Search the Community

Showing results for 'optimization model'.

-

Hi, I have an issue related to workers going off-shift and abandoning the reserved entities in different servers, depending on when the shift change happens (picture attached is an example). The shift change is based on switching from Worker of x number of population to y number of population to meet my WorkSchedule. The Worker should always carry different entities throughout, entities cannot travel alone. The logic issue happens as a result of entities left in servers or buffers that were not picked up by workers due to the end of shifts, causing too many objects/entities in the system not destroyed. An expert suggested to build process that checks the Worker's Allocation Queue when it goes off shift to see if there are any entities in it, and if there are, turn the Worker back on shift. I tried to build that process, but I could find the right steps. Any help on identifying the right steps or a different way to model workers shifts is appreciated.

-

Maybe you can refer to the attached model for some hints. Best regards/Jeff Zhou Vehicle Weight SUM.spfx

-

Anyone has a model example to illustrate this issue please ?

-

Entities in a buffer at the start of the simulation

gocken replied to Ondrej's topic in SI General Discussions

Try the logic included in this model. Note that you can use the same logic at any time over the simulation run. In this specific example the entities are created at the begining of the simulation run. If you need to create them at any time over the simulation run then you should define a seperate process then embed the same logic into that process. Then, all you need is to trigger that seperate process. For example, you can trigger by using timer element. Hope it helps?. CreateEntities.spfx -

I'm interested in calculating a yearly production rate. Essentially I could do this if I ran my simulation for 1 year and looked at the output. The number of entities destroyed by my "completed" sink will be what I'm looking for. How do I determine this value if I'm running for longer than 1 year? For example; If I run for 5 years, and I'm watching my model run, at week 186 I'd like to know how many entities had been destroyed by my "completed" sink between weeks 134 and 186 to determine my yearly production rate.

-

Hi Cwitte, can not open your model? I think the we are using different editions of simio or your file is corrupted?

-

refueling_Routing2withaddin.spfxHere is my model. I'm specifically dealing with ModelwithFailure and looking at Experiment2.

-

at this point it is very hard to say anything without seeing the modeling logic? I suggest u to track your model run using track.

-

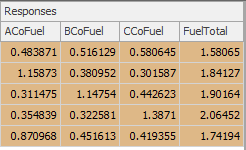

I am running some experiments on my model. I have a couple of transporters delivering fuel to three server nodes. I am trying to have the model maintain adequate fuel levels at the servers despite disruptions. Currently I have 4 responses (1 for each server and 1 that sums their fuel levels) and the responses are based on the expressions: Input@LineCompany1.AssociatedStationLoad Input@LineCompany2.AssociatedStationLoad Input@LineCompany3.AssociatedStationLoad and FuelTotal: Input@LineCompany1.AssociatedStationLoad + Input@LineCompany2.AssociatedStationLoad + Input@LineCompany3.AssociatedStationLoad I get responses as such: with the ACoFuel, BCoFuel, and CCoFuel ranging between 0 and 2 and FuelTotal ranging from 0 to 3. The capacities of these server nodes are 0 to 12 and everything is handled in integers. I am confused on how these responses are being calculated and any light that could be shed on this would be greatly appreciated.

-

RandomRow for only part of a table

Alberto Lacort replied to JaimeSotomayor94's topic in SI General Discussions

@JaimeSotomayor94 did you solve your problem? I will be interested how did you finally model it. Thank you in advance -

Hello, I'm new to both the forum and the world of simio in general. I am trying to simulate how much the maximum buffer could be in 2 points of my process which are defined by the Buffer_ST1 and Buffer_ST2 servers. My problem is that I would like the Buffer_ST2 server based on a condition that would be every time an entity passes on Input @ Buffer_ST1, the Buffer_ST2 server releases only one processed entity and not all those inside the server as it happens now, I hope for being clear and thank you in advance. I put the model in the attachment Buffer varianti trazioni V2.spfx

-

Hello, We are evaluating Simio and really like what we see from exploring the Simio Personal Edition. Custom Dashboards are a high priority for us and we appreciate the fact that Simio seems to allow creation of custom dashboards from within a model; however, we would like to know if Simio allows the creation of custom dashboards that are portable from model to model. For example, we would like to: Create a dashboard that displays a chart depicting activity cost per entity (for a selectable set of entities) over the simulation period. Reuse/import this dashboard into any model to display the activity cost per entity over the simulation period (for a selectable set of entities). Two questions: Is this possible with Simio? If yes, which edition(s) of Simio support this capability? Thanks in advance! Donovan

-

Hi, I want to generate one type of product with one interarrival time. I have one source and one model entity. However, this entity can have different lengths following probabilities. Depending on these properties, the processing times at the servers will be shorter or longer. I tried to assign a state to the entity before this entity exits the source so ModelEntity.Length becomes DataLength.prob.randomrow. where DataLength is a table with the different lengths and the probabilities associated with those Lengths. The only thing is that it is a property and not a state, but I do not know how to do it in another way. Afterwards, I have different processing times at the servers depending on the different characteristics of my entity. For example, server1 will have different processing times depending on the length. How can I reference to the good processing time say I have added a column to the table DataLength with the associated processingtimes according to the lengths? Finally, I would also like keep track of those different lengths generated and see what the model produced in the end. Thank you for your help, Emilie

-

AssociatedStationOverload is always -infinity

jsmith replied to Sreenath Chalil Madathil's topic in SI General Discussions

Yes, the buffer is set to 0 in the model distributed with the book. The book verbiage mentions that using Infinity for buffers will cause a tie in the selection logic, but we need to add some additional discussion about the differences between using values of 0, 1, 2, etc. for the buffer capacities. -

I am trying to make a routing decision based on the Candidate node's routerequestqueue's summation of the entities user-defined property. If there are different types of entities with ex. different priority levels. I would like the routing process to choose the transfernode which has the smallest total sum of it's entities priority level. the transfernode that needs to be chosen also has a routing group attached to its entity destination type rule where its final machine has 0 buffer and due to a blocked destination rule, there will be a queue build up at the transfernode that needs to be chosen. I have thought about using a state variable for each node and using add-on process each time a unit enters and leaves a node but because the main model has many multiple nodes the node's entity priority sum has to be able to be accessed through the candidate.transfernode._________________. For example during the routing step in the process section, I have candidate.transfernode.destinationroutinggroupname.routerequestqueue which gives me the node's number of units waiting, but i need to be able to access the candidate nodes summed queued property. Is there either a way to directly access this information, have looked at the expressions and having a hard time finding something. failed attempt: candidate.transfernode.destinationroutinggroupname.routerequestqueue.population.defaultentity.priority.summation or is there a way to use the add-on process where i am adding/subtracting the priority levels, but somehow attach it to the candidate.transfernode's property Hopefully this makes sense. If you look at the file, please ignore the upper half and focus on the transfer nodes maintransfer, transfernode1 and transfernode1_1. maintransfer has an entered add-onprocess which is the subject of this question. the route process and it's selection expression is what I'm trying to adjust but find a way to express the candidate transfernodes of transfernode1 and transfernode1_1 (which are part of the XferRouting group). I'd like to choose and compare the total summed priority level of each node's queue. Simple_Routing.spfx

- 2 replies

-

- routing

- expressions

-

(and 2 more)

Tagged with:

-

Hello, I'm working on a project where we want to build a scheduling model. But there is one think that I'm dealing with for a while now. I want to capture mid phase stock. For example if we have part A, which has 5 sequences to be produced. But at previous order we did not push all the parts through production, so now we have some stock on different operations. What I want to achieve is, that when my order come I firstly look at general stock of finished products (OK). If there is not enough stock I want to look at how many parts I have on the stock before last operation, if there is enough I don't want to create new entities but use this stock and produced new parts. If there is not enough parts before last operation we of course look at every previous sequences and if there are still not enough parts only then I want create new manufacturing order and with that new entities. If any of you guys deal with system like that before it will be really helpful. If you haven't but have some idea how to solve this problem, it will also be helpful because I've already tried a lot of options and now I'm stuck. Best regards!

-

I am recreating the model 5.3 of the Simio and Simulation textbook. When I create the list and run the model, with selection expression in the output@placement node as below candidate.Node.AssociatedStationOverLoad, all entities goes only to finepinchfaststation. However, when I use Candidate.Node.AssociatedStationLoad it selects all desitnation loads. Is there any change to the Candidate.Node.AssociatedStationOverLoad? I displayed the values in the facility window and it is coming as -infinity. Model_05_02.spfx

-

About the job Position: Industrial Simulation Services, Simulation Developer Location: Kitchener, Ontario Experience: 3-5 Years of relevant work experience Division: OTTO Motors Area of Study: Industrial/ Mechanical/ Mechatronics/ Systems Engineering NOTE: Must be able to travel to the U.S at time of application. About Clearpath Robotics Inc. Clearpath Robotics Inc. develops the future of robotics technology through development and sale of industry-leading self-driving technology, products, and services to over 500 of the world’s most innovative brands. Proprietary hardware, software, and services are delivered through the company’s research and industrial divisions: Clearpath Robotics and OTTO™ Motors. Clearpath Robotics Inc. is an award-winning company with recent awards including Robotics Business Review Top 50 Robotics Company, Edison Award for Innovation, Business Insider Top 40 under 40, and Canada’s Top 100 Employers. About Clearpath Robotics Research Solutions Clearpath Robotics’ research solutions group is a global leader in unmanned vehicle robotics for research and development, and provides hardware, software, and services to enable self-driving vehicle development, deployment, and operation. Clearpath Robotics works with over 500 of the world’s most innovative brands in over 40 countries, serving markets that span mining, military, agriculture, aerospace, and academia. Visit Clearpath Robotics atwww.clearpathrobotics.com. About OTTO™ Motors OTTO™ Motors is making material handling in industrial settings safer, easier, and more efficient through development of hardware and software that automates movement of goods in busy factories and warehouses. The company’s industry-leading self driving technology provides automated and on-demand material handling in the most demanding industrial environments, spanning automotive, medical device, aerospace, logistics, and more. Customers trusting their mission-critical material handling needs to OTTO Motors include Fortune 100 brands GE, Toyota, and Caterpillar. For more information visitwww.ottomotors.com. About the Job Having 10’s of robots run around our offices is great, but having hundreds of robots running around inside our computers is even better. Rich simulation environments offer a wide range of benefits to many aspects of our business: fast research, development and validation, sharp marketing tools and strong customer experience / support. We're looking for a Simulation Developer to create and run simulations that will help us optimize our robot fleets and system solutions. As a part of the Industrial Simulation Services (ISS) team, you will act as a subject matter expert and lead modeling and simulation activities. The ISS team works closely with our Systems Engineering, Applications Engineering and Project Management team, to support overall solution design from initial concept all the way to full system design and deployment. You will be building material flow strategies (based on self-driving vehicles) for products already in our arsenal and ones that do not yet exist. Your goal is to develop accurate and robust simulations to evaluate design, lower risk, and enhance the elegance of our solutions to fuel our growth. Primary Responsibilities Creating discrete event simulations for real and hypothetical systems, estimating fleet sizes, identifying traffic bottlenecks, testing what-if scenarios to optimize performance of robot fleets Consulting with project leads, sales team members and customers to obtain understanding of the requirements and to collect the necessary inputs Advising on simulation based metrics to evaluate system risks and performance Analyzing results and making recommendations for facility and material flow design Presenting your simulation results to our team of engineers, our sales team, and to clients Validating models against real world data to maintain accuracy relative to product portfolio Growing and improving our simulation library and internal templates for functionality, accuracy, scalability and efficiency Drafting functional specifications, proposals and effort estimation Recommending product feature and improvement ideas to our Product and Engineering teams, that lead to greater system optimization in the real world Additional tasks may include: Interacting with our development team as necessary to assess impact of new feature or product Developing simulation models to assist Sales & Marketing in demonstrating Clearpath's products and capabilities Using your expertise to assist our engineering services group in developing the more complex system concepts About You You're excited about the role that robots will play in the future, and intrigued by the challenge of joining a young company in this high-growth market. You have skills and experience that you know can make a difference with the Clearpath team, whether we're looking for them or not. You are driven and view work as more than just a job. You are motivated by making an impact on your workplace and you thrive on challenging and rewarding problems. Most of all, you want to be on the right side during the coming robot revolution. The ideal candidate will have: Proven success using simulation solutions to evaluate feasibility of facility design or operational changes Experience with discrete event simulation tools like Simio, AutoMod, AnyLogic, FlexSim, Delmia, and understanding of its limitations Experience collaborating with cross-functional and external client teams to gather comprehensive data required for model development and/or analysis Fearless in questioning to ensure end users get the most value out of your work. You understand the importance of early goal alignment and scope definition Effectively communicate complex model functionality to the client or internal team for assurance of model results accuracy Customer-first mindset Avid self-learner Ability to work independently with minimal supervision and manage deadlines. Able to cope with sudden jarring changes in projects, priorities, and the local gravity field. Bonus Points for: Experience identifying traffic and material flow bottlenecks and mitigating risk Experience in manufacturing industry Understanding of different industry warehouses. You see block diagrams and flowcharts everywhere and speak the language. Experience with Object-Oriented programming Working knowledge of one or more of C#, Python, VB.NET Exposure to working with ROS, Gazebo Past participation in simulation challenges What’s in it for you: Flexible Hours, Health Benefits, Parental Leave, Vacation, Equity, Community Days (paid), Half-Day Birthdays, Passionate and Dedicated Teams Curious to know more about the culture at Clearpath & OTTO, check out: https://clearpathrobotics.com/blog/category/blog/culture/ Come join us if you feel like our values resonate with you, and if you are interested in being a part of making industrial workplaces safer and revolutionizing automation. At Clearpath, we are committed to building and supporting a culture of diversity, inclusion, and accessibility. We hire the best talent regardless of race, color, creed, national origin, ancestry, disability, marital status, age, veteran status, six, sixual orientation, gender identity, and expression. If you require special accommodation to complete any portion of the application or interview process, please contact 1-800-301-3863.

-

Hi All,

In my model, I have a transfer node and the entity could go to either of the next 2 serves as in the picture.

I have assigned product number(1,2,3...) to entities …., if product “1” moves from transfer node to S1 and the next product is also “1”, it should also move to S1 and if the product number changes its should change the server to S2. So the entire batch gets processed on one server.

After processing from S1 and S2 the entity should flow in batch so that at S3 I have batch production

Right now the entities go based on “By Link Weight” and randomly goes to the server which affects S1,S2,S3 servers setup time

Any thoughts how can that be achieved, I do not want to setup a sequence table.

-

Machine Learning and Simio

Arun Kumar Thandapani replied to MarcoJHB's topic in SI General Discussions

Thank you for the paper, quite interesting, we will think about how to use such an approach in our model. -

Hi, I have 6 entities arriving at exactly 8am each day. Each of the 6 entities will create a certain number of entities on arrival from their respective distributions. How do I model in my source? I cannot have multiple sources as each entity has its own server processing times. Please can you help? Thank you

-

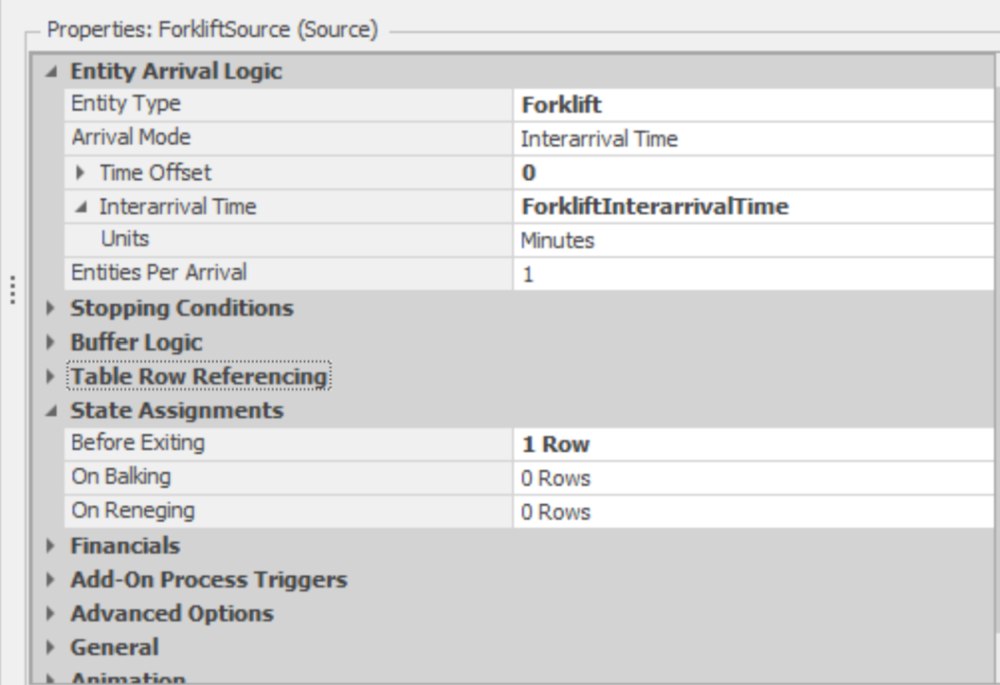

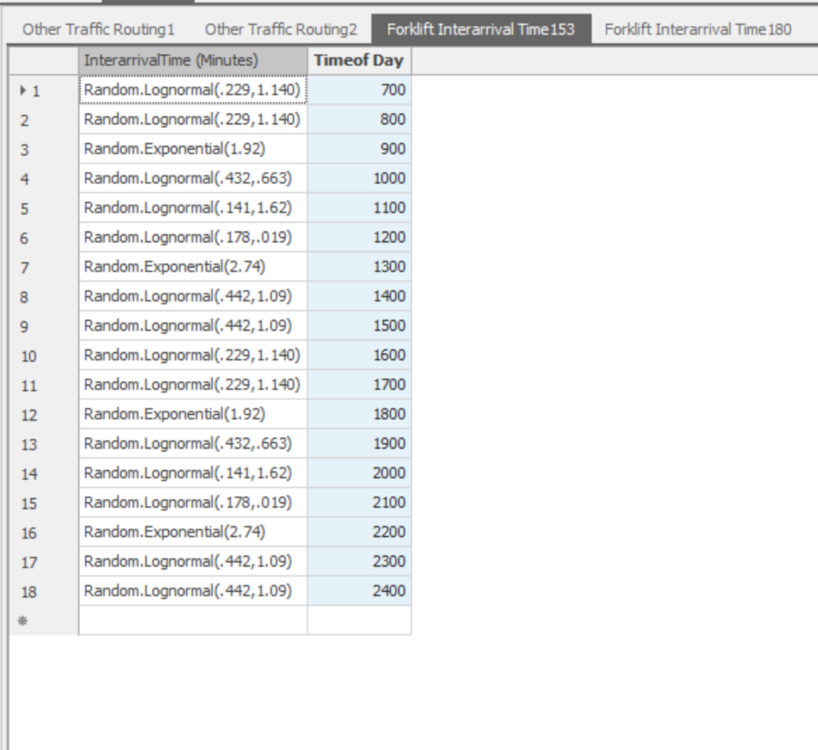

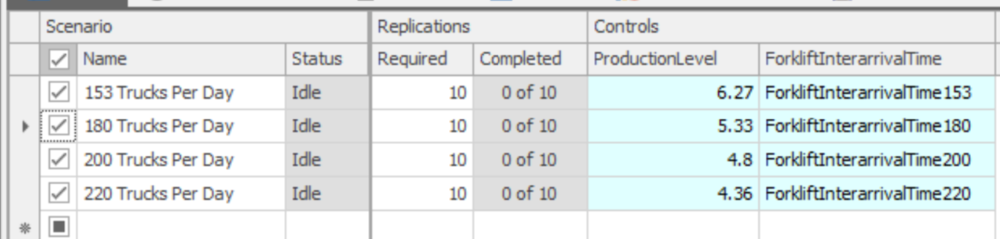

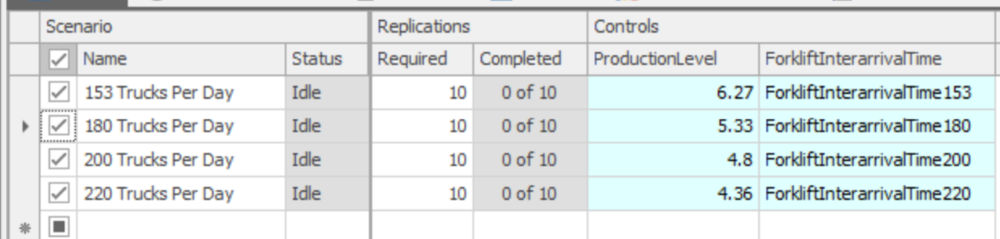

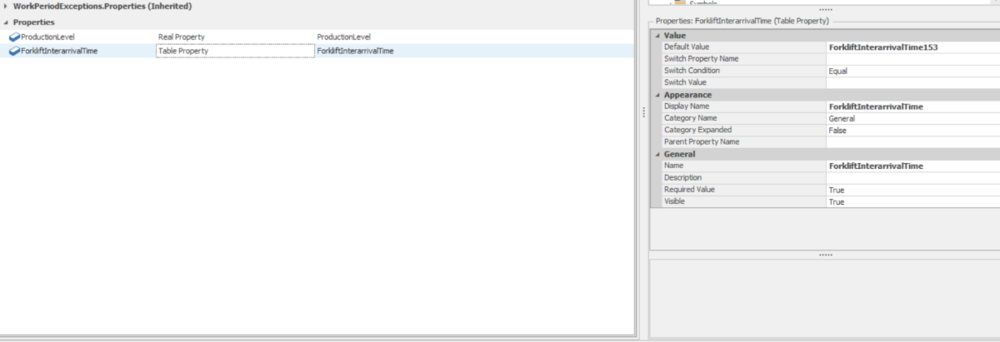

I have a source, called forklift source, that has a varying interarrival time based on the time of day. To do this, I created a time indexed table with the different interarrival times in different rows and the interval period set to one hour. This source also depends on the interarrival time of another source called Newtrucksource, but not on an hourly basis. I am trying to conduct an experiment where the interarrival time of newtrucksource changes with different experiments and a different time indexed interarrival table for source 1 is used for each of these different interarrival times. To do this, I created a real property for newtrucksource's interarrival time and a table property for forkliftsource's time indexed interarrival table. However, I can't get this to work because in the model, the interarrival time property for the forkliftsource must be a "number" and I am referencing a table which comes up as using "string". Trying to find a way to make this work.

-

Property of type Table - pretend Schema-Definition

jzhou replied to bennodual's topic in SI General Discussions

Hi bennodual You can create a table inside your customised object(say MyObject) and the column type match your properties, ie,he first of type datetime and the second of type real. and then convert it to a repeatgroup ,for example its name : tableA and on parent model you can instantiate your object and on the property panel, you will see the repeatgroup to assign. you can create a table directly via the schema dropdown list with the name MyObject, select MyObject.tableA and the table will be automatically created. the next step is refer to this table on the properties panel.