Search the Community

Showing results for 'find process'.

-

Before you start adding state variables to a library object, I suggest that you first familiarize yourself with all of the existing states. One easy way to do this is to instantiate the object (e.g., Worker1) and then go to any expression field and type "Worker." and look at the list. In the case of Worker, there are over 100 states, functions, and properties built-in to the Worker object. Another way is to subclass the Worker, then go to the Definitions tab of the MyWorker object and you can see all of the built-in definitions by category: There is a pretty good chance that what you need is already there. But if not, use the same screen illustrated above and add whatever state (or property, event, ...) that you need. As far as referencing or assigning that custom state or a built-in state, it is done using ObjectName.StateName. For example if you added a state named TimeStartedMove to MyWorker, and you wanted to assign that value, you might assign MyWorker.TimeStartedMove to TimeNow. The tricky part, especially with more complex objects like Workers, is to determine exactly when/how to assign that value. Sometimes you can interact with the model itself to insert an Assign at the correct location (let's say in the Loaded Add-on Process). Or sometimes you might need to override the process logic in your custom object. The SimBits RecordDistanceTraveled and ElectricVehicle are examples to review.

-

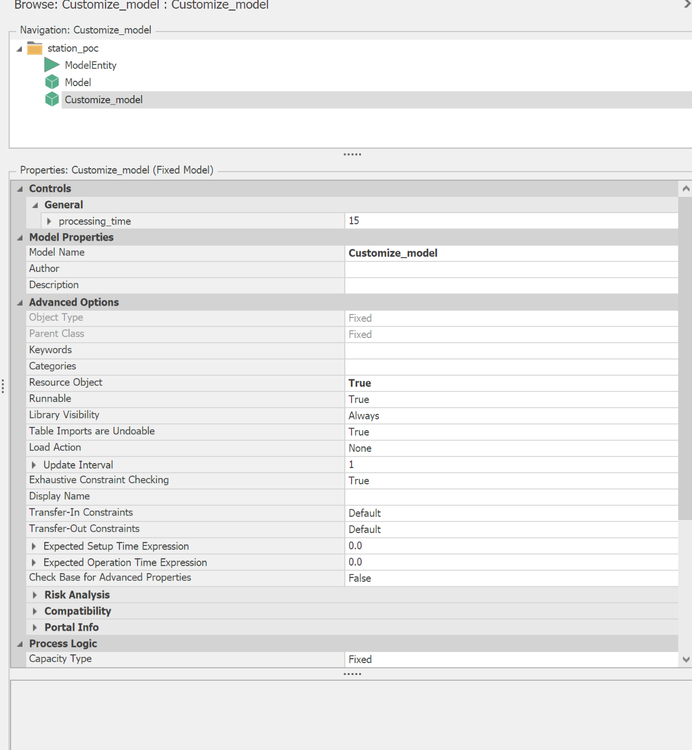

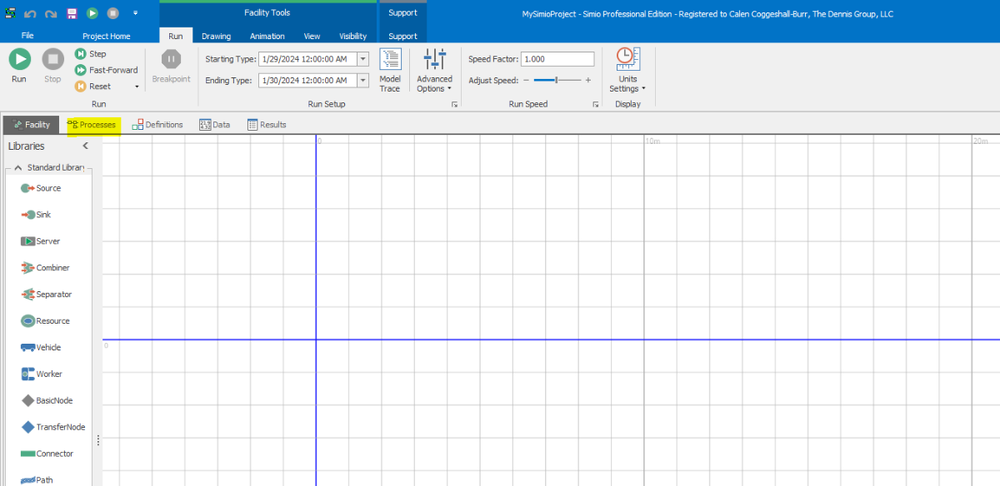

Hello everyone, I am creating a new "customize" model and try to enable addon process, but I cannot find this option in the following list.

-

A simple approach is to create the highest resolution image you can find using any map program or other software. Save it off in one of the import formats: Hint: some software allows export as a high-resolution pdf. Then you can convert that pdf to a png file for import into Simio. Then import that as a symbol and place that in your model (preferably to its original scale). Then lock that to the background and build your model on top of it. The main down side of this approach is that it is limited by the resolution of your image, so if you zoom in, it might appear fuzzy.

- 1 reply

-

- visualization

- simio

-

(and 1 more)

Tagged with:

-

Hi all! I am simulating a facility with nearly 40 servers, each one starting with some entities in the input node at initialization and having a different capacity. Each server has a 0 input buffer capacity. My entity creation is currently set to having an interarrival time to be 4.33 weeks (1 month) with a random number of entities created. Currently, it runs 24/7 and does not care about the time, but I want to incorporate that. How can I make it so that the entities arrive once a month, let's say the first Monday, at 8am? How can I make it so the servers are only processing between 8am and 4pm Monday - Friday? The work schedule doesn't seem to work for me, but I could be doing it wrong, since I have a 0 input buffer, which I can't change as it's part of my routing logic for overflow. I would be happy with using timers or a process logic if someone can explain it to me. Ideally, the entities only arrive when it's during the working time, and the entities remaining after 4pm are just put on hold until 8am the next day. Thanks in advance!

- 2 replies

-

- server

- work schedules

-

(and 2 more)

Tagged with:

-

Hello all, Can I use "print" command or similar process steps to print some information into console or a file for debugging? For example, in other programming environment, such as Javascript, I can insert ```console.log("xxxx");``` into program. Thank you!

-

Enable add-on process option in a customize model

deod replied to GHao's topic in SI General Discussions

Hello, You can go to the process tab in the model. Once in the process tab you can click on create process to create add on processes at the model level. -

I have a multiple combiners into which a single worker provides entities. While the worker is at a specific combiner, I want to check if that combiner's output buffer is full. I'd prefer not to create a separate process for each combiner as I have dozens. How do I code the process so that it is generic and that 1 process can work for any combiner? I'm hoping this is an easy question. Sorry if it's obvious. Thanks for your help.

-

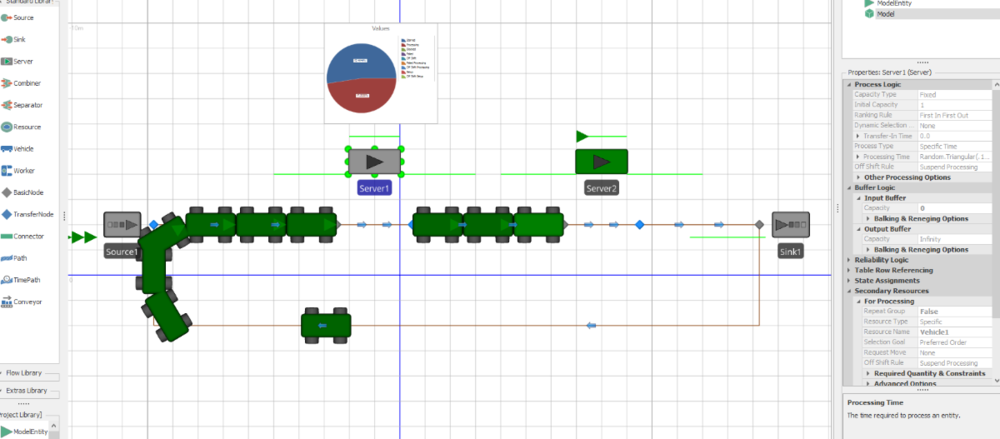

Happy new year! One thing that I noticed is that with this model, the server never have a state of "blocked". I increased the processing time of Server2 and added a status pie to Server1. The server 1 is either Processing or starved, but never blocked according to the pie. But it should be blocked part of the time since I increased the processing time of Server2 to force this. It looks like the Server1 only accepts a new item to process if the path between Server1 and Server2 has room for at least one more vehicle. So the time that it should be blocked is considered as part of the "Starved" instead. I tried to figure out why this happens without success. Anyone knows why this happens? I attach the model to the post. Thank you! Input Server1 not blocked.spfx

-

Hello everybody, I'm trying to make this work but I cant Type/Conteiner BinBig BinMed BinSmall Product1 1 1 - Product2 - 1 1 Product3 1 - 1 Product4 1 1 1 I want to make a node where these entities (Products and Bins) are convined in one batch, I try to use a process based in decitions and search.. the file is attached if you wanna take a look on it.. (the product have to be the parent) OptimoContenedores2.spfx

-

Hi All, I want to do some calculations just before the simulation ends. I did it previous versions without problem but now on version 15.247, "on run ending" add-on process is not being executed.I tested it even on a new simple model file with source server sink. There is just two assign steps with breakpoints on the add-on process. But in model trace it doesnt show the add-process name, the state variable value is not assigned, and breakpoint is not reached. Anyone experiencing the same problem in this version? Is there a quick solution to this? Or do I have to install older version? Kind regards, Tolgahan

-

Hi, You won't need batch logics of the definition. Just the combiner is enough. I made a simplified version of your model. Producto1 requires 1 med and 1 big, while Producto 2 requires 1 small and 1 big. Pay attention to the process that I created at TransferNode1, you'll need to adjust it for the Producto3 and 4. Watch the Combiner Object aswell. Hope it helps. ExampleSimplified.spfx

-

Hello, I wouldn't use process for this one. There is a simple approach that you can use by modifying the SimBit "CombineMultipleEntityTypeOntoPallets". You'll need 3 ModelEntity Integer States to identify the quantity required of each Bin according to the Product. Let's say ModelEntity.Big, ModelEntity.Small and ModelEntity.Med. You can modify "Ops_Exited" step to assign those quantities. For the Producto1 for example, you'll have ModelEntity.Big == 1, ModelEntity.Med == 1 and ModelEntity.Small == 0. A little tip: you can use "Is.Producto1" (or "Is.Producto2", etc) on a decide step to identify which Producto is it. Now on the Combiner Object, follow the Simbit and change the BatchQuantity, to ModelEntity.Big, ModelEntity.Med and ModelEntity.Small. This should work.

-

Hello there, this is my first post here and I hope someone can help me with my problem. I´m quite new to Simio and working on my first project. I have some "return entities" that are considered "bad" at the end of the production. So they will get collected in a server which is used as a storage and get returned to the factory every 24 hours, to get reworked, if there is capacity left. Now, I want to check if there is capacity left in the destinated server and in best case, reserve the needed capacity before, before I route these entities towards it. After the entity arrived in the server, the reserved capacity should get released again. I couldn´t find a good example here in the forum or via google search, as in the SimBits, how to solve this the correct way. Maybe someone here can give me a tip, how to. Thanks in advance. Aljonator

-

I can't say enough good things about working for McDonald's. If you'd like to join in on the fun and work on simulation and process improvement projects that have an impact around the world--for one of the most recognized brands in the world--you might check out this opportunity... McDonald's Corporation Supervisor Process Design and Simulation | SmartRecruiters

-

Job Description Energetic and personable professional who applies operational research to best utilize workforce, data, technology, and other resources to achieve maximum productivity within budgetary constraints. Guides current practices and facilitates through more efficient and effective ways to achieve operational excellence. Experience in discrete event simulation, agent-based modeling, and predictive analytics is a plus Job Responsibility Develops metrics, creates dashboards, reports, and identifies areas of improvement across the organization using various analytical tools and techniques. Identifies current process gaps through the use of observations, data collection, data analysis, process ideologies and communication with management and frontline staff. Identifies issues, root causes, strategies for improvement, and development of implementation and sustainment plans. Supports project management, development of project timelines, and follow-up action items for process improvement initiatives. Develops the summary of findings, recommendations, and action plans to management. Applies principles, techniques and procedures to the design and implementation of technology and process solutions (i.e. Lean, Six Sigma, Kaizen). Supports development of principles and methods for curriculum and training design, teaching and instruction for individuals and groups, and the measurement of training effects. Work assignments are varied and require interpretation and independent decisions on the course of action. Decisions may be guided by precedent, previous experience, and known professional guidelines and compliance requirements. Often required to interpret policies, standards, requirements, and approaches to meet work objectives. Regularly exercises independent judgment on matters of significance within defined procedures to determine appropriate actions/approaches. Normally receives general instructions on routine work, and detailed instructions on new projects or assignments. Performs related duties as required. All responsibilities noted here are considered essential functions of the job under the Americans with Disabilities Act. Duties not mentioned here, but considered related are not essential functions. Job Qualification Bachelor’s Degree or equivalent combination of education and related experience as Continuous Improvement Engineer, Industrial Engineer, Operations Process improvement Engineer, Process Engineer, or Lean Six Sigma Black Belt. 1-3 years of technical experience, required. Technical Skill preferred: Experience in discrete event simulation (preferably Simio), Lean, Black Belt Six Sigma Certificate, Statistical Analysis, Graphical Analysis, Facilitation, and Presentation Skills, Operational Research, Programing (i.e., R or Python), Predictive Modeling, Agile Project Management. Here is the link to apply: https://jobs.northwell.edu/job-3/16580688/process-improvement-engineer-lake-success-ny/

-

Dear all. I'm dealing with an issue that I want to import data from WebAPI where I need self signed certificate. Is there an option for self signed certificate in Simio, because I can not find it. BR

-

Changing Sequence table over time

Rebecca Obasi replied to antonio6vieira's topic in SI General Discussions

I used the "DashboardForScheduling" simbit as an example for this case. For the order that is using "FinishedGoodA" material, I want to change the sequence after the welding process is complete if both shape stations are not available. So, I created an alternative sequence table and referenced in the process logic I created. Whenever this happens, I get same type of error message. Do you think this is happening because the normal routing table is referenced at the source object? -

Changing Sequence table over time

Rebecca Obasi replied to antonio6vieira's topic in SI General Discussions

Ok I can do a trace and see what I find. Also, I do have different entity/job types getting processed. In my routing tables, I do have the entities specified in the table. I'm trying to use the "ChooseAlternateSequence" simbit as a reference. Is it possible to do this if you have more than one entity type? -

Changing Sequence table over time

Rebecca Obasi replied to antonio6vieira's topic in SI General Discussions

I'm trying to do something similar to do this where an order has 4 different routes or paths it can go (My model currently doesn't have paths). I created 3 separate sequence tables and created a process logic depending on if a certain workstation is already processing an order/entity, to go through this sequence. For some reason, whenever it gets to the "set row" step, there is a table reference error mentioning "no entries found" if though in the process step, I specify which row to start the new sequence. What is the reason behind this error? -

Hi I have an entity that is moved through the network via vehicles. The vehicle will drop of the entity at the first server which then gets processed through two servers. I would like to use the vehicle that dropped off the entity at the Input to the first server to be used to pick up the next entity at the output of the second server. Is there a way to save the exact Vehicle that was used and specify that as the Vehicle to use at the second pick up point? Hopefully to a global variable and not to the entity (in my actual model, the entity going in to Server 1 is not the next entity coming out of Server 2). At the moment I am using 'Reserve Closest' as the reservation method at Server 2. I know that is incorrect, but I'm not sure how to setup this up using the other methods. In the attached model, process works for the first entity, but does not for the second entity onwards. Due to other limitations in the model, I need to have the Vehicles to 'Remain in Place' during idle. Thanks in advance for the help. SpecificVehicle.spfx

-

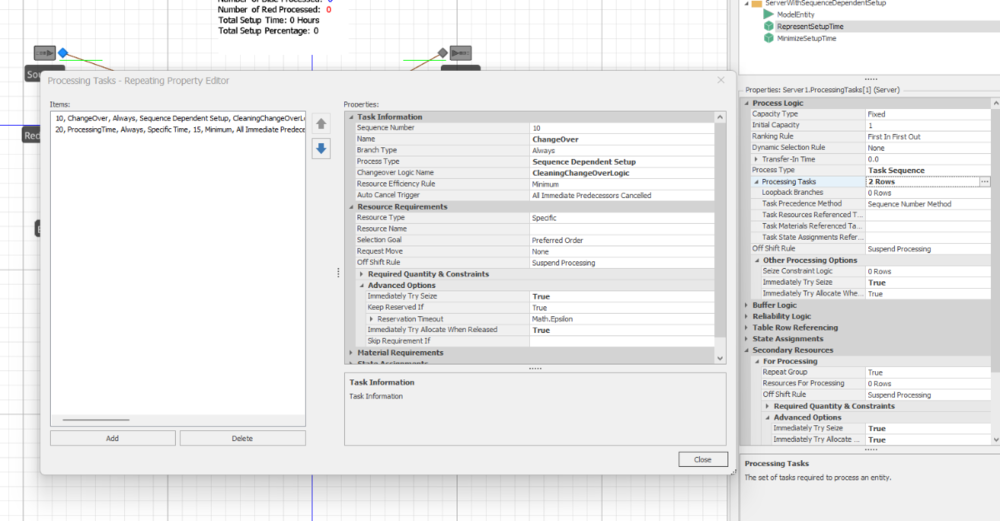

Hello, I'm having strugles trying to configure the setup for the next process: some entities have a diferent processing time and setup time, before to enter to be processed in the workcenters, the workcenter have to be cleaned. I looked the simbit, "ServerWithSequenceDependenrSetup" but I'm confused with the configuration of the processing task. I dont know why we have two lines and o why only one have associeted the change-over matrix.

-

I've hunted through the forums and online and cannot seem to find a fix for my simple application. I have 1 worker operating multiple work centers (Simio server). He should finish all work at one "server" before moving on to the next server. Otherwise, his utilization goes down substantially due to him bouncing back and forth between the servers and walking all day. I.e. Server A: Parts in Que: 1,2,3,4,5,6 Server B: Parts in Que 1,2,3,4,5,6 Worker is doing A1, B1, A2, B2, A3, B3, A4, B4, A5, B5, A6, B6 with a walking time inbetween each part. I want worker to do A1, A2, A3, A4, A5, A6, walk, B1, B2, B3, B4, B5, B6 I would prefer not to use constraint logic due to the complexity. I've read that somehow the solution seems to lie in setting the Secondary Resources "Repeat Group" status to false and attempting to use the "keep reservation" function, however I have not had any luck. I set the "keep reservation if" function to "ServerA.InputBuffer.Contents.NumberWaiting > 0" which in theory should fix the problem, however my worker continues running back and forth. Any help would be appreciated. Thanks, Jon

-

Hi all, I have a model with several servers, each with their own Changeover Matrix for cleaning between jobs. This is done by a Sequence Dependent Setup within the Servers Task Sequence steps. This is working fine when the Cleaning is either done 100% Automatic or 100% Manual with a Worker called as a Secondary resource. Some servers however require partial support from a Worker. For example a COMatrix of X mins needs to include 5 mins support from a Worker at the start and 10 mins support from a worker at the end of the Changeover period, with the middle X - 15 mins in the middle of the CO cleaning period (There are other more complex examples too where the operator will be required half way through the process too to empty the cleaning waste container). Is there a way of saving the COMatrix time, rather than running this delay, so that I can then build an add on process or add further task sequences to break the time into its Automated and Manual Components? Thanks in advance for any suggestions. J

-

Worker to "empty" queue before moving to next server.

jopendle replied to jopendle's topic in SI General Discussions

This helped in some applications, especially use cases where multiple servers are in series and I need the operator to focus on the start or end of the process. Thanks! However, when servers are in parallel the operator tends to run back and forth between them. If I were to assign a higher priority to one line, the worker would focus on that line only. i.e. if he empties the que of parts in the input buffer of Server 1, he goes down to work on only 1 part at Server2 before going right back to Server1. Rather, I'd like for the operator to clear all parts in the que at Server1 before walking down to Server2 and vice-versa. I've tried doing this through process logic however I get stuck trying to evaluate which server the worker is supporting. -

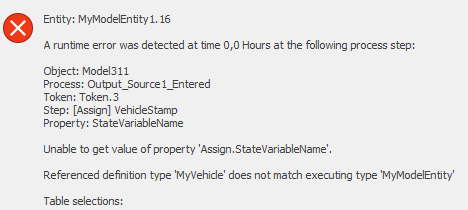

Model.spfx Hello, i am trying to stop the transport time for my entity. The process logic is as follows: hen the entity exits the Source output, the time stamp (MyVehicle.Stamp) is assigned with the value "TimeNow". When the transporter drops the entitys to the servers input the time is stopped (New Value = TimeNow- MyVehicle.Stamp) and simio calculates the transport costs. The error is attached. I get the same error, when i use MyModelEntity instead of MyVehicle. The model name is "Model311" in the attached project "Model". How or where do I have to set the stamp correctly? Thank you!