Search the Community

Showing results for 'processing contents'.

-

You want to make the servers have a Capacity Type of Schedule and follow the default Standard Week. If you don't want to give them a lunch break, just change the definition of the Standard Day. Leave the default Off Shift Rule of Suspend Processing. The easiest approach for arrivals is to have a Source with an Interarrival time of 4.33 weeks (or 4 weeks) and an integer random distribution for the Entities Per Arrival. Doing a "first Monday" is possible, but a bit complicated because Simio time does not have the concept of Month because months are of varying size. You could probably specify the initial Time Offset to be early in a month, then maybe make the interarrival time be something like DateTime.DaysInMonth(DateTime.Month(Timenow),DateTime.Year(TimeNow)) which would make the next arrival be exactly one month later (same day of the month). When you say you have no buffers, what do you mean? If an entity arrives when all servers are busy, should it be balked (possibly disposed) or should it wait somewhere like on the server input node, on a path or in the Source output node? If the above arrival approach isn't exact enough, you can put exact arrivals in a data table. The arrival time could be specified at any exact datetime you desire and still have the Entities Per Arrival be a distribution.

- 2 replies

-

- server

- work schedules

-

(and 2 more)

Tagged with:

-

Hi all! I am simulating a facility with nearly 40 servers, each one starting with some entities in the input node at initialization and having a different capacity. Each server has a 0 input buffer capacity. My entity creation is currently set to having an interarrival time to be 4.33 weeks (1 month) with a random number of entities created. Currently, it runs 24/7 and does not care about the time, but I want to incorporate that. How can I make it so that the entities arrive once a month, let's say the first Monday, at 8am? How can I make it so the servers are only processing between 8am and 4pm Monday - Friday? The work schedule doesn't seem to work for me, but I could be doing it wrong, since I have a 0 input buffer, which I can't change as it's part of my routing logic for overflow. I would be happy with using timers or a process logic if someone can explain it to me. Ideally, the entities only arrive when it's during the working time, and the entities remaining after 4pm are just put on hold until 8am the next day. Thanks in advance!

- 2 replies

-

- server

- work schedules

-

(and 2 more)

Tagged with:

-

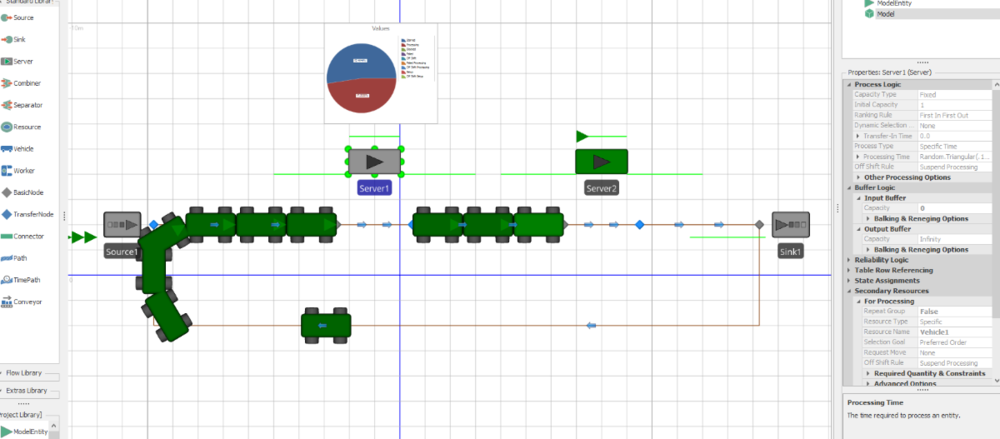

Happy new year! One thing that I noticed is that with this model, the server never have a state of "blocked". I increased the processing time of Server2 and added a status pie to Server1. The server 1 is either Processing or starved, but never blocked according to the pie. But it should be blocked part of the time since I increased the processing time of Server2 to force this. It looks like the Server1 only accepts a new item to process if the path between Server1 and Server2 has room for at least one more vehicle. So the time that it should be blocked is considered as part of the "Starved" instead. I tried to figure out why this happens without success. Anyone knows why this happens? I attach the model to the post. Thank you! Input Server1 not blocked.spfx

-

Changing Sequence table over time

Rebecca Obasi replied to antonio6vieira's topic in SI General Discussions

I'm trying to do something similar to do this where an order has 4 different routes or paths it can go (My model currently doesn't have paths). I created 3 separate sequence tables and created a process logic depending on if a certain workstation is already processing an order/entity, to go through this sequence. For some reason, whenever it gets to the "set row" step, there is a table reference error mentioning "no entries found" if though in the process step, I specify which row to start the new sequence. What is the reason behind this error? -

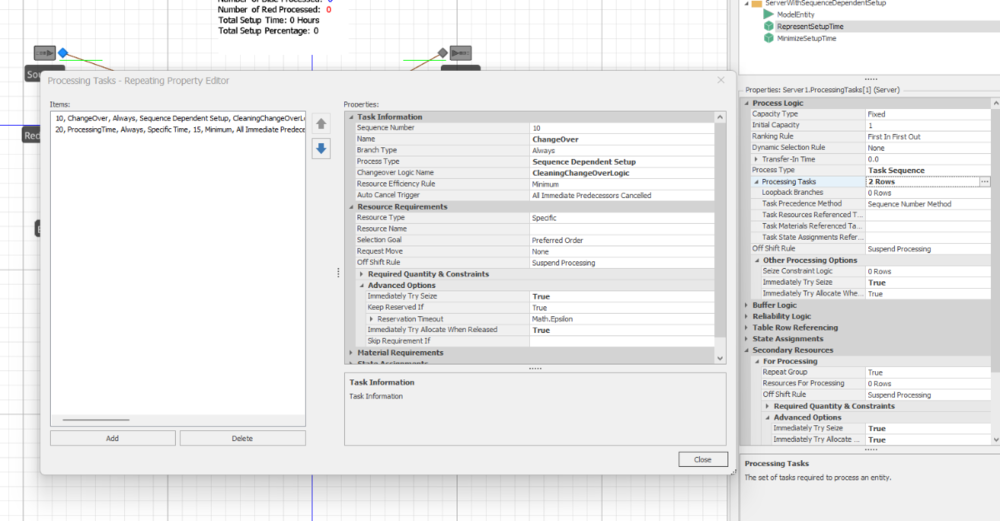

Hello, I'm having strugles trying to configure the setup for the next process: some entities have a diferent processing time and setup time, before to enter to be processed in the workcenters, the workcenter have to be cleaned. I looked the simbit, "ServerWithSequenceDependenrSetup" but I'm confused with the configuration of the processing task. I dont know why we have two lines and o why only one have associeted the change-over matrix.

-

Pick up entitys in different locations and drop them off to a server

Gashi replied to Gashi's topic in SI General Discussions

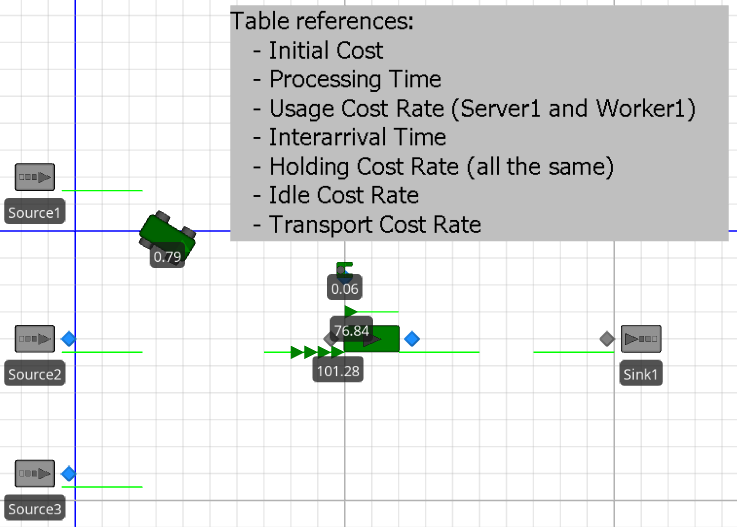

Thank you for the quick answer! Yes I know the ABC Costing Calculation in Simio, but I forgot to add, that I want to divide the total transport costs among the individual components that are transported at the same time. I think it would work with the calculation: TransportCostRate / TransportQty * TransportTime , so I just have to track the transport quantity for example with MyVehicle.RideStation.Contents. And my small model is just a example. My goal is to set up a cost analysis tool with calculation of transport costs, bufffer costs, processing costs, ... for finished production models. And for example the buffer costs, i want to use more specific cost rates (footprint dependence for example, ...) The disadvantage of my custom way is that so far I can determine the costs only at certain points (for example pick up and drop off) in time and not "continuously" as it is now with the automatic calculation. Or do you know if there is a way to adjust these "custom" times so that they are also calculated continuously? -

How to track the different values of ModelEntity.Cost

Gashi posted a topic in SI General Discussions

Hello, i am using the Financials Properties in Simio. In this simple model, i have parameters for different cost types (see in the picture). All the cost types are used with the default financial states. The dynamic label of the ModelEntiy shows the expression "ModelEntity.Cost", so it roll all the cost components up in the particular entity. The entity in the processing has a value of 76.84. (rolled up) Now my question is, is it possible to see all the cost components for all my model entity, for example as a expression in a floor label or in a data table. Thank you! -

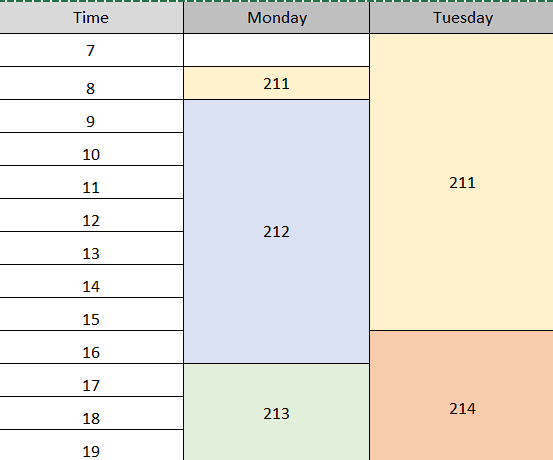

there are several easy ways to do this. 1) Subclass the Resource or Worker object with the only change is to add a property or state (ex PTime) to hold the processing time specific to that resource. 2) Put your process times in a table and reference the correct table row for the doctor that is working. The SimBit WorkerPoolWithEfficiency does something somewhat similar.

-

Hi, everyone I am developing a postgraduate project related to hospital OPD simulation. In one examination room, there will have a round 5 to 6 doctor using this room during the week. Now I am facing one problem, because every doctor process have difference processing time(function) as picture below(The number is doctor ID). Is there any method to set a difference process time during every shift in one server? or I have to create a process for this them?

-

Hi. I am trying to simulate aircraft boarding considering different groups of passengers with different speeds. I do not know how to define different speeds for each group that I have. one more challenging problem that I have is that I want to have a waiting time before each seat if the passenger have luggage to let them store their luggage. But I do not want to impose the processing time to other passengers. How can I impose the processing time for, lets say 4 passengers that want to take the seat and let the others go to the next server in the aisle?

-

Server Capacity Depends on # of Seized Resources

Liz Millar replied to nObeso23's topic in SI General Discussions

Hi Nicolas, I would investigate the Server property called Initial Capacity. This sets how many units of capacity are going to be available for the Server. You could also change this during the run by Assigning the Server's CurrentCapacity State Variable. I suggest checking out the SimBit titled "Worker Uses Work Schedule". You can access the SimBits in the Support ribbon in Simio. In this SimBit, I recommend changing the Initial Capacity for the Servers. You could set them to '6' or any value. When you run, you will see that the entities only move into the Process Station when they have successfully Seized the Secondary Resource. So even though there is 6 units available only 1 will be use when the Worker is able to process the entity. You can also experiment with giving the Worker a different Initial Number In System value so there can be more Workers. You will still see the same behavior; the number of entities that move into the Server for processing will be the number of Workers that were available to be seized. Happy Modeling! Liz -

So lets say task B is dependent on Task A, hence Task A has sequence value 10 and Task B has sequence value 20 (Task A preceeds TaskB). Task A branch type should be conditional and for the condition formula should be written in to the "condition or probability" fieldç For Task B enter the processing time and other data as usual. If the auto-cancel trigger is set to "All immediate predecessors cancelled" (as it is by default), Task B will be cancelled if the condition for Task A didnt return true value. Hope this helps

- 1 reply

-

- 1

-

-

You can also use produce consume material method to add requirements to a process or processing step. You can see it when you change the process type to Task Sequence from Specific time. You can add more than one material requirement by adding tasks in parallel with same sequence number and specificying the material name and quantitiy that will be consumed for each parallel task. In that way you dont need to create and destroy uncessary entitites.

-

Hello Javiera, Based on how the model is set up, Guardian_1 and Guardian_2 follow Work Schedules with specific Day Patterns. Looking through the Trace lines, it appears that Pedido_PU.597 arrives and seizes Guardian_1 which, not much longer after it was seized, was scheduled to go off shift based on Work Schedules. The current Off Shift Rule is 'Suspend Processing' which causes the entity being processed to be suspended until the exact Resource is back on shift. To allow the entity to choose an alternative on shift resource, the Off Shift Rule property can be changed it to 'Switch Resources if Possible'. Best Regards, Khaled

-

Worker stagnates after some simulation time

piedz replied to piedz's topic in SI General Discussions

Hey, Thanks for your reply. No I have not used a move or size step, I use the worker as a resource. I use it for processing, and have a resource seize and release before processing. -

Thank you very much for your help, but simio says I can't use the Release step with the server because I don't have any resources to release. In addition, although the Search step works very well, since I don't have any step that keeps the entities inside the server even if they are not called, they continue to leave the server and merge with entities that should not be merged. If I set the processing time to infinity, despite calling entities with the Search process, the entity does not leave the server. I tried to condition the processing time of each entity according to the "Ventana_de_entrega" state, but as expected, it is not the most appropriate. 21.10.spfx

-

Hi There, I have lots of experience in simulation but I'm new to Simio - my apologies if my Simio vocabulary/conceptualization is off or if this question has been asked already. I'm working to build a queue model simulation with a network of services and multiple staff types. In my mind, it makes the best sense to do this using the standard library of servers and resource pools (to visualize the network for stakeholders and be able to model multiple staff with different schedules that can each respond to multiple services). Right now, I am starting with a single stage M/M/c type queue to make sure that my implementation is correct before scaling this upwards. I checked out the SimBit titled 'Source – Server – Sink' that has three different M/M/c implementations; however, none of them use Resource Pool objects or combine process triggers with the standard library. I was able to implement a basic model that tries to combine a resource pool with a server by triggering separate Seize and Release process triggers on entry to the server object and after the processing time is completed, respectively. It runs without error; however, the results for average time in system (calculated by an average of a tally statistic that is only recorded for every 500th customer/entity), the results are one third less than in a scenario where I don't use a resource pool and set the capacity of the server explicitly, (which I validated against M/M/c formulae results). Does anyone have tips for how to link servers and resource pools and troubleshoot this scenario? Is there a SimBit or other example out there that is relevant? Am I triggering the seize/resource processes at the wrong points in time? Or is my framework for how to conceptualize this in the Simio environment missing a key concept? Thanks!!

-

You need to put the search, release and transfer steps into the Add-on Process Triggers "Parent Entered" of the Combiners. For example, for the "Juntar_secos" combiner, at the "Parent Entered" Addon process, you would search for Slots.Processing.Contents, matching "Candidate.ModelEntity.Id_Del_Pedido == ModelEntity.Id_del_pedido". After that you should use a release step, to release Server "Slots", and a transfer step to transfer what have been found to Output@Slots.

-

Well, first thing, you don't need your entities to be bouncing between the output and the input of your server like that. If you want to use it as sort of storage, set both the processing time and the capacity to infinity. After that, at the moment that the parent entity enters the combiner "Parent Entered" you could search the queue of your storage using a search step with something like "Server1.Processing.Contents", with the condition of "Candidate.ModelEntity.State == ModelEntity.State", release the server and transfer what have been found to the output. You need to take some care on some situations, like what if the parent entity arrives first at the combiner then the member at the storage? And some care with batching quantities aswell. But I think you can handle it.

-

I have a task sequence model using the Immediate Predecessor method. I would like to add in a rejection rate for each task, and then a unique processing time for the rework. Is this possible?

-

Hello, I'm working on a problem where at some point a worker will transport a specific amount of pallets. Whereafter these pallets are processed by a server and a server wil process them. Once processed, a different worker (or the same worker) will move the pallets to the next server. How do I save these entities as a batch and let workers know how much pallets they can process? At the moment I have two approaches. One where I create a 'batch' as an entity and assign to it the amount of pallets. The 'problem' in that case is that I do need to count the amount of pallets at a server, since it has a certain capacity. And sometimes an initial batch whitch comes from a truck needs to be split to fit the capacity of workers. But once this would be fixed, the worker will always transport the right amount of pallets. A second approach that I have tried is to create the pallet entities normally, and assign a 'PalletHistory' in the modelEntity properties, but I find that after processing I can't find this palletHistory for the workers to get a sign of how many pallets to transport. Do any of you guys have an idea how I can approach this? Greetings

-

I have a problem with producing/consuming within my TaskSequence. I need multiple task operation (prepare -> work -> clean -> produce), where I'm also consuming/producing material defined inside my BOM table. When I'm trying to reference material requirements on the BOM table I get an error: "Could not determine the row to use in the referenced table or repeat group ...", references to the processing time and other parameters are working fine. If I set the task sequence reference to the BOM table, then material requirements works OK, but I could not add more than 1 task. I'm using version 15.241.27814 . Best regards, Žan

-

MOSIMTEC is looking for smart people to solve interesting problems for the world’s leading organizations. MOSIMTEC uses simulation modeling to help our clients understand the best ways to solve their most complex challenges. At MOSIMTEC, you will work on exciting projects covering a wide range of domains including material handling, mining, chemical processing, manufacturing, supply chains, maritime and port operations, and healthcare. You will be joining a diverse team of passionate individuals that can support your growth as a simulation consultant. Entry to early career positions will be located in Herndon, VA or Nashville, TN. Occasional travel to client locations or company-wide meetings will be required. Learn more & apply at: https://www.indeed.com/cmp/Mosimtec-1/jobs

-

I was inspired by the VehicleX3 (vehicle with operator) that was shared on this forum. I would like to use this type of VehicleX3 with an operator who is a worker to simulate a process where the operator is required to take breaks after certain periods of activity. To implement this logic, I think it would be helpful to have Reliability Logic for the worker object in Simio. This doesn't seem to be part of the standard library so I tried to create my own subclass version of Worker with the Reliability Logic "copied" from the Resource object. My attempt to implement this custom object seems to work as long as the custom worker object doesn't "move". If the custom worker object moves, I get the Runtime error "Possible infinite loop detected in process logic". Any assistance in getting the logic working properly, or pointing me to an existing custom worker object that has Reliability Logic incorporated would be greatly appreciated. I'm attaching my small example model to illustrate the error when the worker (P1) is required to move to the Dest1 server as a required secondary resource for processing. WorkerWithFailuresExample.spfx

-

Hi, I have a production line with 2 sources. The arrival of entity A in source 1 triggers an arrival of entity B in source 2. Entity A and entity B then enter their respective servers for a processing time. Entity A is processed at table_openings between 10 and 15 minutes with probabilities whereas Entity B is processed at table_MF for 10 minutes. The process type is task sequence. Both Entity join at a combiner. Entity A is the parent and Entity B is the member. Afterwards, the combined entity continue along the production line. I have expected processing times for each task at each server. Before starting a task, a process starts where a state statistic registers the state processing time of the entity. I also put list state to verify the schedule utilization. I have verified visually and the state value for processing time is correct for every station while the simulation is running. What I have observed is that the state statistic average processing time for the servers before the combiner is the expected value, however, all the other stations are 10 minutes off. The simio output has the right processing times for all the stations after the combiner but not for the two stations before the combiner. Moreover, the list state average time busy value are ok for all the stations after the combiner but again the station before the combiner, it gives the total number of minutes it was busy. Also, if i do the average of the state log observation for each station in excel afterwards, I get all the correct processing times. I am guessing it has something to do with the combiner, but I am lost. How can the processing time for table_MF be 10,48 when the processing time is a fixed 10 minutes in the facility window? Why is the list State MF and OP different from all the other list states? Thank you for your help!