The Solution: Simio Discrete Event Simulation

In 2024, Seegrid began searching for a simulation partner to enhance their autonomous solution design capabilities. After evaluating various options, they selected Simio for its powerful discrete event simulation capabilities and collaborative approach.

“We went with Simio because we saw that there was going to be a great partnership there,” Schooley explains. “We can’t give enough praise to our developer, Adam [Sneath] from Simio. He created a positive collaborative environment, was always interested in our product, and made sure to understand our concerns. We were confident that this Simio model represented how Seegrid would do automation in the real world.”

Key Simulation Capabilities

The Simio simulation model provided Seegrid with several critical added capabilities:

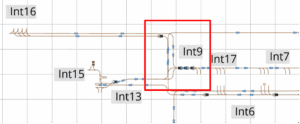

- Visualization of AMR Interactions: The simulation allowed the team to see how Seegrid AMRs would interact at key junctions, identifying potential congestion points before implementation.

Figure 2: Congestion at intersection 9 seen in the simulation.

- Job Sequencing Modeling: Simio enabled the modeling of complex job dependencies, ensuring that one AMR would complete its task (e.g., removing an empty container) before another AMR would begin its related task (e.g., delivering a full container).

- Traffic Analysis: The simulation provided detailed analytics on intersection wait times, helping to identify bottlenecks and optimize routing.

- Experimentation Framework: Simio’s experiment capabilities allowed the team to test different AMR fleet sizes and configurations to find the optimal solution for each customer’s needs.

- Multiple AMR Type Support: The model could simulate different types of Seegrid AMRs (like the Lift CR1, Lift RS1, and Tow Tractor) operating simultaneously within the same facility.

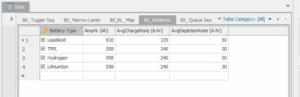

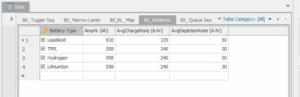

- Power Management: The model has the ability to account for the charging of AMRs during production. This logic is similar to Seegrid’s Fleet Central software, where once an AMR reaches a minimum battery level, it will go to the charger and be unavailable to receive new jobs until a minimum charge time has been met.

Figure 3: Battery Data Chart with charge and depletion rates per battery type.

Implementation Process

The implementation of Simio simulation at Seegrid followed a structured approach:

- Model Development: Seegrid formed a “Tiger team” consisting of Sydney Schooley, Application Systems Engineer Sofia Panagopoulou , and Application Engineer Abby Perlee, to collaborate with Sneath from Simio on developing the initial model.

- CAD Integration: One of the early challenges was integrating CAD drawings of facility layouts into the simulation model. The team developed a Python script that extracted route networks from CAD files and converted them into a format that could be imported into Simio.

- Fleet Management Logic Implementation: Seegrid’s enterprise fleet management software logic, Fleet Central, was translated into the Simio model to enable the simulation to accurately represent how the AMRs would behave in complex, real-world environments.

- Template Creation: The team created a template model that could be easily adapted for different customer scenarios, streamlining the simulation process for future projects.

- Team Training: Once the initial model was developed, the entire Application Engineering team was trained on using the Simio simulation tool, with a focus on practical application to real customer scenarios.

Schooley explains. “Our Tiger team was responsible for collaborating with Simio to help develop the model. Throughout the process—once we felt the model was in a good spot—our expanded team of 9 became more involved.”

Results and Benefits

The implementation of Simio simulation has delivered significant benefits to Seegrid’s Application Engineering team and their customers:

Enhanced Solution Design

The simulation model has allowed Seegrid to design more efficient and effective AMR solutions for their customers. By visualizing complex interactions and identifying potential bottlenecks before implementation, the team can optimize routes, fleet sizes, and job sequencing to maximize efficiency.

“Does this solution over time see major traffic jams at intersection 10? Does this add significant time to our cycle time? How can I reduce this traffic jam?” Schooley asks. “This is more problem solving on the [Seegrid] Application Engineers to better understand the customer situation.” It is on the skilled team of Application Engineers to determine how the model can optimize the final automated solution presented to the customer.

Improved Customer Communication

The visual nature of the simulation has elevated Seegrid’s ability to communicate complex solutions to customers. Being able to show a 3D visualization of how the AMRs will operate within the customer’s facility helps build confidence, internally and externally, for the proposed solution.

“And that visual is very impactful for my team,” Schooley notes.

Optimized Fleet Sizing

The ability to experiment with different fleet sizes has helped Seegrid optimize the number of AMRs required for each customer application. This promotes customers to invest in the right number of vehicles to meet their unique needs without over-purchasing.

“We’ll compare how changing volumes affect AMR fleet count,” Schooley explains. “For instance, if the customer has an average volume throughout most of the year, but then they peak during holidays, can we still use the same number of vehicles to help them at peak time as well?”

Efficient Job Sequencing

The simulation model has been particularly valuable for optimizing job sequencing in modern industrial manufacturing environments. By confirming that empty containers are removed before full containers are delivered, Seegrid can minimize the time that operators are without parts, boosting production efficiency.

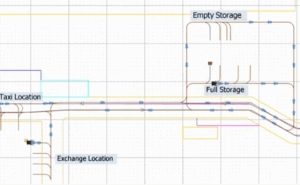

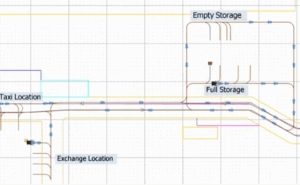

“A process flow of job sequencing in manufacturing might look similar to this: An operator calls a container [Exchange Location] to be replaced through an integrated button press,” Schooley describes. “That signal starts a job. We’ll call it ‘Empty-for-Full Container- Parts 1, 2, 3, 4’. Then the Seegrid Lift AMR #1 will pick up the empty container from the assembly line and take it to a location designated for empty containers [Empty Storage]. Then AMR #2 would pick up a full container from a staging area [Full Storage] and place it in that same position at the line [Exchange Area]. AMR #2 will not start its job until AMR #1 has fully completed its job.”

Figure 4: Job Sequencing simulation of “SimGrid” Assembly plant.

Bottleneck Identification and Resolution

The simulation’s ability to track wait times at intersections has helped identify and resolve potential bottlenecks in AMR routing. This has led to more efficient material flow and reduced congestion in customer facilities.

“Bottlenecks can be created in the application, however they cannot be easily identified without specific data,” explains Panagopoulou. “Traffic management is configured based on our Fleet Central fleet management software. By using the Simio dashboards that show the wait times per intersection, we can accurately identify the bottlenecks.”

Implementation Challenges and Solutions

While the implementation of Simio simulation has been highly successful, the team did face several challenges along the way:

Team Education and Training

One of the primary challenges was educating the entire Seegrid Application Engineering team on the new simulation tool and process. To address this, the team developed comprehensive documentation, including an initial release training program, troubleshooting guides, and feature-specific tutorials.

“As always, it takes time to get used to a new process and work with a new tool,” Panagopoulou notes. “Initially, we asked the team for feedback during the development, including an initial release training that the whole team completed and provided feedback on to make sure that the simulation was beneficial for everyone.”

Translating Fleet Management Logic

Another significant challenge was translating Seegrid’s sophisticated fleet management software logic into the Simio model. This required careful balancing between model accuracy and development time.

“Seegrid’s fleet management software is based on years of development and vehicle capabilities which all had to be considered for the simulation template,” Panagopoulou explains. “The key to overcoming this hurdle is to identify the capabilities that are really needed. You need to find a balance between model accuracy and development time because you never want to spend a lot of time making the simulation identical to the product when not using all of its capabilities.”

Keeping the Model Updated

Keeping the simulation model updated can also be challenging. The team developed processes so that changes made in CAD drawings are then reflected in the simulation model. This was needed, as the CAD may change from the original scope to what is installed.