Search the Community

Showing results for 'output table functions'.

-

Hello, I am trying to run over 100 different scenarios in a design of experiments approach. I have a data table that references different vehicles and sources to set certain conditions, but I'm having a hard time converting the table (which has 100 rows) into the experiment section to run. Any advice appreciated, thank you!

- 5 replies

-

- table referencing

- experiment dashboards

-

(and 1 more)

Tagged with:

-

Hi everyone! In the project I'm developing I need something similar to what was done on the Simbit "EntityFollowsSequence". The difference is that I need to be able to change the destinations (update the contents of the sequence table) over time (the number of rows of the table can be fixed, although it would be ideal if they could be dynamically created). Could someone please explain how it would be possible to do this? My edition is NOT Enterprise. Thanks.

-

Hi I have an entity that is moved through the network via vehicles. The vehicle will drop of the entity at the first server which then gets processed through two servers. I would like to use the vehicle that dropped off the entity at the Input to the first server to be used to pick up the next entity at the output of the second server. Is there a way to save the exact Vehicle that was used and specify that as the Vehicle to use at the second pick up point? Hopefully to a global variable and not to the entity (in my actual model, the entity going in to Server 1 is not the next entity coming out of Server 2). At the moment I am using 'Reserve Closest' as the reservation method at Server 2. I know that is incorrect, but I'm not sure how to setup this up using the other methods. In the attached model, process works for the first entity, but does not for the second entity onwards. Due to other limitations in the model, I need to have the Vehicles to 'Remain in Place' during idle. Thanks in advance for the help. SpecificVehicle.spfx

-

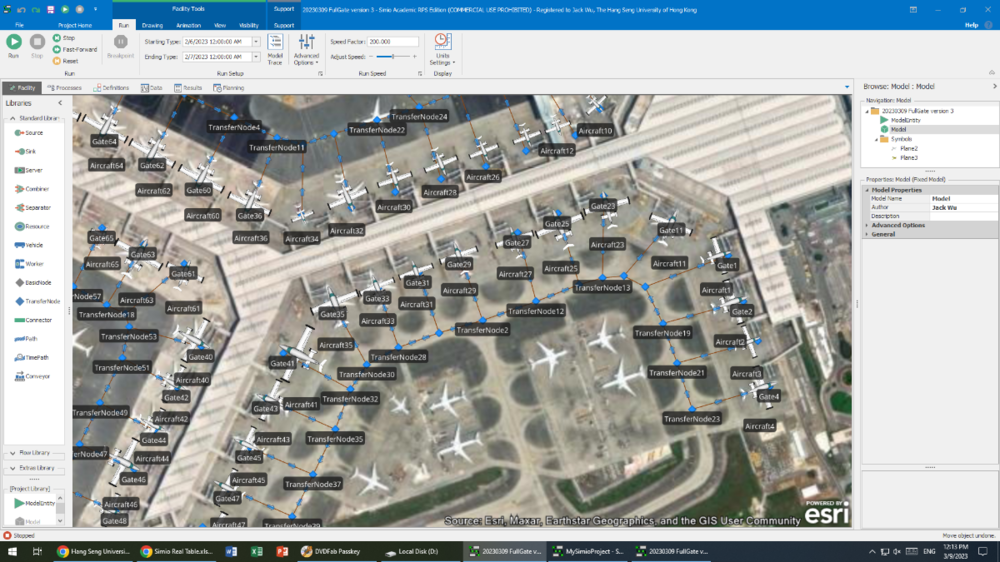

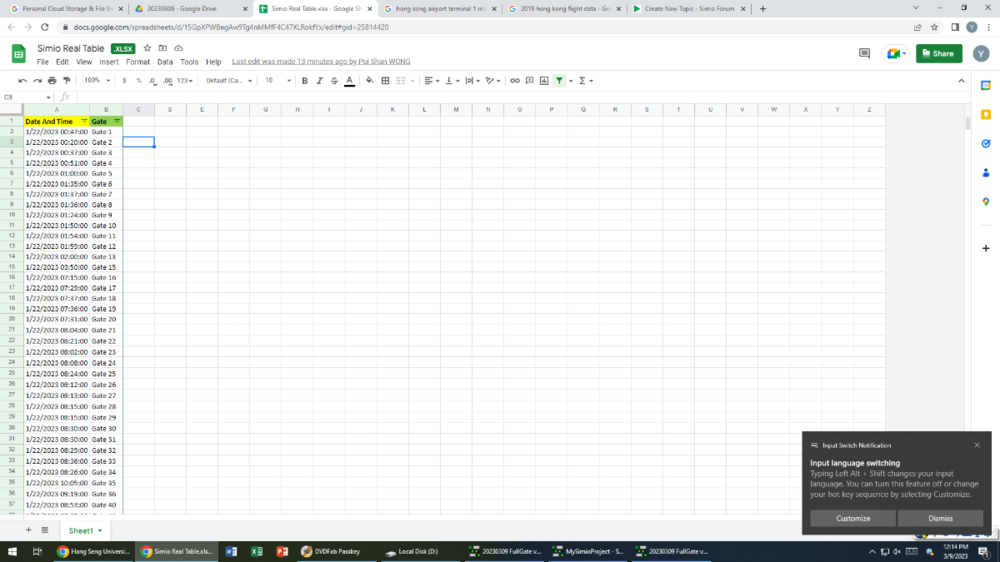

We are simulating the aircraft will leaving the gate according to our real data history. How can i import the table in simio and let the aircraft leave the gate accouring to the time and date? Also some gate will have more than one different time and date that aircraft will departure the gate. How can i do it as well?

-

Hello! So I am using a source that is sending out 9 different entities, each with a priority 1-9. They are listed in a Data table called 'Part Data' This is the 'Table Row Referencing' call I am using in 'Before Creating Entities' in the 'Row Number' section: PartData.Priority.RandomRow I want to switch this to use a Random.Normal(mean, sd) - is that possible with discrete values in the table? Thank you for any help you can provide!

-

-

Hi I want to know if there is any possibility to have same schedule table, where you refer to different Table based WorkingSchedules? If you look in attached file you can see Example1, that represent what I need but I don't like this approach because there will be too many tables. Example3 on the other hand is something I want to achieve. Workers_MM.spfx

-

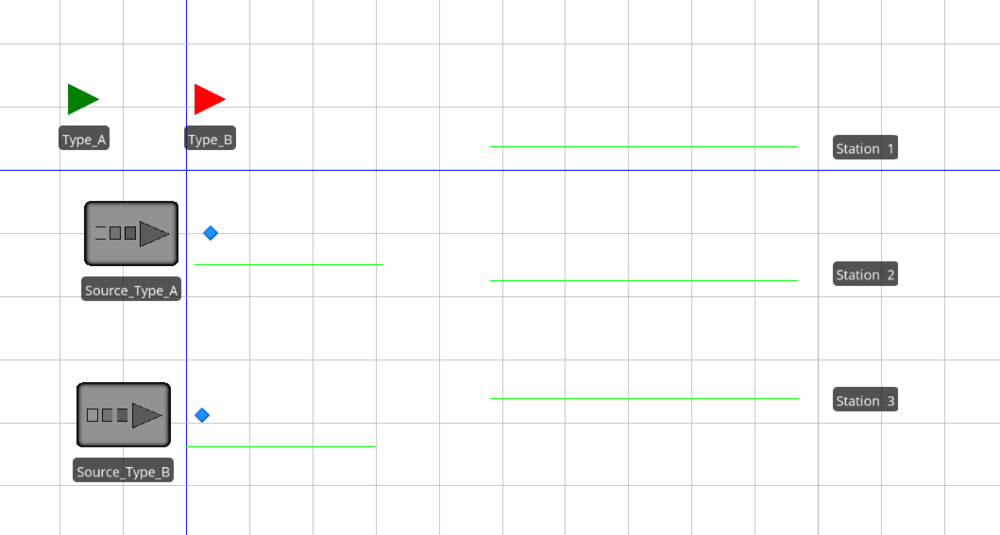

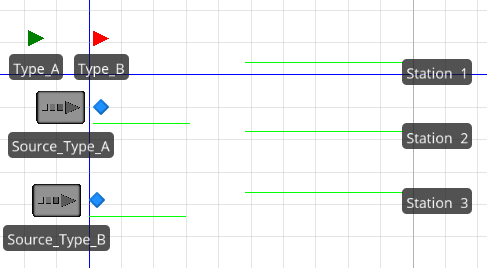

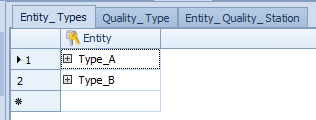

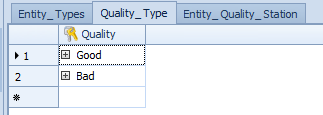

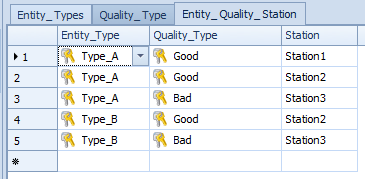

In the attached model, I want to transfer entities to stations depending on some criteria defined in a table. I have 2 types of entities, "A" and "B", defined in a table as primary keys. Also I have 2 states, "Good" or "Bad", also in a table as primary key. Finally I have 3 stations. I have a table that has 3 columns, “Entity_Type”, “Quality_Type” and “Station”. For example a row could be "A"; "Good"; "Station 1". It is possible for entity "A" with "Good" quality to end up in either "Station 1" or "Station 2", and in that case I want to randomly select one. The problem is that I cannot use a RandomRow based in more than one criteria. Either I use RandomRow for the rows of the table that are type "A" or quality "Good", but I am not finding a way to do more than one combination. This model is a simplification of the real model which is more complex and has hundreds of combinations. Model_RandomRow_FilteredTable.spfx

-

Hi I have created an object and need now a property of type table for this object. The tables which can set for this property should have a defined schema (two columns, the first of type datetime and the second of type real). My question is: Is it possible to pretend the Definition of the Schema for the tables, which can be assigned to my property? Thanks for your help. Thomas

-

Hi All,

I have defined the input buffer capacity and output buffer capacity for my servers, If the input buffer of destination server is full the vehicle still picks the entity(from output buffer of previous server) and moves to the destination(next) server and just waits with the entity unless input buffer capacity is available , how can I restrict the forklift from not picking up the entity or should only pick when the next server/destination has input buffer capacity available. any thoughts on this would be helpful.

-

To model shelves, I am trying to create a series of custom "Shelf" objects (subclass of servers) located in a grid pattern. I used a spreadsheet to automatically calculate the coordinate locations and generate a name (string) for each object based on its position within the grid. With just the Shelf object types in the spreadsheet, can bind the file to my object reference table no problem, import the data, and populate the facility window with my objects. That part works fine! Next, since I have an aisle running between the rows of objects, I wanted to set it up so that the objects all face "inwards", ie. the input and output nodes for the objects are facing the aisle. Originally I thought of rotating the Shelf object, but I ran into 2 issues: first, I discovered that I can't set the Shelf yaw orientation from the table, so that's not going to work. Second, I realized that even when I rotate the Shelf in the facility window, the nodes do not rotate with their parent object. I decided I would leave the Shelf in the same orientation as it is placed, but I would just re-locate the input/output nodes to the opposite edge of the Shelf objects on the far side of the aisle. For this I would need to make sure I can set locations for the input/output nodes in the same object reference table. When I added a row to the object reference table from within Simio (prior to binding to a spreadsheet), a drop down appeared, and I could select the input or output nodes for any object that already existed in the table, and then define the node's location in the cartesian coordinate columns. When creating a node this way, the node location is still relative to the object, ie. I can drag the object in the facility window and the node moves relative to the object, which is perfect. This input/output node creation and relative location definition via table is exactly what I am trying to automate, but this is where I started running into problems. In my spreadsheet I used formulas to generate names for the nodes to match the formatting of the input and output nodes in Simio (ex. "Input@..."/"Output@..."). I also added a formula to assign all input node object types to BasicNodes and all output nodes to TransferNodes and calculate the desired location coordinates for the nodes. The spreadsheet I made has the same format as the table in Simio where I tested manually creating and positioning the nodes. The issue is that when I bind the table and import the spreadsheet data to my model, the node names automatically change and are no longer formatted to reference the parent object. Because of this, these name-changed node objects are created in addition to the input and output nodes that are created for each Shelf object. However, if I remove the binding and add a new row, once again I can find the node name in the drop down list and assign the coordinates manually, and the input/output node that references the parent object will move to where I send it. My question is: how can I set the input/output node locations for the objects when creating objects from a table? There are over 500 Shelf objects in the table so I do not want to locate them manually, but the automated method is not working either. The only idea that I have is to make a new object "Shelf2" and define the external view to have the nodes on the opposite side, but that seems like a less-than-idea solution because then I would have 2 custom objects to update and maintain, that are otherwise identical. I am hoping that I don't have to do this hacky solution but I am interested to see if anyone else has dealt with this and has ideas. Thanks!

-

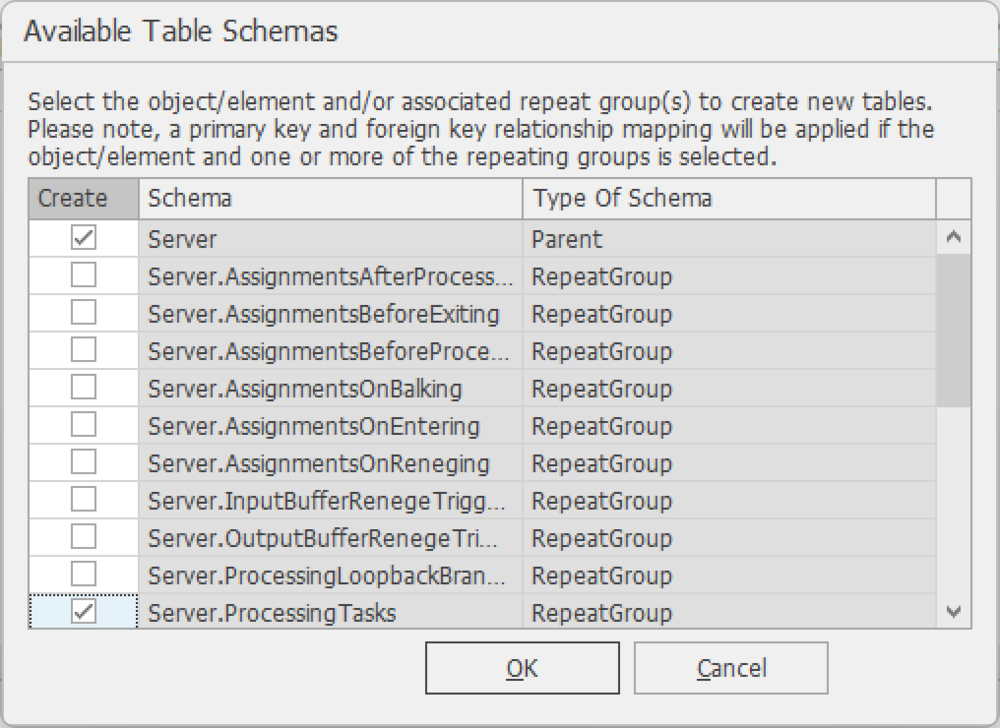

My model currently reads tasks from a table and I am trying to model material consumption. For each task there are groups of materials: A, B, C, and priority values: 1, 2, 3. To complete a task, only one material type from each group A, B, and C must be consumed, and the order they are consumed in should be based of the priority. For example, if task one had entries like the table below, if all materials were available, materials 1,4,6 would be consumed. If material 1 was no longer available materials 2,4,6 would be used, and if material 6 was not available the task could not be done. The material requirement section in the processing task editor does not seem to support groupings and priority and was wondering if anyone had an idea on how to accomplish this. Task MaterialName Group Priority Quantity Task1 Material1 A 1 1 Task1 Material2 A 2 2 Task1 Material3 A 3 1 Task1 Material4 B 1 1 Task1 Material5 B 2 3 Task1 Material6 C 1 1

-

Hello, I have a model, that's producing parts (Multiple Parts A,B, C,D) with a server, sever works based on a work schedule and off shift days and holidays and the simulation is run for 1 year. Note: processing time for each part is different i need to extract the number of parts produced each month. Also need to determine the monthly efficiency of server , since some months may have holidays. Please provide a solution to get the dat on a monthly basis.

-

Hi All,

In my Model I have a input table and while trouble shooting if I have to pick a particular order as in the below screen shot, it takes a while to search the same( I have approx. 2000 rows). Are their any efficient methods to search a particular row in table if not can this be added as a feature in Simio's next update? Right now its a drop down and then the order needs to be searched.

Thank you.

Regards,

Unmesh

-

How do I access a table column by name using a table property defined for the model? In my model, I have multiple data tables each with the same named columns defined for each. Each table has a different number of rows. For a run or a set of replications, I want to select a table to use. I have defined a model-level table property named _SelectedTable to support this. During simulation runs, I want to access this selected table's data by row and column name. Specifically, I want to use this data to update model entity state variables. I also want to stop creating entities when all of the rows of the table have been accessed. I've tried two partial solutions to this problem (attached), but neither are ideal. 1. Create a large set of decide add-on processes to choose the decide the correct table and explicitly reference it by its name. This requires a lot of redundant steps and maintenance if tables are added or removed. The attached example contains just two tables. Controls OptionId and _SelectedTable must be set to either (Option1 and tableOption1) or (Option2 and tableOption2). The first control selects the Entity Type and the second selects the Table. 2. Using the column index number instead of the column name, I found I can use the table property to access the selected table. This method is prone to error if the table schema changes. It is also unclear which table properties, such as "AvailableRowCount" are accessible via this approach. The attached example contains two tables just as the previous. The control _SelectedTable chooses which table from which data is acccessed. In practice, the data tables will be substantially larger than the ones included in the attachments. Looking forward to constructive guidance, Ryan table_selection_by_name.spfx table_selection_by_column_number.spfx

-

Hi, I have a source with a rate table, it is set to make an output of 100 entities every day. The problem is that the entities comes out one at a time trough that day, but they should all arrive together at the start of the day, so that the servers has the whole day to process them.

-

Hi guys, I have searched this topic but cannot get a solution to that: is it possible to remove a certain row from a output table? There is a step called "RemoveRows" which removes all rows in the table. What I would like to have is i set a search step first and use the index i found to locate the row in the output table and delete it. Many thanks! Regards Yutong

-

Hi all, I made a model of a production line (starting with 2 servers) and I am wondering whether it is possible to change the processing time of the second server based on the actual output of the first server. Theoretically seen the processing time of the server 2 = Speed of server 1 * E , in which E is a fixed formula (connected to server 2) to correct the speed. So if the first server performs according to expectation (without failures) for example 40 the processing speed of the second server is equal to 40*E with a delay of the conveyor time between server 1 and server 2. If the server has failure and thus have a lower output (for example, 30), I want to change the processing time of the second server accordingly to 30*E with a delay of the conveyor time between server 1 and server 2. Does anybody have an idea of how to do the following: How can you monitor the actual output of the first server at each timestep? Is it possible to fix the proposed formula and use it in an add-on process? How can you take the conveyor time delay into account (using a delay step in the add-on process?)? I am quite new to the software so I am not sure whether it is possible to model this in Simio. Thank you in advance!

-

Is there a way to create a column of Time property without date using Simio Table, just like the start time and end time of day pattern of the work schedules? The work schedule doesn't suit my needs.

-

Hello together, would be very thankful for any advice: I have a sequence table with sequences according to their workstations: A - B - C - D If I only have one operator, they can just be done one after another. If I have 2 Operators A and B can be done simultaneously to C. How can I model this? The problem is probably, that the entity (batch) has to be splitted to let workstation A and C run at the same time. I tried it with process-add-ons like creating a second entity and transfer it to Station C. There might be a much easier solution?! Thank you in advance!

-

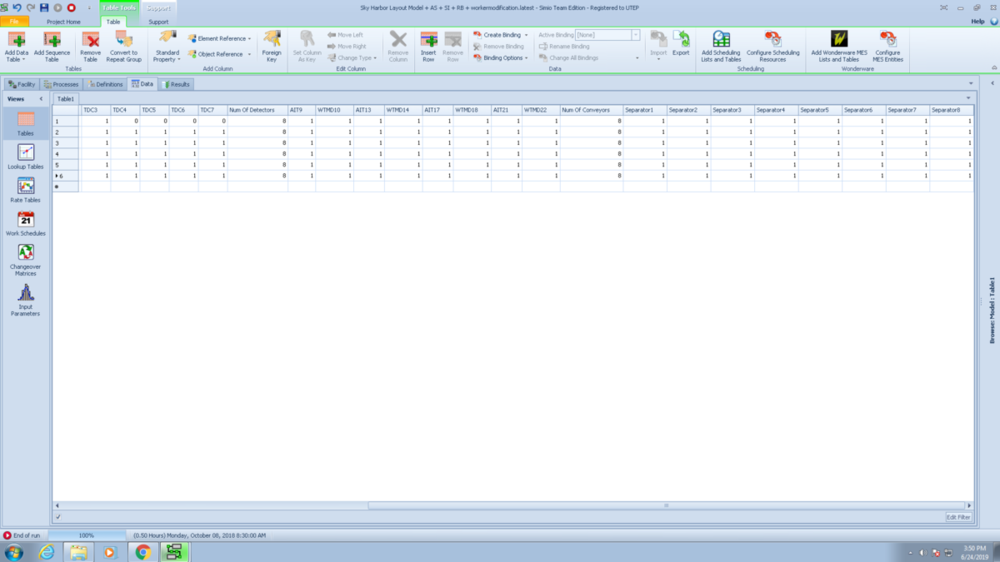

Hello, I have been utilizing SIMIO for a couple of months, but I am still relatively new to some of the features and I recently encountered a difficulty that leads me to the following question. Is it possible to include an entire table in the model as a reference property in an experiment? I have a Table that controls the capacity of all servers at specific intervals within the simulation time, but I would like to include a warm up period in my simulation. The only manner I encountered to make this possible is through an experiment. The attached picture shows the Table, but there are too many parameters to reference them individually. If not possible, or perhaps an easier solution, is there a manner to include a warm up period in the simulation without having to perform an experiment? I would only like to take the model into a steady state prior to collecting statistics, but a need does not necessarily exist for me to perform an experiment.

-

Hello, Server (reflecting the storage/kitting area) in my push model is connected to multiple servers. I have below conditions to fulfill while routing entities from an output node of this server - After every 5 minutes, 1. Scan through the sequenced entities at kitting area (output buffer) 2. Scan through the output destinations to check if they have space available for transfer. 3. Route all the possible parts in sequence from the origin server. Can someone help with advice or any reference model to replicate this scenario in Simio. Thanks in advance. -Mohmed

-

Hello All, I am new to Simio and trying out a simulation of an aircraft component assembly shop. I am using Sequence table for my jobs routing and processing scenarios which is - Source -> Set A (4 servers) -> Set B (7 servers) -> Set C (5 servers) -> Set D (2 servers) -> Sink Here each Set denotes similar workbenches to any of which a job can be routed based on utilization and availability at that point of time. So for routing job based on above criteria from Source, I created sequence table with 'Node list property' (which is list of input nodes on 4 servers of Set A) instead of 'SequenceDestination Property' as required by Sequence table. I want to replicate the sequencing from Source -> Set A -> Set B and so on. But want simio to pick the server of these sets based on my criterion. Unfortunately it is not working as I assume Sequence table need to have specific node as SequenceDestination. I am not sure if I am doing it right or what is correct and way to do it. I will highly appreciate any suggestions to make this happen in Simio. Thank you. -Mohmed

-

Hi, I want to have a source that creates entities according to a date. But also, I want each entity to carry some information like Code, Processing Time and Type. It is possible to do that? And After, how I can use the information that each entity carry? For example, Each entity has their own processing time (according to the table), how I can use that procesing time in a server? Thanks for your help!!!

-

Hi all!, would you help me with this? I want to do a discrete simulation of the current situation in a Hospital in the inpatient unit. I have the data of one year of patients, (over 18,000 people) and I want to use that data in the simulation. That would make more easy to model the server processing times, while we will use the real server times and sequences that each patient had, instead to use probabilities and distributions for the sequence and server times respectively. So, I created a table where each row represent a patient with a sequence (which bed he was assigned due to his level of acuity) and the time that he spent in that bed before he was dispatched. The are more times involve, but we can focus in those parameters to have it more simple. So, the table have the patient name (entity) ,bed (sequence) and Length of Stay in the bed (server processing time). I don't know if is possible that when I create each entity, I can assign, based on that table, the sequence and the server processing time for each patient. How I can do that? Thanks for your time and help