Search the Community

Showing results for 'how to change property of one specific entity and not all of them'.

-

How do I access a table column by name using a table property defined for the model? In my model, I have multiple data tables each with the same named columns defined for each. Each table has a different number of rows. For a run or a set of replications, I want to select a table to use. I have defined a model-level table property named _SelectedTable to support this. During simulation runs, I want to access this selected table's data by row and column name. Specifically, I want to use this data to update model entity state variables. I also want to stop creating entities when all of the rows of the table have been accessed. I've tried two partial solutions to this problem (attached), but neither are ideal. 1. Create a large set of decide add-on processes to choose the decide the correct table and explicitly reference it by its name. This requires a lot of redundant steps and maintenance if tables are added or removed. The attached example contains just two tables. Controls OptionId and _SelectedTable must be set to either (Option1 and tableOption1) or (Option2 and tableOption2). The first control selects the Entity Type and the second selects the Table. 2. Using the column index number instead of the column name, I found I can use the table property to access the selected table. This method is prone to error if the table schema changes. It is also unclear which table properties, such as "AvailableRowCount" are accessible via this approach. The attached example contains two tables just as the previous. The control _SelectedTable chooses which table from which data is acccessed. In practice, the data tables will be substantially larger than the ones included in the attachments. Looking forward to constructive guidance, Ryan table_selection_by_name.spfx table_selection_by_column_number.spfx

-

I have a model where I have 7(seven) entities and for each entity there are many possibilities paths. Is possible an entity be programmed with multiple sequences tables? For example, the entity can go to source -> server1 -> sink, and also randomly it can go to source -> server2-> sink, something like that.

-

Hi, How can I change a state variable of a flow entity? For example, I want to change the color (i.e. picture state) of the entity based on the flow connector that the entity enters. Any suggestions how to do that (apart from converting the flow entity into a discrete entity and then back to a flow entity)? Especially, because flow connectors do not have Add-On processes. Any ideas are appreciated. I have already reviewed the SimBits for flow library and could not figure out. Thanks!

-

Hi, I have several sources that create the same container entity, yet every container entity created carries out different tasks throughout the model. I would like to change properties of specific container entities, for example, each time the container entity in "lane 1" gets filled, it changes the speed of that container entity (not of all the population of container entities). How can I do this? Thank you!!!

-

I have one data table to create Order entities(based on SimBit - Entity by data table). Each order has properties such as type of Part and number of Parts. Each Order entity needs to reference a Part data table (based on SimBit - Leveled Arrivals) for that type of Part to create all the part entities for that order. Each Order type has an associated Part data table. I'm not sure how to establish the relationship between the order entity and the correct part data table. Any suggestions would be appreciated. Thank you.

-

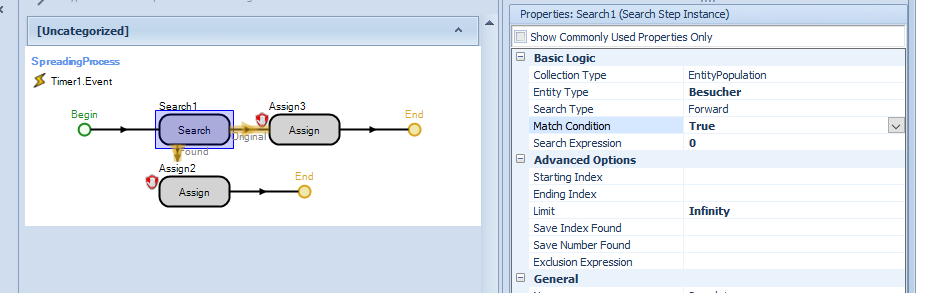

Hi I want to change a state-variable of each entity of a specific type. I am trying to reach this goal by using a search-step in a Process. The process is executed correctly but the search-step is not doing anything. I have set the following values for the search-step: CollectionType: EntityPopulation Entity Type: Besucher Search Type: Forward Match Condition: True Limit: Infinity The goal is that each entity of Type Besucher should flow to the "Found"-Branch where I have created an assign-step for changing the state. But the Step following the "Found"-Branch is never reached and also the Step following the "Original"-Branch is never reached (I have set a breakpoint at thia steps.) I have also attached a screenshot. I hope, someone can help me.

-

task sequence Multiple Operations on Single Entity

ayaraneri posted a topic in SI General Discussions

I have an application where a single entity gets worked on by two different operators at the same time with different completion times. This occurs on 10+ workstations in the flow line in the application. What is the best mechanism to model this in Simio? Ideally, I would like to be able to adjust the processing time of each operator to engage in line balancing, and the ability to create standard WIP processes. Thanks, Aytac -

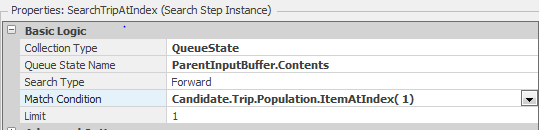

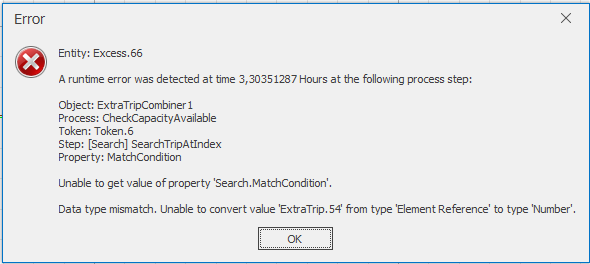

Hi, I would like to return information from an entity in a queue (parent input buffer) at a specific index. If I use the search step with following property values (see attached image) I receive an error (see attached image). What does this error exactly mean and how can I solve this problem? Thanks in advance! Christa

-

Hi everybody! I want to know if it is possible that an entity can change from one server to another if the another server is available and the entity isn't still processing. It means if it is possible that an entity can exit from the input buffer of the first server. Thanks for your help. Best, Albert.

-

Hello everyone, I am a master's student in operations management trying my hand at Simio for the first time. I want to develop a model that simulates the delays incurred by variable supply lead times which may lead to stock-outs at a manufacturing plant. I would like to model demand so that each entity generated by a single source module corresponds to a sales order. Each order should have a probability to include orders for several specific product types (since sales orders may contain orders for different product types). As such, entities should have an arrival rate which corresponds to the arrival rate of orders at the company, and the product mix of each order should reference the probability of a given product type being included in that order (i.e. product A has 25% probability to be included, product B has 50%, etc.). Is it possible to do this? I would also like for each product type to be associated with a specific BOM. I.e., a server module should reference each entity instance to consume material as defined by the BOM’s of the products stated by the entity instance. I have defined each component as material elements and defined a BOM for each finished product that references the materials needed. However, in the server module I am only able to input a specific type of finished product as material requirements... Your help is greatly appreciated!

-

Does someone know how to create a changeover matrix property?

-

Dear Simio employee, I have two questions about 'getting' the average holding time for all the realisations of my subclassed vehicle. I want to know how long an entity is on a vehicle, on average. I tried it with two processes, but both don't work. I don't understand why the following doesn't work (process GemTijdOpAGV): And I also don't understand why the process TijdContainerOpVoertuig doesn't work. I don't understand the error: 'Model Entity does not match the model', or something like that. I created two instances of de model entity, named 'container and pallet', but it seems like I can't use model entity in some processes and in others I can. Why is that and when can you use model entity and when not? (This is also true for instances of a vehicle.) I have attached the model below, but it is still in progress. I hope to hear from you soon! With kind regards, Thomas Haven_v1 project DS model met RS en dus intelligent MTS.spfx

-

Just curious if there's an easier way to go about doing this... Long story short if I am representing multiple physical positions within capacity of a server and I create my own Gantt outside Simio, it's important for me to know WHICH resource (in this case which one of the servers) is utilized by each entity. I was trying to utilize Entity.Location.Parent.Server.Processing.Contents.IndexOfItem( Entity ) and assigning it to a state on the entity and then ultimately writing to an output table. However, this doesn't seem to be working accurately. It may be a timing issue on when this step is called, but is there a default function I'm just not aware of that could be of assistance?

-

Change Server Capacity over time with WorkSchedule

JanainaF posted a topic in SI General Discussions

I have a model where I need to set a server had a maximum of 15 entities from 7 A.M to 10 A.M. I Use the WorkSchedule but I don't know how to limit the number of entities. Can someone help me? *This server it is parallel with other servers. -

I have a question regarding the use of a model state value at a specific timestep. I used a Tallystatistic and processes to calculate the output of a server for a specified interval, based on the Simbit Hourly Statistics. This works, however I dont want the value of the same timestep, but I want to use it two timesteps later. So for example if a server A output variable equals 10 at timestep t=1, I want to save this value as part of the input for server B for timestep t=3. So the value should be 'memorised' for two timesteps. I was wondering whether there are any suggestions on how to model this?

-

Hi!! I want to know in which object (in this case filler) my container entity is when certain event occurs. Is there a way to access this info? Thank you so much! Teresita

-

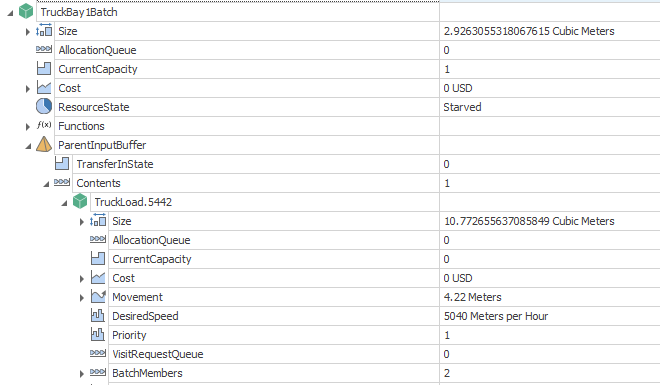

Sorry if this is obvious, but can someone tell me how I can reference the number of batchMembers in the example above without having to reference the specific entity, which in this case is TruckLoad.5442. I need something like "the number of batchMembers in the entity currently in the ParentInputBuffer" please. e.g. TruckBay1Batch.ParentInputBuffer.Content.???.BatchMembersCount? As you'd expect, this number changes constantly during the simulation run. At this moment of simulated time, the answer is 2. Thanks for your help!

-

Hi all, I made a model of a production line (starting with 2 servers) and I am wondering whether it is possible to change the processing time of the second server based on the actual output of the first server. Theoretically seen the processing time of the server 2 = Speed of server 1 * E , in which E is a fixed formula (connected to server 2) to correct the speed. So if the first server performs according to expectation (without failures) for example 40 the processing speed of the second server is equal to 40*E with a delay of the conveyor time between server 1 and server 2. If the server has failure and thus have a lower output (for example, 30), I want to change the processing time of the second server accordingly to 30*E with a delay of the conveyor time between server 1 and server 2. Does anybody have an idea of how to do the following: How can you monitor the actual output of the first server at each timestep? Is it possible to fix the proposed formula and use it in an add-on process? How can you take the conveyor time delay into account (using a delay step in the add-on process?)? I am quite new to the software so I am not sure whether it is possible to model this in Simio. Thank you in advance!

-

Hi, In my project, I have the (main) model of object type 'fixed' and a model of object type 'server'. In one of the processes executed by the model 'server', I want to add a search step that searches a specific entity in the entity population of the main model. How can I do this? Thanks in advance! Kind regards, Christa

-

I have a project where I would like to see snapshots of the output state of the system at specific time points. For example I would like to see output reports at 12, 24, 36, 48 hours and so on. Ideally I would like to set up experiments where I can observe, say 100 runs at each run length and saving capacity on my PC might be nice. I was thinking I could set up a reference property for Run Length; however, it does not seem to have that option. Is there a way to do something like this? Thoughts would be appreciated! Thanks, Jim

-

I am working on a simulation of a number of firms processing raw products. If I represent the firms as resources in a server -so that the server capacity represents the number of firms, how could I identify which resource/firm processed a certain batch of products? Can this be done with a server having a capacity of its own, or should I use a pool of (secondary) resources with id labels so I can use that id to label the product batch?

-

Hi, Is it possible to set the state variable of the parent entity in a batch equal to the sum of state variables of all member entities in the batch? Context of the case; a truck (parent) is loaded with x number of orders (members). These orders have a specific value for the state variable 'NumberOfRollContainers'. The truck has the state variable 'TotalRollContainers', which should equal the sum of the 'NumberOfRollContainers' in that batch. Kind regards, Christa

-

Hi all, I was wondering, is it possible to record the time in system of entity instances and subsequently plot the values in a histogram? Of course, I can see the average, min and max values in the results tab, but I am interested in knowing what the distribution is like for model validation purposes. If it is not possible to plot the values in Simio, is it perhaps still possible to access and export the values, i.e. to a .csv document? Hopefully my question is clear. Best regards, Michkel Mariegaard

-

Let's say I want exactly 100 entities arrive where the arrival of each one follows a normal distribution with mean 1 hour and standard deviation of 5 minutes from the start of the simulation. How can I model that within SIMIO? The interarrival time doesn't make sense because I don't know / care what the interrarrival time between each entity is. I realize that I could randomly generate 100 normal random variables outside of SIMIO and input them all as an appointment, but I am wondering if there is a better way especially if I want to do many replications with a different set of 100 random variables each time.

-

Hi I have draw a Conveyor and conntected it to a InputNode of Server. Now I have to change the model and connect the Conveyor to another BasicNode. How can I do this without removing and redrawing the conveyor?