Search the Community

Showing results for 'remove parent'.

-

Note: set selection weight of the path's (from source to picking object's parent input node) selection weight property as modelentity.ParentTrue==True and the path's (from source to picking object's member input node) selection weight property as modelentity.ParentTrue==False.

-

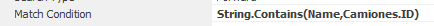

i want o find it in a data table named Camiones in column ID (CA123), in my faciliity i have an object named CA123 inherits from type Camion which inehrits from Vehicle, now what i try to do is get just the parent name which would be CA123 and not CA123.123 (instance of object created in facility with population 1)i have tried this: Where Name is CA123.123 and Camiones.ID represents all rows in data table Camiones and column ID eg. CA123,CA99,CA82

-

Separator does not seem to be splitting correctly

CWatson replied to JanWai's topic in SI General Discussions

If you have a batched entity (through Batch step or Combiner object), there is only one parent entity and the rest member entities. Thus, one entity exits the parent node, the others exit the member node. If the Separator instead did a Make Copies instead of the Split Batch, you still have the original parent entity (incoming entity) and the member entities (copies). If you need to split the entities in different directions, you should look at having both of those nodes connected to a single node where you then make the decision to go in two different directions. -

Hi, I currently have a model as follows. I have a separator, and I want to divide entities that enter through it evenly across the 2 nodes. So half of the entities go out from the parent node and half go out of the member node. Currently right now, I did not manage to do it for the separator, even when I tried all possible methods in SIMIO for splitting the batch itself. How may I go about the problem? Thank you!

-

In my model, I have a combiner that batch 1 parent entity and 9 member entities together. I then need these 10 entities, when travelling out of the output node of the combiner, to go to 2 different paths. 5 of them should go on a path to node A and 5 of them should go to another path to node B. I tried using Combiner.BatchQuantity at Output_Combiner_Entered Add-on process but it doesn't work. May I have some suggestions? Note that the batch number is not fixed and will vary during the simulation run.

-

Assign different states to members of a batch

Luu Khanh Minh replied to Luu Khanh Minh's topic in SI General Discussions

Hello I would like to revive this thread. So In my model, there is a combiner that generates a batch by batching 1 parent entity and 29 member entities together. After the combiner, I want to assign exactly 30% of 30 entities(i.e: both the parent and the member entities) to state "A" and the remaining 70% of the 30 entities to state "B". May I have some suggestions as to how to do so? Thank you! -

Store Entities During Processing (Combiners in Series)

MEagar replied to Mike@CFAN's topic in SI General Discussions

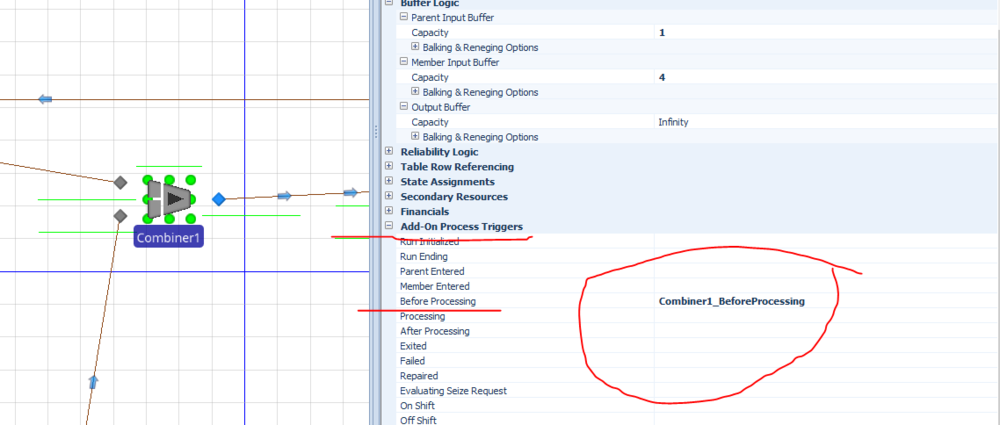

Oh so you need to use an add on process to set the memberinputbuffer to zero, once a parent entity has entered the processing station. Remember to re-assign the capacity to 4 once processing has completed. As you are using paths, it would be good to set there capacity to 0 and 1 during the same process as to keep the member entities in the output buffer. Hope this helps. -

This is my first post on Simio forums so please let me know if this is the incorrect place. I have Default (Parent) entities that must go through only one series of combiners for processing the members (ModelEntity 1,2,3) that get attached. At the end of the series, a separator removes all members and the parent entity circles back to the start to acquire new members. No parent entity can start processing in the combiner series while another entity is going through that combiner series. I cannot figure out how to stop entities from entering the first combiner in a series while there is another entity processing in the same series. Ideally I would like to store these parent entities at a location until a series of combiners are free for processing. CombinersInSeries.spfx

-

Good day everyone, I need to acess the average waiting time in a member input buffer of a combiner. First of all, how is there not an easy option to acess average time in queues? Most of the times I have to tally everything, which in turn doesnt work with experiments... It has been a real struggle. Anyways, I was using the approach of using an entyti state variable to record the time when it enters the member queue and another one to register when it leaves the given queue and then tally it. The problem is with combiners, the parent entity "wins" and so using ModelEntity.State Variable - reffering the one from the member - does not work. Any ideas? Thanks

-

Hello All, In one of models, I have to use Storage queues and remove/reinsert items into the queue; however, even after removing a particular entity when I try to reinsert it Simio gives an error. Any idea how to avoid this issue. Thanks, Ankit

-

An alternate approach is to place a monitor element which looks at the TimeTillDeath State variable. If this reaches zero, within the monitor element you may choose to execute a user defined process named "proc_WhateverYouWantToCallIt". Within this process, I will use the "remove" block if the entity is in a queue, or simply just utilise the "destroy" block. You may have to utilise the aforementioned blocks with a conditional "search" block as to ensure the correct entity is destroyed. Hope this helps.

-

First define a real state variable to your modelentity named "livingtime" after its creation. Then make a copy of your modelentity and send the copy of modelentity to a process (maybe called as death_process). Place a delay step and set delay time as modelentity.livingtime. Of course the original one should go its way. Then place a search step and find the original modelenity in the system when the time is up at delay step (while finding the original entity you should set a match condition such as candidate.modelentity.ID==modelentity.ID etc. I am not sure whether the ID's of both entities are same, you should try. If it does not work you should try to match creation times of them (both should be same) or any other user defined state variables or properties). If the search is succesful make necessary controls (i.e., if it owned any resource release them etc.) by placing necessary steps following found branch. You should remove and transfer the found modelentity (it is the original one) to appropriate place. At the end you should place a destroy step following the original branch or even transfer it to appriate place. It depends on your goals.

-

How can I schedule a randomly distributed death event for each entity, and pull them out of the system (or perhaps route to a "mortality" sink) if it occurs before they have already left? Somewhat similar to reneging, but I need mortality to be possible during a service, not only in queues. If an entity is removed from service, I also need the seized resources to be released. What I have tried so far: When an entity is created, I provide them with a state variable for TimeTillDeath, lets say exponential(2) hours. This is a real number, not a datetime. As they enter each queue, I set the reneg trigger as ModelEntity.TimeTillDeath subtract any elapsed time since creation, min 0. This works to model mortality while they are waiting for service, but not during a service. Any help is appreciated, KO

-

Combine several entities in to one entity

gocken replied to BTECHStudent's topic in SI General Discussions

It seems the best way to achieve to what u want is to define three storage elements (called barstorage, gridstorage, sheetstorage) just before the combiner object or combiner node. Whenever an entity is put into any of these storages check the the condition u defined (i.e., exactly 4 bars, 4 grids and 8 sheets are exist in the individiual storage) is valid. If the condition is satisfied remove appropriate number entities (exactly 4 bars, 4 grids and 8 sheets) from appropriate storage by using search and remove step and transfer them to combiner object from standard library (or even combiner node object you get from forum) to combine them all. Else wait for the condition to be met. By this way you are able to collect some extra statistics from storages (averge waiting times and average number of each materials in the storage etc...). -

Hello Simio team. My group and I are currently working on solutions reguarding queue related issues. We are working on a case where we can implement a loop system similar to the Sim Bit called "Add and remove server capacity", altough we would like relate the opening and closing of capacity based on the maximum queue time (5 minutes = Open another server) and (3 minutes = Closer a server) in the TransferRode instead of the numbers entities in the TransferNodes. We have tried to follow the pdf step by step in the Sim Bit, but we have not been able to get it to work. I hope you guys can help us resolve this issue. -Mlars11 Pharmacy.spfx

-

Since you are learning, I'll give you a nudge in the right direction, rather than providing the answer. Investigate Random.Discrete distribution Use a combiner to create a batch of burgers to be cooked together. The batch size must be specified in the parent. The batch of entities moves to the grill together. The cooking time is a function of the parent entity's batch size.

-

Accessing the Batch Quantity of Combiner

dsturrock replied to poudenx's topic in SI General Discussions

I believe that when each parent arrives to a combiner, Simio evaluates the Batch Quantity expression in the context of that parent entity. So if your taxi entity has a state name Qty and your Batch Quantity expression was ModelEntity.Qty, then the first taxi might have a value of 3 and the second taxi might have a value of 1. You could assign the value of that state at any time and look at it from elsewhere as well. -

I've ran into the following problem with a combiner: I'm using it to model a load zone where taxis arrive to the parent node, passengers arrive to the member node, and the number of passengers boarding each vehicle is set by a random.discrete distribution (so that for instance 50% of the taxis have 1 passenger, 30% over 2, and 20% have three). This all works great. But now, instead of having my passengers queue at the input node, I was hoping to make them queue at another upstream node, connected to the member input node by a path and every time a taxi arrives, I would like to send to the combiner only the number of passengers that will be batched with the taxi. I tried using Combiner.BatchQuantity but without success so far. From what I've seen by looking at a display showing Combiner.BatchQuantify, it seems it's continuously going through its possibilities, whether a taxi is at the parent input node or not. Then I thought that maybe the number picked to batch passengers with taxis, was selected from that continuously changing value when a taxi entered the parent node, so I tried using the event ParentInput@Combiner1.Exited (as well as ParentInput@Combiner1.Entered) to extract the batchquantify assigned to that taxi but the value did not match the actual batching. So I guess my question is: is there a way to access the value that is picked by the batching process to use it to send the right number of members to the combiner? Thank you very much for your help. Pascal

-

Adding a Reference property itself to the table

Kjd0019 replied to Kjd0019's topic in SI General Discussions

Okay So this is what I have already done till now. The problem is I want my combiner to understand that the batch quantity is based on the entity type. If type A , Batch quantity =2 , If Type B, Batch Quantity = 4 and for type C , it's 6. I have tried using state assignments option at combiner 1 parent input but to no avail. Ideally, I would want the combiner to take the batch quantity value from the table itself but i cant get my way around it as of now . I know this can be done using add-on process but somehow figured that if I could make this work using a table, it would make it a lot easier when you have more entity types. Thanks. Combiner Exploring.spfx -

moving premium customers ahead of regulr customers

CWatson replied to wwang7f's topic in SI General Discussions

There is a SimBit (see Support ribbon, Sample SimBit Solutions) named 'RemoveFromAllocationQueue' that uses a execute step/additional process to determine if the entity has waited for 5 minutes and if so, will remove it from the queue and have it exit. You could use a similar concept, except change the delay time to 2 minutes and instead of removing it from the queue, reassigning the priority (or first determining if it is a premium customer and then resetting the priority of the entity in the queue. You have the option of removing/inserting back into the queue if you need to have it do any other tasks as well. -

Using excelRead process step multiple times during simulation

DHouck replied to ebabtain's topic in SI General Discussions

Hi ebabtain, Your instincts are correct. The ExcelReadWrite Add-In only reads in each worksheet once. This is by design, since the steps are generally executed many times and very quickly, and re-reading the file would consume a great deal of time. Within the ExcelReadWrite Add-In there is a worksheet cache of sheets (called _sheets) that is checked against and does not bother to read the file if the worksheet if it is already cached. So, I would suggest a few possibilities: 1. Modify the Add-In to remove the caching. or 2. Use another Add-In (such as text file read-write... this has less overhead) In either case, make sure your logic in the simulation does not call the step more than - say - once a second. Let me know if you have more questions and/or if I am missing the mark. Cheers, Dan -

Hey, guys. Quick question: Can a vehicle from a model enter another model within the same project? I have a warehouse as a parent model and I need my forklift (vehicle) to enter another model while carrying an entity. I tried setting a transporter reference property, but without much success. Any sugestions? Thanks.

-

Assuming that you are using the word submodel to represent an independently defined object (say WorkCenter) that will be placed in another object (say Plant). In your WorkCenter, every time you reference a resource that is not defined within the scope of WorkCenter, you must define it as a Referenced Property (right click on the property name). In general, you would set the value of that property when the instance of WorkCenter is placed in Plant, so you are "passing in" the name of the object. If you KNOW the object name ahead of time, then you may get away with a trick... when you define the Referenced Property, give it a default value of the object defined in the parent (Plant) object. This will display as an error in the WorkCenter object, but that error will be resolved when WorkCenter is placed in Plant which contains the object. UsingObjectDefinedInParentObject.spfx

-

Servers Processing Time for each Entity in Batch

KatieP replied to AR1995's topic in SI General Discussions

If you batch the Entities together, you can Search the ModelEntity.MemberBatch queue. Then sum the lead time for each member entity and the parent entity to get the total lead time. -

Dear all, I am currently simulating a 3D printing facility in the frame of my Bachelorthesis and I have a specific problem which I cannot solve by myself. I have four Entity types with different lead times which are specified in a datatable as shown in one of the SimBit solutions. However, I need to batch the entities before they arrive in the workstation to simulate that several parts are processed within one 3D printing build job. The problem is that the workstation only calculates the leadtime of the parent entity and not of each individual member. Instead of calculating: 5hr + 4hr + 3hr + 2hr= 14hr for a batch of four entities, the machine only calculates 5hrs. Is there any solution with a search step to explain the workstation that it should define the batch members and then to add the lead time for each of them according to my datatable and to use the sum as processing time? I am really thankful for any help you can provide, so thank you very much in advance! Greetings from Hamburg, Armin R.