Search the Community

Showing results for 'how to change property of one specific entity and not all of them'.

-

Just curious if there's an easier way to go about doing this... Long story short if I am representing multiple physical positions within capacity of a server and I create my own Gantt outside Simio, it's important for me to know WHICH resource (in this case which one of the servers) is utilized by each entity. I was trying to utilize Entity.Location.Parent.Server.Processing.Contents.IndexOfItem( Entity ) and assigning it to a state on the entity and then ultimately writing to an output table. However, this doesn't seem to be working accurately. It may be a timing issue on when this step is called, but is there a default function I'm just not aware of that could be of assistance?

-

How to increase the distence between entity to entity ?

River replied to River's topic in SI General Discussions

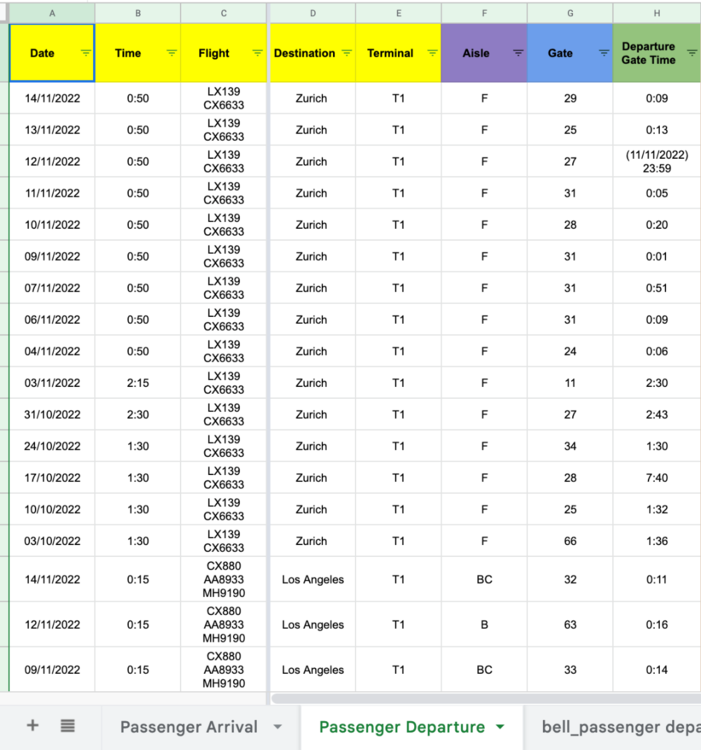

Many Thx for your help. We have another problem : As we want to be more realistic, we have the data from Hong Kong. How can we input those data (such as departure Gate time) into the simio to let the enttity will departure as schedual ? We already have atleast one month data, can you show us how to make the entity dearture as the time we set accordingly? -

How to increase the distence between entity to entity ?

ViniciusF replied to River's topic in SI General Discussions

To make an entity wait until the runway is free what you could do is set the Initial Traveler Capacity of the Runway path to 1. This way entities will wait at the node before entering the path. I did not understand the first question, but if you need entities to visually appear behind one another, set Allow Passing to False on the path. Alternatively, you could use conveyor instead of path to make entities allign and respect some distance. Hope it helps. -

Change Server Capacity over time with WorkSchedule

JanainaF posted a topic in SI General Discussions

I have a model where I need to set a server had a maximum of 15 entities from 7 A.M to 10 A.M. I Use the WorkSchedule but I don't know how to limit the number of entities. Can someone help me? *This server it is parallel with other servers. -

I have a question regarding the use of a model state value at a specific timestep. I used a Tallystatistic and processes to calculate the output of a server for a specified interval, based on the Simbit Hourly Statistics. This works, however I dont want the value of the same timestep, but I want to use it two timesteps later. So for example if a server A output variable equals 10 at timestep t=1, I want to save this value as part of the input for server B for timestep t=3. So the value should be 'memorised' for two timesteps. I was wondering whether there are any suggestions on how to model this?

-

Hi!! I want to know in which object (in this case filler) my container entity is when certain event occurs. Is there a way to access this info? Thank you so much! Teresita

-

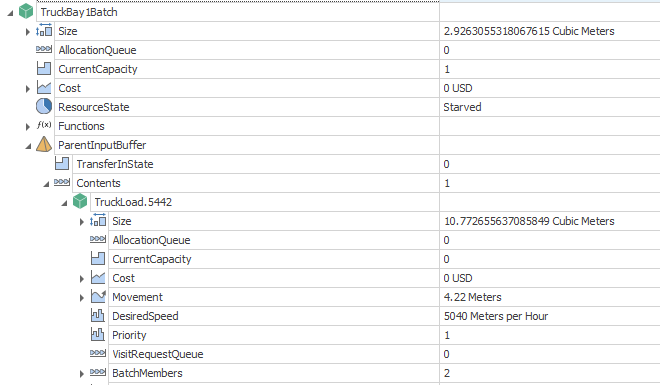

Sorry if this is obvious, but can someone tell me how I can reference the number of batchMembers in the example above without having to reference the specific entity, which in this case is TruckLoad.5442. I need something like "the number of batchMembers in the entity currently in the ParentInputBuffer" please. e.g. TruckBay1Batch.ParentInputBuffer.Content.???.BatchMembersCount? As you'd expect, this number changes constantly during the simulation run. At this moment of simulated time, the answer is 2. Thanks for your help!

-

Hi all, I made a model of a production line (starting with 2 servers) and I am wondering whether it is possible to change the processing time of the second server based on the actual output of the first server. Theoretically seen the processing time of the server 2 = Speed of server 1 * E , in which E is a fixed formula (connected to server 2) to correct the speed. So if the first server performs according to expectation (without failures) for example 40 the processing speed of the second server is equal to 40*E with a delay of the conveyor time between server 1 and server 2. If the server has failure and thus have a lower output (for example, 30), I want to change the processing time of the second server accordingly to 30*E with a delay of the conveyor time between server 1 and server 2. Does anybody have an idea of how to do the following: How can you monitor the actual output of the first server at each timestep? Is it possible to fix the proposed formula and use it in an add-on process? How can you take the conveyor time delay into account (using a delay step in the add-on process?)? I am quite new to the software so I am not sure whether it is possible to model this in Simio. Thank you in advance!

-

Normal Distribution for Table Row Referencing

ViniciusF replied to Grant S's topic in SI General Discussions

Hi, What you could do is set up another column with the weights (likelihood) of creating each entity type... so you can set up probabilities any way you want it. Look SelectEntityTypeFromTable - SimBit to learn how to do it. -

Hi, In my project, I have the (main) model of object type 'fixed' and a model of object type 'server'. In one of the processes executed by the model 'server', I want to add a search step that searches a specific entity in the entity population of the main model. How can I do this? Thanks in advance! Kind regards, Christa

-

I have a project where I would like to see snapshots of the output state of the system at specific time points. For example I would like to see output reports at 12, 24, 36, 48 hours and so on. Ideally I would like to set up experiments where I can observe, say 100 runs at each run length and saving capacity on my PC might be nice. I was thinking I could set up a reference property for Run Length; however, it does not seem to have that option. Is there a way to do something like this? Thoughts would be appreciated! Thanks, Jim

-

I am working on a simulation of a number of firms processing raw products. If I represent the firms as resources in a server -so that the server capacity represents the number of firms, how could I identify which resource/firm processed a certain batch of products? Can this be done with a server having a capacity of its own, or should I use a pool of (secondary) resources with id labels so I can use that id to label the product batch?

-

Entity Distance travelled on Transporter

Liz Millar replied to ttarkan's topic in SI General Discussions

I would recommend using a Data Table. One column could have all your entity types defined. The next column could be a Tally Statistic Element Reference Property. This column would match up the Tally statistic you want to correspond with the Entity Type. You could choose to auto-create these Tally Statistics from the Data Table. If you change the Tally Statistic Property's column Reference Type property from 'Reference' to 'Create', this will make the Tally Statistics for you. I recommend the Help page "Table-Based Elements (Auto-Create)" in Simio for more information. If your Entity Instances noted in the Data Table are unique, no duplicates, you can set that column as a Key. With that column as a Key, you could use just the Tally step and use the RowForKey expression. RowForKey will allow a key input to search for in that column. If the model entity is driving the process, you could use an expression like this for the Tally Statistic Name 'Table1[Table1.EntityInstanceProperty1.RowForKey(ModelEntityReference)].TallyStatisticProperty'. Since it seems this process will be on the OnRunEnding, it will not have a reference to a specific entity, so you will most likely need a Search step to find the entities still in the system. I would set the Search step to find Infinite things and let each entity reference exit on the found branch. If the EntityInstanceProperty column in your Data Table has the Auto-set Table Row Reference property to 'True', the entities will already know the row reference and your Tally step Tally Statistic Name property could be 'Table1.TallyStatisticProperty'. -

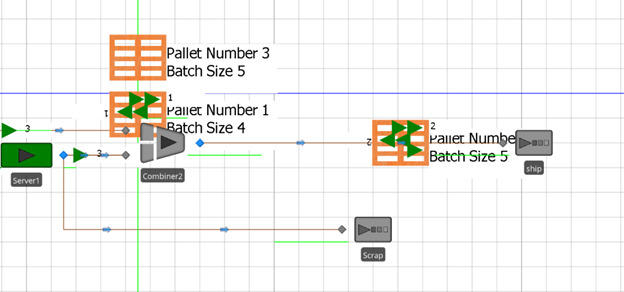

Got issues with a combiner. i have a server that processes the member parts but has a 0.1 probability of going to scrap, this means the batch size has changed. the parent part has a integer state that gets updated when this happens but doesn't update the combiner batch quantity property. I have attached an image showing this issue. you can see the pallet number displayed which is the way i match the parts with the correct pallet. the pallet(parent) also displays the batch size using the same integer state which i use in the combiner logic. Theres a pallet with 4 items on it and it shows the batch is 4 so why wont that process it? Also attached the whole model so you can look at it all Batch and Scrap.spfx

-

Hi, I'm making a manufacturing line sumilations where 2 entities representing components enter combiner, where they are being proccessed to a new single entity. How I'm suppoused to terminate those 2 entities that are entering the combiner and generate one new that is leaving? Also, can you combine more that 2 entities in one combiner?

-

Hi, A Separator is creating copies of the entities that enter it, the number of copies depends on a probability distribution, I want the worker to transport all the entities created from the same parent entity at once. Is this possible? I attach the model for better understanding. Thank you so much! Model.spfx

-

Hi, Is it possible to set the state variable of the parent entity in a batch equal to the sum of state variables of all member entities in the batch? Context of the case; a truck (parent) is loaded with x number of orders (members). These orders have a specific value for the state variable 'NumberOfRollContainers'. The truck has the state variable 'TotalRollContainers', which should equal the sum of the 'NumberOfRollContainers' in that batch. Kind regards, Christa

-

Hi all, I was wondering, is it possible to record the time in system of entity instances and subsequently plot the values in a histogram? Of course, I can see the average, min and max values in the results tab, but I am interested in knowing what the distribution is like for model validation purposes. If it is not possible to plot the values in Simio, is it perhaps still possible to access and export the values, i.e. to a .csv document? Hopefully my question is clear. Best regards, Michkel Mariegaard

-

Let's say I want exactly 100 entities arrive where the arrival of each one follows a normal distribution with mean 1 hour and standard deviation of 5 minutes from the start of the simulation. How can I model that within SIMIO? The interarrival time doesn't make sense because I don't know / care what the interrarrival time between each entity is. I realize that I could randomly generate 100 normal random variables outside of SIMIO and input them all as an appointment, but I am wondering if there is a better way especially if I want to do many replications with a different set of 100 random variables each time.

-

Hi I have draw a Conveyor and conntected it to a InputNode of Server. Now I have to change the model and connect the Conveyor to another BasicNode. How can I do this without removing and redrawing the conveyor?

-

I have an entity type. 50% of that entity is one counter type while the other 50% is two counter type. After the entity exits the server, 50% must exit while the other 50% must go to the second counter. How do i do this thanks

-

Hi, Have an issue relating to trying to track a segmented entity with the camera. I've attached a very simple model that demonstrates the problem. As soon as i set the draw type to 'Segemented' the camera tracking just doesn't work. One possible solution i am aware of is to simulate the segmented object as individual entities. In the context of what i'm trying to do this creates a lot of additional complexity that i don't want to address. Any other bright ideas? Thanks, Lucas Camera Tracking Segmented Entity.spfx

-

Hello All, I am new to Simio and trying out a simulation of an aircraft component assembly shop. I am using Sequence table for my jobs routing and processing scenarios which is - Source -> Set A (4 servers) -> Set B (7 servers) -> Set C (5 servers) -> Set D (2 servers) -> Sink Here each Set denotes similar workbenches to any of which a job can be routed based on utilization and availability at that point of time. So for routing job based on above criteria from Source, I created sequence table with 'Node list property' (which is list of input nodes on 4 servers of Set A) instead of 'SequenceDestination Property' as required by Sequence table. I want to replicate the sequencing from Source -> Set A -> Set B and so on. But want simio to pick the server of these sets based on my criterion. Unfortunately it is not working as I assume Sequence table need to have specific node as SequenceDestination. I am not sure if I am doing it right or what is correct and way to do it. I will highly appreciate any suggestions to make this happen in Simio. Thank you. -Mohmed

-

I am trying to set up a custom object subclass for a conveyor that emulates an accumulating conveyor which has configurable "zone" lengths and overall lengths. Zones can be equated to "cells" in Simio. For example, if I have a 6' long conveyor with 12" zones, then I would have QTY 6 zones on the 6' long conveyor, which means a traveler capacity of 6 and a cell count of 6. For a 6' conveyor with 24" zones, I would have QTY 3 zones, traveler capacity of 3 and cell count of 3, and so on. In my custom object subclass, I have custom properties for the conveyor length and zone length. I have a function that calculates the traveler capacity based on this. The issue I am having is setting the initial traveler capacity and fixed cell count properties to reference the output of this function. The problem is two fold: 1) How do I create a default property value that references another property or function within the same object instance? For example, say my object subclass is called "Conveyor_Custom" and my capacity calculation function is called "CapacityCalculation". I am able to reference the function output by typing Conveyor_Custom1.CapacityCaculation in the property pane of the first object instance (which is Conveyor_Custom1) on the main model, but I have to type this out for each instance that I create (ie. Conveyor_Custom1, Conveyor_Custom2, etc.). I am looking for a way to set the default value for the entire object subclass to reference the calculation from it's own instance. This default would need to be set within the object definition itself, so that I could drop many instances of the object into the model without needing to type in the name of each instance into the property pane manually. For example, something like Self.CapacityCalcuation would be great, but I am not sure there exists a generic self-reference placeholder and I can't find it in the documentation. 2) Even when I type in the capacity calculation reference manually for each object instance, I still get an error for the NumberOfCells property. For example, in the main model, in the property pane for the first object instance, I can manually set the InitialTravelerCapacity to Conveyor_Custom1.CapacityCalculation and get the correct value returned with no errors. However, when I set NumberOfCells to Conveyor_Custom1.CapacityCalculation, I get the error "Invalid numeric value". The output of the function is an integer (I have some rounding in there to make it so) so I am not sure why the value is invalid. I also tried setting it to Conveyor_Custom1.InitialTravelerCapacity and this also throws the same error. It would be convenient to be able to set the traveler capacity and cell count to the same value, since on accumulation conveyors with defined zone lengths, this is the real physical situation. It doesn't make sense for me to have to manually calculate this and input the actual integer value when there is already a function set up to do this and other properties are able to reference the output of that function. If anyone has experience with this please let me know, in the meantime I am doing it manually but it is very tedious. Thanks!

- 2 replies

-

- properties

- subclass

- (and 16 more)

-

Hello. I'd like to change the value of timer time interval dynamically. I have manufacturing order table which Columns are orderID, PartType, Quantity and ReleaseDate. The model has only one workstation and three resources. When the order is arrived, check which part type is going to process. If part type is A or B, Just process. If part type is others, wait until specific date time and process. To do this, I created a timer element which interval is state type property. However, the value of interval never change during the run I attached the model below. Can anyone know how to change time interval dynamically ? Or, Can anyone have better idea to do this? Thank you. TimeIntervalChange.spfx