Search the Community

Showing results for 'add Queue tto entity like Batch Member'.

-

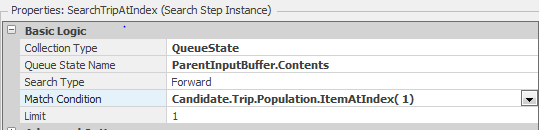

Hi, I would like to return information from an entity in a queue (parent input buffer) at a specific index. If I use the search step with following property values (see attached image) I receive an error (see attached image). What does this error exactly mean and how can I solve this problem? Thanks in advance! Christa

-

Record Statistics Per Entity Throughout Simulation

Emiliano posted a topic in SI General Discussions

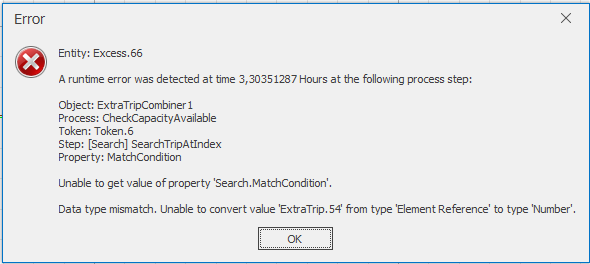

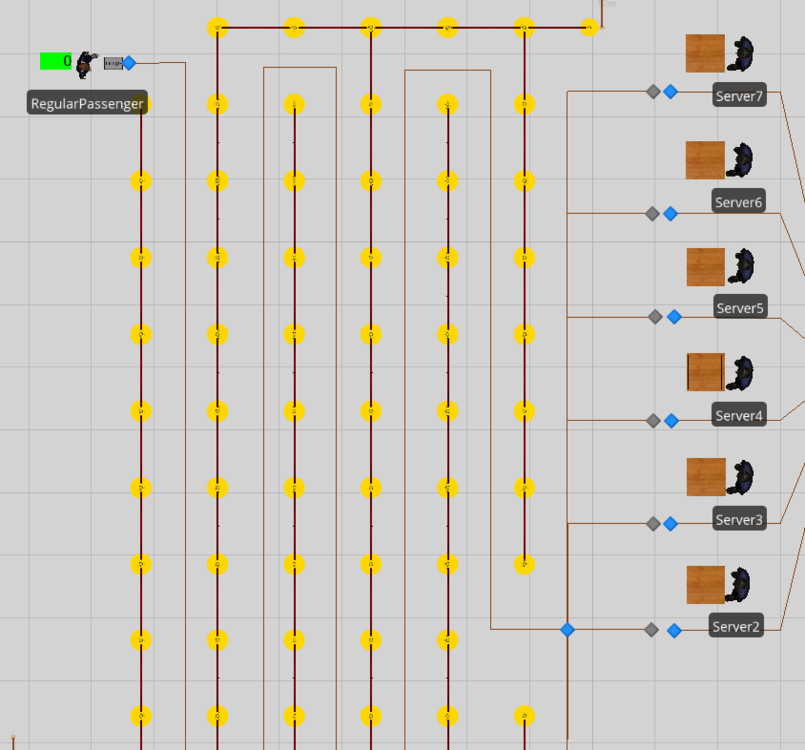

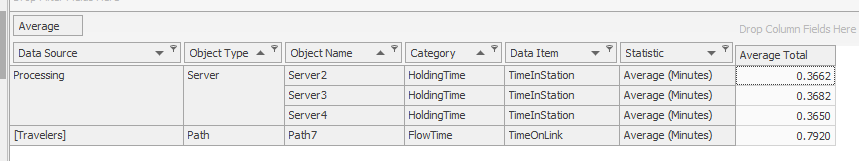

Hi! I have been using SIMIO for quite some time now, but I have barely come across this need. I need to record the time spent per entity at any given path/server in the simulation, rather than obtaining the average time for all entities at the end of the simulation. Take the image below as an example. I need to record the time spent in the link (TimeOnLink) per entity generated. The path corresponds to that connecting the source to servers 2-7. Then, I need to record the time spent per entity on servers 2-7 (TimeInStation). I can display the unique ID number for each entity by Entity.ID, now I need to match the statistics. I figure the best way to model is trough ExcelWrite, but I can't manage to make it work. Any hints? The plan is to get the following information per entity, rather than a summary of all entities.- 1 reply

-

- excelwrite

- entity

-

(and 1 more)

Tagged with:

-

Hi All, In examining a medical system, we have a requirement to log snapshots of the patient details being processed at specific points in time during experiment replications. For each server, we would like to know the state values for entities currently in processing in each functional area ( a mix of servers and storage queues). I suppose I am looking for an "Easy Button" which would quickly capture a Work In Process snapshot of the system. Are there any thoughts on accomplishing something like this? Any kind comments would be greatly appreciated. Thanks, Jim

-

Hi Everyone, I have 100s of different products in a warehouse and I want to get statistics for all of them such as distance travelled, number entered and exited. So I created the entity instances for each product automatically through data table. The entity.totaldistancetraveled function doesnt increase since the entity doesnt moveby itself but moved by forklift instead. So I have created a state variable called "distanceonforklift" and increased by the difference between the forklift total distance travelled value when entity exits and enters to forklift. I have also created a function called "distancefunction" on the entity and equated it to "distanceonforklift" state variable of the entity. For the return type of function I have chosen "number" and set the unit to "length". I validated that both distance state variable and function is calculated correctly in the facility window. However I cannot output the result of this state variable on the model results screen. I used the following expression under model outputstatistic but it didnt work. "ProductA.DistanceFunction". That expression gives me 0 value although there are some entities of this product which enters and exits the system. How can I see the average total distance travelled on forklift for the whole population of Product A?

-

I have a model where I have 7(seven) entities and for each entity there are many possibilities paths. Is possible an entity be programmed with multiple sequences tables? For example, the entity can go to source -> server1 -> sink, and also randomly it can go to source -> server2-> sink, something like that.

-

Hi, I'm modeling an automated warehouse and I would like to know how can I only release an ítem to be processed if a release state (that the entity has) is set to true. Otherwise I want that entity to stay in queue until the release state is set to true (so it should be evaluating that condition all the time in order to know when it changes. Thank you in advance

-

Hi, What is the best way to access entities in a queue and select entities of a certain type to be processed first? I want to do this dynamically as the model is running. Thanks!

-

Hi, We have a model where we have multiple entity states. This creates interface challenges in defining and populating these states or changing many of them at a time. My question is, can the UI be bypassed in some way using some kind of batch operations? For example suppose I want to assign 150 entity states using string construction and naming conventions easily set up in a spreadsheet. Is there a way to define all those states and import them from a file rather than hand editing each one in the Definitions UI? Another example is I want to set large numbers of these states at appropriate points in processing. Is there any way to do so by just importing name value pairs from a file rather than hand editing each one and copy pasting from a spreadsheet built up accordingly. Thanks Very Much, Jim

- 2 replies

-

- state array

- repeat group

-

(and 4 more)

Tagged with:

-

Dear all, I am currently simulating a 3D printing facility in the frame of my Bachelorthesis and I have a specific problem which I cannot solve by myself. I have four Entity types with different lead times which are specified in a datatable as shown in one of the SimBit solutions. However, I need to batch the entities before they arrive in the workstation to simulate that several parts are processed within one 3D printing build job. The problem is that the workstation only calculates the leadtime of the parent entity and not of each individual member. Instead of calculating: 5hr + 4hr + 3hr + 2hr= 14hr for a batch of four entities, the machine only calculates 5hrs. Is there any solution with a search step to explain the workstation that it should define the batch members and then to add the lead time for each of them according to my datatable and to use the sum as processing time? I am really thankful for any help you can provide, so thank you very much in advance! Greetings from Hamburg, Armin R.

-

I am working on a simulation of a number of firms processing raw products. If I represent the firms as resources in a server -so that the server capacity represents the number of firms, how could I identify which resource/firm processed a certain batch of products? Can this be done with a server having a capacity of its own, or should I use a pool of (secondary) resources with id labels so I can use that id to label the product batch?

-

task sequence Multiple Operations on Single Entity

ayaraneri posted a topic in SI General Discussions

I have an application where a single entity gets worked on by two different operators at the same time with different completion times. This occurs on 10+ workstations in the flow line in the application. What is the best mechanism to model this in Simio? Ideally, I would like to be able to adjust the processing time of each operator to engage in line balancing, and the ability to create standard WIP processes. Thanks, Aytac -

Dear Simio employee, I have two questions about 'getting' the average holding time for all the realisations of my subclassed vehicle. I want to know how long an entity is on a vehicle, on average. I tried it with two processes, but both don't work. I don't understand why the following doesn't work (process GemTijdOpAGV): And I also don't understand why the process TijdContainerOpVoertuig doesn't work. I don't understand the error: 'Model Entity does not match the model', or something like that. I created two instances of de model entity, named 'container and pallet', but it seems like I can't use model entity in some processes and in others I can. Why is that and when can you use model entity and when not? (This is also true for instances of a vehicle.) I have attached the model below, but it is still in progress. I hope to hear from you soon! With kind regards, Thomas Haven_v1 project DS model met RS en dus intelligent MTS.spfx

-

Hi All, I am attempting to model a triage logic where I want to periodically, sequentially search the contents of a storage queue associated with a station and test the availability of resources to handle processing it. If the resources are not available in the system, I would like to move to the next entity in the queue and test it until all the current queue has been examined. The goal is to sequentially walk the queue organized by priority using the lowest value first of a state variable on the entities. Is there a suggested "best" way to approach this sort of problem? Essentially I want to do a loop to examine entities in a storage queue and transfer the best one with a match to available resources. I tried using a search based on index but ran into an error getting the state values of the entity and also seem to have challenges sorting the storage queue correctly. I would be grateful if someone has a basic example of such a sequential search. Thanks Very Much, Jim

-

Hi!! I want to know in which object (in this case filler) my container entity is when certain event occurs. Is there a way to access this info? Thank you so much! Teresita

-

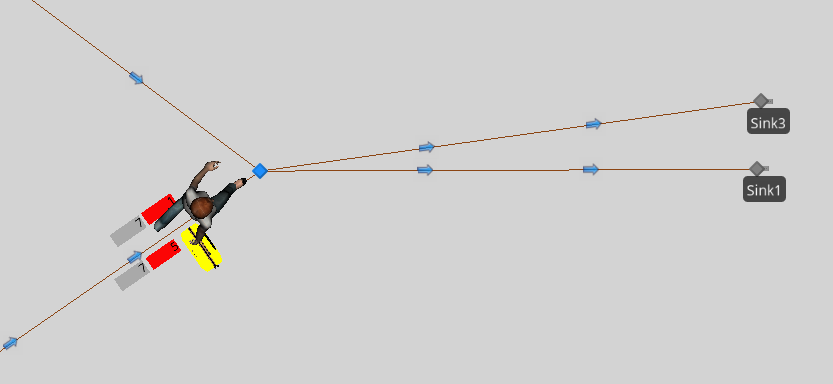

Hello, I have recently encountered an issue while simulating an airport checkpoint and thus leading to the following question: Is it possible to match member and parent priorities under certain conditions? I am trying to differentiate between those travelers (parent entity) and baggage (member entity) going though an additional screening process prior to exiting the model. Take the following image as an example. I managed to provide a priority (red status label) to those entities going through the additional screening while also providing a rule for those with a priority of 5 to exit though Sink 3 (Those with a priority of 1 should exit through Sink1 ). However, the rule seems to only apply to the parent for a reason I assume to be that the baggage is an entity initiated by a "create" step in the processes window, rather than at its own source as the parent. The current rule I have is to decide the following ModelEntity.Priority==5.0, then assigning the desired node (Input@Sink3). In the picture, although the baggage (member) has a priority of 5, the traveler (parent) has a priority of 1 and the rule only applies to the parent. How could I match the priority of the parent, only under the case in which the parent has a higher priority? (Perhaps match the greatest priority of the member and the parent to generalize) I have tried everything possible and I cannot figure it out. Any help is greatly appreciated!

-

Hi all, I was wondering, is it possible to record the time in system of entity instances and subsequently plot the values in a histogram? Of course, I can see the average, min and max values in the results tab, but I am interested in knowing what the distribution is like for model validation purposes. If it is not possible to plot the values in Simio, is it perhaps still possible to access and export the values, i.e. to a .csv document? Hopefully my question is clear. Best regards, Michkel Mariegaard

-

I've ran into the following problem with a combiner: I'm using it to model a load zone where taxis arrive to the parent node, passengers arrive to the member node, and the number of passengers boarding each vehicle is set by a random.discrete distribution (so that for instance 50% of the taxis have 1 passenger, 30% over 2, and 20% have three). This all works great. But now, instead of having my passengers queue at the input node, I was hoping to make them queue at another upstream node, connected to the member input node by a path and every time a taxi arrives, I would like to send to the combiner only the number of passengers that will be batched with the taxi. I tried using Combiner.BatchQuantity but without success so far. From what I've seen by looking at a display showing Combiner.BatchQuantify, it seems it's continuously going through its possibilities, whether a taxi is at the parent input node or not. Then I thought that maybe the number picked to batch passengers with taxis, was selected from that continuously changing value when a taxi entered the parent node, so I tried using the event ParentInput@Combiner1.Exited (as well as ParentInput@Combiner1.Entered) to extract the batchquantify assigned to that taxi but the value did not match the actual batching. So I guess my question is: is there a way to access the value that is picked by the batching process to use it to send the right number of members to the combiner? Thank you very much for your help. Pascal

-

Hello everyone, I am a master's student in operations management trying my hand at Simio for the first time. I want to develop a model that simulates the delays incurred by variable supply lead times which may lead to stock-outs at a manufacturing plant. I would like to model demand so that each entity generated by a single source module corresponds to a sales order. Each order should have a probability to include orders for several specific product types (since sales orders may contain orders for different product types). As such, entities should have an arrival rate which corresponds to the arrival rate of orders at the company, and the product mix of each order should reference the probability of a given product type being included in that order (i.e. product A has 25% probability to be included, product B has 50%, etc.). Is it possible to do this? I would also like for each product type to be associated with a specific BOM. I.e., a server module should reference each entity instance to consume material as defined by the BOM’s of the products stated by the entity instance. I have defined each component as material elements and defined a BOM for each finished product that references the materials needed. However, in the server module I am only able to input a specific type of finished product as material requirements... Your help is greatly appreciated!

-

Let's say I want exactly 100 entities arrive where the arrival of each one follows a normal distribution with mean 1 hour and standard deviation of 5 minutes from the start of the simulation. How can I model that within SIMIO? The interarrival time doesn't make sense because I don't know / care what the interrarrival time between each entity is. I realize that I could randomly generate 100 normal random variables outside of SIMIO and input them all as an appointment, but I am wondering if there is a better way especially if I want to do many replications with a different set of 100 random variables each time.

-

I have an entity type. 50% of that entity is one counter type while the other 50% is two counter type. After the entity exits the server, 50% must exit while the other 50% must go to the second counter. How do i do this thanks

-

I'm pretty sure my whole approach is flawed, but I don't see how else to do this. The attached is a very simplified version of what I'm trying to do. In the real problem, I have empty containers that enter a detached queue based on when they are retrieved from customers. I also have workers that need to select (through a fairly complicated process) which of these containers to batch together to enter a filling station. This selection process is complicated because it depends on filling material, pressure, volume, and safety stock of the sku (multiple skus can be combined in same batch provided filling material, pressure, and volume of container match). Anyway, what I'm aiming for is Create a batch When the worker is idle, he will go to a node and search among empty containers in the detached queue to assemble a complete batch. If there aren't enough containers, the worker will wait, idle. As empty containers arrive at the detached queue, they should trigger, somehow, the worker to try to create a batch again. There are new containers now, so maybe a batch is possible. (Preferably, since hundreds of containers could arrive at a time, this trigger would be for all the containers arriving at this specific time, not each container doing a separate trigger.) With the batch, the worker should move to a server, seize it and wait while the containers are filled. Then move to a separator to separate out the batch, moving the containers to full inventory and the worker should go back to try to create another batch. I'm stuck in a couple of places, specifically (so far) . . . I can't seem to get the worker, once batched, to move to the filling station. In fact, the Move block in PickingStation_Entered doesn't even fire. I can't figure out how to get the entity to trigger the worker to reevaluate the batching process. However I try this, the batching process is executed by either the entity's token or a model token. I can't see how to get the worker to be the executing token. Any help or guidance would be appreciated. Model.spfx

-

In my model, I have a combiner that batch 1 parent entity and 9 member entities together. I then need these 10 entities, when travelling out of the output node of the combiner, to go to 2 different paths. 5 of them should go on a path to node A and 5 of them should go to another path to node B. I tried using Combiner.BatchQuantity at Output_Combiner_Entered Add-on process but it doesn't work. May I have some suggestions? Note that the batch number is not fixed and will vary during the simulation run.

-

Hi, Have an issue relating to trying to track a segmented entity with the camera. I've attached a very simple model that demonstrates the problem. As soon as i set the draw type to 'Segemented' the camera tracking just doesn't work. One possible solution i am aware of is to simulate the segmented object as individual entities. In the context of what i'm trying to do this creates a lot of additional complexity that i don't want to address. Any other bright ideas? Thanks, Lucas Camera Tracking Segmented Entity.spfx

-

I want to assign a state variable to the batch members of a parent entity, is this possible? the reason for this: I have 2 types of entities (passengers and bags), they separate, then go through different processes and then are combined again. but since the passenger entities have to be combined with "their own" bags, a state (or something else) should be assigned which can be referenced as "match expression" in the combiner. is this the right way of modeling this type of process? or should i do this another way?

-

New to Simio and learning as I go. The attached model includes a CombinerNode1 that batches entities in groups of 2 & 5 (random.discrete). I would like Server1 to use different processing times for the different batch sizes. For example, a batch of 2 entities should be processed in 5 seconds; Batches of 5 entities in 7 seconds, etc.. Eventually I will create batches of up to 6 entities. I have tried using Server1.Processing.Contents for Processing Time, but seems to return the value of 1 all times. Any help is appreciated! Thanks! Processing time based on BatchSize.spfx