Search the Community

Showing results for 'process time depending on entity count'.

-

Changing Sequence table over time

dsturrock replied to antonio6vieira's topic in SI General Discussions

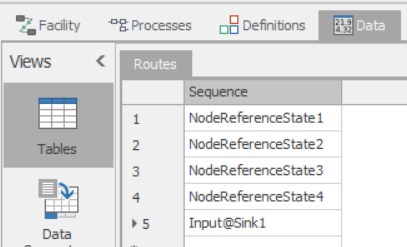

I have attached a simple model using model states to illustrate. I think it should work in a similar fashion using entity states. First, I define the states: Then use those states as Sequence destinations: Until you provide each of those states a value, the Sequence will make no sense and the entity won't know where to go. So on the Source I use an Assign to initialize all the values. This will direct the entity sequentially through Servers 1-4, and then to the Sink: Finally, just to illustrate the technique, on the output node of Server3, I interrupt the normal sequence by Assigning it to instead go to Server5 as its 4th step: If you convert these states to Entity states instead (I was just lazy), I think it should work the same but allow you to selectively override any Sequence Step at any time. UsingStatesInSequences.spfx -

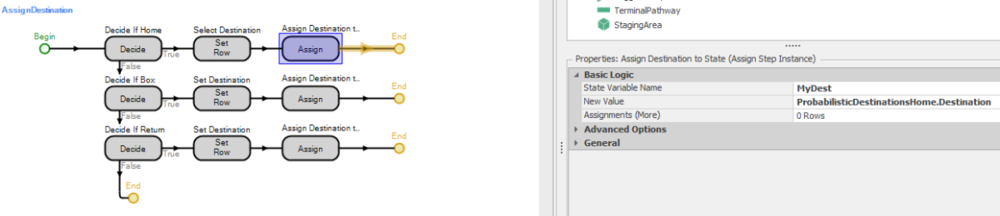

Hi David, I am trying to get your option 3 to work in my model, as the solutions sounds brilliant. I created an Add-On Process that probabilistically assigns destinations to the Entity and by assigning the destination node to the Entity's State Variable MyDest. In the Routing Logic, I've set the Initial Sequence to the sequence table called Routes that holds all possible routes. However, the entities now only follow the first sequence Routes (Input@LoadingDock9, Input@Sink_HTB), whereas Entities with the destination Input@Sink_RTM should follow the sequence Input@LoadingDock10, Input@Sink_RTM. How can I let the Entity follow a specific sequence from my Sequence Table Routes?

-

I am working on a model of a production line where one of the work stations is a long work table with six workers at it. These workers perform identical assembly tasks and will sometimes leave the table in order to transport finished items to the next step in production. I am currently representing the work table as a single server. I am wondering if it is possible to dynamically change the server's capacity based on how many workers it is able to seize at a given time. Essentially, the server can process with just one seized worker but can seize up to six. Is this something I can implement with Simio's built in functionality, or is it easier just to represent the six spots in the table as individual servers? Thank you!

-

Server Capacity Depends on # of Seized Resources

Liz Millar replied to nObeso23's topic in SI General Discussions

Hi Nicolas, I would investigate the Server property called Initial Capacity. This sets how many units of capacity are going to be available for the Server. You could also change this during the run by Assigning the Server's CurrentCapacity State Variable. I suggest checking out the SimBit titled "Worker Uses Work Schedule". You can access the SimBits in the Support ribbon in Simio. In this SimBit, I recommend changing the Initial Capacity for the Servers. You could set them to '6' or any value. When you run, you will see that the entities only move into the Process Station when they have successfully Seized the Secondary Resource. So even though there is 6 units available only 1 will be use when the Worker is able to process the entity. You can also experiment with giving the Worker a different Initial Number In System value so there can be more Workers. You will still see the same behavior; the number of entities that move into the Server for processing will be the number of Workers that were available to be seized. Happy Modeling! Liz -

Hi I've got a model where the situation is like this: 1. 3 Worker: W1 W2 W3 2. 3 Server: S1 S2 S3 On Monday (work schedule), W1 will work in S1 in the morning and work in S2 in the afternoon. W2 will work on S2 in the morning and S1 in the afternoon. But on Tuesday, W1 will work in S2 in the morning and S3 in the afternoon. W2 will work in S3 in the morning and S2 in the afternoon. The server properties in the secondary resource are "select from the node list." But since the node list for S1 and S2 contain both W1 and W2, and they both have the same hour of working (4+4), when the S1 server seized the resource on Tuesday morning, instead of W1, W2 got allocated instead( W2 should be in S3). I have tried: 1. Using server selection goal to " smallest distance," but it didn't work since the worker will keep swapping the room every day 2. Giving each worker a new initial value and setting the selection goal to "smallest value," but they still have the issue. 3. Try setting idle action for the worker to stay at the node, but sometimes the worker will go to the wrong destination from the first entity, hence no one working in the other room. (2 worker stay together) Is there any method to realize this idea? Thanks in advance

-

Thank you very much for your help, but simio says I can't use the Release step with the server because I don't have any resources to release. In addition, although the Search step works very well, since I don't have any step that keeps the entities inside the server even if they are not called, they continue to leave the server and merge with entities that should not be merged. If I set the processing time to infinity, despite calling entities with the Search process, the entity does not leave the server. I tried to condition the processing time of each entity according to the "Ventana_de_entrega" state, but as expected, it is not the most appropriate. 21.10.spfx

-

Hi There, I have lots of experience in simulation but I'm new to Simio - my apologies if my Simio vocabulary/conceptualization is off or if this question has been asked already. I'm working to build a queue model simulation with a network of services and multiple staff types. In my mind, it makes the best sense to do this using the standard library of servers and resource pools (to visualize the network for stakeholders and be able to model multiple staff with different schedules that can each respond to multiple services). Right now, I am starting with a single stage M/M/c type queue to make sure that my implementation is correct before scaling this upwards. I checked out the SimBit titled 'Source – Server – Sink' that has three different M/M/c implementations; however, none of them use Resource Pool objects or combine process triggers with the standard library. I was able to implement a basic model that tries to combine a resource pool with a server by triggering separate Seize and Release process triggers on entry to the server object and after the processing time is completed, respectively. It runs without error; however, the results for average time in system (calculated by an average of a tally statistic that is only recorded for every 500th customer/entity), the results are one third less than in a scenario where I don't use a resource pool and set the capacity of the server explicitly, (which I validated against M/M/c formulae results). Does anyone have tips for how to link servers and resource pools and troubleshoot this scenario? Is there a SimBit or other example out there that is relevant? Am I triggering the seize/resource processes at the wrong points in time? Or is my framework for how to conceptualize this in the Simio environment missing a key concept? Thanks!!

-

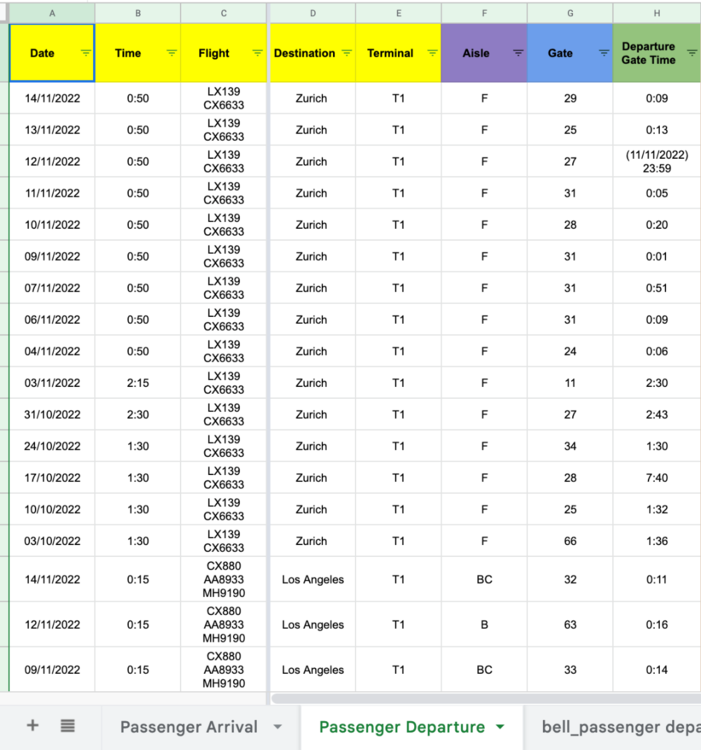

It sounds like you are already set up to use a Source with Arrival Mode of Arrival Time and the Arrival Time Property of MyTable.TimeOffset (assuming that your table above is named MyTable). If the column named Object in your table above is the entity type you want to create, then specify the EntityType in the source to MyTable.Object. If the entity you want to create is something different, then add that new column to your table (say PassengerType) and specify EntityType as MyTable.PassengerType.

-

Hello, I'm working on a problem where at some point a worker will transport a specific amount of pallets. Whereafter these pallets are processed by a server and a server wil process them. Once processed, a different worker (or the same worker) will move the pallets to the next server. How do I save these entities as a batch and let workers know how much pallets they can process? At the moment I have two approaches. One where I create a 'batch' as an entity and assign to it the amount of pallets. The 'problem' in that case is that I do need to count the amount of pallets at a server, since it has a certain capacity. And sometimes an initial batch whitch comes from a truck needs to be split to fit the capacity of workers. But once this would be fixed, the worker will always transport the right amount of pallets. A second approach that I have tried is to create the pallet entities normally, and assign a 'PalletHistory' in the modelEntity properties, but I find that after processing I can't find this palletHistory for the workers to get a sign of how many pallets to transport. Do any of you guys have an idea how I can approach this? Greetings

-

I've hunted through the forums and online and cannot seem to find a fix for my simple application. I have 1 worker operating multiple work centers (Simio server). He should finish all work at one "server" before moving on to the next server. Otherwise, his utilization goes down substantially due to him bouncing back and forth between the servers and walking all day. I.e. Server A: Parts in Que: 1,2,3,4,5,6 Server B: Parts in Que 1,2,3,4,5,6 Worker is doing A1, B1, A2, B2, A3, B3, A4, B4, A5, B5, A6, B6 with a walking time inbetween each part. I want worker to do A1, A2, A3, A4, A5, A6, walk, B1, B2, B3, B4, B5, B6 I would prefer not to use constraint logic due to the complexity. I've read that somehow the solution seems to lie in setting the Secondary Resources "Repeat Group" status to false and attempting to use the "keep reservation" function, however I have not had any luck. I set the "keep reservation if" function to "ServerA.InputBuffer.Contents.NumberWaiting > 0" which in theory should fix the problem, however my worker continues running back and forth. Any help would be appreciated. Thanks, Jon

-

Hi All, is there a way to make the server waiting for two (or any defined number) entities to begin the processing? I would like the server to begin processing only when two entities has arrived. Then the two entities leaves the server at the same time, and other two begin being processed. Can I do it without defining a process?

-

Hi , I have a system with a combiner, that combines different variations of batches. On exiting the combiner the crane picks the combined entity up and drops up at a server. Each of the different batches will have a different load and unload time. Is there a way to do this? Basically, does batch contain product ‘A’ if so crane time is ‘X Mins’ Does batch contain product ‘B’ if so crane time is ‘Y Mins’ Thanks for any help!

-

Worker to "empty" queue before moving to next server.

ViniciusF replied to jopendle's topic in SI General Discussions

Hi, One way to do this is put a Dynamic Selection Rule: Smallest Value First on the Worker, with the value expression of: Candidate.Entity.DirectDistanceTo.Object(Worker). This could work. -

Hi, I need to execute a process only during three hours per day, but I cannot use the timer because It just represent a point in time and I need a period of time Someone can recommend me an simbit, or give me some advice in topic Thanks in advance

-

Worker to "empty" queue before moving to next server.

jopendle replied to jopendle's topic in SI General Discussions

This helped in some applications, especially use cases where multiple servers are in series and I need the operator to focus on the start or end of the process. Thanks! However, when servers are in parallel the operator tends to run back and forth between them. If I were to assign a higher priority to one line, the worker would focus on that line only. i.e. if he empties the que of parts in the input buffer of Server 1, he goes down to work on only 1 part at Server2 before going right back to Server1. Rather, I'd like for the operator to clear all parts in the que at Server1 before walking down to Server2 and vice-versa. I've tried doing this through process logic however I get stuck trying to evaluate which server the worker is supporting. -

Hi all, I made a model of a production line (starting with 2 servers) and I am wondering whether it is possible to change the processing time of the second server based on the actual output of the first server. Theoretically seen the processing time of the server 2 = Speed of server 1 * E , in which E is a fixed formula (connected to server 2) to correct the speed. So if the first server performs according to expectation (without failures) for example 40 the processing speed of the second server is equal to 40*E with a delay of the conveyor time between server 1 and server 2. If the server has failure and thus have a lower output (for example, 30), I want to change the processing time of the second server accordingly to 30*E with a delay of the conveyor time between server 1 and server 2. Does anybody have an idea of how to do the following: How can you monitor the actual output of the first server at each timestep? Is it possible to fix the proposed formula and use it in an add-on process? How can you take the conveyor time delay into account (using a delay step in the add-on process?)? I am quite new to the software so I am not sure whether it is possible to model this in Simio. Thank you in advance!

-

How to increase the distence between entity to entity ?

River replied to River's topic in SI General Discussions

Many Thx for your help. We have another problem : As we want to be more realistic, we have the data from Hong Kong. How can we input those data (such as departure Gate time) into the simio to let the enttity will departure as schedual ? We already have atleast one month data, can you show us how to make the entity dearture as the time we set accordingly? -

Hi All,

In my model, I have a transfer node and the entity could go to either of the next 2 serves as in the picture.

I have assigned product number(1,2,3...) to entities …., if product “1” moves from transfer node to S1 and the next product is also “1”, it should also move to S1 and if the product number changes its should change the server to S2. So the entire batch gets processed on one server.

After processing from S1 and S2 the entity should flow in batch so that at S3 I have batch production

Right now the entities go based on “By Link Weight” and randomly goes to the server which affects S1,S2,S3 servers setup time

Any thoughts how can that be achieved, I do not want to setup a sequence table.

-

Pick up entitys in different locations and drop them off to a server

Gashi replied to Gashi's topic in SI General Discussions

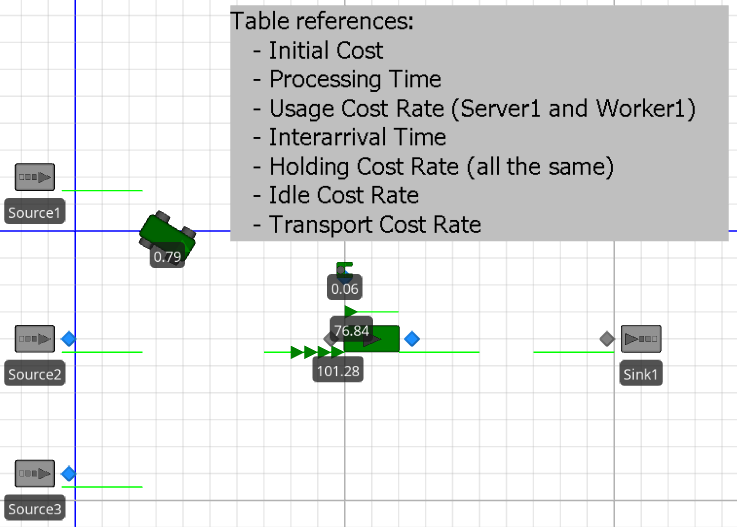

Thank you for the quick answer! Yes I know the ABC Costing Calculation in Simio, but I forgot to add, that I want to divide the total transport costs among the individual components that are transported at the same time. I think it would work with the calculation: TransportCostRate / TransportQty * TransportTime , so I just have to track the transport quantity for example with MyVehicle.RideStation.Contents. And my small model is just a example. My goal is to set up a cost analysis tool with calculation of transport costs, bufffer costs, processing costs, ... for finished production models. And for example the buffer costs, i want to use more specific cost rates (footprint dependence for example, ...) The disadvantage of my custom way is that so far I can determine the costs only at certain points (for example pick up and drop off) in time and not "continuously" as it is now with the automatic calculation. Or do you know if there is a way to adjust these "custom" times so that they are also calculated continuously? -

Referenced definition type and executing type error

Gashi replied to Gashi's topic in SI General Discussions

Thank you for the quick answer! But i get the same error type when using MyModelEntity instead of MyVehicle. Referenced definition type "MyModelEntity" does not match executing type "MyVehicle". In the Transport Logic of the Output@Source1 (Properties), i have the MyVehicle as a transporter. It seems like both of them are executing the add on process trigger... -

How to track the different values of ModelEntity.Cost

Gashi posted a topic in SI General Discussions

Hello, i am using the Financials Properties in Simio. In this simple model, i have parameters for different cost types (see in the picture). All the cost types are used with the default financial states. The dynamic label of the ModelEntiy shows the expression "ModelEntity.Cost", so it roll all the cost components up in the particular entity. The entity in the processing has a value of 76.84. (rolled up) Now my question is, is it possible to see all the cost components for all my model entity, for example as a expression in a floor label or in a data table. Thank you! -

Hi All, In examining a medical system, we have a requirement to log snapshots of the patient details being processed at specific points in time during experiment replications. For each server, we would like to know the state values for entities currently in processing in each functional area ( a mix of servers and storage queues). I suppose I am looking for an "Easy Button" which would quickly capture a Work In Process snapshot of the system. Are there any thoughts on accomplishing something like this? Any kind comments would be greatly appreciated. Thanks, Jim

-

hey Simio insiders, I am experiencing a problem using rate tables. I want to utilize rate tables to generate a non-stationairy poisson process. I have generated a table with values for 21 hours and the last three hours should be 0. I thought i could either use a rate table with 24 intervals with the last 3 intervals given a value of 0 arrivals. Or i can set a stopping condition at 21 hours. I have set the start time of my simulation at 07:00 (due to worker schedules). I am experiencing the following problems. The rate table seems not to generate the right values at the right times. (i have tried both setting the 0700 values at 0000 and 0700 in the rate table). The rate table does not stop after generating 21 hours of arrivals. In my eventual experiments i want to use 2 different rate tables (using different sources) that I scale to vary arrivals in a specif way. It is quite important that I understand how I can make this work. Do any of you know how I can fix this?

-

Hello Gosia, I recommend using two State Variables to record the start and end times using the function TimeNow upon the Vehicle’s arrival to a Node. A Decide step is needed to check if the Current Node is different from the Destination Node and that is when values of the State Variables are assigned using the Assign step. The Processes will be set at the Vehicle’s Add-On Process Triggers On Entered Node and On Exiting Node. You can visit the SimBit section under the Support ribbon and check the SimBit titled “Record Distance Traveled” to see a similar example. Another approach is to create a custom Vehicle Class and use a Level State Variable instead of the two Real State Variables to collect information of the travel time. I suggest exploring the Level State Variable in the Help pages under the chapter titled “States”. I recommend checking the SimBit titled “Using Level States (from project Infection Propagation Using Continuous And Flow)” as well. Best Regards, Khaled

-

You can also use produce consume material method to add requirements to a process or processing step. You can see it when you change the process type to Task Sequence from Specific time. You can add more than one material requirement by adding tasks in parallel with same sequence number and specificying the material name and quantitiy that will be consumed for each parallel task. In that way you dont need to create and destroy uncessary entitites.