its own add-on process, but it doesn't know where to search for the member entity because it's still at server2. How do I get a process to fire to determine what to batch whenever either a parent or a member arrives? using combiner.spfx

-

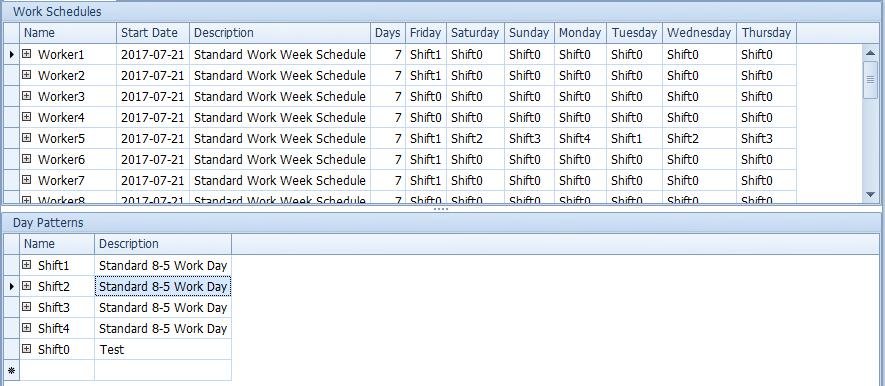

Anyone has a solution for this? I still didn't figure out an easy way to get many workers with individual schedules where each worker has its own start and end time. Especially when I want to run my simulation for multiple weeks I need a way to get this from my Excel data file into my model.

-

I have multiple workers for different tasks and I want the workers to work according to different work schedules. When I use the work schedule option, all workers of one process use the same work schedule. In the examples they use different workers for each shift, but since workers come and go at different time during the day this would require a lot of different workers for each process.. For a server the capacity of the server can be changed during the simulation, is there a way to do the same for the amount of workers in the system? Or let each worker work according to their own custom work schedule imported from a table?

-

Only routing to server if second resource seized

MasterMind posted a topic in SI General Discussions

Hello, I am modeling a store with a few workers and 3 cash desk. Two of them are always open. If the Queue in front of the two cash desk gets to long a 3rd worker is opening the 3rd cash desk. The Problem is: I dont know how to tell the Entities to only chose the 3rd cash desk if it is in use/open. Thanks in advance -

Only routing to server if second resource seized

gocken replied to MasterMind's topic in SI General Discussions

examine AddAndRemoveServerCapacity simbit. you will find a similar logic but you have to extend the logic by including worker object. -

I got a file where each worker has a unique ID for every time they work, and a start and end time of their shift. I also converted to to time intervals and the amount of workers that are working at that particular time interval. I tried using the table based schedule for both tables, but this does not seem to work since all workers get the same start and end time.. Your method requires many different workers for the same process, each with their specific work schedule which looks like a lot of work for something that looks quite simple... Is there no easier way to do this ? Thanks for the quick reply!

-

-

The easiest way to do this dynamically is to use the Dynamic Selection Rule property on the Server (or other object, such as Combiner, Worker, etc.). You can use the 'Standard Dispatching Rule' option for that property to then include a Dispatching Rule, such as FirstInQueue, LeastSetupTime, EarliestDueDate, LargestPriorityValue, etc. This allows you to specify a TieBreak Rule as well. Using the dynamic selection will not determine which entity will be selected from the queue until the resource (object) has released an entity and is available.

-

I'm trying to model airport ground operations using workers for the different processes, servers for the gates, entities for arriving airplanes and TransferNodes to control the flow of entities and workers. My research is focused on the control of these ground processes, but I can't get my process logic correct.. I attached a simple model to help answering the question. I want the workers to move to the right server before the entity arrives there and can immediately start processing the entities. One method is to use a global queue from which workers decide which entity to process next based on some criteria and dynamic rule selection. In the attached model I use two entities which go to Gate1 and Gate2. Gate 1 needs workers move to the node before it can start processing, Gate 2 does not. Using an add-on process, I move the worker to the gate before it is requested and wait for the entity to arrive. But for some reason it does not start processing immediately when the entity arrives and I can't figure out how to model this correctly.. It's the first time I'm using Simio, so I some help would be appreciated on how to set up the logic for my processes.. I'm kinda stuck now on how to get some basics thing in my model right or if I'm using the right processes steps.. Thanks in advance! TestModelWorkers.spfx

-

Worker Positioning and Distance covered

tahsinmullick replied to tahsinmullick's topic in SI General Discussions

Hi Tulach, I have a process attached to the output@server1 and as such each entity is sent to a random cart and based on the cart number a specific worker picks up the package to the respective destination cart.- 4 replies

-

- worker

- distance covered

-

(and 1 more)

Tagged with:

-

Hello Team, Question, on the simulation that I'm working. I want to be able to choose the worker that could do the task. for example I have 4 stations where we perform welding and grinding. the Welder can do welding and grinding, but the grinders can only do grinding. since I have 4 stations i'm using the process time as the welding time and the teardown as grinding time. currently, I have as secondary resources the welders for setup and process and the grinders for teardown. I have 2 welders and 2 grinders. I would like to be able to call either a welder or grinder to perform the grinding (teardown) task. because on most time both grinder are busy and I can use a welder to do the task. Thanks for your inputs. Htatton

-

Worker Positioning and Distance covered

tahsinmullick replied to tahsinmullick's topic in SI General Discussions

Thanks Gocken, I appreciate the answer, I have seen the model you proposed, My problem is specific to my objective and replacing worker object isn't an option unfortunately. Increasing their capacity will deviate from the real scenario I am trying to model so , won't be able to pull that off either. I will however, try to play around with the dwell time as you suggested . I want to imitate a real life scenario where the path you see in the model is a gravity roller conveyor that isn't motorized. As a result the workers (worker3 and worker4) which are further down the line in my model don't always need to come to the very Output of Server1(Shooter) after placing a package onto a cart. But can instead be able to collect packages from near their vicinity and place them accordingly to respective carts- 4 replies

-

- worker

- distance covered

-

(and 1 more)

Tagged with:

-

Worker Positioning and Distance covered

gocken replied to tahsinmullick's topic in SI General Discussions

In its current version you have nothing to do with your model (because the worker object has only one ride capacity). Instead you should use vehicle object (with ride capacity of 4 for each) to be able to select the modelentities to minimize the distance traveled. You can try different ways of transferring entities (i.e., you can set "Minimum dwell time type" as "specific" and can define a specific time etc.). see the attached file. 16sinks_edit3_-_Kopya.spfx- 4 replies

-

- worker

- distance covered

-

(and 1 more)

Tagged with:

-

A worker may be assigned a work schedule similar to that of a server or vehicle. I would just leverage the default logic by throwing the worker into an Off shift State. There are numerous options as to how assign a work schedule. From your problem description, a Table Based Schedule may be more optimally suited.

-

I've got multiple workers going to single server. As the title implies, I'd like these workers to mimic the real-life behaviour of randomly going on leave for a random amount of time. Ideally I'm looking for something that's shown in vehicles or servers, but for workers. Does anyone here know an easy workaround for this? I did think about adding in a add-on process after the worker releases an entity with a counter, and after a certain count the worker is seized for a random amount of time. I just thought there would be a better way. Another alternative would be creating a work schedule for each worker, but there's over 60, so that might take a while.

-

I tried the first option you told me, but it doesn't work, is there an specific process that make it work? because I think that the process I choose could be wrong, I tried with other options but when I run the simulation the worker dissapears and then return to the node that I need it to be, but it doesn't return to its main place.

-

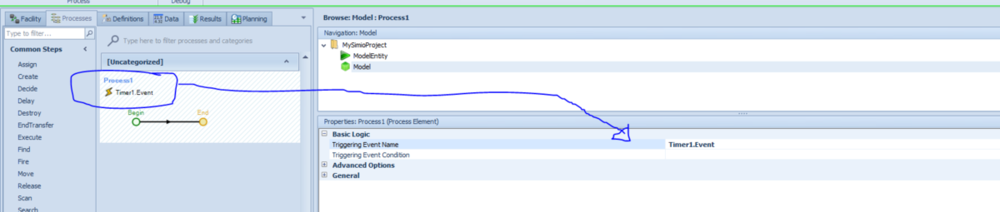

Yes it is possible. You can exceute a process by picking the hourly event as fired by the timer (as attached). Subsequently you can use process logic to release the worker, move the worker, then re-seize the worker. A second alternate is to use the default functionality included under advanced options within a server's "On Resource Releases" option. This should allow for you to specify the hourly interval for release as you require.

-

Interrupt server while Process Type is Task Sequence

jzhou replied to FloraPhyll's topic in SI General Discussions

Dear Flora, I build a sample model to interrupt a task and afterwards resume that task with the remaining processing time pls kindly find the attched model. thanks! I am not quite understanding your approach, however the error you mentioned is the token is not targeting at Worker, thus the error... InterruptingTaskExample_byJeff2.spfx- 2 replies

-

- interrupt server

- process type

-

(and 1 more)

Tagged with:

-

Hi all, in my model I have a specific transfer node where a worker transfers an entity to a vehicle. I cant add the load unloading times in the worker or vehicle due to the fact that there is only loading time in this transfer point exactly. I was wondering if there is a way to directly add a "processing time" to this transfer point. Maybe by creating a subclass? Thanks

-

Testing if resource is seized before releasing it

PierreUL replied to PierreUL's topic in SI General Discussions

With a decide step just before the release step in my process logic, I was able to test if the worker is seized. The condition I used is : ServerName.Processing.Contents.FirstItem.SeizedResources.Contains(WorkerName[1]). So thanks a lot! It's exactly what I needed! -

Hello every body, I try to model a 3 servers process and I'm getting some trouble. The model is composed of 3 servers and 3 operators . Each operator is a "specialist" for a server, Worker 1, 2, 3 for the server 1, 2, 3 respectively. However the workers 2 and 3 can help the worker 1 at the server 1 if they are not busy. The processing time of server 1 will adjust proportionally to the number of workers working at the server. (There is a 4th worker whose task is to move parts to the server 3 or the sink. But I don't think it plays any role in the problem.) I've implemented some processes so that workers work at the right server. It was working perfectly. But then, as I modified the model to add the variable processing time, the Interrupt steps in the processes don't work anymore. Indeed, the worker 2 or 3 stay at the server 2 or 3 and don't go to help the worker 1 when servers 2 or 3 are blocked, or idle. As well, if workers 2 or 3 are busy at server 1 they are not interrupted when a part arrive to the server 2 or 3. I hope I'm clear enough. I've enclosed the model so that you can better picture the problem. Thank you for your attention and thank you in advance for any help I may get! three_workers_Interrupt.spfx

.thumb.jpg.d86860331a58e852a3b64f28348c2d88.jpg)