Search the Community

Showing results for 'optimization model'.

-

I'm dealing with a similar situation with my model. I'm trying to tell my model to seize 1 resource object for every 3 entities. How can I go about this?

-

Hi, I am working on a transportation model where the vehicle drops off customers at a station and is parked at the node until it is further required. Is there a way to limit the number of vehicles a station can hold? Thanks, Amit Sinha

-

Hello, I am new to Simio, and I am still trying to figure out which Simio product will be most valuable in my case. I have some specific questions: I would like to confirm the following: If I build a simulation model in Simio Simulation Software, can I import it into Simio Scheduling Software and build on it? When you say that Simio Scheduling Software allows performing risk analysis in real time, do you mean that: You can actually connect the software to sensors where the software automatically performs the analysis based on real-time data? OR you manually import data and you run the simulation model to update the results? This question overlaps with my second question, but it will help me better understand. When you talk about the Simio Digital Twin, are you referring to the Simio Scheduling Software? Their functionalities look similar except for the clearly mentioned physical connectivity to real-time data in case of Simio Digital Twin which is not directly implied in case of the scheduling software. At this stage, Simio Simulation Software fulfills my current needs. However, I would like to leave the door open for building a digital twin after achieving my current objectives. I would greatly appreciate your input on this. Thank you for giving me the chance to join your community! Cheers, Fatima Alsakka

-

Record Statistics Per Entity Throughout Simulation

lstretton replied to Emiliano's topic in SI General Discussions

Hi, See attached model that uses an output table to log information on each entity. You could just as easily you an ExcelWrite/Write Step to do the same thing. Cheers, Lucas. Data Table Entity Log.spfx- 1 reply

-

- excelwrite

- entity

-

(and 1 more)

Tagged with:

-

Record Statistics Per Entity Throughout Simulation

Emiliano posted a topic in SI General Discussions

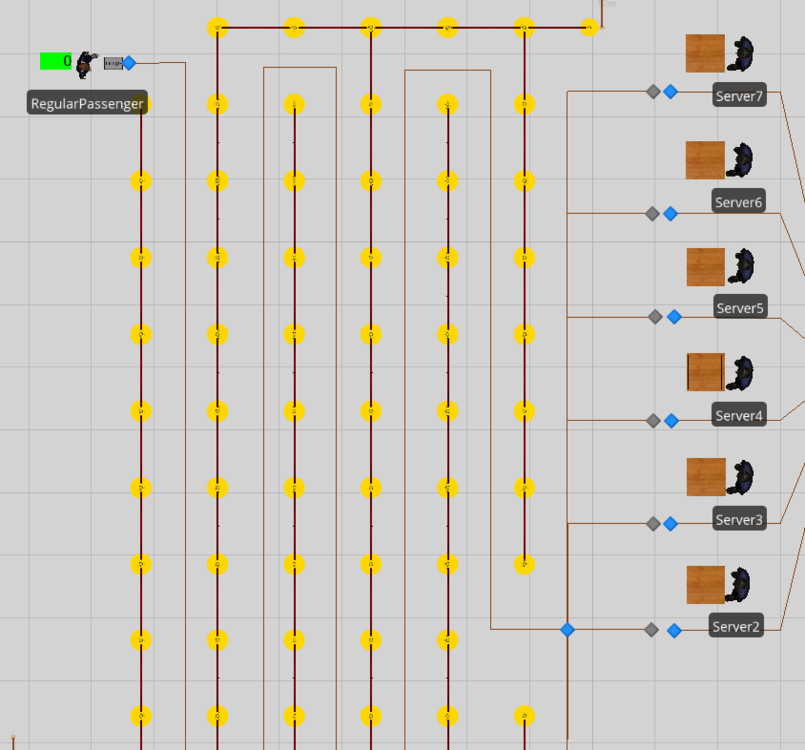

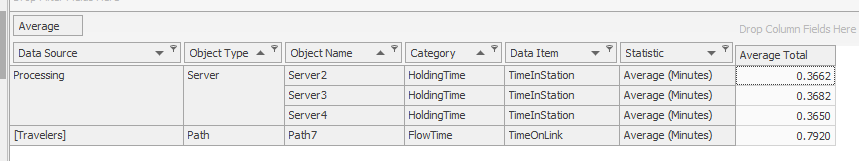

Hi! I have been using SIMIO for quite some time now, but I have barely come across this need. I need to record the time spent per entity at any given path/server in the simulation, rather than obtaining the average time for all entities at the end of the simulation. Take the image below as an example. I need to record the time spent in the link (TimeOnLink) per entity generated. The path corresponds to that connecting the source to servers 2-7. Then, I need to record the time spent per entity on servers 2-7 (TimeInStation). I can display the unique ID number for each entity by Entity.ID, now I need to match the statistics. I figure the best way to model is trough ExcelWrite, but I can't manage to make it work. Any hints? The plan is to get the following information per entity, rather than a summary of all entities.- 1 reply

-

- excelwrite

- entity

-

(and 1 more)

Tagged with:

-

Crane Library - Bridge and Underhung bridge cranes

Rylan Carney replied to dsturrock's topic in SI Shared Items

Hello ttarken, A simplified approach might be use a Resource to constrain the system until the required operator is available. If the operator should move with the Crane, a good starting point might be to try seizing a Worker and requesting a move to the pickup Node. Then, you could try using a Move step to move the Worker from the pickup Node to the drop-off Node with the Crane. Please see below a link to a similar post discussing how to use two Cranes to move a single entity. The example model attached to the other post might provide guidance for your application. -

Greetings. I need to model the operation plan for a new warehouse. The model must do the following tasks Receive great amount of bundles from production line (5 lines) Fill the storage cells based upon a strategy (this required an order to do the sloting. this orders must be satisfied by the vehicles). i have tried to do this by using sequence, but i need to repeat the sequence table rows until the cells capacity were completed. this is go to the same cell until its been filled and then change the destination cell (i can't achieve this). Do the prepicking task (again trough disptching rules). Load train or trucks in order to dispatch,. Any help or orientation willbe appreciated Best regards.

-

Hi Jim, May be there are many possible ways to follow to get the information you want. But, I suggest you to use a search step for searching a server's (or any other object's) processing queue to get such information. You can search not only the server's processing queue but also the whole "entity population" to get whole state variable's defined on them at any arbitrary time thoughout the simulation run. All you have to do is to define additional expressions on search step. In the example file attached a simple model is developed to get entities' state variables residing at server1's processing queue. Here note that, you have to click button at arbitrary times. Then, if 3 or more entities exist at server1.processing queue, the search step founds the first 3 of them (since a forward search is performedin this sample model) then later an excel write step writes entities created time (you can get many state variables of entities written on the same excel file). You can change search limit, queue state name, include a match condition etc. If you want to get such information at the beginning or at the end of the simulation run you should use this same logic at appropriate processes (onrunending, onruninitialized etc...). Also, you can get these information written on either a database or an output table as well. Hope this helps? getting a snaphot of Entity WIP via a button.spfx entities_processing.xlsx

-

Hi Jim, I uploaded a simple model related to the concept how to get instant information about any object in simio by using button. If you need more do not hesitate to ask more? getting a snaphot of Entity WIP via a button.spfx

-

Hi Mohmed, You are able to assign ServerInstance.ResourceState.TotalTime(4) to a Real State through an Add-On Process. I have attached a model illustrating this. Note: The Notify step in both the OnRunInitialized and OnRunEnding Add-On Processes are used as a verification method. All the best, Caleb CaptureTotalOffShiftTime.spfx

-

Blocking a server through a waiting room

gocken replied to Sebastian Vicencio's topic in SI General Discussions

Since I am not allowed to save my changes on your file directlt I am not able to upload your revised model. But, it is so simple to follow the steps to get what you wnat. First delete all your processes in your model and only for Volvo server define an afterprocessing add-on where you should include a decide step, an assign step and a wait step (see the attached file). Then, 1) set decide type as conditional and set its condition as: (M1.Capacity.Remaining > 0 && Input@M1.NumberTravelers.RoutingIn == 0) && (M2.Capacity.Remaining > 0 && Input@M2.NumberTravelers.RoutingIn == 0) && (T4.Capacity.Remaining > 0 && Input@T4.NumberTravelers.RoutingIn == 0) 2) at assign step set state variable as: Volvo.ResourceState and set the new value as: 2 (setting this to 2 will block the volvo server) 3) at wait step set event name as Output@T4.Entered. I hope this works for you. -

Blocking a server through a waiting room

Sebastian Vicencio posted a topic in SI General Discussions

Hello! I need to block a specific server in my model, preventing this server from starting its the processing time. The conditions for this to happen are dictated by the following servers, according to a number. In this simplified model I made, if the entity went through the server M1, then this server will stay suspended until T4 finished its processing time. At the same time, M2 will have the same behavior. Following the above, the server just before M1 and M2, called Volvo, must not start its processing time if M1 and M2 are working or if either one is working while the other one has suspended its processing time due to T4 is working with the entity just went through. The thing is I already tried 2 approaches, the first one was through suspending the server called Volvo (Bloqueo volvo file), and resuming when T4 finished its processing time, but despites it is suspending Volvo's processing time, it doesn't resume it correctly. On the other hand, I tried using a waiting room that blocks the pass of entities trying to reach the Volvo server, but it works erratically (Bloqueo volvo cancha file). I would appreciate any suggestion or help of any kind. Thanks in advance. bloqueo volvo.spfx bloqueo volvo cancha.spfx -

Entity Distance travelled on Transporter

ttarkan replied to ttarkan's topic in SI General Discussions

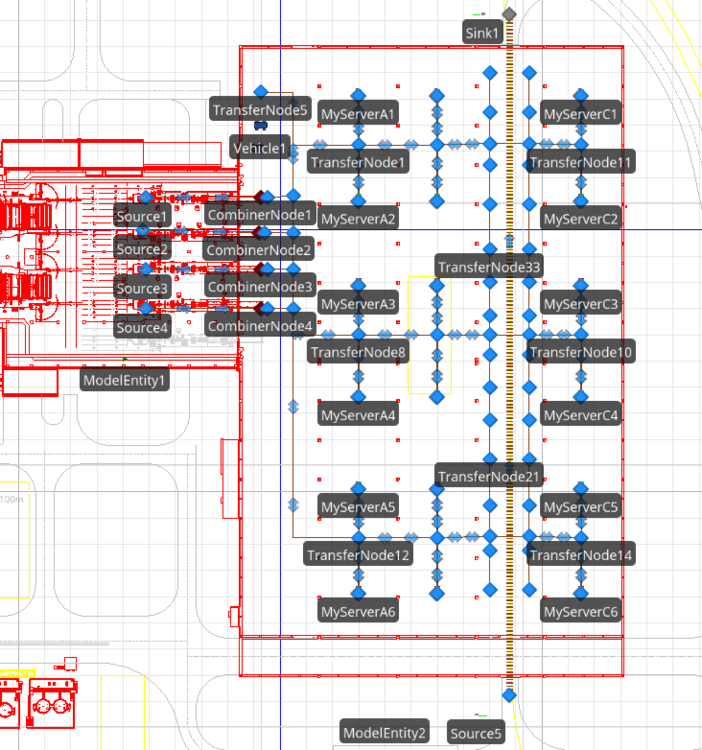

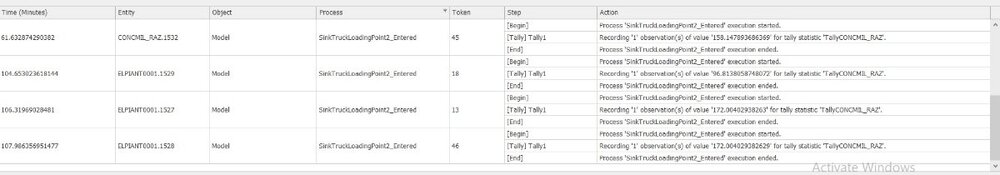

Thanks you so much for you help Liz. That's such an advanced modeling techinique I had never heard of before. I would never be able to figure it out myself. It has almost worked but correctly. It has recorded the results for some tallies correctly but recorded some tallies on the wrong tally. I think there is a problem with the set row feature somewhere. I have no problem with setting rows elsewhere in the model such as arrivals from production and arrivals from truck tables create entities correctly with all their state variables. The product list table also has unique "productnames" (entity instances), set as key and auto set-row property is set to true. I have added another coloumn with element tally statistics reference (DistanceOnForklift) to products table. I have auto created it as you suggested and turned on the auto-set row feature to true. Both my product names and tally statistics coloumn are set as key in same "products" table. But the tally step still doesnt record them to the correct tally statistics. Where am I doing wrong? Would you still be able to help me? Shall I send you the model in private message? Here is the formula I have inputted 'Products[Products.ProductName.RowForKey(ModelEntity.EntityType.Name)].DistanceOnForklift' and in the picture below you can see that tally step records into wrong tally element on last three entries. I would be glad if you could help me. -

Source working as per the work schedule for server and worker

Alen replied to Alen's topic in SI General Discussions

Hi Caleb, Appreciate your effort in providing a reference model. Process Logic approach was useful. Thanks A lot. Regards, Alen -

The processing time left in a server

cwhitehead replied to Sebastian Vicencio's topic in SI General Discussions

Hi, There is not a direct function to access how much Processing Time is left for an entity in the Processing Station, however you can use a workaround that I have attached in a model. The ability to access the function you are referring to in your post is on our Product Backlog, but not being able to access the direct function makes this difficult to achieve. Once you save off the time remaining in a ModelEntity level State Variable, you can use a separate process to compare the value to the "certain amount" that it could exceed and then perform other steps following that. All the best, Caleb CheckRemainingProcessingTime.spfx -

Entity Distance travelled on Transporter

Liz Millar replied to ttarkan's topic in SI General Discussions

I would recommend using a Data Table. One column could have all your entity types defined. The next column could be a Tally Statistic Element Reference Property. This column would match up the Tally statistic you want to correspond with the Entity Type. You could choose to auto-create these Tally Statistics from the Data Table. If you change the Tally Statistic Property's column Reference Type property from 'Reference' to 'Create', this will make the Tally Statistics for you. I recommend the Help page "Table-Based Elements (Auto-Create)" in Simio for more information. If your Entity Instances noted in the Data Table are unique, no duplicates, you can set that column as a Key. With that column as a Key, you could use just the Tally step and use the RowForKey expression. RowForKey will allow a key input to search for in that column. If the model entity is driving the process, you could use an expression like this for the Tally Statistic Name 'Table1[Table1.EntityInstanceProperty1.RowForKey(ModelEntityReference)].TallyStatisticProperty'. Since it seems this process will be on the OnRunEnding, it will not have a reference to a specific entity, so you will most likely need a Search step to find the entities still in the system. I would set the Search step to find Infinite things and let each entity reference exit on the found branch. If the EntityInstanceProperty column in your Data Table has the Auto-set Table Row Reference property to 'True', the entities will already know the row reference and your Tally step Tally Statistic Name property could be 'Table1.TallyStatisticProperty'. -

Source working as per the work schedule for server and worker

cwhitehead replied to Alen's topic in SI General Discussions

Hi Alen, I have attached a model with two different approaches to this question. 1. RateTableApproach - the arrival data is stored within a Rate Table. Note: The Rate (events per hour) is influenced by offsets from when the model begins its run, not by the hour of the day. For example, a model begins its run at clock time 7:00:00, the first entry with a Starting Offset of Day 1, 00:00:00 and Ending Offset of Day 1, 01:00:00 would actually correspond to clock time 7:00:00-8:00:00 and not 00:00:00-01:00:00. 2. ProcessLogicApproach - the Arrival Mode is 'Interarrival Time' which is turned on and off via an Add-On Process. Note: You will need to set the Delay step up to correctly account for the clock time you wish to delay before turning on/off arrivals. All the best, Caleb SourceWorkingAsPerTheWorkScheduleForServerAndWorker.spfx -

Entity Distance travelled on Transporter

Liz Millar replied to ttarkan's topic in SI General Discussions

Hello! With your current approach, you need a way to aggregate the distance traveled per each entity. Each entity in the population is collecting their own distance traveled, but on the Output Statistic, you are looking at just the Instance, ProductA. The Instance will not automatically aggregate the population's values. If you were to specify a specific population index, for example ProductA[5].DistanceFunction, the Output Statistic would return the 5th entity in the population's distance function and you should see a value. However, making an Output Statistic for each population index would be inefficient and tedious to collect. I recommend using a global/model level State Variable. This State Variable could be summed as a ProductA entities leave the system. So the Product A entities will continue to collect their individual distance traveled as you have set it up, but then prior to exiting through the Sink, add their distance traveled to a running total State Variable. That total could then be divided by the number of entities destroyed giving you an average distance traveled. -

Hi Guys, I have a source producing the entities, which is processed by the server with a worker. server and worker are assigned to work schedule (7Hrs) (12am-7am) arrival model of the server is set to time varying arrival rate. to control the source on holidays. But with current scenario the source is producing the entities on off-shift time. Please help out with a logic, so that source is produces the entities matching to the timings of work schedule. Note: Simulation run is for a period of 1 year. Regards, Alen

-

Hi Everyone, I have 100s of different products in a warehouse and I want to get statistics for all of them such as distance travelled, number entered and exited. So I created the entity instances for each product automatically through data table. The entity.totaldistancetraveled function doesnt increase since the entity doesnt moveby itself but moved by forklift instead. So I have created a state variable called "distanceonforklift" and increased by the difference between the forklift total distance travelled value when entity exits and enters to forklift. I have also created a function called "distancefunction" on the entity and equated it to "distanceonforklift" state variable of the entity. For the return type of function I have chosen "number" and set the unit to "length". I validated that both distance state variable and function is calculated correctly in the facility window. However I cannot output the result of this state variable on the model results screen. I used the following expression under model outputstatistic but it didnt work. "ProductA.DistanceFunction". That expression gives me 0 value although there are some entities of this product which enters and exits the system. How can I see the average total distance travelled on forklift for the whole population of Product A?

-

Hello, I have a model, that's producing parts (Multiple Parts A,B, C,D) with a server, sever works based on a work schedule and off shift days and holidays and the simulation is run for 1 year. Note: processing time for each part is different i need to extract the number of parts produced each month. Also need to determine the monthly efficiency of server , since some months may have holidays. Please provide a solution to get the dat on a monthly basis.

-

Hello Mauricio, Your model is a good approach but it is incomplete because I explained myself a little wrong: What I really meant was that the server the entity came from should not start its processing time. Anyway, thanks for the effort. In case anyone is wondering a similar question, I attach the solution i came up with in a even more complex version. block.spfx

- 2 replies

-

- 1

-

-

- blocked server

- queueing

-

(and 1 more)

Tagged with:

-

Referencing tables/properties from other models

Liz Millar replied to TweeMansLeger's topic in SI General Discussions

Hi Jason, I recommend checking out the SimBit, found in the Support ribbon in Simio, titled "Hierachy with Tables". This could show you an idea of how you might use a Repeat Group Property to read in a Data Table at the parent model in to the sub model. Liz -

Hello, I have the following situation, I have a source followed by 3 servers in parallel. These servers are then connected to a fourth server, which finally leads to the sink. The thing is I need that the 3 first servers must hold the entity (stay blocked) until the fourth server is free. Additionally, if one of the 3 servers in parallel has capacity available, this one must stay blocked until de fourth server finishes its process. I attached the model I made, and the main problem are the three servers in parallel which are staying blocked after the first entity pass through. Thanks in advance block.spfx

- 2 replies

-

- blocked server

- queueing

-

(and 1 more)

Tagged with:

-

Start simulation with entities at nodes

Sebastian Vicencio replied to Janur25's topic in SI General Discussions

Hello! I have a similar question. The thing is that in my model I have 4 different entities and I need my servers to start full of these. How should I change the process you made or a different one must be made? I want to create a kind of warm-up situation, but only my servers must be at their top initial capacity. Thanks in advance