Aegis FactoryLogix MES: Manufacturing Execution System Digital Twin Integration

Transform manufacturing operations through intelligent digital twin technology that connects real-time production data with advanced simulation capabilities.

What is MES Software and Why It Matters

Manufacturing Execution Systems (MES) serve as the critical bridge between enterprise planning systems and shop floor operations. Modern MES software solutions provide real-time visibility into production operations, enabling manufacturers to track work orders, monitor quality metrics, and manage resources effectively across the entire production lifecycle.

Traditional manufacturing environments often rely on paper-based work instructions and manual data collection processes. This approach creates information silos, delays decision-making, and increases the likelihood of errors throughout production operations. The manufacturing execution system digital twin approach fundamentally changes this paradigm by creating intelligent virtual replicas of production processes.

Key MES capabilities include:

- Real-time production tracking and monitoring

- Digital work instruction delivery and execution

- Quality management and compliance documentation

- Resource allocation and scheduling optimization

- Traceability throughout the manufacturing process

- Integration with enterprise resource planning systems

The evolution toward digital twin technology represents a significant advancement in MES functionality. Rather than simply collecting and displaying production data, intelligent systems now enable predictive analytics, what-if scenario testing, and proactive decision-making that drives operational excellence.

What is Aegis FactoryLogix: Advanced MES Platform

Aegis FactoryLogix represents a comprehensive MES software platform designed to accelerate digital manufacturing transformation across diverse production environments. The system provides digital manufacturing engineering capabilities, manufacturing process execution, materials management, and quality management systems that integrate seamlessly with existing production infrastructure.

The platform addresses a fundamental challenge in modern manufacturing: resistance to change within organizations. Testimonials from Aegis’s customers demonstrates that “human beings don’t like change, but with Aegis’ MES solution, operators readily accepted the change because they experienced the benefits themselves immediately.” This acceptance stems from the system’s intuitive design and immediate operational improvements.

Core FactoryLogix capabilities:

- Digital Work Instructions: Video-enhanced guidance replacing paper-based processes

- Real-time Production Visibility: Live dashboards showing production status and performance metrics

- Quality Management Automation: Integrated inspection workflows and compliance tracking

- Equipment Integration: Direct connectivity with manufacturing equipment and IoT devices

- Mobile Accessibility: Tablet and smartphone interfaces for shop floor flexibility

- Cloud Deployment Options: Scalable infrastructure supporting distributed operations

The platform’s strength lies in its ability to transform traditional manufacturing workflows without disrupting existing operations. Operators can easily access detailed specific instructions and information on screens, including videos and references, making their jobs easier while improving overall production efficiency.

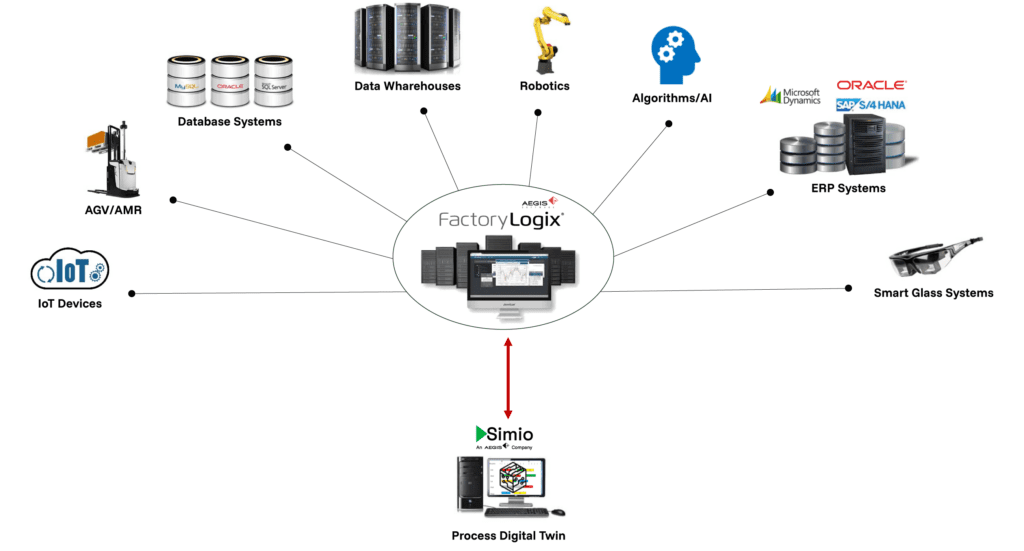

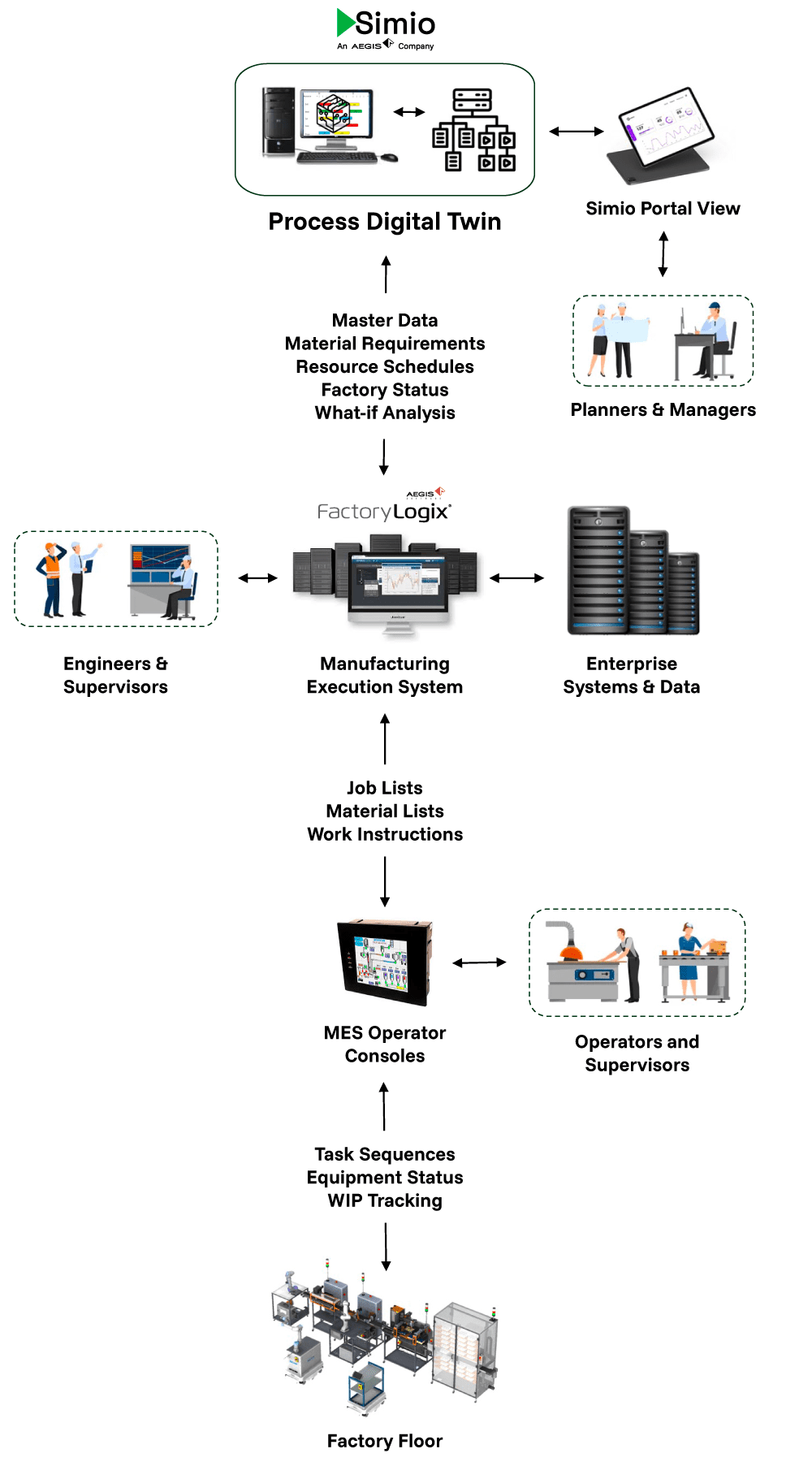

When integrated with Simio’s advanced analysis, planning, and scheduling capabilities, FactoryLogix and Simio create dynamic virtual replicas of manufacturing processes that enable unprecedented operational insight, optimization, and control—where FactoryLogix provides the critical execution and control capabilities that complement Simio’s analytical strengths.

The Power of What-If Simulation in MES

Manufacturing execution system digital twin technology transforms production operations by creating intelligent virtual replicas of your entire manufacturing environment—from equipment and processes to workforce and materials. This revolutionary approach enables true what-if scenario testing within MES operations before implementation. By leveraging an intelligent digital twin integrated with your MES software, organizations can:

Generate, test and optimize production schedules

Simulate the impact and optimize different production schedules and sequencing strategies before committing resources to implementation on the shop floor.

Evaluate equipment configuration changes

Test the effects of adding, relocating, or reconfiguring manufacturing equipment in a risk-free virtual environment without disrupting actual operations.

Optimize workforce allocation strategies

Predict how changes in staffing levels, shift patterns, or skill distributions will affect throughput and overall production efficiency.

Plan for operational disruptions

Analyze the ripple effects of unexpected equipment failures, supply delays, or quality issues and develop robust contingency plans before problems occur.

Refine quality management processes

Optimize inspection workflows, quality control checkpoints, and corrective action procedures to minimize delays and maximize first-pass yield.

Balance resource utilization priorities

Balance competing priorities between production targets, material availability, and resource constraints to achieve optimal business outcomes aligned with operational objectives.

The digital twin addition to MES systems represents a paradigm shift from traditional reactive manufacturing execution. Instead of relying on work instructions or simplified scheduling models, intelligent digital twin technology captures the complex, dynamic nature of real-world production environments. This advanced simulation capability ensures that manufacturing execution plans are not only feasible but optimal across all relevant dimensions of your operation.

How Digital Twin Technology Enhances MES Operations

Traditional manufacturing execution systems provide visibility into current production status but offer limited predictive capabilities. Digital twin technology transforms MES functionality by creating intelligent, dynamic models that continuously learn from operational data and provide forward-looking insights that drive operational excellence.

Traditional MES

- Reactive monitoring

- Static work instructions

- Historical reporting

- Static factory models

- Fixed scheduling

Digital Twin-Enhanced MES

- Predictive analytics

- Dynamic, context-aware guidance

- Real-time forward-looking optimization

- Dynamic auto-created factory models

- Adaptive, simulation-based planning and scheduling

The benefits of digital twins in manufacturing become evident through enhanced monitoring and diagnostic capabilities as well as dynamic planning and scheduling. Digital twins process diverse streams of data captured from sensors, IoT devices, MES and enterprise systems, creating continuously updated virtual representations of physical assets and processes within the production environment.

Core Digital Twin MES Capabilities

The integration of digital twin technology with manufacturing execution systems creates intelligent operational environments that transform traditional production management. These advanced capabilities enable manufacturers to achieve unprecedented visibility, control, and optimization across their entire production ecosystem.

Intelligent Operations

- Context-aware work instructions: Dynamic guidance systems adapt based on current production conditions, operator experience levels, and real-time quality requirements, improving operator efficiency by 15% while reducing training time for new personnel.

- Continuous process optimization: Analysis and simulation of current production data enable continuous adjustment of specific process parameters to maintain optimal performance, reducing variability, and improving consistency across manufacturing operations.

- Smart resource allocation: Continuous analysis of workforce availability, equipment status, and production priorities refines resource assignments to maximize operational efficiency and minimize resource constraints.

Visualization & Interface

- Immersive production environment visualizations: Dynamic visual representations of manufacturing operations, enhanced with real-time performance data, provide intuitive interfaces that enable rapid response to changing conditions and immediate access to critical operational information.

- Interactive dashboards: Customizable displays that present key performance indicators, production status, and predictive insights in formats tailored to different roles and responsibilities across the manufacturing organization.

- Mobile accessibility: Tablet and smartphone interfaces that provide shop floor personnel with immediate access to work instructions, quality data, production schedules and production status, enabling flexible and responsive operations.

Integration Capabilities

- Enterprise system connectivity: Seamless data exchange with ERP, PLM, and supply chain management systems ensure consistent information flow across the entire manufacturing ecosystem, eliminating data silos and facilitating improved coordination.

- IoT device integration: Direct connectivity with manufacturing equipment, sensors, and monitoring devices creates comprehensive data collection networks that support real-time decision-making and predictive analytics.

- Cloud deployment options: Scalable infrastructure that supports distributed manufacturing operations while maintaining real-time data synchronization and stakeholder access across multiple locations.

Security & Compliance

- Cybersecurity protection: Advanced threat detection and prevention systems that safeguard manufacturing data, intellectual property, and operational technology against increasingly sophisticated cyber threats while maintaining production continuity.

- Regulatory compliance monitoring: Automated tracking of changing regulations across global markets with real-time alerts for potential compliance issues, reducing risk exposure and simplifying audit processes.

- Access control and authentication: Role-based security frameworks that ensure appropriate data access throughout the manufacturing ecosystem while maintaining detailed audit trails of system interactions and modifications.

Aegis FactoryLogix and Simio Integration: Unified Manufacturing Intelligence

The strategic integration of Aegis FactoryLogix MES with Simio’s advanced planning and scheduling capabilities creates a unified manufacturing intelligence platform that addresses modern production challenges through intelligent automation and real-time optimization.

This integration enables seamless data flows between enterprise resource planning systems, manufacturing execution platforms, and simulation environments. The result is a manufacturing execution system digital twin that provides unprecedented visibility into production operations while enabling proactive decision-making through advanced analytics.

Key integration benefits:

- Real-time Schedule Generation: Automatic recalculation of production schedules based on current factory conditions and unexpected events

- Enhanced Coordination: Improvement in synchronizing operations between customer service, logistics, and production functions

- Quality Management Automation: Integrated inspection workflows that automatically adjust processes when deviations are detected

- Scalable Cloud Deployment: Centralized schedule generation and analaysis with global stakeholder access across distributed manufacturing operations

- Advanced Analytics: Data-driven insights into production performance, resource utilization, and operational efficiency

The integration supports Industry 4.0 principles by connecting cyber-physical systems, IoT devices, and advanced analytics into everyday production operations. This approach enables manufacturers to achieve operational resilience and continuous improvement while maintaining alignment with evolving industry standards and performance criteria.