Search the Community

Showing results for 'response maximum'.

-

Thank you for the quick and detailed response! I see the error I was making with work schedule and have tested it on one server, it seems to work as intended. Since each of my servers have a different capacity, would I need to create a unique work week and unique day type for them all? Or is there a quicker work around? The manual inputs for the date time are a great work around, I'm only modeling for a few years so I don't mind inputting a few dates. What I mean by there being no buffers is that no server can have a queue. I used a list for selecting the destination on the output node of each source (total of 8 ) where it's a hierarchy. It can go to a select number of servers and if all of them are full it goes to a dummy server of infinite capacity that exits the items to an overflow sink.

- 2 replies

-

- server

- work schedules

-

(and 2 more)

Tagged with:

-

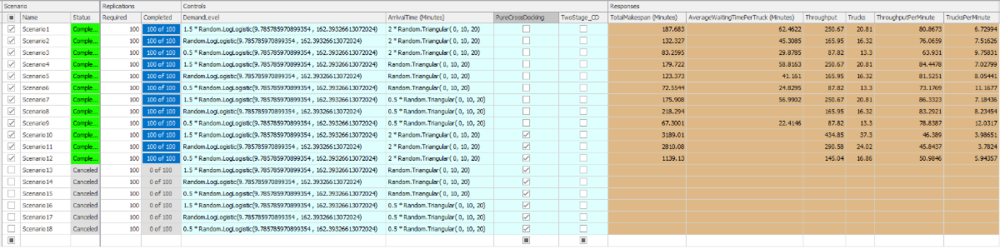

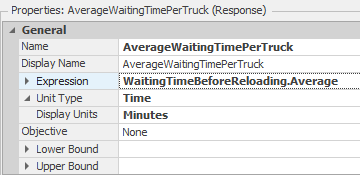

Hello everyone, I'm thrilled to share that I've successfully established my simulation model and conducted extensive verification and validation. Now, I'm ready to take the next exciting step: experimentation! While I've made considerable progress, I've encountered a minor setback. It seems that for certain scenarios, the response 'AverageWaitingTimePerTruck' isn't displaying any values. Interestingly enough, this issue only arises when conducting experiments with higher throughput values. The response is defined by averaging the tally statistic 'WaitingTimeBeforeReloading' of the Truck Entities in my model. Have any of you experienced a similar situation before? If so, I would greatly appreciate your insights on resolving this matter. Thank you in advance for your support! Best regards, Toon

-

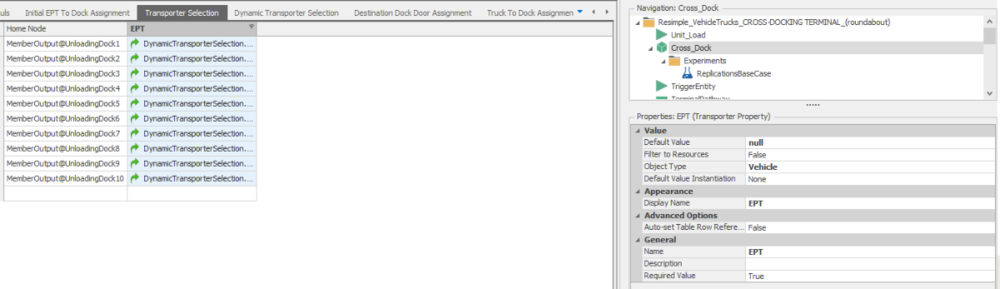

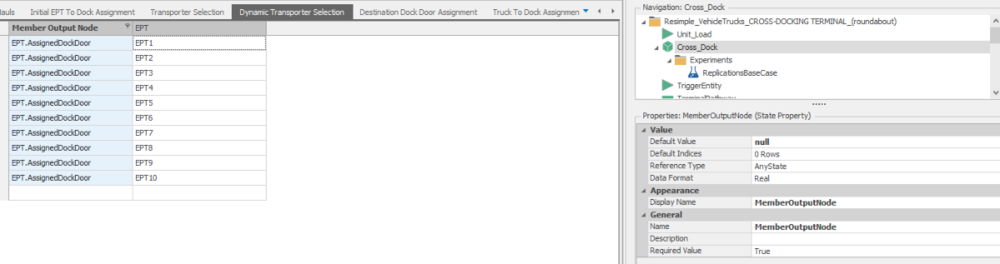

Hi all, I am building a simulation of a system with multiple separators which MemberOutput nodes two different routing policies can occur: 1. Standard Policy In the 'Standard Policy', each separator has its dedicated transporter assigned to it and entities arriving at the MemberOutputNode can only select the defined transporter. To this end, a DataTable has been constructed. 2. Power Hour policy In the 'Power Hour Policy', operations are shifted into a higher gear. We select a maximum number of three nearest transporters whose ride request is 0 and include them in the DataTable which specifies the Transporter Selection. Entities arriving at the MemberOutputNode can now request rides from any transporter in the DataTable. I tried to reference to a DataTable called 'TransporterSelection.EPT' in the Transport Logic of each MemberOutput Node. Each value in the EPT column is cross-referencing to a DataTable in which I try to assign the MemberInput Nodes as a Node Reference State Variable of the Transporter (EPT). Is there any way to dynamically assign more (or less for that matter) Transporters to a TransferNode? Hope that anyone knows how to do this! Cheers, Toon

-

Great, thank you! My current problem is that workers should carry a specific amount, so sometimes 14 sometimes 17 with a max of 30. This maximum is given at the transport logic I think. Do you have a suggestion on how to deal with the specific numbers (depending on the amount of pallets in a given truck)?

-

Job Description Energetic and personable professional who applies operational research to best utilize workforce, data, technology, and other resources to achieve maximum productivity within budgetary constraints. Guides current practices and facilitates through more efficient and effective ways to achieve operational excellence. Experience in discrete event simulation, agent-based modeling, and predictive analytics is a plus Job Responsibility Develops metrics, creates dashboards, reports, and identifies areas of improvement across the organization using various analytical tools and techniques. Identifies current process gaps through the use of observations, data collection, data analysis, process ideologies and communication with management and frontline staff. Identifies issues, root causes, strategies for improvement, and development of implementation and sustainment plans. Supports project management, development of project timelines, and follow-up action items for process improvement initiatives. Develops the summary of findings, recommendations, and action plans to management. Applies principles, techniques and procedures to the design and implementation of technology and process solutions (i.e. Lean, Six Sigma, Kaizen). Supports development of principles and methods for curriculum and training design, teaching and instruction for individuals and groups, and the measurement of training effects. Work assignments are varied and require interpretation and independent decisions on the course of action. Decisions may be guided by precedent, previous experience, and known professional guidelines and compliance requirements. Often required to interpret policies, standards, requirements, and approaches to meet work objectives. Regularly exercises independent judgment on matters of significance within defined procedures to determine appropriate actions/approaches. Normally receives general instructions on routine work, and detailed instructions on new projects or assignments. Performs related duties as required. All responsibilities noted here are considered essential functions of the job under the Americans with Disabilities Act. Duties not mentioned here, but considered related are not essential functions. Job Qualification Bachelor’s Degree or equivalent combination of education and related experience as Continuous Improvement Engineer, Industrial Engineer, Operations Process improvement Engineer, Process Engineer, or Lean Six Sigma Black Belt. 1-3 years of technical experience, required. Technical Skill preferred: Experience in discrete event simulation (preferably Simio), Lean, Black Belt Six Sigma Certificate, Statistical Analysis, Graphical Analysis, Facilitation, and Presentation Skills, Operational Research, Programing (i.e., R or Python), Predictive Modeling, Agile Project Management. Here is the link to apply: https://jobs.northwell.edu/job-3/16580688/process-improvement-engineer-lake-success-ny/

-

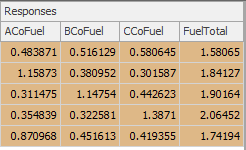

I am running some experiments on my model. I have a couple of transporters delivering fuel to three server nodes. I am trying to have the model maintain adequate fuel levels at the servers despite disruptions. Currently I have 4 responses (1 for each server and 1 that sums their fuel levels) and the responses are based on the expressions: Input@LineCompany1.AssociatedStationLoad Input@LineCompany2.AssociatedStationLoad Input@LineCompany3.AssociatedStationLoad and FuelTotal: Input@LineCompany1.AssociatedStationLoad + Input@LineCompany2.AssociatedStationLoad + Input@LineCompany3.AssociatedStationLoad I get responses as such: with the ACoFuel, BCoFuel, and CCoFuel ranging between 0 and 2 and FuelTotal ranging from 0 to 3. The capacities of these server nodes are 0 to 12 and everything is handled in integers. I am confused on how these responses are being calculated and any light that could be shed on this would be greatly appreciated.

-

Hello, I'm new to both the forum and the world of simio in general. I am trying to simulate how much the maximum buffer could be in 2 points of my process which are defined by the Buffer_ST1 and Buffer_ST2 servers. My problem is that I would like the Buffer_ST2 server based on a condition that would be every time an entity passes on Input @ Buffer_ST1, the Buffer_ST2 server releases only one processed entity and not all those inside the server as it happens now, I hope for being clear and thank you in advance. I put the model in the attachment Buffer varianti trazioni V2.spfx

-

Hi Gocken, Thank you for your kind and quick response! I really like this use of a button! Unfortunately, I was not clear enough. As entities move through the system they carry quite a lot of state information. Our desire is at end or replication or an arbitrary time like a button click which a neat idea, to take an inventory of all the entities AND their states. This would mean capturing all the entities in each processing queue and through a write step. writing them out, either to an output table or a CSV. This operation is a bit complex. It does not seem one can search a processing queue to sequentially write out its members properties. I believe it is possible to maintain the residence of servers by maintaining that in a special output table which is tedious to maintain and set up. I greatly appreciate your response! Best Regards, Jim

-

Let's see if I can elaborate... The following outlines the relevant characters in simio file "table_selection_by_name.spfx." Model->Definitions: Properties: OptionId (Entity Property, default=null) _SelectedTable (Table Property, default=tableOption1) States: RowId (integer, default=1) maxEntities (integer, default=2) ModelEntity->Definitions: States: _id (Integer, default=0) row_num (integer, default=0) temp (integer, default=0) Model->Facility: ModelEntity Types: Option1, Option2 Source1, Server1, Sink1 Source1->Entity Arrival Logic: Entity Type = OptionId (Reference Property) InterarrivalTime = 1 second Source1->Stopping Conditions->Maximum Arrivals = maxEntities Source1->Add-On Process Triggers->Created Entity = Source1_CreatedEntity Sink1->Add-On Process Triggers->Entered=Input_Sink1_Entered Model->Facility->Controls->General: OptionId = Option1 _SelectedTable = tableOption1 Model->Processes: Input@Sink1 Add-On Processes Input_Sink1_Entered: [Begin-> Tally(temp = ModelEntity.temp) End] Source1 Add-on Processes: Source1_CreatedEntity: ************************* [Begin->Decide1(IsOption1 = True)-> Assign(maxEntities = tableOption1.AvailableRowCount)-> SetRow(tableOption1, RowId)-> Assign(ModelEntity._id = tableOption1.id, ModelEntity.row_num = tableOption1.row_num, ModelEntity.temp = tableOption1.temp)-> Assign(RowId = RowId + 1)->End Decide1(IsOption1 = False)-> Decide2(IsOption2 = True)-> Assign(maxEntities = tableOption2.AvailableRowCount)-> SetRow(tableOption2, RowId)-> Assign(ModelEntity._id = tableOption2.id, ModelEntity.row_num = tableOption2.row_num, ModelEntity.temp = tableOption2.temp)-> Assign(RowId = RowId + 1)->End Decide2(IsOption2 = False)-> End] ************************* It is here that I could like to simply the logic using something like _SelectedTable instead of tableOption1 and tableOption2. I would like to know how to replace Source1_CreatedEntity's above step definitions with something like: [Begin-> Assign(maxEntities = _SelectedTable.AvailableRowCount)-> SetRow(_SelectedTable, RowId) Assign(ModelEntity._id = _SelectedTable.id, ModelEntity.row_num = _SelectedTable.row_num, ModelEntity.temp = _SelectedTable.temp)-> Assign(RowId = RowId + 1)-> End] But this replacement does not work. The following works, but I'm searching for a way to do this without replacing the column name with an indexed value: [Begin-> Assign(maxEntities = _SelectedTable.AvailableRowCount)-> Assign(ModelEntity._id = _SelectedTable.id[RowId, 1], ModelEntity.row_num = _SelectedTable[RowId, 2], ModelEntity.temp = _SelectedTable[RowId, 3] )-> Assign(RowId = RowId + 1)-> End]

-

Hi M_A, Just setting the Sequence property to 'Sequence1' should be enough since you set up relational tables. Because you have Maximum Arrivals set to '1', it is going to produce 1 entity type. I would switch your Maximum Arrivals to '35' and number of entities per arrival to '1'. You will also need to set your interarrival time to '0', so all 35 show up at the same time. It might be best to use a second Source object to create your second shift. I would increase the length of the Ride Station Queue in order to see all 6 passengers boarding the Vehicle. I think the network is fine, but hard to debug. Be sure all travel destinations for the Vehicle are possible. Thanks, Ryan

- 6 replies

-

- sequence table

- model trace

- (and 3 more)

-

Hi Ryan, Thank you for the corrections. As always, spot-on advice, that is very appreciated. I do have a few follow up questions. - Do I set the Initial Sequence property to 'Sequence1' or do I need to tell it the row too? 'Sequence1.Sequence'? Sequence 1 is working, but just wondering. - In the SimBit, Entity Follows Sequence With Relational Tables, there are three types of Entities that all flow through the same source with the Source Property, Table Row Referencing, pulling from the JobTable with the Row Number 'JobTable.ProductMix.RandomRow.' For my model, I have two different entities and the source Bldg is supposed to pull BOTH entities with the Table Row Referencing, "JobsTable" with Row Number: "JobsTable.NumberWorkers.RandomRow." But when the model is run, only one entity is ever used. The Table has an ExpressionProperty of Random.Triangular(3,6,9). Is that the problem? The SimBit's table was an actual number. I tried replacing the Expressions with actual numbers and the Entity switched to use the other one but I am still not able to get half the 34 to be one Entity and the other half to be the other Entity. - How do I get the Vehicle to carry its max capacity? The capacity is set to 6, and it only carries up to 4 entities around at any time. This is incorrect, as the Entities are supposed to be grouped into work teams of Random.Triangular(3,6,9) for their initial Source output move. Afterwards they can be individuals or work teams. The Bldg has the Entity Type defined as the JobsTable.Specialty so it should pull from one or the other (like the below mentioned SimBit), and the with Entities Per Arrival Set at 35; and the Entities themselves are set to a population maximum of 17 each and I get a Runtime error of maximum number exceeds limit for the entities. Why doesn't it hit the limit and then pull from the other Entity? - I'm confused about the network you mentioned above. I thought the nodes had to be linked directly (output to input node). So the busy nodes have a lot of paths radiating out from them and it makes it a little messy. Is there a cleaner way to show the routing? Thank you,

- 6 replies

-

- sequence table

- model trace

- (and 3 more)

-

12-hour Shifts with Lunch Breaks and Vehicle Transport

Ryan Welch Lutttrell replied to M_A's topic in SI General Discussions

Hi M_A, 1. This is one is a bit difficult to provide direction on without seeing how the rest of the model is structured. If all your processing times are deterministic and you are using a sequence table to route your entities, then you should be able to add the lunch break into the sequence. Similarly, make sure the sink is included at the end of all your entity sequences. Also, make sure the model run time is long enough to process all employees. That may be why they aren't showing up at the sink. 2. Change your interarrival time to 12 hours, and set your Maximum arrivals to 2. Thanks, Ryan -

Change Server Capacity over time with WorkSchedule

JanainaF posted a topic in SI General Discussions

I have a model where I need to set a server had a maximum of 15 entities from 7 A.M to 10 A.M. I Use the WorkSchedule but I don't know how to limit the number of entities. Can someone help me? *This server it is parallel with other servers. -

Change processing time depending on previous server output

Wsimio replied to Wsimio's topic in SI General Discussions

Thank you for your response! But im not sure: Is this also possible if the model is extended to 6 servers? So each server processing time is dependent upon the one in front? I thought I would need to make different state variables for every server (machine) For example:a machine in a production line needs to slow down with a delay if the machine upfront has reduced or zero speed because of failure. -

Visualize Utilization in Facility Window or Dashboard Reports I have a source – several servers – sink model. It’s a model of an assembly line production meaning that the entity cannot continue to Server 2 if Server 2 is occupied. The servers have different production times and I want to compare the different utilizations of the servers. I did this over the experiment window and the expression Server1.ResourceState.PercentTime(1) . In a next step I want to visualize these utilizations next each other with something like a bar chart. I came up with two possible ways of doing so but both didn’t work. In the facility window with the animation tools like the linear gauge. The problem here is probably that the expression “PercentTime” has no reference to what the overall time is, while the model is running, and therefore the gauge shows constant 100% the whole time. Or in the experiment window in the dashboard reports which doesn’t have percent time as a response. Is there any other way of visualizing the utilization?

-

Hello, Would you be able to provide background on your use case? My first response would be no, but I"m curious what your use case is. I believe we should be able to find a solution (perhaps using a function) if you can provide a little background on the use case. Thanks, Jason

-

Hello I need to forecast costs using an exponential model and then use it for simulation input. Basically, I want to tell simio that the price for this hour is given by this equation, and this price is used at this place and then minimized as part of response in optquest. Any ideas how this can be done? TIA!

-

Conditional Routing (by link weight) is not working

AlexDCave replied to AlexDCave's topic in SI General Discussions

Hello, In response to JBeltran: I can figure out how to grab the variable member.priority. If I was able to do that, the rest would be easy I think. I played around with the search function and it didn't seem to work (maybe I am using it wrong?) In response to ATSProThiede: The instance I uploaded was only using the InitialPriority because that was my latest attempt. I had attempted other options that I noted in the OP. Also, you can change the InitialPriority away from 0 in the entity's options. My problem is that only the parent's values are able to be seen. I have no criteria to change the ModelEntity.Priority because the decision needs to be based off of the entity type of the member. The file you attached does not work properly. I turned off the H1BUnits source, so everything should go to packlane1, yet some go to packlane2 or even bypass both to the sink. I have done quite a bit of digging and have found probably 3-4 other feeds that were never answered as member data seems to be difficult to access. Thank you both for the feedback. Please let me know if you have other ideas or I didn't properly test your reply. Best regards, Alex -

Hello In my simulation model I need to scan rows for maximum value within a column, and then assign this maximum value to say a state variable so I can reference it in the responses to optimize using optquest. It would also be useful if I can add all the values within the column and use that instead for optimization. I am not quite able to figure out how to do this. Would appreciate any help in pointing me towards right direction! TIA!

-

- process

- optimization

-

(and 3 more)

Tagged with:

-

I have recreated a system to see theoretical capacities and it has multiple sources (1 parent and 2 different members that I combine). I have turned off balking because that interferes with my unit mix. I have also changed all buffers to a finite number and crossing logic capacities to 1. Even with all of this, I still hit the 2500 max entities and an error pops up. This system should only be able to hold a couple hundred, so I know I don't need to adjust my capacity size. I made the units stop at the 1st server so I could isolate the issue and it appears to be upon creation or in the combiner. My question is, how can I have unit production pause (not stop) when the buffers and capacities are full? I have attached the file for reference. APS Design 2.spfx

-

Hi George, thank you for your response! If you have a other question. You are welcome :-)! Have a great day too! Best regards Pascal

-

Dynamic destination based on multiple conditions

craigw replied to craigw's topic in SI General Discussions

As an update to this, I think I have (at least so far) found something which provides the desired behaviour and will detail below for others. I used the SimBit 'SelectServerWithShortestLine' as a reference. I created a Node list with the inputs nodes at each Sink listed. I created an integer Property to hold the variable which represents the maximum number entities that can go to a sink (e.g. MaxContainerCapacity). On the feeding TransferNode I changed the 'Entity Destination Type' to 'Select from List' and selected the list created in Step 1. Change 'Selection Goal' to 'Smallest Value' and set the 'Selection Expression' to Candidate.Node.AssociatedStationLoad, which accounts for everything en route, in the queue and processing at a node. Therefore, the select goal is to minimise this station load. I set the selection condition to (Candidate.Node.AssociatedStationLoad + Candidate.Sink.InputBuffer.NumberExited) < MaxContainerCapacity. Which is saying only select the Node found in Step 4 if the sum of the station load and the number of entities that have 'exited' the Sink are less than the MaxContainerCapacity. -

Can you limit the amount of entities in the simulation?

GFurtado replied to jush198's topic in SI General Discussions

Alternatively, you could limit the number of entities created by the source. Check Maximum Arrivals property under your source's Stopping Conditions. -

Can you limit the amount of entities in the simulation?

gocken replied to jush198's topic in SI General Discussions

Drag and drop an ModelEntity into the facility layout. Then, select ModelEntity and see "Maximum number in system limit" property under "Population" section of properties window. Set this property as how many entities you desire throughout the simulation run. -

Run Length Reference Property Experiments

jrobinson replied to jrobinson's topic in SI General Discussions

This is just what I need! I was thinking of trying something like this. Thank you so much for your kind response! Best Regards, Jim