Search the Community

Showing results for 'sink percentage of entities'.

-

Hello, I have a DataTable that one source can use to create multiple entities. I would like these entities to be named properly. Instead the just come out named ent.11XX (a random four digit number starting with 11). Here is my table, I would like the entities to be the name of the TwiggPN. (Each row produces a different entity):

-

Daniel, Dave is right, the HourlyStatistic simbit includes the logic what u want. I realised that I have missed some assignments. see the attached file for what u want. Periodicals.spfx

-

Hi I have a situation where we receive applications only during week days. I have a source with a Rate Table but this only allows me to add the rate per day. The end result is that I am receiving the same number of applications over weekends as what I am receiving during the week. This results in servers being overloaded and queues building up. I would like to have the entities arrive during the 5 days of the week and not over Saturdays and Sundays. I would appreciate your help, although I suppose the answer is very simple. I have not used Simio for a few years and I am trying to get back into it. CG

-

Hello, Is it possible to change the state of just the entities while they are on a transporter? Because now i get an error when I put an add-on process to change the state of the entities going throug the node because simio tries to change the state of the transporter too. Thanks for the help, would really appreciate it!

-

Hi all! I have built a model, but in order to verify the model behavior I want to get data on individual entities. In my model there are 4 types of entities, of which approximately 1300 are created in total. I would like to get data on these 1300 entities in order to compare it with the real system data. Does anybody know how to get data of the individual entities? Thank you! Kind regards, Roeland

-

Has anyone had an issue of tokens mysteriously building up and not exiting the system? By using a search step in combinations with create steps what I think is happening is a build up of tokens somewhere without it exiting the system. Would appreciate any help in debugging. There should theoretically be only enough tokens to match the number of entities currently in the system but it seems when the search/create action is occurring it doesn't get rid of tokens. Attached is a file if you run should show the problem occurring around 2.5 hrs. simiohelpexceedinglimit.spfx

-

I have 2 transports delivering entities to 3 servers. What should be happening is that Transport 1 loads entities to capacity (12) then moves to Server 1 and delivers all of the entities (12). Transport 2 should load 12 entities and deliver all 12 to Server 2. Transport 1 returns to Home Node and loads 12 more entities for delivery to Server 3... and so on. However, what is happening is that both Transports are loading 12 entities then moving to Server 1 and delivering 4 entities each, then on to Server 2 and repeat and so on. I have removed and added servers to confirm that for some reason the Transports are delivering 1/#ofServers of their total capacity, conducting all of their deliveries and then returning to home once empty. I have limited the timepath to each Server to only allow 1 Transport at a time, but then Transport 2 just waits at the Home Node until Transport 1 is on its way to Server 2. Then it moves to Server 1 and just ends up one node behind Transport 1 at all times. The dispatch logic: (Server1.InputBuffer.Contents.NumberWaiting <= 12)||(Server2.InputBuffer.Contents.NumberWaiting <= 12)||(Server3.InputBuffer.Contents.NumberWaiting <= 12); set at Smallest Value for Selection Goal; Selects from a List of all Server Nodes.

-

A quick solution to force all entities to get dropped at the same place is to add an add-on-process when an entity is loaded. which Checks if the entity is the first item in the vehicle and if not set its destination node to the first item. Decide: Token.associatedobject==Token.ContextObject.Vehicle.RideStation.Contents.FirstItem If False -> SetNode: Token.ContextObject.Vehicle.RideStation.Contents.FirstItem.ModelEntity.destinationnode a more elegant solution would probably involve batching the entities into a bucket that would then get transported to the destination. Upload 11.1.21.spfx

-

Hello, I'm working on a project where we want to build a scheduling model. But there is one think that I'm dealing with for a while now. I want to capture mid phase stock. For example if we have part A, which has 5 sequences to be produced. But at previous order we did not push all the parts through production, so now we have some stock on different operations. What I want to achieve is, that when my order come I firstly look at general stock of finished products (OK). If there is not enough stock I want to look at how many parts I have on the stock before last operation, if there is enough I don't want to create new entities but use this stock and produced new parts. If there is not enough parts before last operation we of course look at every previous sequences and if there are still not enough parts only then I want create new manufacturing order and with that new entities. If any of you guys deal with system like that before it will be really helpful. If you haven't but have some idea how to solve this problem, it will also be helpful because I've already tried a lot of options and now I'm stuck. Best regards!

-

12-hour Shifts with Lunch Breaks and Vehicle Transport

Ryan Welch Lutttrell replied to M_A's topic in SI General Discussions

Hi M_A, 1. This is one is a bit difficult to provide direction on without seeing how the rest of the model is structured. If all your processing times are deterministic and you are using a sequence table to route your entities, then you should be able to add the lunch break into the sequence. Similarly, make sure the sink is included at the end of all your entity sequences. Also, make sure the model run time is long enough to process all employees. That may be why they aren't showing up at the sink. 2. Change your interarrival time to 12 hours, and set your Maximum arrivals to 2. Thanks, Ryan -

yes, it works if the sink objects are in the course of these customer entities.

-

Hi, I am trying to model this situation: One vehicle picks up entities "On Demand" from two locations (TransferNodes) and send them to Sink1. Entities with high priority arrives at TransferNode1, while entities with low priority arrives at TransferNode2. When I choose the Ranking Rule to be Smallest Value First and the Ranking Expression is ModelEntity.Priority in the Resource Logic of the Vehicle, the Vehicle picks up entities probabilistically from the locations. How can I make the Vehicle picks up the entities with the highest priority first and once it is started picking at one location (say TransferNode1), I want it to keep picking up the entities from that location until the RidePickupQueue of that location is empty. Then the vehicle can move to the next location, finish it up, and so on. I think I need to add a logic on the Evaluating Transport Request Add-On Process Trigger on the Vehicle but I do not know how. Any help is appreciated. Thanks, Omar

-

I'd recommend you read the Create help documentation. It provides some detailed info on how the step functions. It also mentions the CONWIP and DynamicallyCreatingVehicles SimBits for examples using the Create step. For my second suggestion, yes this can be done with variables. What I would do is create a new Source and Sink that create entities that just tells the model to perform logic. And since this is just a regular sink, you can specify when to create those entities however you desire (by arrival table, randomly.....).

-

Hi All,

In my model, I have a transfer node and the entity could go to either of the next 2 serves as in the picture.

I have assigned product number(1,2,3...) to entities …., if product “1” moves from transfer node to S1 and the next product is also “1”, it should also move to S1 and if the product number changes its should change the server to S2. So the entire batch gets processed on one server.

After processing from S1 and S2 the entity should flow in batch so that at S3 I have batch production

Right now the entities go based on “By Link Weight” and randomly goes to the server which affects S1,S2,S3 servers setup time

Any thoughts how can that be achieved, I do not want to setup a sequence table.

-

Worker to "empty" queue before moving to next server.

Unmesh.Chandak replied to jopendle's topic in SI General Discussions

Hi Jon, let me know if this helps. I added priorities to entities and changed the dynamic selection. Unmesh Model_worker.spfx -

Hi Alb, What I would suggest is for you to use process logic to create your order entities rather than a source. The Create process step can be used to create entities just like a source, and you can put in logic that looks up the percentages. I would also suggest you use timers or perhaps a source to just create trigger entities that tells your model when to fire events (perform logic). For example, in your above case, perhaps have a source that creates an entity at 7pm, 7:30pm, and 8pm. These entities then trigger the process to be executed that decides the percentage of entities to be created at each time.

-

Hi guys. So, in my model, I have a table (binded to an excel file) with 2 columns - 1 indicates the real number that I want to assign to the state of an entity and the other indicates the probability of that assignment being made. So, I want to assign the values specified on the table, based on the probability also specified... Can anyone give me some hints on how to do this? Thanks.

-

Hi, It's the first time I'm working with the flow library. My question relates to configuring a flow of two liquids that come from a single source, but may be of two kinds (different densities). I would like to have one table, describing the properties of the entities, and another table, having one field as a model type, and another one as the weight limit in the flow sequence. So, basically Table1: --Entity--- ---Density (kg/cubic meter)--- ... some other props TypeA 5000 TypeB 10000 Table2: RowNumber (not a field, just for sequence) --Entity--- ---Amount (cubic meters)--- 1 TypeA 10000 2 TypeA 20000 3 TypeB 30000 4 TypeB 25000 5 TypeA 10000 6 TypeB 12000 7 TypeB 10000 I need to make pauses between the sequential flows of different (or the same) liquids, in the order presented in 2nd table, but I believe, I'll figure out how to achieve this. The question is - how do I configure the source? I need to reference both tables, since I need to limit certain values by weight in the source, but have input in volume. I also have some other entity properties that I would need to access further in the simulation. They are in Table1, which is the descriptive table, not the one used for initializing the flow source. What I tried to do - is 1. Specified the entity type as a referenced property from the Initialization table (Table2) 2. I created the RunInitialized trigger for the flow source to SetRow to number 1 (I will further increment the rownumber - if there is a better solution, please advise) 3. I tried to limit MaximumVolume by accessing another table - and here I'm stuck. I need to lookup Table1, but not by id (integer), but by the entity type. So, the lookup table seems not to fit here. Please advise of this design, how do I lookup in a Table1, when I have an entity of known type.

-

Senior Industrial Engineer - Simulation Req #: 67308BR York, Pennsylvania, United States Engineering & Technology Platforms & Services Posted on:03/29/2021 Job Summary Career Level Experienced Travel Percentage 10% Full-Time / Part-Time Full-Time Clearance Level - Must Currently Possess None Shift 1st Shift Relocation Available Yes ITAR: U.S Citizen or Green Card Required Yes Clearance Level - Must Be Able to Obtain None Job Description What motivates you? If the answer is a position where you can develop your skills and earn opportunities for advancement while being part of a forward looking team then this is what awaits you in a career at BAE Systems. Our employees work on the world’s most advanced combat vehicle systems. From the M109A7 Mobile Howitzer with its long range firepower to the Amphibious Combat Vehicle that transports America’s Marines from ship to shore, we are developing the technology of tomorrow while delivering the most cutting-edge equipment available today. Our flexible work environment provides every opportunity to positively impact the company without giving up your personal life and we welcome all those who understand the importance of improving production velocity, having big ideas, and craving innovation. We draw strength from our diversity and always put our customers first through an unwavering commitment to bring the warfighter home safe. Does this sound like a team you want to be a part of? If so, come build your career with BAE Systems. The Combat Vehicles line of business within the Platforms & Services (P&S) Sector of BAE Systems is looking for a self-motivated Senior Industrial Engineer to support the production scheduling of armored military vehicles. Working as a team member of a larger Industrial Engineering Group, this Engineer will be required to build and maintain simulations for varied fabrication, assembly, and testing processes. The candidate must also be comfortable with soliciting input through face to face interaction and, in general, must demonstrate that they possess strong analytical, problem-solving, and interpersonal skills that will support individual and team growth. A strong background in discrete event simulation, specifically with the use of SIMIO, is necessary. Specific responsibilities include: Day-to-Day · Complete simulation support activities such as time studies, production line balancing and production metric development · Evaluate complex Technical Data Packages (Drawings, Bills of Material) and be able to understand how a component or vehicle is assembled · Utilize a strong understanding of integration activities like implementation of standard work, material kitting, metric tracking, and process improvement to advance manufacturing methods. · Work on the manufacturing floor with other Engineering disciplines, production supervisors, and employees that directly interact with the components or vehicles being produced. Internal and External Customer Relationships · Engage in regular communications with production support, planning, logistics, quality, manufacturing supervisors, and direct labor workforce to assess operations performance. · Summarize and present findings to internal customers to gain buy-in for improvement efforts · Discuss the status of metrics and key performance indicators with appropriate decision makers Development · Work with Industrial Engineering leadership to understand the expectations of new Engineer within the organization and company · Share responsibility of self-development with immediate supervisor · Maintain a safe work environment and ensure compliance with safety objectives and policies. Required Education, Experience, & Skills - 4+ years of simulation experience within SIMIO - BS degree from an accredited university Preferred Education, Experience, & Skills Demonstrated capability with the use and application of SIMIO discrete event simulation software. About BAE Systems Platforms & Services BAE Systems, Inc. is the U.S. subsidiary of BAE Systems plc, an international defense, aerospace and security company which delivers a full range of products and services for air, land and naval forces, as well as advanced electronics, security, information technology solutions and customer support services. Improving the future and protecting lives is an ambitious mission, but it’s what we do at BAE Systems. Working here means using your passion and ingenuity where it counts – defending national security with breakthrough technology, superior products, and intelligence solutions. As you develop the latest technology and defend national security, you will continually hone your skills on a team—making a big impact on a global scale. At BAE Systems, you’ll find a rewarding career that truly makes a difference. The Platforms & Services (P&S) sector under BAE Systems, Inc does the big stuff: the armored combat vehicles, naval guns, missile launchers, and naval ship repair…just to name a few. Our employees take pride in the work they do and why they do it. They are on the front lines every day, building our products to protect the lives of those who serve. We may be biased, but we think P&S does some of the coolest work around, and we think you will too. At BAE Systems, we celebrate the array of skills, experiences, and perspectives our employees bring to the table. For us, differences are a source of strength. We’re laser-focused on high performance, and we work hard every day to nurture an inclusive culture where all employees can innovate and thrive. Here, you will not only build your career, but you will also enjoy work-life balance, uncover new experiences, and collaborate with passionate colleagues. https://jobs.baesystems.com/global/en/job/67308BR/Senior-Industrial-Engineer-Simulation Thanks, Jenny Ridings, PHR Principal Talent Acquisition Specialist BAE Systems My pronouns are she / her M: +1 904 570 2489 | E: jenny.ridings@baesystems.com https://jobs.baesystems.com Connect with BAE Systems: Join our talent community!

-

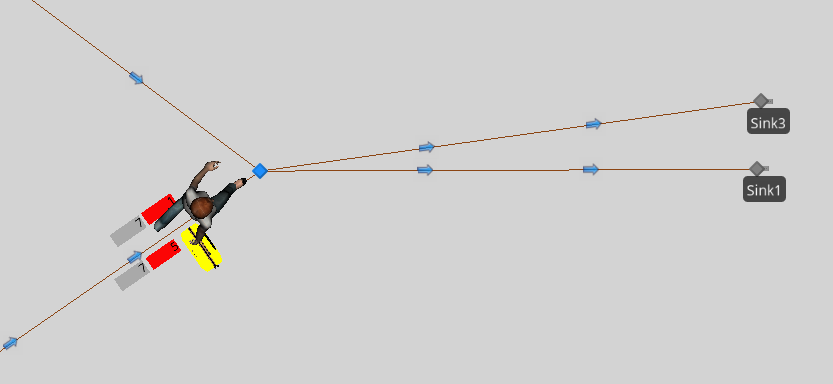

Hello, I have recently encountered an issue while simulating an airport checkpoint and thus leading to the following question: Is it possible to match member and parent priorities under certain conditions? I am trying to differentiate between those travelers (parent entity) and baggage (member entity) going though an additional screening process prior to exiting the model. Take the following image as an example. I managed to provide a priority (red status label) to those entities going through the additional screening while also providing a rule for those with a priority of 5 to exit though Sink 3 (Those with a priority of 1 should exit through Sink1 ). However, the rule seems to only apply to the parent for a reason I assume to be that the baggage is an entity initiated by a "create" step in the processes window, rather than at its own source as the parent. The current rule I have is to decide the following ModelEntity.Priority==5.0, then assigning the desired node (Input@Sink3). In the picture, although the baggage (member) has a priority of 5, the traveler (parent) has a priority of 1 and the rule only applies to the parent. How could I match the priority of the parent, only under the case in which the parent has a higher priority? (Perhaps match the greatest priority of the member and the parent to generalize) I have tried everything possible and I cannot figure it out. Any help is greatly appreciated!

-

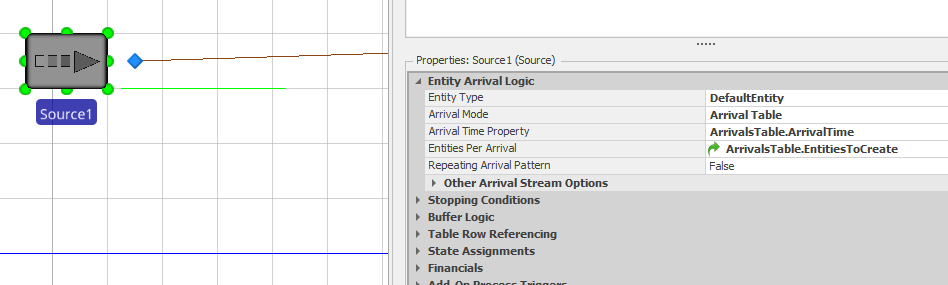

Multiple entities arriving at exactly 8am each day.

lstretton replied to Kameswara Sukesh's topic in SI General Discussions

You might want to look into Arrival Tables. See the following screen grabs. Configure the source to create entities based on the arrival table as follows: Setup the arrival table to define the arrival time and the number of entities per arrival as follows: Hope this helps, Lucas. -

Hi! I want to model the loading of containers at a terminal. On each terminal there is a queue with containers. Each container has different properties, like the size in TEU (is equal to 1 or 2) and their destination. I want to batch a vehicle (parent entity) to a group of containers (member entities). When the capacity of the vehicle is for instance 10 TEUs, you have to batch an amount of containers to that vehicle. The problem is that I cannot express the Batch Quantity in containers, but only in TEUs. Per container the size in TEUs is known and the containers (member entities) must all have the same destination. What should be the expression for the Batch Quantity? It is the most optimal when the vehicle with a capacity of 10 TEUs will be loaded fully. So, when the first number of containers in the list that will be loaded on the vehicle has a common size of 9 TEUs, the last spot can only be occupied by a 1 TEU container. When the first container waiting is 2 TEUs, this one must wait, but the first 1 TEU container waiting in the queue can be taken by the vehicle. How to model this? Does someone has an idea to model this problem? Thanks!

-

Hi, I am trying to make it so that at the end of a process all of my combiners (say 10 or 20) collect all entities (assigned to a particular combiner when they enter the system) but wait to release to the sink until the simulation reaches a certain time (say 9:00 AM) AND all entities have been processed through the system and are in their assigned combiner. I use a combiner because they turn into a different type of entity before exiting the system. I've tried a few different things but cannot seem to get the process logic down. Any help?

-

Dynamic destination based on multiple conditions

craigw replied to craigw's topic in SI General Discussions

As an update to this, I think I have (at least so far) found something which provides the desired behaviour and will detail below for others. I used the SimBit 'SelectServerWithShortestLine' as a reference. I created a Node list with the inputs nodes at each Sink listed. I created an integer Property to hold the variable which represents the maximum number entities that can go to a sink (e.g. MaxContainerCapacity). On the feeding TransferNode I changed the 'Entity Destination Type' to 'Select from List' and selected the list created in Step 1. Change 'Selection Goal' to 'Smallest Value' and set the 'Selection Expression' to Candidate.Node.AssociatedStationLoad, which accounts for everything en route, in the queue and processing at a node. Therefore, the select goal is to minimise this station load. I set the selection condition to (Candidate.Node.AssociatedStationLoad + Candidate.Sink.InputBuffer.NumberExited) < MaxContainerCapacity. Which is saying only select the Node found in Step 4 if the sum of the station load and the number of entities that have 'exited' the Sink are less than the MaxContainerCapacity. -

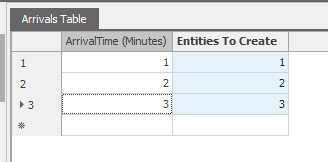

Hello, I have been utilizing SIMIO for a couple of months, however I am relatively unfamiliarized with some of the features. I have recently encountered a difficulty while simulating an airport screening checkpoint. Take the attached picture as a reference. I have entities arriving from a single Source, processed initially at Server 1, and then following a series of separators and additional servers along the way. At Separator 1, the member (luggage) is separated from the parent (passenger). (Luggage is created by a "create" step in an add on process, rather than at its own Source). However, I would like to distinguish statistics between those travelers and luggage going twice through a server. For example in Server 10, I have a loop going from the output node to the input node for the re-scanning of passengers. I managed to provide a priority value to the passengers going though that created loop, and an add on process rule to send those with that priority value to Sink 3, while those without the priority value to Sink 1. I tried applying the same concept to the loop seen in Server 9. However, when the passenger picks up the luggage at the transfer node located at end of the conveyor belt, both the member and the parent exit through Sink 1, rather than Sink 3. It appears that only the member obtains the priority, but not the parent. Although I tried, I did not manage to match the priorities and thus have the combined entities exit the model as anticipated. Any thoughts on how I could match the priorities, or perhaps, any suggestions to make this possible? Any help is greatly appreciated!