Search the Community

Showing results for 'combiner parent'.

-

Hello All, This is my first post and I am relatively new to the program, so my apologies if my strategies are not the best. Essentially what i am trying to simulate is a simple picking process with AMRs (automated mobile robots). The ideal workflow is: 1. 3 Totes are created and attached to ARM's shelves 2. Shirts are created and processed through a server (already done) 3. Worker picks 5 shirts from the servers (already done) 4. Worker takes the 5 shirts and places it on the Totes 5. Once the 3 totes are full, the AMR will navigate to an unloading destination so another worker can unload the boxes So i realized that simio does not have any "attach" features where i could attach a box to a robot so instead of attaching, i will just make a combiner near the robot of the totes and shirts that its output leads to the unloading destination via transporter AKA the AMR So far, I have been able to create shirts, put them on servers and have the worker pick and place them. I have been looking into using a Combiner to merge the totes and the shirts, but for some reason the worker keeps fetching totes and not shirts (yes, I set the Batch Quantity to 5, so the worker should fetch 1 totes and 5 shirts right?). I simply need one tote/5shirts and would like the process in that order, in other words, the worker fetches a box places it on the robot ("feeds the parent input of the combiner") and fetches for 5 shirts to place on the box ("feeds the member input of the combiner"). Im more worried about these first steps, i know it may take more understanding to have the robot move once the 3 boxes are full. Any help, helps. Thank you.

-

Connecting conveyors with vehicles

JuliaGeurs replied to JuliaGeurs's topic in SI General Discussions

Thank you very much for your help, though this does not help me solve my problem, i'll try to explain it a bit better. in my model, a passenger (parent entity) arrives at a separator object with one or multiple batched entities (bags), these then separate from each other. to represent the real system, a tray should also be available to put the bag on (this should be available before the separation starts), i modelled the tray as a vehicle because then i could model the "need for the tray to be available" as a secondary resource. After the separator the tray (with bag) should move on a conveyor through the system, and at the end the tray is taken back to the beginning of the system and the bag leaves the system. so the vehicle does not take the bag to the conveyor, but rather transports the bag on the conveyor. I didn't know how to model this with the tray being represented by another type of object, therefore i choose the vehicle object. I added a simplified version of the part of my model (of the part where i have issues) here, what i would like is that when the tray/bag move through TransferNode 1 (and/or 2) that the bag(modelentity) stays on the tray (transporter). VehicleThrough.spfx -

If the parent entity knows how many bags belongs to they, you could set this expression in combiner's Batch Quantity property, something like my new attached model. Then you set the bag and passager IDs in the Ranking Rule property. Match Quantity.spfx

-

Thank you for your help, though this does not work for my model. The amount of (member)entities that are batched differs (since the amount of bags that a passenger carries with them differs), i am able to make sure the parent entity "knows" how many bags they should batch with at the combiner, but i can only get 1 right member entity to batch. so what i would like to do is give all member entities that "belong to a passenger" a state which is the same as a state for the parent entity (passenger), so this can be used as "match expression".

-

You can assign each entity an individual ModelEntity.Priority and set your Combiner to only match entities with the same priority. Check my attached model to see an example. Match Priority.spfx

-

I want to assign a state variable to the batch members of a parent entity, is this possible? the reason for this: I have 2 types of entities (passengers and bags), they separate, then go through different processes and then are combined again. but since the passenger entities have to be combined with "their own" bags, a state (or something else) should be assigned which can be referenced as "match expression" in the combiner. is this the right way of modeling this type of process? or should i do this another way?

-

To model shelves, I am trying to create a series of custom "Shelf" objects (subclass of servers) located in a grid pattern. I used a spreadsheet to automatically calculate the coordinate locations and generate a name (string) for each object based on its position within the grid. With just the Shelf object types in the spreadsheet, can bind the file to my object reference table no problem, import the data, and populate the facility window with my objects. That part works fine! Next, since I have an aisle running between the rows of objects, I wanted to set it up so that the objects all face "inwards", ie. the input and output nodes for the objects are facing the aisle. Originally I thought of rotating the Shelf object, but I ran into 2 issues: first, I discovered that I can't set the Shelf yaw orientation from the table, so that's not going to work. Second, I realized that even when I rotate the Shelf in the facility window, the nodes do not rotate with their parent object. I decided I would leave the Shelf in the same orientation as it is placed, but I would just re-locate the input/output nodes to the opposite edge of the Shelf objects on the far side of the aisle. For this I would need to make sure I can set locations for the input/output nodes in the same object reference table. When I added a row to the object reference table from within Simio (prior to binding to a spreadsheet), a drop down appeared, and I could select the input or output nodes for any object that already existed in the table, and then define the node's location in the cartesian coordinate columns. When creating a node this way, the node location is still relative to the object, ie. I can drag the object in the facility window and the node moves relative to the object, which is perfect. This input/output node creation and relative location definition via table is exactly what I am trying to automate, but this is where I started running into problems. In my spreadsheet I used formulas to generate names for the nodes to match the formatting of the input and output nodes in Simio (ex. "Input@..."/"Output@..."). I also added a formula to assign all input node object types to BasicNodes and all output nodes to TransferNodes and calculate the desired location coordinates for the nodes. The spreadsheet I made has the same format as the table in Simio where I tested manually creating and positioning the nodes. The issue is that when I bind the table and import the spreadsheet data to my model, the node names automatically change and are no longer formatted to reference the parent object. Because of this, these name-changed node objects are created in addition to the input and output nodes that are created for each Shelf object. However, if I remove the binding and add a new row, once again I can find the node name in the drop down list and assign the coordinates manually, and the input/output node that references the parent object will move to where I send it. My question is: how can I set the input/output node locations for the objects when creating objects from a table? There are over 500 Shelf objects in the table so I do not want to locate them manually, but the automated method is not working either. The only idea that I have is to make a new object "Shelf2" and define the external view to have the nodes on the opposite side, but that seems like a less-than-idea solution because then I would have 2 custom objects to update and maintain, that are otherwise identical. I am hoping that I don't have to do this hacky solution but I am interested to see if anyone else has dealt with this and has ideas. Thanks!

-

I assume that your worker is located at the MemberInput Node of the Cominer I search Queue State, the Queue Name is: MyWorker.Location.Parent.Node.AssociatedObject.MyCombiner.OutputBuffer.Contents

-

I have a multiple combiners into which a single worker provides entities. While the worker is at a specific combiner, I want to check if that combiner's output buffer is full. I'd prefer not to create a separate process for each combiner as I have dozens. How do I code the process so that it is generic and that 1 process can work for any combiner? I'm hoping this is an easy question. Sorry if it's obvious. Thanks for your help.

-

I want to simulate a touring group utilizing 2 different buses to the same destiny, concurrently there are multi-types of model entities with a unique percentage distribution; "Adult, Teen and Senior", passengers. Finally, at arrival, both groups unloaded from their buses at the same time. My Question is: How I can to batch each group in a separate assembling area, so then they would follow a different group routing? I studied the "Combiner Node" example in the SimBit, can I do it without parent priority logic?

-

I will try to use the match expressions to determine which containers to batch. It would make things simpler. In the meantime, I discovered I could insert an extra server with 0 processing time just to store the worker and trigger the processing. Then, if a member entity is ready to batch, the worker can perform the batch. If there is no member entity yet, the worker waits in the output buffer and then when the member entity arrives at his detached queue (I needed to add that back in for this to work) it transfers the worker back to the input of this server so the worker can execute the batching logic again. Then, the parent and members arrive together at the combiner and they're ready to be combined. Again, I'll try again to use the match expressions, but if I can't figure that out, this should suffice. thank you very much for your help. using combiner.spfx

-

1) The model seems working as you intended. The animation seems the logic is not working but in fact the animation is delayed (in the animation the modelentity is at output node of server2 i.e., seems behind the scheule but if you examine trace window the modelentity is just at combiner memberinput buffer.) 2) I think the process logics are not required if you will not use them for further modeling purposes. I mean If you set appropriate parent match expression and member match expression at combiner1 object, the object itself will combine them automatically (it will perform all the operations you performed in your processes). Try not to use them?

-

Thank you gocken. This is so helpful. It makes things much simpler. I created an example with an entity which uses the worker as a transporter to go to the parent node at the combiner. the batch is created and they move on together. This seems to work well. But, I need to be able to perform the batch selection in a process. This is where things keep falling apart for me. I made the combiner match on member and parent, giving the entities a state variable set to True if those items were to be batched. I want to set this in an add-on process. Further, I need to be able to trigger this process when either a parent or a member entity enter their input buffers. I have an example attached that uses the add-on process. Once the parent enters the input buffer, the parent can choose what to batch. The batched items move on to server1 and the separator. Then, the worker (entity and transport) return to parent input of combiner, but it's empty. The unbatched entity goes to server2 (just to ensure it arrives after the parent). I thought it would leave server2 and trigger an add-on process on arriving at the member input node, but the add-on process is triggered when still at the server2 output node. So, in the add-on process, I transfer the parent to the parent input node (just to get the parent to kick off its own add-on process, but it doesn't know where to search for the member entity because it's still at server2. How do I get a process to fire to determine what to batch whenever either a parent or a member arrives? using combiner.spfx

-

Note: set selection weight of the path's (from source to picking object's parent input node) selection weight property as modelentity.ParentTrue==True and the path's (from source to picking object's member input node) selection weight property as modelentity.ParentTrue==False.

-

It seems that you can employ the same logic by using combiner (named picking) and seperator (name it as filling, I have forgotten) objects from standard library. This simplifies your model development efforts. Since using a different version I can not save the model I developed. But, attached some screenshots as a guidline.

-

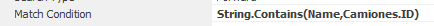

i want o find it in a data table named Camiones in column ID (CA123), in my faciliity i have an object named CA123 inherits from type Camion which inehrits from Vehicle, now what i try to do is get just the parent name which would be CA123 and not CA123.123 (instance of object created in facility with population 1)i have tried this: Where Name is CA123.123 and Camiones.ID represents all rows in data table Camiones and column ID eg. CA123,CA99,CA82

-

Separator does not seem to be splitting correctly

CWatson replied to JanWai's topic in SI General Discussions

If you have a batched entity (through Batch step or Combiner object), there is only one parent entity and the rest member entities. Thus, one entity exits the parent node, the others exit the member node. If the Separator instead did a Make Copies instead of the Split Batch, you still have the original parent entity (incoming entity) and the member entities (copies). If you need to split the entities in different directions, you should look at having both of those nodes connected to a single node where you then make the decision to go in two different directions. -

Hi, I currently have a model as follows. I have a separator, and I want to divide entities that enter through it evenly across the 2 nodes. So half of the entities go out from the parent node and half go out of the member node. Currently right now, I did not manage to do it for the separator, even when I tried all possible methods in SIMIO for splitting the batch itself. How may I go about the problem? Thank you!

-

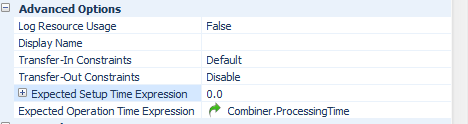

Within the Server, Combiner and Separator, if you change the Process Type property (under Process Logic section of properties) to 'Task Sequence' then you will get a repeating editor for Processing Tasks property - within that editor for adding multiple processing tasks, you can specify the Process Type as 'Sequence Dependent Setup' where you then reference a Changeover Logic element. This allows all three of these objects to include setup times.

-

Is there any way for me to assign a setup time to a combiner? Is the setup time property only available in workstation object? Under the Advanced Options of the combiner, there is this Expected Setup Time expression. Can I use it to specify the setup time needed before a batch can be processed? Thank you

-

Batch Members and Parents Routing

gocken replied to Luu Khanh Minh's topic in SI General Discussions

You should place a seperator just after the combiner object. After seperating them all send five of them to node A and the other to node B. There exist many different ways to perform this. -

Assign different states to members of a batch

gocken replied to Luu Khanh Minh's topic in SI General Discussions

If I were you I made these assignments before sending modelentities to combiner object. Then combine them all... Sometimes "think different" works for simulation -

In my model, I have a combiner that batch 1 parent entity and 9 member entities together. I then need these 10 entities, when travelling out of the output node of the combiner, to go to 2 different paths. 5 of them should go on a path to node A and 5 of them should go to another path to node B. I tried using Combiner.BatchQuantity at Output_Combiner_Entered Add-on process but it doesn't work. May I have some suggestions? Note that the batch number is not fixed and will vary during the simulation run.

-

Assign different states to members of a batch

Luu Khanh Minh replied to Luu Khanh Minh's topic in SI General Discussions

Hello I would like to revive this thread. So In my model, there is a combiner that generates a batch by batching 1 parent entity and 29 member entities together. After the combiner, I want to assign exactly 30% of 30 entities(i.e: both the parent and the member entities) to state "A" and the remaining 70% of the 30 entities to state "B". May I have some suggestions as to how to do so? Thank you! -

The various resource type objects, such as Server, Combiner, Resource, etc. as well as moveable resources, such as Workers and Vehicles have Resource States that are automatically assigned by Simio. See the List States page in Simio for a listing of the resource states for each object. You can evaluate the state by using the ResourceName.ResourceState in an expression, such as in a Decide step - Server1.ResourceState == 3. These resource states can also easily be viewed by clicking on the object itself and going to the Active Symbol section of the Symbols ribbon to display the animation symbol and listing of the various states and their associated numbers.