Search the Community

Showing results for 'create entities on event'.

-

Well, first thing, you don't need your entities to be bouncing between the output and the input of your server like that. If you want to use it as sort of storage, set both the processing time and the capacity to infinity. After that, at the moment that the parent entity enters the combiner "Parent Entered" you could search the queue of your storage using a search step with something like "Server1.Processing.Contents", with the condition of "Candidate.ModelEntity.State == ModelEntity.State", release the server and transfer what have been found to the output. You need to take some care on some situations, like what if the parent entity arrives first at the combiner then the member at the storage? And some care with batching quantities aswell. But I think you can handle it.

-

Hi! In my model I have entities called "Pedido" which have a state called "id_del_pedido" which is equal to the ID of the entity. These entities will enter a Separator that will create copies of the entity according to a probability distribution. Since the new entities are copies of the parent entity, they will have the same "id_del_pedido" status as the parent entity. Subsequently, the entities created will enter a Server that acts as a warehouse. This Server is linked to a Combiner, when the parent entity reaches the Combiner's parentinput I want only entities whose "id_del_pedido" is equal to the ID of the entity that reached the Combiner's parentinput to leave the server. This works perfectly in the first Server-Combiner set of my model, but, the Combiner's outputnode is attached to another Combiner and I want to repeat the same activity as in the first Combiner but I get an error that I don't know how to solve. I attach my model so that my problem is better understood. Thank you very much in advance! 18.10.spfx

-

Hi! can you help me please? In my model I have a server that I want to function as storage, this server is linked to a combiner which will combine the member entities that leave the server with a parent entity that will arrive at it from another node. Each member entity has a state with a unique number linking it to a parent entity (there may be more than one member entity with the same state number). How can I extract from the server only the member entities whose state is equal to the state of the parent entity that arrives at the parentinput of the combiner? Thank you so much! 18.10.spfx

-

I want to create a list of materials from data table. I can refer to inventory replenishment policy from table by adding by adding "replenishment policy" property from data tables. But how do I define the default values of Re order point and Up to Level parameters for these auto-created materials? I cannot see such option even in the built in Material Table Scheme. Any help is really appreciated. Kind regards

- 1 reply

-

- materials

- data tables

- (and 6 more)

-

Hello Everyone, please can someone help me with this situation? I want to use a Server as a storage place, entities coming out of it go into the MemberInput of a Combiner. I want the number of entities that leave the Server to depend on the state of the entity that will enter the ParentInput of the Combiner. How can I access the state of the parent entity that will enter the combiner from the Output Node of the Server? Thank you very much, Greetings! 14.10.spfx

-

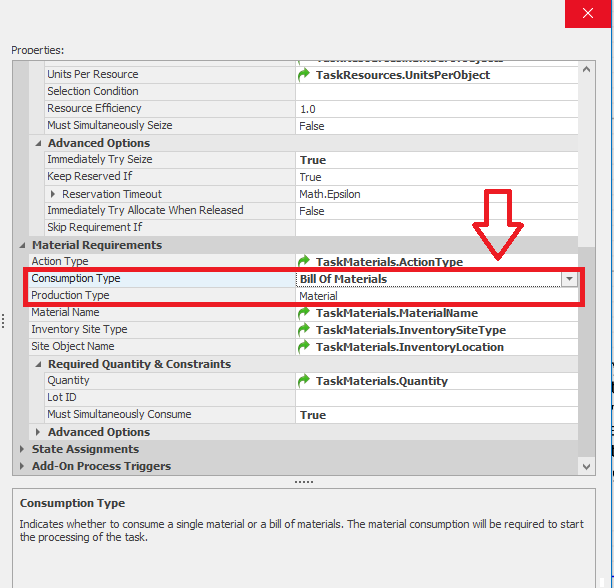

Hi all, I want to create a list of tasks from data table which I will use in the server objects tasks sequence. When I want to refer to all of the properties of material requirements to data tables, I am facing a restriction as follows: a) I can refer the material "Action Type" (Consume\Produce) property from server object to data table by adding an "MaterialActionType" enumeration property to data table. b) If referencing in a) was NOT done, for the selected action type (lets say produce was selected), I can refer the "production type" (Material/Bill of Materials) property by adding a "MaterialOptions" enumeration property to data table. However, when I do the task in a) an additional row appears in server object, now showing both consumption type and production type in properties. Then I am unable to set reference to data table as in b) any more. Is it possible to refer BOTH "Action Type" (Consume/Produce) and "Material Options" (Material/BOM) simulatenously? If yes how? Could you please guide? Kind regards, Tolgahan

-

Hello, I'm working on a problem where at some point a worker will transport a specific amount of pallets. Whereafter these pallets are processed by a server and a server wil process them. Once processed, a different worker (or the same worker) will move the pallets to the next server. How do I save these entities as a batch and let workers know how much pallets they can process? At the moment I have two approaches. One where I create a 'batch' as an entity and assign to it the amount of pallets. The 'problem' in that case is that I do need to count the amount of pallets at a server, since it has a certain capacity. And sometimes an initial batch whitch comes from a truck needs to be split to fit the capacity of workers. But once this would be fixed, the worker will always transport the right amount of pallets. A second approach that I have tried is to create the pallet entities normally, and assign a 'PalletHistory' in the modelEntity properties, but I find that after processing I can't find this palletHistory for the workers to get a sign of how many pallets to transport. Do any of you guys have an idea how I can approach this? Greetings

-

Thank you, Glen! That worked. Also, a while back ago I did create my own VS project and compiled - I don't recall setting Copy Local to false, so wouldn't surprise me if that's how my environment got in this state. Thanks again!

-

Make sure SimioAPI.dll, SimioAPI.Extensions.dll and SimioAPI.Graphics.dll are not in the ...\Documents\SimioUserExtensions folder. If there are older version of these DLL in this folder, you will get this error message. It is best practice to not have these DLL in this folder. If there are not in this folder, Simio will find them in its executable folder. If you create your own Visual Studio project and compile into this folder, make sure you set the "Copy Local" == False.

-

I think if you set the max to 30, if 14 are generated all 14 (or other <30 number) will enter the workers ride queue and will be transported. You could also keep the ride capacity at 1, model the 14 pallets as 1 entity (lets call this a shipment entity), have the worker move that 1 entity to the next location, and then use a separator to turn the shipment entity into some number of pallet entities. Attached is an example. example 9.23.22.spfx

-

I wonder if it is possible to pick one particular entity from the BatchMembersQeue and unbatch it. For example I have a pallet with 10 entities batched (9 red and 1 blue) and I want to remove only the blue one. I was able to find the entity with a search step, but I cannot transfer it or unbach it. Any ideas? TnksUnbatch one entity.spfx

-

Job Description Energetic and personable professional who applies operational research to best utilize workforce, data, technology, and other resources to achieve maximum productivity within budgetary constraints. Guides current practices and facilitates through more efficient and effective ways to achieve operational excellence. Experience in discrete event simulation, agent-based modeling, and predictive analytics is a plus Job Responsibility Develops metrics, creates dashboards, reports, and identifies areas of improvement across the organization using various analytical tools and techniques. Identifies current process gaps through the use of observations, data collection, data analysis, process ideologies and communication with management and frontline staff. Identifies issues, root causes, strategies for improvement, and development of implementation and sustainment plans. Supports project management, development of project timelines, and follow-up action items for process improvement initiatives. Develops the summary of findings, recommendations, and action plans to management. Applies principles, techniques and procedures to the design and implementation of technology and process solutions (i.e. Lean, Six Sigma, Kaizen). Supports development of principles and methods for curriculum and training design, teaching and instruction for individuals and groups, and the measurement of training effects. Work assignments are varied and require interpretation and independent decisions on the course of action. Decisions may be guided by precedent, previous experience, and known professional guidelines and compliance requirements. Often required to interpret policies, standards, requirements, and approaches to meet work objectives. Regularly exercises independent judgment on matters of significance within defined procedures to determine appropriate actions/approaches. Normally receives general instructions on routine work, and detailed instructions on new projects or assignments. Performs related duties as required. All responsibilities noted here are considered essential functions of the job under the Americans with Disabilities Act. Duties not mentioned here, but considered related are not essential functions. Job Qualification Bachelor’s Degree or equivalent combination of education and related experience as Continuous Improvement Engineer, Industrial Engineer, Operations Process improvement Engineer, Process Engineer, or Lean Six Sigma Black Belt. 1-3 years of technical experience, required. Technical Skill preferred: Experience in discrete event simulation (preferably Simio), Lean, Black Belt Six Sigma Certificate, Statistical Analysis, Graphical Analysis, Facilitation, and Presentation Skills, Operational Research, Programing (i.e., R or Python), Predictive Modeling, Agile Project Management. Here is the link to apply: https://jobs.northwell.edu/job-3/16580688/process-improvement-engineer-lake-success-ny/

-

I was inspired by the VehicleX3 (vehicle with operator) that was shared on this forum. I would like to use this type of VehicleX3 with an operator who is a worker to simulate a process where the operator is required to take breaks after certain periods of activity. To implement this logic, I think it would be helpful to have Reliability Logic for the worker object in Simio. This doesn't seem to be part of the standard library so I tried to create my own subclass version of Worker with the Reliability Logic "copied" from the Resource object. My attempt to implement this custom object seems to work as long as the custom worker object doesn't "move". If the custom worker object moves, I get the Runtime error "Possible infinite loop detected in process logic". Any assistance in getting the logic working properly, or pointing me to an existing custom worker object that has Reliability Logic incorporated would be greatly appreciated. I'm attaching my small example model to illustrate the error when the worker (P1) is required to move to the Dest1 server as a required secondary resource for processing. WorkerWithFailuresExample.spfx

-

The below postings are for site based positions (Bothell, WA and Summit, NJ) within BMS BIA (Business Insights and Analytics), which is a corporate function with the mission to create objective analytics and insights for business units to drive competitive advantage and accelerate growth. The Global Product Development and Supply (GPS) business unit is responsible for the development, manufacturing and supply of quality clinical and commercial drugs to the right patients at the right time. BIA GPS teams partner with GPS stakeholders to develop advanced analytics capabilities and drive fact-based decision-making. This role will build analytics capabilities for GPS Cell Therapy Operations (CTO) manufacturing sites. You will serve as an active partner with a range of site teams, including manufacturing operations, supply chain, quality, and operational excellence to develop data driven insights and reporting, and improve manufacturing site performance through automation, simulation and predictive modeling. Within BMS GPS CTO, Simio has served as an invaluable tool for supporting our sites and network with operational readiness efforts, capacity analysis and optimization, and project impact evaluation. As we mature these capabilities, we are increasing our focus on intelligent object design as well as data engineering to support data driven and data generated model architecture. If you are passionate about the interface of data engineering, simulation, and object design and have relevant experience, we would strongly encourage you to apply. BOTHELL WA - BMS BIA GPS CT SUMMIT NJ - BMS BIA GPS CT

-

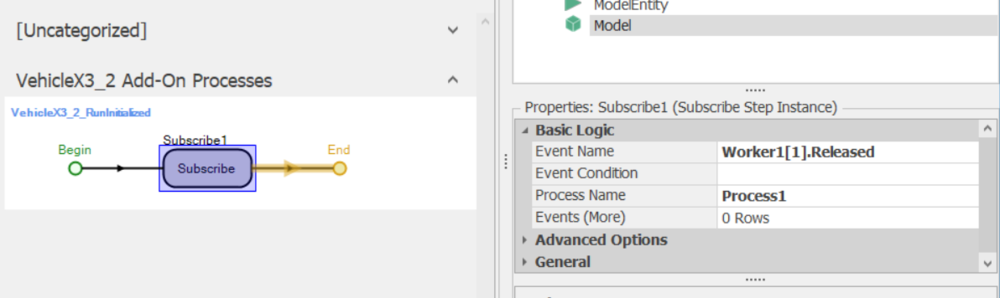

Hi John, The entity is requesting a ride from the vehicle and the vehicle will seize the driver if available. However, if the vehicle is unable to seize the driver, it will reject the ride request and the entity will move to the Global Visit Request Queue, as you are seeing. You can attempt to have the Vehicle check again if it can now pick up the entity, and it will run the process to check if a driver is available. To have the Vehicle check the Global Request Queue to see if it can give a ride, use a PlanVisit step. Ensure that the Vehicle, in this case Vehicle_A, is the object executing this step. By default, the Vehicles are not aware if the Driver they need becomes available. You might consider using a Subscribe step on the Vehicle's OnInitialized process. This Subscribe step can watch for an Event and if that Event occurs, can trigger a related process. For example, the Vehicle might wait for the Driver.Released Event. When this Event occurs Process1 could run. In Process1, the Vehicle could execute the PlanVisit step. For more information, I recommend the Help pages in the Simio Reference Guide titled "PlanVisit" and "Subscribe". Happy Modeling!

-

Hi, I have an issue related to workers going off-shift and abandoning the reserved entities in different servers, depending on when the shift change happens (picture attached is an example). The shift change is based on switching from Worker of x number of population to y number of population to meet my WorkSchedule. The Worker should always carry different entities throughout, entities cannot travel alone. The logic issue happens as a result of entities left in servers or buffers that were not picked up by workers due to the end of shifts, causing too many objects/entities in the system not destroyed. An expert suggested to build process that checks the Worker's Allocation Queue when it goes off shift to see if there are any entities in it, and if there are, turn the Worker back on shift. I tried to build that process, but I could find the right steps. Any help on identifying the right steps or a different way to model workers shifts is appreciated.

-

Entities in a buffer at the start of the simulation

gocken replied to Ondrej's topic in SI General Discussions

Try the logic included in this model. Note that you can use the same logic at any time over the simulation run. In this specific example the entities are created at the begining of the simulation run. If you need to create them at any time over the simulation run then you should define a seperate process then embed the same logic into that process. Then, all you need is to trigger that seperate process. For example, you can trigger by using timer element. Hope it helps?. CreateEntities.spfx -

Greetings, I would like to know if there is a way to include the volume of the entities into the vehicles capacities ? E.g. let's say that i have 5 entities with different volumes, and the vehicle has the capacity to transport X m^3, how can i include this in simio ? Best regards,

-

Hello everyone, I have a simple production line of 15 servers, some combiners, nothing too complicated. I need to somehow setup the input buffer at each server to have 1 entity at the start of the simulation and then run it. Or having filled servers with 1 entity at each server. Could anyone please help me and show me how to set it up? I need to start counting the stats once all the workstations are filled, but warmup period does not seem to work for that case, because it destroys the enitities at the servers and starts over. The filled-input-buffer-way looked to me like the easiest solution. But if there is another way, please let me know. Thank you!

-

I'm interested in calculating a yearly production rate. Essentially I could do this if I ran my simulation for 1 year and looked at the output. The number of entities destroyed by my "completed" sink will be what I'm looking for. How do I determine this value if I'm running for longer than 1 year? For example; If I run for 5 years, and I'm watching my model run, at week 186 I'd like to know how many entities had been destroyed by my "completed" sink between weeks 134 and 186 to determine my yearly production rate.

-

Hi, I have a bottleneck at the end of my assembly line. I cannot dupplicate that station as my total number of workers is already high. Before hiring, I would like to try and reallocate and have satellite employees. I want to allocate my workers to that station when the input buffer has exceeded one entity. Every worker has to finish the entity they are presently working on at the other stations and the first workers that are done need to go the bottleneck station. The rest of the time, the workers can be allocated based on the smallest distance to the work stations. The bottleneck station usually requests 4 workers. That information is already set up in a table. When there is two entities in queue in that buffer, I want workers to be able to go finish the work and hence increase the processing time by X. I have tried a lot of different things, and all my data is stored in relational tables. Thanks!

-

Conditional entity release one at a time

gocken replied to Amine3225's topic in SI General Discussions

Hi Amine, I have defined a new process named process1 which is triggered by Input@BUFFER_ST_1.Entered event. Then, I used interrupt step (in process 1) to get one entity from processing station whenever process 1 is triggered. Note that I set the processing time of BUFFER_ST_2 server to infinity to hold entitys until Input@BUFFER_ST_1.Entered event is occured. I am not sure if setting this to infinity is a problem?. Other than this everything is ok and it seems it works. Buffer varianti trazioni V2.spfx -

https://jobs.arup.com/jobs/aviation-analyst-9522 Arup is proud to be recognized by Fast Company in their third annual Best Workplaces for Innovators list, which honors businesses and organizations that demonstrate a deep commitment to encouraging innovation at all levels. We find solutions for some of the world’s most complex problems. From climate action to social value, we consider the broadest impacts of our work. We strive to build a more sustainable, resilient, and equitable future. This purpose shapes our culture and has made us leaders in sustainable development. You’d be joining our multi-disciplinary design teams focusing on technical excellence and innovative solutions that create a better future for people, places, and the planet. Start Here, Go Anywhere! Want to work for a company that invests in innovation and people who catalyze impact in the built environment? Arup is proud to be recognized by Fast Company in their third annual Best Workplaces for Innovators list, which honors businesses and organizations that demonstrate a deep commitment to encouraging innovation at all levels. We find solutions for some of the world’s most complex problems. From climate action to social value, we consider the broadest impacts of our work. We strive to build a more sustainable, resilient, and equitable future. This purpose shapes our culture and has made us leaders in sustainable development. You’d be joining our multi-disciplinary design teams focusing on technical excellence and innovative solutions that create a better future for people, places, and the planet. During your career at Arup, you’ll have the chance to engage in a fulfilling career and work with some of the most highly respected engineers and specialists in the world. You’ll also get the opportunity to work on exciting and significant projects, delivering quality work that has a positive and lasting influence on the community and the environment. Responsibilities of this specific role will include, but not be limited to the following: • Perform capacity/demand assessment for planning studies using various tools, methods and techniques • Conduct passenger and baggage flow simulation modelling, interpret results and identify solutions • Develop spatial requirements and program development for infrastructure and facilities planning • Undertake data driven analysis to gather insights including research-based projects • Assist with development of automation tools using programming languages • Assist with development and review of forecast demand • Collect and collate data from surveys, benchmark studies and other sources as needed in support of planning studies • Assist in preparation of reports, presentations and deliverables including illustrations, tables and drawings to communicate complex technical ideas through a graphical and visual approach for a wide range of clients • Generate and contribute to planning and operational reports and provide advice to planning and design teams, airports and airline clients • Project work includes many of the most significant complex airport developments globally • Some travel may be required in the longer term Qualifications Required: • Bachelor’s degree (Master’s degree preferred) in Civil/Industrial/Operations Research/Transport engineering or other relevant disciplines • 2-5 years of increasingly responsible experience in airport planning and analysis • Knowledge/experience of analytical techniques and tools applied in airport planning including spreadsheet, database and simulation software such as Simio, CAST or others • Python or R or similar programming skills preferred • Proficiency in Microsoft Office applications (Word and PowerPoint); advanced Excel user • Demonstrated strong numeric analytical competence and strategic thinking capability • Good written and verbal communication skills essential for team-based working • Excellent planning and organization skills and attention to detail for our fast-paced environment • Must be highly motivated, proactive and willing to take on new challenges Arup is the creative force at the heart of many of the world's most prominent projects across our industry. We offer a broad range of professional services to clients around the world that combine to make a real difference to our clients and the communities in which we work. Notable Projects: • Toronto Pearson International Airport • Montreal Trudeau International Airport • New York John F. Kennedy International Airport • Chicago O’Hare International Airport • Los Angeles International Airport • Istanbul International Airport • London Heathrow International Airport • Singapore Changi International Airport Benefits that Work - At Arup, we have a comprehensive and valuable benefits program that works for our employees and their families. These are 100% paid for by Arup expect for optional life insurance. These benefits provide health and welfare security for you as well as paid time off for rest and renewal. Our Global Profit Share Plan (paid bi-annually) provides an opportunity for you to share in the success of the Firm. As a valued employee of Arup, you can also choose to participate in our GRRSP 5% company match to help you save for your future. COVID-19 Vaccination Requirement - Arup requires all new employees to be vaccinated for COVID-19. Arup is an equal opportunity employer and consistent with federal, state, and local requirements, will consider requests for reasonable accommodation based on disability or sincerely held religious beliefs where it is able to do so without undue hardship to Arup. Flexible Working - We believe that flexible arrangements create a more inclusive way of working that supports our diversity and the wellbeing of our people. Options for alternative schedules and the ability to work outside of the office for a portion of your workweek are available. Arup is an Equal Opportunity Employer. We consider all qualified candidates regardless of national origin, veteran, disability, sixual orientation, gender, gender identity or other status protected by law. If you need any assistance or accommodations due to a disability, please contact us at americasbenefits@arup.com. For the fourth consecutive year, Arup has been named one of Greater Toronto’s top employers! Greater Toronto’s Top Employers for 2021 are recognized for exceptional human resources programs and forward-thinking workplace policies. Find out more about what makes our Toronto office an outstanding place to work here: https://bit.ly/2B3QYL8

-

Hello, We are evaluating Simio and really like what we see from exploring the Simio Personal Edition. Custom Dashboards are a high priority for us and we appreciate the fact that Simio seems to allow creation of custom dashboards from within a model; however, we would like to know if Simio allows the creation of custom dashboards that are portable from model to model. For example, we would like to: Create a dashboard that displays a chart depicting activity cost per entity (for a selectable set of entities) over the simulation period. Reuse/import this dashboard into any model to display the activity cost per entity over the simulation period (for a selectable set of entities). Two questions: Is this possible with Simio? If yes, which edition(s) of Simio support this capability? Thanks in advance! Donovan