Search the Community

Showing results for 'output table functions'.

-

You can use seperate servers (each has 1 capacity) each represents individual firms. Create entities (raw products) via a data table where you should also include one column (a node property from object reference property) to represent where the created entity will be processed (as its destination). Then at the output node of the source object set entity destination type property to specific. Then set node name to Table1.NodeInstanceProperty1. The entities will be routed appropriately.

-

RandomRow and random streams

MauricioBiolato replied to thomas_lienert's topic in SI General Discussions

If what you are looking for is to define a specific row in a table you might check the SET ROW step. Rds. -

Hi guys. I attached a sample of the problem Im facing in my project. In my main model I have a table that has a column of the type date and my entities have to be created, on a submodel, on the times specified on the table that has the column of the type date. I was able to reference the table on the main model to the submodel and thus pass the values. However, on the create object of the submodel I was not able to set/reference the property for the ArrivalTimeProperty property of the Source. Can somebody help me please? Thanks. Model.spfx

-

Hi! Is there an immediate way to get the row number of a table without looping through all the rows? Thanks

-

I've been having issues with binding Excel files (XLSX and CSV format) into SIMIO. Every time I try to bind a file with SIMIO I get the same message of "Data has not been imported or is of an unknown age." Even when I create a table in SIMIO, save to CSV, and then try to reimport the exact same table by creating a CSV binding I get the same error. For further context I am using the Academic RPS version of SIMIO. All online tutorials I can find are using older/ different versions of SIMIO that don't have the same options as I do. Does anyone else have experience with this issue or is able to share some advice to help me get pass this error? Thank you

-

I'd recommend you read the Create help documentation. It provides some detailed info on how the step functions. It also mentions the CONWIP and DynamicallyCreatingVehicles SimBits for examples using the Create step. For my second suggestion, yes this can be done with variables. What I would do is create a new Source and Sink that create entities that just tells the model to perform logic. And since this is just a regular sink, you can specify when to create those entities however you desire (by arrival table, randomly.....).

-

Hi All,

In my model, I have a transfer node and the entity could go to either of the next 2 serves as in the picture.

I have assigned product number(1,2,3...) to entities …., if product “1” moves from transfer node to S1 and the next product is also “1”, it should also move to S1 and if the product number changes its should change the server to S2. So the entire batch gets processed on one server.

After processing from S1 and S2 the entity should flow in batch so that at S3 I have batch production

Right now the entities go based on “By Link Weight” and randomly goes to the server which affects S1,S2,S3 servers setup time

Any thoughts how can that be achieved, I do not want to setup a sequence table.

-

Hello, in general it sounds like your approach is good. You could use either an Object Reference State Variable or String State Variable (called something like 'WhichServer'), defined on ModelEntity, depending on the expression you use to make the assignment. For instance, with an Object Reference State Variable you could use 'ModelEntity.Location.Parent.Server'. With a String State Variable you would use 'ModelEntity.Location.Parent.Server.Name'. In terms of timing, you could make the assignment really anytime the ModelEntity is in the Server. You might use the Servers' On Entering State Assignments for example. Then somewhere downstream, perhaps the Entered Add-On Process at a Sink, you could use Add Row and Assign steps to populate the Output Table. Again, just be mindful to make the column types (Object Reference State Variable or String State Variable) match up with the assignments you are making. For instance you might have a String State Variable column named 'Entity' and, in the Add-On Process at the Sink, you assign 'OutputTable1.Entity' the New Value of 'ModelEntity.Name'. Then you could have an Object Reference State Variable column named 'Server' and in the same process assign 'OutputTable1.Server' the New Value 'ModelEntity.WhichServer' (since it is also an Object Reference State Variable). The result will be a list of each ModelEntity (Name) and the Server that processed it. Hope this helps! Adam

-

Just curious if there's an easier way to go about doing this... Long story short if I am representing multiple physical positions within capacity of a server and I create my own Gantt outside Simio, it's important for me to know WHICH resource (in this case which one of the servers) is utilized by each entity. I was trying to utilize Entity.Location.Parent.Server.Processing.Contents.IndexOfItem( Entity ) and assigning it to a state on the entity and then ultimately writing to an output table. However, this doesn't seem to be working accurately. It may be a timing issue on when this step is called, but is there a default function I'm just not aware of that could be of assistance?

-

Hi All, Is there a way to assign Table Assignments on Entity Created like is via the properties panel but via process logic? I am still working on learning process logic. Essentially I have different product tables to use data from during different part of the day, so I am trying to have a decide step that say "what time is it when the entity is created" and then assign the right table and subsequent random.row values from that table to the entity. All help appreciated! Thanks! David

-

Hello, Is there any way that I can use data that I have pulled into Simio from Excel to be used as processing times for a server?

-

Hi, It's the first time I'm working with the flow library. My question relates to configuring a flow of two liquids that come from a single source, but may be of two kinds (different densities). I would like to have one table, describing the properties of the entities, and another table, having one field as a model type, and another one as the weight limit in the flow sequence. So, basically Table1: --Entity--- ---Density (kg/cubic meter)--- ... some other props TypeA 5000 TypeB 10000 Table2: RowNumber (not a field, just for sequence) --Entity--- ---Amount (cubic meters)--- 1 TypeA 10000 2 TypeA 20000 3 TypeB 30000 4 TypeB 25000 5 TypeA 10000 6 TypeB 12000 7 TypeB 10000 I need to make pauses between the sequential flows of different (or the same) liquids, in the order presented in 2nd table, but I believe, I'll figure out how to achieve this. The question is - how do I configure the source? I need to reference both tables, since I need to limit certain values by weight in the source, but have input in volume. I also have some other entity properties that I would need to access further in the simulation. They are in Table1, which is the descriptive table, not the one used for initializing the flow source. What I tried to do - is 1. Specified the entity type as a referenced property from the Initialization table (Table2) 2. I created the RunInitialized trigger for the flow source to SetRow to number 1 (I will further increment the rownumber - if there is a better solution, please advise) 3. I tried to limit MaximumVolume by accessing another table - and here I'm stuck. I need to lookup Table1, but not by id (integer), but by the entity type. So, the lookup table seems not to fit here. Please advise of this design, how do I lookup in a Table1, when I have an entity of known type.

-

Senior Industrial Engineer - Simulation Req #: 67308BR York, Pennsylvania, United States Engineering & Technology Platforms & Services Posted on:03/29/2021 Job Summary Career Level Experienced Travel Percentage 10% Full-Time / Part-Time Full-Time Clearance Level - Must Currently Possess None Shift 1st Shift Relocation Available Yes ITAR: U.S Citizen or Green Card Required Yes Clearance Level - Must Be Able to Obtain None Job Description What motivates you? If the answer is a position where you can develop your skills and earn opportunities for advancement while being part of a forward looking team then this is what awaits you in a career at BAE Systems. Our employees work on the world’s most advanced combat vehicle systems. From the M109A7 Mobile Howitzer with its long range firepower to the Amphibious Combat Vehicle that transports America’s Marines from ship to shore, we are developing the technology of tomorrow while delivering the most cutting-edge equipment available today. Our flexible work environment provides every opportunity to positively impact the company without giving up your personal life and we welcome all those who understand the importance of improving production velocity, having big ideas, and craving innovation. We draw strength from our diversity and always put our customers first through an unwavering commitment to bring the warfighter home safe. Does this sound like a team you want to be a part of? If so, come build your career with BAE Systems. The Combat Vehicles line of business within the Platforms & Services (P&S) Sector of BAE Systems is looking for a self-motivated Senior Industrial Engineer to support the production scheduling of armored military vehicles. Working as a team member of a larger Industrial Engineering Group, this Engineer will be required to build and maintain simulations for varied fabrication, assembly, and testing processes. The candidate must also be comfortable with soliciting input through face to face interaction and, in general, must demonstrate that they possess strong analytical, problem-solving, and interpersonal skills that will support individual and team growth. A strong background in discrete event simulation, specifically with the use of SIMIO, is necessary. Specific responsibilities include: Day-to-Day · Complete simulation support activities such as time studies, production line balancing and production metric development · Evaluate complex Technical Data Packages (Drawings, Bills of Material) and be able to understand how a component or vehicle is assembled · Utilize a strong understanding of integration activities like implementation of standard work, material kitting, metric tracking, and process improvement to advance manufacturing methods. · Work on the manufacturing floor with other Engineering disciplines, production supervisors, and employees that directly interact with the components or vehicles being produced. Internal and External Customer Relationships · Engage in regular communications with production support, planning, logistics, quality, manufacturing supervisors, and direct labor workforce to assess operations performance. · Summarize and present findings to internal customers to gain buy-in for improvement efforts · Discuss the status of metrics and key performance indicators with appropriate decision makers Development · Work with Industrial Engineering leadership to understand the expectations of new Engineer within the organization and company · Share responsibility of self-development with immediate supervisor · Maintain a safe work environment and ensure compliance with safety objectives and policies. Required Education, Experience, & Skills - 4+ years of simulation experience within SIMIO - BS degree from an accredited university Preferred Education, Experience, & Skills Demonstrated capability with the use and application of SIMIO discrete event simulation software. About BAE Systems Platforms & Services BAE Systems, Inc. is the U.S. subsidiary of BAE Systems plc, an international defense, aerospace and security company which delivers a full range of products and services for air, land and naval forces, as well as advanced electronics, security, information technology solutions and customer support services. Improving the future and protecting lives is an ambitious mission, but it’s what we do at BAE Systems. Working here means using your passion and ingenuity where it counts – defending national security with breakthrough technology, superior products, and intelligence solutions. As you develop the latest technology and defend national security, you will continually hone your skills on a team—making a big impact on a global scale. At BAE Systems, you’ll find a rewarding career that truly makes a difference. The Platforms & Services (P&S) sector under BAE Systems, Inc does the big stuff: the armored combat vehicles, naval guns, missile launchers, and naval ship repair…just to name a few. Our employees take pride in the work they do and why they do it. They are on the front lines every day, building our products to protect the lives of those who serve. We may be biased, but we think P&S does some of the coolest work around, and we think you will too. At BAE Systems, we celebrate the array of skills, experiences, and perspectives our employees bring to the table. For us, differences are a source of strength. We’re laser-focused on high performance, and we work hard every day to nurture an inclusive culture where all employees can innovate and thrive. Here, you will not only build your career, but you will also enjoy work-life balance, uncover new experiences, and collaborate with passionate colleagues. https://jobs.baesystems.com/global/en/job/67308BR/Senior-Industrial-Engineer-Simulation Thanks, Jenny Ridings, PHR Principal Talent Acquisition Specialist BAE Systems My pronouns are she / her M: +1 904 570 2489 | E: jenny.ridings@baesystems.com https://jobs.baesystems.com Connect with BAE Systems: Join our talent community!

-

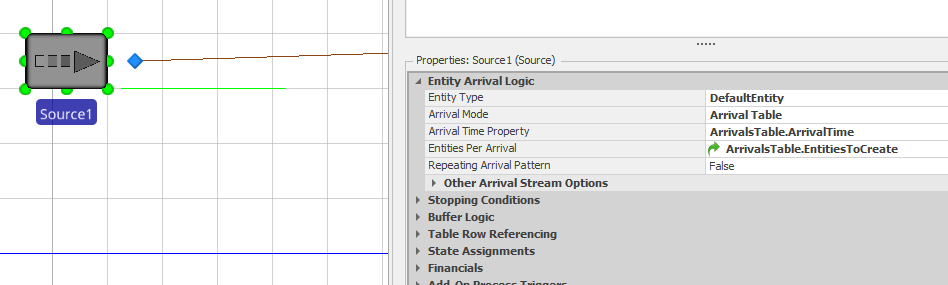

Multiple entities arriving at exactly 8am each day.

lstretton replied to Kameswara Sukesh's topic in SI General Discussions

You might want to look into Arrival Tables. See the following screen grabs. Configure the source to create entities based on the arrival table as follows: Setup the arrival table to define the arrival time and the number of entities per arrival as follows: Hope this helps, Lucas. -

Hi everyone! In my simulation model I created a sub-model and placed many on its facility. On the main model I have a table that only has 1 object column and I want to pass the table to the sub-model as a property. I've done this many times with processes: I create a process property on the object and on the main model I pass the process through its properties. However I can't do this with table property: *On the main model Simio accepts the name of the table I write -> Ok *On the sub-model at Controls I write the name of the table property and Simio returns an error... Why is this? Please, some help.. Thanks.

-

Hello, I'm creating a model with different entities, and I want each entity to follow its own rate table. I created the Data Table (called "PatientData") that lists several properties such as mix, service times, priority, and Rate Table. I also created the 8 Rate tables (1 for each type of entity) and entered each one on the Data Table under the Rate Table column accordingly. On my main source, I set the relevant properties as follows: Entity Arrival Logic Entity Type: PatientData.PatientType Arrival Mode: Time Varying Arrival Rate Rate Table: PatientData.RateTable Rate Scale Factor: 1.0 Entities per arrival: 1 When I run the model, I get an Error at 0:00 with the following information: Item: Source'MainEntr' Item Property: Rate Table A runtime error was detected at time 0.0 hours. Error evaluating the value of property 'Rate Table'. Invalid data table reference PatientData. There might be a really easy fix, but I can't seem to find what I'm doing wrong. I was following the same way I'm used to calling columns from table. Thanks for the help!

-

I would like to refer to a specific row in a date table for a specific property. I found the syntax for this as TableName[RowNumber].PropertyName. However, I want to use a model entity state variable that returns an integer for the row number. The model gives an error saying "invalid syntax". A model state variable works fine, but I can't use a modelentity variable. (TableName[ModelEntity.StateName].PropertyName). Are there any suggestions to solve this issue? Thank you.

-

Simio doesn't have "Link" type lists, however, we do have functions for nodes which would allow you access to the various links that are incoming or outgoing from that node. Depending upon your objectives for having these links, you could create output table information related to the node/link lists. So, for example, let's say you have a Source that contains 3 outgoing links. You could, within a process at the start of the simulation, use the Search step to search NodeOutputBoundLinks for the Output@Source* node and add that information to an output table (the node name as one column, the links as another column) by using the AddRow step to add a row to the output table, and Assign step to assign OutputTableName.LinkColumnName equal to the Link found in the Search step, for example. Again, not sure what information you are trying to gather related to the links, but this is one possible way to get a listing of links either inbound or outbound from a node.

-

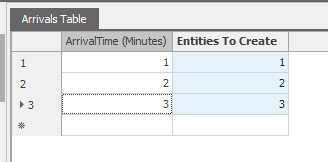

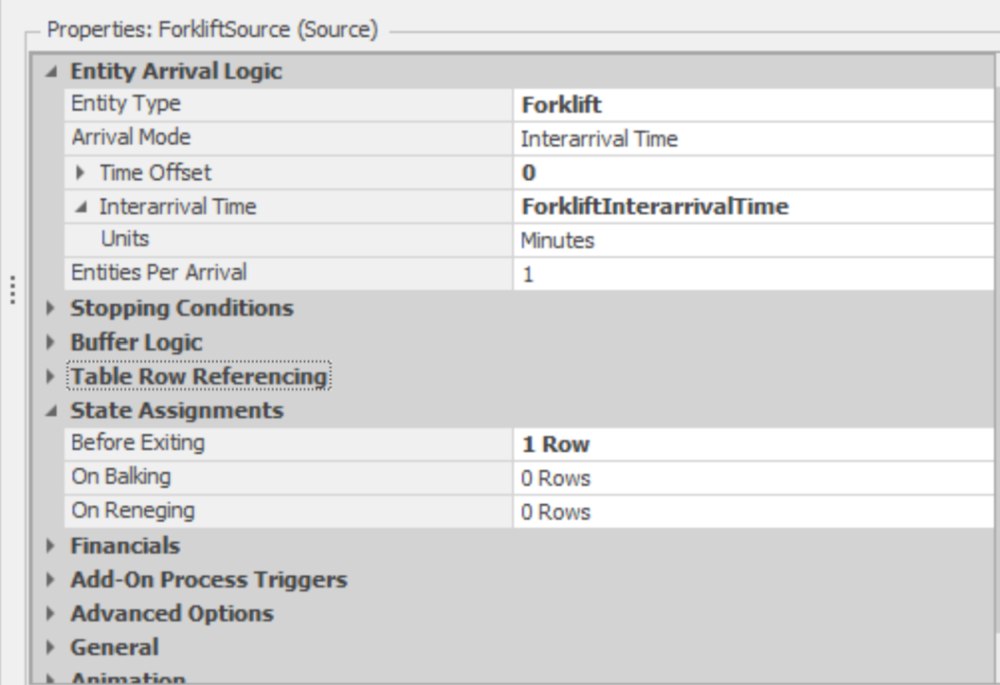

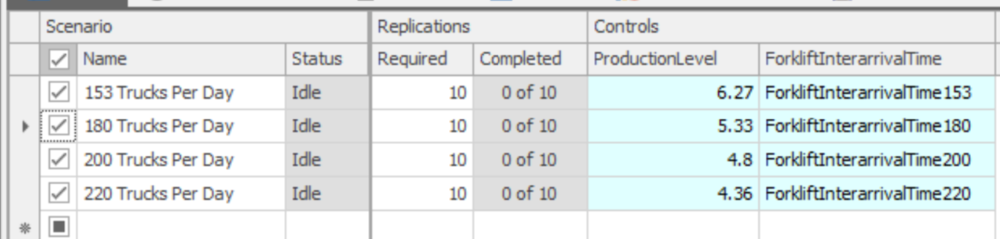

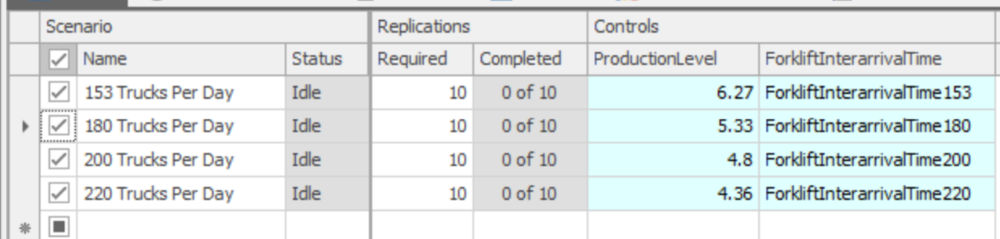

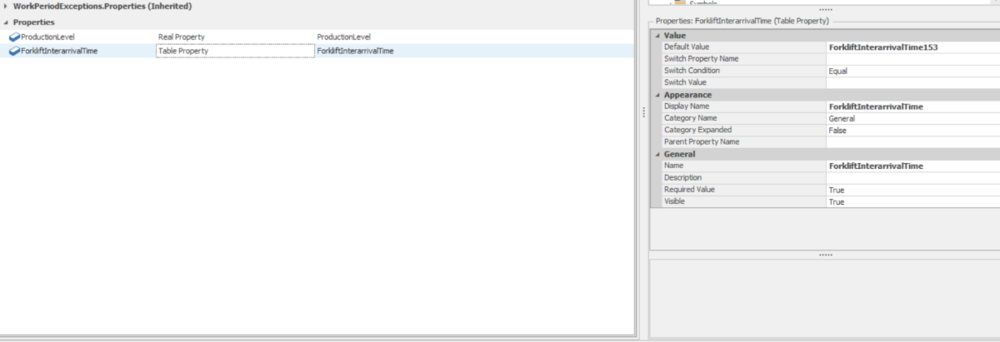

I have a source, called forklift source, that has a varying interarrival time based on the time of day. To do this, I created a time indexed table with the different interarrival times in different rows and the interval period set to one hour. This source also depends on the interarrival time of another source called Newtrucksource, but not on an hourly basis. I am trying to conduct an experiment where the interarrival time of newtrucksource changes with different experiments and a different time indexed interarrival table for source 1 is used for each of these different interarrival times. To do this, I created a real property for newtrucksource's interarrival time and a table property for forkliftsource's time indexed interarrival table. However, I can't get this to work because in the model, the interarrival time property for the forkliftsource must be a "number" and I am referencing a table which comes up as using "string". Trying to find a way to make this work.

-

Property of type Table - pretend Schema-Definition

jzhou replied to bennodual's topic in SI General Discussions

Hi bennodual You can create a table inside your customised object(say MyObject) and the column type match your properties, ie,he first of type datetime and the second of type real. and then convert it to a repeatgroup ,for example its name : tableA and on parent model you can instantiate your object and on the property panel, you will see the repeatgroup to assign. you can create a table directly via the schema dropdown list with the name MyObject, select MyObject.tableA and the table will be automatically created. the next step is refer to this table on the properties panel. -

Hi, i have version 5.9, and for some reason my input buffer, output buffer and processing lines go away or are hidden. when i say lines i'm referring to when you bring in a server it automoatically has the output buffer line that you can move around, etc. is there a way to turn this on and off? maybe i turned them off somehow. or maybe it's hidden under the floor plan i imported? anyway for me to bring those lines up to front if they are indeed under the floor plan? any help is greatly appreciated, thanks!

-

Hi, I have a problem when that I describe bellow in full detail. I have seen a simbit which is similar to my issue but do not know how to extend it. I have uploaded the model the description refers to. Your help is highly appreciated. Regards, Overview The idea is to allow the user choose the processing time for a server but not his entering the experssion himself, but by means of some intermmediate option. In particular, the user is have two options: ‘regular’ or ‘reduced’ for the processing time. According to the user’s pick, regular and reduced will lead to specific expresions contained in a table. The model There are three objects: • Source1 (default values from the estándar library) • Server1 (the processing time is to be chosen by the user) • Sink1 (default values from the estándar library) List There is a String List (named strUserOptions) containing the user can choose from, and contains two ítems: “Regular” and “Reduced”. Properties There is a List Reference Property rpUserOption, whose list is strUserOptions, so that the user can pick one of the above mentioned ítems. Its Display Name property is “Server Processing Time Speed” Table There is a Data Table (tabUserOptionInfo), with two columns: • Column 1 (name UserOption), List Property = strUserOptions • Column 2 (name ProcessingTime): Expression, Unit Type = Time, Default Units = Hours The table has two rows, as follows: Regular random.exponential(5) Reduced random.exponential(4.5) The objective My intention is that the user chooses either Regular or Reduced from the model property window and the corresponding value for the Server Processing Time is chosen for Server1 case_unsolved.spfx description.docx

-

I have a series of gated processes that are defined in a sequence table. Occasionally sequential gates will use the same server. In our process, the entity doesn't actually move out of the server, but in Simio the entity has to exit the server and re-enter. What winds up happening is that if another entity is queuing for that server, it will enter first during the approximately 2 seconds it takes for the entity to travel from the output node to the input node , causing the entity that was in the server to queue. I would like the entity to stay in the server through multiple gates, according to the routing logic, without getting bumped by other entities in the queue. It's important to keep the gates separated instead of combining them into a single entry on the routing table, because I need to look at performance statistics for each gate separately. Thank you

-

Sequence Table - Destination as 'Node list property'

CWatson replied to mohmed Shaikh's topic in SI General Discussions

You can still use your various 'lists' of servers in SetA, SetB, etc.). You still will need a Sequence table with the Sequence Destination property column. This tells Simio within the Sequence table the destination to route. So, within your Facility window, add a TRANSFERNODE before each 'set' of areas, let's say named SetA, SetB, SetC, SetD. Then, within the TransferNode, use the 'Select From List' for Entity Destination Type property and specify the appropriate list (SetAList, etc.). Then, within the Sequence table, route to the TRANSFERNODE that uses the particular list - so in the above, you would have within your Sequence table, SetA, SetB, SetC, SetD and Input@Sink. Within each of your Server's output nodes, specify Entity Destination Type as 'By Sequence'. You may wish to look at the example named SchedulingDiscretePartProduction to see the layout of the nodes within each section and the Routings table used (this is a much larger example, but the concept of the nodes, the sequence table and in that case a RoutingDestinations table (which is like a node list in Lists) is basically the same.