Search the Community

Showing results for 'machine specs'.

-

Is it possible to use neural networks with continious flow library? I have a microgrid simulation model with solar panels which charges a battery and grid are energy sources for a house. Grid charges at different rates based on time of use (TOU, i.e time of day and winter summer holiday etc) and solar company charges at fixed rate as energy is filled into battery. I would like to optimize the system using machine learning so that the house minimizes their bill by deciding when to chose grid and solar.

-

Simio’s neural network implementation allows the import and export of ONNX files, which ensure that Simio is compatible with many machine learning frameworks. This format is well-documented, and there are many third-party packages and applications that can help you convert machine learning models to/from ONNX, or to open and view ONNX files. The attached document provides a basic summary for several of these packages, including tensorflow-onnx, onnx2pytorch, and Netron. Please note that none of these packages are affiliated with Simio, so any issues or limitations of these packages can be discussed on the package’s GitHub page. ONNX Format Utilities.pdf

- 1 reply

-

- 2

-

-

Please excuse a naive question from a newbie. Building a simulation for material flows in selective mining. Entities, "low_grade" and "high_grade", supplied at different rates by two sources, both go into a server (the mining machine) which passes them to a separator. I want the high_grade entity to go to a processing subsystem, and the low_grade entity to go to backfill (or a waste dump). Do I presume correctly that I should use a Separator for this? If so, how do I set it up to send the two entity types to different destinations ? At present, all seem to be going to the same destination. Instead of having different entities, could I use one entity type and assign grade values according to a probability distribution? If so, how would I then use a separator to send below-cutoff material to backfill?

-

I am trying to make a routing decision based on the Candidate node's routerequestqueue's summation of the entities user-defined property. If there are different types of entities with ex. different priority levels. I would like the routing process to choose the transfernode which has the smallest total sum of it's entities priority level. the transfernode that needs to be chosen also has a routing group attached to its entity destination type rule where its final machine has 0 buffer and due to a blocked destination rule, there will be a queue build up at the transfernode that needs to be chosen. I have thought about using a state variable for each node and using add-on process each time a unit enters and leaves a node but because the main model has many multiple nodes the node's entity priority sum has to be able to be accessed through the candidate.transfernode._________________. For example during the routing step in the process section, I have candidate.transfernode.destinationroutinggroupname.routerequestqueue which gives me the node's number of units waiting, but i need to be able to access the candidate nodes summed queued property. Is there either a way to directly access this information, have looked at the expressions and having a hard time finding something. failed attempt: candidate.transfernode.destinationroutinggroupname.routerequestqueue.population.defaultentity.priority.summation or is there a way to use the add-on process where i am adding/subtracting the priority levels, but somehow attach it to the candidate.transfernode's property Hopefully this makes sense. If you look at the file, please ignore the upper half and focus on the transfer nodes maintransfer, transfernode1 and transfernode1_1. maintransfer has an entered add-onprocess which is the subject of this question. the route process and it's selection expression is what I'm trying to adjust but find a way to express the candidate transfernodes of transfernode1 and transfernode1_1 (which are part of the XferRouting group). I'd like to choose and compare the total summed priority level of each node's queue. Simple_Routing.spfx

- 2 replies

-

- routing

- expressions

-

(and 2 more)

Tagged with:

-

Translators Wanted - Please Help

dsturrock replied to dsturrock's topic in Simio News and Announcements

Llario, Thank you for the offer. You are correct that I don't see many current sales in Bulgaria. Do you think a Bulgarian translation of the software would make a significant difference? It is fairly easy to generate a machine translation, but can be fairly tedious to clean up mistakes in the machine translation. -

I have a model where there are 4 servers with Processing Count Based failures. So every 5 cycles, the specific machine has a lockout and needs to be serviced by a worker. I am trying to have status label that shows how many cycles are left before the machine goes into lockout. I am having trouble figuring out the logic for it.

-

Multiple machine failures and multiple machine repairs

AHak posted a topic in SI General Discussions

Hi everyone, In my model, I'm trying to simulate an assembly line that has five machines. First machine needs to define seven types of failure event, and seven type for time to repair, four types of failure for second machine, three types for the third machine, six type for fourth machine and five types of failure for the last machine, each failure event and repair type has its own distribution. However, in the reliability logic properties on the Server only allow for one way to generate failure. How can I model this condition? Any suggestion will be appreciated! -

You can just use a process with a WAIT step. On entity arrival you will fire and event and the process will go on. I also belive that a worker is derived from entity so you can use workers instead of entities. Or the best fitting thing is to use consume step to consume a material (the tools). And have two inventories for it (one near the machine, one in the warehouse of tools). There are some simbits with the basic inventory concepts.

-

I am trying to model a repair process. A major part of this process is the time to get the tools from their storage locations to the machine that needs repair. My thought was to have the tools be modeled as entities that a fork lift or worker has to go grab and bring back to the server. The problem is I need to wait for all those entities to be there before the server can start to process. Then I want to destroy the entities because they aren't actually being processed (only 1 entity would be processed as a representation). Does anyone have a suggestion on how this might be accomplished? Thanks.

-

Change processing time depending on previous server output

Wsimio replied to Wsimio's topic in SI General Discussions

Thank you for your response! But im not sure: Is this also possible if the model is extended to 6 servers? So each server processing time is dependent upon the one in front? I thought I would need to make different state variables for every server (machine) For example:a machine in a production line needs to slow down with a delay if the machine upfront has reduced or zero speed because of failure. -

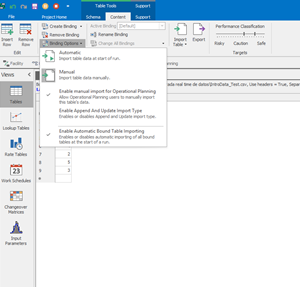

Hi GFurtado! Thanks for your answer! I'm using Simio 11.189 as my testing ground, and even though the ribbon is not the same, I can import data trough it, the problem is, even tho the data is imported into the table, it is not updated mid run so Simio keeps using the values previous to the new import, I'll elaborate a bit. Imagine these are the original values in the binded table I created. With those original values, I start the simulation and after a while I update the binded file (the .csv where Simio is taking values from) and I click on update table with the following options enabled. (Bear in mind! I've tried all of the options in the image below to no avail!) (Options used before clicking update mid-run) (Updated mid-run table, values get updated but Simio doesn't use them!) While the values get updated, Simio doesn't use them in this run (in the example I posted, it would only use the original first 9 values instead of all of the 19 values provided). As further context, I am indeed trying to make kind of a 'wacky' simulation, my idea is to update the .csv providing the data to the table at periodic intervals with new data from a real life reading from a machine, or something similar, and use that data as the entity creation time to try and make kind of a 'parallel' simulation with the actual readings of the system. But of course, for me being able to do that I need to know if Simio can update tables with new data and USE that new data mid - run! Thank you so much for your reply and for your time! Have a great one!

-

Dear Simulationists, I am trying to model a manufacturing cell consisting of a metrology station, CNC machine, and an airblast station. Each processed batch contains 3 different parts. The batch is inspected in the metrology station, then is mounted on the CNC where the first part is machined. After the first part is machined, it is then taken out of the CNC machine and transported to the airblast station, and after that to the metrology station and the finished parts store, while the CNC machines the second part of the batch. The same is repeated for the second and third part of the batch. After all three parts are machined, the plate used as a fixture for the batch is also processed on the CNC, followed by transportation to the metrology station and the plate store. There are defect rates of different magnitude associated with different operations. My idea was to represent each of the operation steps as separate servers (4 CNCs, 4 metrology stations, 3 airblast stations) and create a process logic that assigns a single shared processing capacity on all servers performing the same function. For example, this would not allow the second CNC to start operating if the first is already operating. I have been struggling to define this process logic for three days now, and as my desperation levels grew progressively higher, I decided to seek assistance from the experts in this forum. I would deeply appreciate it if you share your ideas on how this process logic might look like, ideas about more efficient methods to model the scenario and any general feedback or suggestions! This is a repost of the thread from the public forum to allow file attachments. Thanks, Hristiyan

-

Dear Simulationists, I am trying to model a manufacturing cell consisting of a metrology station, CNC machine, and an airblast station. Each processed batch contains 3 different parts. The batch is inspected in the metrology station, then is mounted on the CNC where the first part is machined. After the first part is machined, it is then taken out of the CNC machine and transported to the airblast station, and after that to the metrology station and the finished parts store, while the CNC machines the second part of the batch. The same is repeated for the second and third part of the batch. After all three parts are machined, the plate used as a fixture for the batch is also processed on the CNC, followed by transportation to the metrology station and the plate store. There are defect rates of different magnitude associated with different operations. My idea was to represent each of the operation steps as separate servers (4 CNCs, 4 metrology stations, 3 airblast stations) and create a process logic that assigns a single shared processing capacity on all servers performing the same function. For example, this would not allow the second CNC to start operating if the first is already operating. I have been struggling to define this process logic for three days now, and as my desperation levels grew progressively higher, I decided to seek assistance from the experts in this forum. I would deeply appreciate it if you share your ideas on how this process logic might look like, ideas about more efficient methods to model the scenario and any general feedback or suggestions! Thanks, Hristiyan

-

I'm simulating a workflow, now between two servers, there's a delay between them, we could understand it as some out-of-control waiting time or simply travel time between 2 servers. I don't know how to set this travel time perfectly. I tried set 'path' speed, but I don't think it setting that can make the time randomly… because in my situation, the delay processing time can be random. I can add another server called 'delay/travel machine' to solve this problem perfectly, but it just looks ugly and weird… So I'm wondering if there's a better solution for this?

-

I am confused at your words'failure' , it is actually FPY, not the same concept...failure is the Machine breakdown, FPY is the first pass rate for products.

-

Accessing the Batch Quantity of Combiner

SimioSimulation replied to poudenx's topic in SI General Discussions

Greetings! I am trying to make a model in which materials arrive from source to CNC in a batch of 20 and after processing goes for shearing operation in a batch of 10, also checking which shearing machine is free to accept material. After shearing the parts are divided into various small parts (how to divide 1 entity into multiple entities?) and are moved to the bending machine depending upon specific parts are bent on specific machines. I have 1CNC, 2 Shear Machines, and 3 Bending machines. How should I simulate? I have attached my model. Practice -1.spfx -

Hello, this is probably a trivial question but I've already read a lot of material and tried a lot of things but I've been unable to do what I need. I have a Top Model which represents the general view of my facility, and a submodel consisting of a Workstation and some additional logic of combiners and separators. This submodel represents a machine that I want to instantiate in my Top Model multiple times. Now, I'll need to assign an operator present in the Top Model to perform the setup and teardown steps in my Workstation. And so, I've tried to reference the Secondary Resources, so I can assign the operators in the top model. But referencing the secondary resources it does not seem to work since the top model does not get access to the subfields in the Secondary Resources (Object type, Object Name etc.). I've also tried to individually reference each subfield but this also does not seem to work, since the referenced subfields do not seem to be part of the Secondary Resources Repeat Group. Which is the cleanest way to achieve want I want? Thank you in advance, Pedro Prates

- 3 replies

-

- workstation

- secondary resources

- (and 3 more)

-

Dear all, I do have a table called machineProperties which describes properties of machines: Machine | ProcessingTime | ... machine1 | 2 |... machine2 | 1.5 | ... In my model I would like to assign the property "Processing time" to machineProperties(DisplayName;"ProcessingTime"). I guess Lookup tables might be working, but unfortunately I do not know how to link them to an Excel file. Does anyone know how to do this? Thank you! Best regards, Stefan

-

Simio does not have a specific machine learning feature, but many people still implement a form of machine learning in one of two ways: 1) Data-driven models, and particularly data-generated models, will improve their operation with better data. As you system runs, and the data improves, the model will automatically improve. 2) Particularly in scheduling applications - a model is never static. Every time your run a model and discover the possibility of creating a better solution (better schedule) you manually improve the built-in heuristics to it generates a better solution the next time.

-

Hi all, Was wondering if Simio has machine learning capabilities? If so, are there examples/tutorials on how to do it? If not, are there plans for it to be included in the future?

-

Moving Worker to a-priori unknown position

dsturrock replied to bscandi's topic in SI General Discussions

Entities don't have a facility view , so they can't contain nodes, so they cannot themselves be a destination. --One option is that when the machine fails, have it move to a node to fail, and then have the worker go to that node to work on it. --Another possible approach is to model the machine as a node or a server. As long as there are no links to the node(s), you can use the RelocateObject user defined step to move the object around at runtime. Then you could move the worker through free space to get to the machine's current location. -

Hello everyone, I would be glad if someone could help me with this: I have a machine defined as a subclass entity that suspends its movement when it goes in failure. I would like to move a worker to the machine when that happens in order to fix the failure. How can I do this, since I do not know the exact position of the machine when the failure occurs? Thanks

-

One machine in my model needs to realize three type of failure event during the simulation. The first type of failure will happen every random.expo(3) minutes and need an operator to adjust it, the second type of failure will happen after every 100 entities be processed and need the same operator to deal with, the third type of failure is random.exponential(3) days and need engineer to repair. All the three types are independent occurred. How can I model this condition? Any suggestion will be appreciated!

-

Seize and release corresponding resource from list or table

clarkwym replied to clarkwym's topic in SI General Discussions

I have made a model for using table through referring list. In this model, I create 10 entities represent for 10 machines, and 10 resources for the animation of status of counterpart entities, and also import 2 engineers for repairing the failed machine. Any list only consist 1 resource such that the entity can seize the specific resource by using the instruction table1[modelentity.SN_ResourceSeized].RS. Is there any method more simpler especially when the number of entity grows very fast, e.g 200 entities? MachineRepair.spfx -

Hello! In my model, there are 5 machines running for production. Each machine has opportunity to be failed, the mean time between two failures is exponential(4.5) hours, and the repair time will last triangular(20,25,30) minutes. I use 5 Resource to represent these 5 machines and place them on the canvas because I want to see the state changing of each machine during the model running. Five entities will be created at the time zero simultaneously and the Source will only create 5 entities, those entities arrive at a Server which capacity be set to 5 and the Server’s processing time is exponential(4.5) hours. When one entity go out the Server, it means one machine (Resource) failed. My question is how can I find the corresponding resource related to this entity and change its state to failure and then after certain time duration of repairing to change its state to busy. Say, if entity 3 go out the Server, then I need to set the state of Resource 3 to failure and then change it back to busy. I want to use list or table to achieve my job such that the model can fit for very large amount of machine’s condition, e.g. 1000 machines. Thanks!

.thumb.jpg.d86860331a58e852a3b64f28348c2d88.jpg)