Search the Community

Showing results for 'maintenance plan'.

-

Hi Grant, I see your point. Lat of -160 gets you eastern part of Pacific, and Lat of +160 gets you Asia, but it cuts off at Lat 180 regardless (see image below). I will ask about this, but I think your best short-term plan is to get an image from a mapping app (see image below), paste it in and do the lat/lon math.

-

Hello, and thanks for the Vehicle with Driver model; it seems quite useful. However, I've run into a problem when using two different vehicles that require the same driver; wondering if someone can help. Situation is where a Part (Entity) requires Vehicle_A with Driver_1 to go from Source to Station_1, then requires Vehicle_B with Driver_1 to go from Station_1 to Station_2 (Exit). If another Part arrives at Source (requesting Vehicle_A) while Driver_1 is busy with Vehicle_B, the request gets put into the global VehicleRequestQueue. When Driver_1 becomes free/idle, it looks at the global queue and sees the request, but for some reason Driver_1 seems to ignore it ("...failed to find and plan an eligible visit request"). Is that because the request was for Vehicle_A and not the Driver? If so, how would I get Driver_1 matched up again with Part Entity requests for Vehicle_A? Thoughts? Thanks, John

-

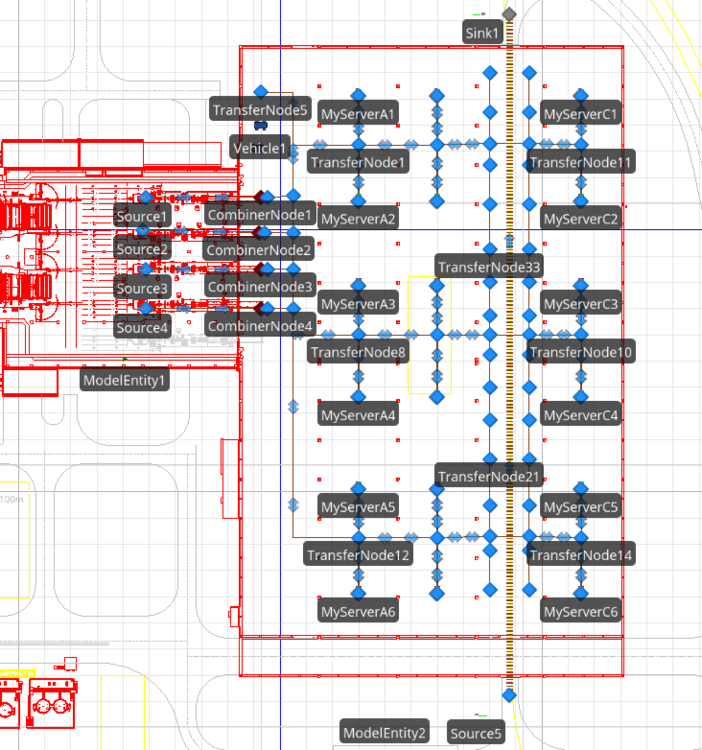

https://jobs.arup.com/jobs/aviation-analyst-9522 Arup is proud to be recognized by Fast Company in their third annual Best Workplaces for Innovators list, which honors businesses and organizations that demonstrate a deep commitment to encouraging innovation at all levels. We find solutions for some of the world’s most complex problems. From climate action to social value, we consider the broadest impacts of our work. We strive to build a more sustainable, resilient, and equitable future. This purpose shapes our culture and has made us leaders in sustainable development. You’d be joining our multi-disciplinary design teams focusing on technical excellence and innovative solutions that create a better future for people, places, and the planet. Start Here, Go Anywhere! Want to work for a company that invests in innovation and people who catalyze impact in the built environment? Arup is proud to be recognized by Fast Company in their third annual Best Workplaces for Innovators list, which honors businesses and organizations that demonstrate a deep commitment to encouraging innovation at all levels. We find solutions for some of the world’s most complex problems. From climate action to social value, we consider the broadest impacts of our work. We strive to build a more sustainable, resilient, and equitable future. This purpose shapes our culture and has made us leaders in sustainable development. You’d be joining our multi-disciplinary design teams focusing on technical excellence and innovative solutions that create a better future for people, places, and the planet. During your career at Arup, you’ll have the chance to engage in a fulfilling career and work with some of the most highly respected engineers and specialists in the world. You’ll also get the opportunity to work on exciting and significant projects, delivering quality work that has a positive and lasting influence on the community and the environment. Responsibilities of this specific role will include, but not be limited to the following: • Perform capacity/demand assessment for planning studies using various tools, methods and techniques • Conduct passenger and baggage flow simulation modelling, interpret results and identify solutions • Develop spatial requirements and program development for infrastructure and facilities planning • Undertake data driven analysis to gather insights including research-based projects • Assist with development of automation tools using programming languages • Assist with development and review of forecast demand • Collect and collate data from surveys, benchmark studies and other sources as needed in support of planning studies • Assist in preparation of reports, presentations and deliverables including illustrations, tables and drawings to communicate complex technical ideas through a graphical and visual approach for a wide range of clients • Generate and contribute to planning and operational reports and provide advice to planning and design teams, airports and airline clients • Project work includes many of the most significant complex airport developments globally • Some travel may be required in the longer term Qualifications Required: • Bachelor’s degree (Master’s degree preferred) in Civil/Industrial/Operations Research/Transport engineering or other relevant disciplines • 2-5 years of increasingly responsible experience in airport planning and analysis • Knowledge/experience of analytical techniques and tools applied in airport planning including spreadsheet, database and simulation software such as Simio, CAST or others • Python or R or similar programming skills preferred • Proficiency in Microsoft Office applications (Word and PowerPoint); advanced Excel user • Demonstrated strong numeric analytical competence and strategic thinking capability • Good written and verbal communication skills essential for team-based working • Excellent planning and organization skills and attention to detail for our fast-paced environment • Must be highly motivated, proactive and willing to take on new challenges Arup is the creative force at the heart of many of the world's most prominent projects across our industry. We offer a broad range of professional services to clients around the world that combine to make a real difference to our clients and the communities in which we work. Notable Projects: • Toronto Pearson International Airport • Montreal Trudeau International Airport • New York John F. Kennedy International Airport • Chicago O’Hare International Airport • Los Angeles International Airport • Istanbul International Airport • London Heathrow International Airport • Singapore Changi International Airport Benefits that Work - At Arup, we have a comprehensive and valuable benefits program that works for our employees and their families. These are 100% paid for by Arup expect for optional life insurance. These benefits provide health and welfare security for you as well as paid time off for rest and renewal. Our Global Profit Share Plan (paid bi-annually) provides an opportunity for you to share in the success of the Firm. As a valued employee of Arup, you can also choose to participate in our GRRSP 5% company match to help you save for your future. COVID-19 Vaccination Requirement - Arup requires all new employees to be vaccinated for COVID-19. Arup is an equal opportunity employer and consistent with federal, state, and local requirements, will consider requests for reasonable accommodation based on disability or sincerely held religious beliefs where it is able to do so without undue hardship to Arup. Flexible Working - We believe that flexible arrangements create a more inclusive way of working that supports our diversity and the wellbeing of our people. Options for alternative schedules and the ability to work outside of the office for a portion of your workweek are available. Arup is an Equal Opportunity Employer. We consider all qualified candidates regardless of national origin, veteran, disability, sixual orientation, gender, gender identity or other status protected by law. If you need any assistance or accommodations due to a disability, please contact us at americasbenefits@arup.com. For the fourth consecutive year, Arup has been named one of Greater Toronto’s top employers! Greater Toronto’s Top Employers for 2021 are recognized for exceptional human resources programs and forward-thinking workplace policies. Find out more about what makes our Toronto office an outstanding place to work here: https://bit.ly/2B3QYL8

-

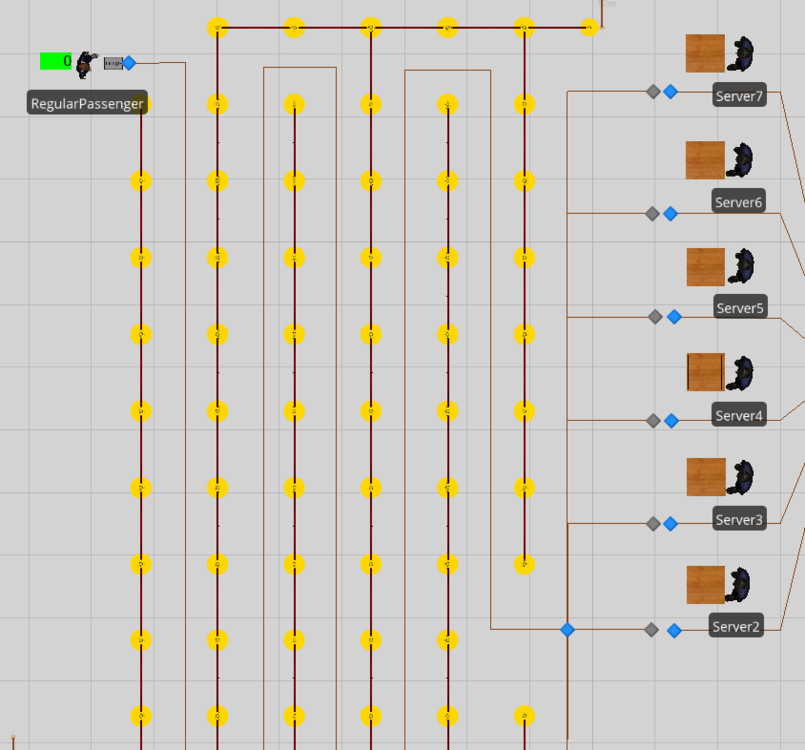

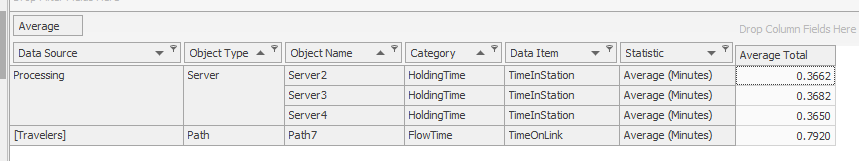

Record Statistics Per Entity Throughout Simulation

Emiliano posted a topic in SI General Discussions

Hi! I have been using SIMIO for quite some time now, but I have barely come across this need. I need to record the time spent per entity at any given path/server in the simulation, rather than obtaining the average time for all entities at the end of the simulation. Take the image below as an example. I need to record the time spent in the link (TimeOnLink) per entity generated. The path corresponds to that connecting the source to servers 2-7. Then, I need to record the time spent per entity on servers 2-7 (TimeInStation). I can display the unique ID number for each entity by Entity.ID, now I need to match the statistics. I figure the best way to model is trough ExcelWrite, but I can't manage to make it work. Any hints? The plan is to get the following information per entity, rather than a summary of all entities.- 1 reply

-

- excelwrite

- entity

-

(and 1 more)

Tagged with:

-

Greetings. I need to model the operation plan for a new warehouse. The model must do the following tasks Receive great amount of bundles from production line (5 lines) Fill the storage cells based upon a strategy (this required an order to do the sloting. this orders must be satisfied by the vehicles). i have tried to do this by using sequence, but i need to repeat the sequence table rows until the cells capacity were completed. this is go to the same cell until its been filled and then change the destination cell (i can't achieve this). Do the prepicking task (again trough disptching rules). Load train or trucks in order to dispatch,. Any help or orientation willbe appreciated Best regards.

-

How do I access a table column by name using a table property defined for the model? In my model, I have multiple data tables each with the same named columns defined for each. Each table has a different number of rows. For a run or a set of replications, I want to select a table to use. I have defined a model-level table property named _SelectedTable to support this. During simulation runs, I want to access this selected table's data by row and column name. Specifically, I want to use this data to update model entity state variables. I also want to stop creating entities when all of the rows of the table have been accessed. I've tried two partial solutions to this problem (attached), but neither are ideal. 1. Create a large set of decide add-on processes to choose the decide the correct table and explicitly reference it by its name. This requires a lot of redundant steps and maintenance if tables are added or removed. The attached example contains just two tables. Controls OptionId and _SelectedTable must be set to either (Option1 and tableOption1) or (Option2 and tableOption2). The first control selects the Entity Type and the second selects the Table. 2. Using the column index number instead of the column name, I found I can use the table property to access the selected table. This method is prone to error if the table schema changes. It is also unclear which table properties, such as "AvailableRowCount" are accessible via this approach. The attached example contains two tables just as the previous. The control _SelectedTable chooses which table from which data is acccessed. In practice, the data tables will be substantially larger than the ones included in the attachments. Looking forward to constructive guidance, Ryan table_selection_by_name.spfx table_selection_by_column_number.spfx

-

Hello, I'm wondering if anyone has a good idea for how to view a resource's utilization according to the day of the week in the pivot grid of an experiment? Currently, my best idea is to just have a status plot in the facility window to illustrate this but I'd prefer to have an average utilization by day of resources in the pivot table. The scenario I'm working with is having "technician" resources that are being seized by server objects to do "maintenance" on the truck entities coming into the maintenance shop. I'd like to see which days of the week are the busiest so I could determine where to schedule new technicians. Any help is greatly appreciated. Thanks! Pit-To-Bay Off-Shift Rule Fixed.spfx

-

I need to build a simulation of a train maintenance workshop. Each of the trains are entering and exiting the workshop with always the same daily schedule (day-hour-minute). I have set up two arrival tables (one for train arrival, the other for train departure) which trigger two timers, and it works well. My current problem is that the simulation should now run over 1 year (simulation time). The arrival table is expecting a time AND a date, and I am looking for a smart solution to avoid writing repeatedly the same schedule for the 365 days of the year in an Exel file. Thanks for your suggestions

-

Hello and thanks for reading, I'm building a model that should replicate how vessels are handled within a port area. Within this area, there are multiple Terminals (servers) and ships (entities) that have to visit any number of terminals. Their processing times at each server vary. With their sequences predefined, I have managed to model this accurately, based on a first come first serve or another dispatching rule. I'd like to implement a dynamic sequence. 1) How can I model a certain degree of freedom in their sequences - e.g. a vessel is free to choose between sequence XABZ or XBAZ, depending on the queue size at A or B at the time of leaving X? However, in reality, these vessels enter the system, draft a sequence that is suitable for their loading plan, and then try to reserve serving times at the various terminals. I have tried wrapping my head around ways to model this, but can't seem to think of a way how. I could create a large amount of state variables for each server, that denotes whether or not a certain slot has been reserved, but that is not suitable for running long simulations. I read on this forum post that I could perhaps use a storage element, and store the reservations in there. How would I go about saving reservation-related information? Should I store that on the barge entity or in the terminal's reservation storage? How should I go about modelling timeslots in itself? 2) How can I model 'future' reservations of entities at the various servers? Finally, if this functions properly, and entities can request reservations at the various servers, I would like to have the servers compare all the requests at a certain cutoff time, and for all the doubly requested slots have it allocate the reservation based on the entities' characteristics. 3) Would I have to store the reservation data on both the entity and the server side for them to both make calculations with them, or is it enough to have them all on the server side, and denote whether they have been accepted with e.g. a boolean property? My apologies for the long post. Do not hesitate to ask for more information. Kind regards, Tom

-

I am trying to simulate a model of a factory where 6 hours of planned maintenance occurs every Wednesday at the same time, from 8am to 2pm on the production line. There is a second almost duplicate line which can then be operated when the maintenance begins, it is attached to the 1st line after the source and the first server. The factory is 24/7 in production. When this occurs the 1st line should clear of all entities and should remain empty for the 6 hours. How is it possible to simulate this 6 hours of no production on the first line after the first server and when this happens the source should continue producing but follow another path to a second line after the first server. From this experiment i want to see how many entities can still be created over a period of time when the maintenance occurs by using the second line.

-

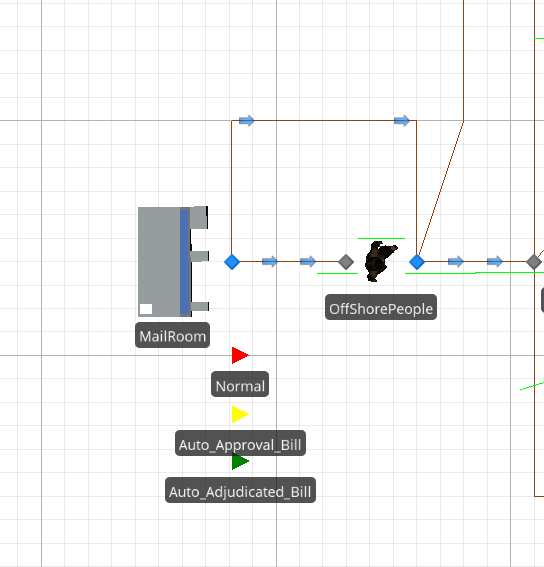

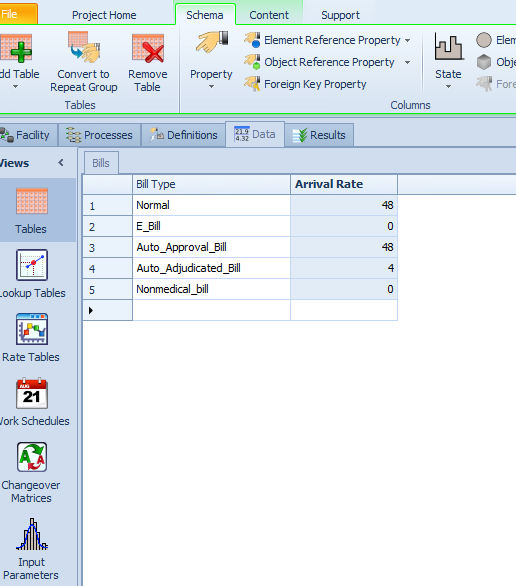

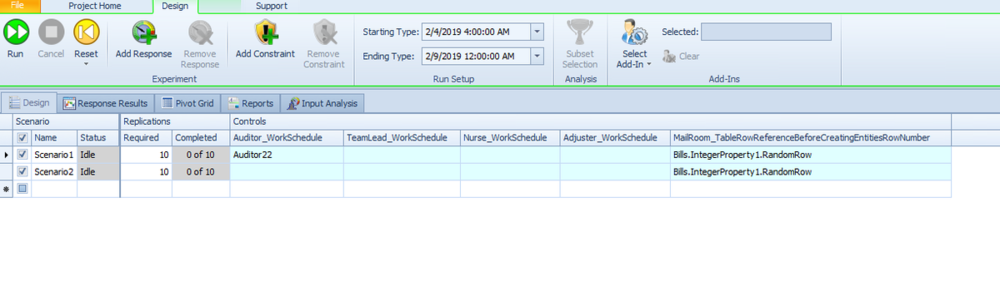

I have several different types of entities. And I want to see the result if I change the distribution of entity types. EG: senario1: A:10, B:20, C:70 senario2: A:20, B:20, C:60 senario3: A:40, B:20, C:40 I want to run experiments for these 3(Actually I plan to run more and more) different experiments and check the results. I don't know How to do these experiments. Anyone has an idea? Thank you!

-

Yes, let's say your entity is created using an Orders table, where the entity has a 'row' in the table associated with it (with arrival time and other data, presumably the customer ID as you mentioned from the excel file). Then, within the ModelEntity object, find the Display Name property (under Advanced Options). The table name/column name can be referenced within the Display Name (and then the Display Name, ModelEntity.DisplayName) referenced from the Dynamic Label Text property - see the SchedulingBicycleAssembly example under Support ribbon, Examples. Then, when the entity moves around the maintenance shop / manufacturing floor, etc., it will be labelled with the information associated with the entity (ID) from the table.

-

Is there a way to label an entity with an ID (customer vechile ID) as it moves around the different maintenance shop? The ID is coming from an excel file. Thanks

-

Yes, I saw the simbits, it wasn't helpful. I have 2 excel worksheet, one list 100 parts, another showing utilization of 50 vechicles for the next 120 months (life span of the vehicle). Each vehicle will have those 100 parts that requires some type of maintenance. Every so often maintenance must be performed based upon the frequency of those parts. How do you traverse the vechicle page both vertially hand horizontally. Plus I need to count up how many parts will be required (with cost) for given year and life span of the vehicle. If i can't get Simio to work, I'll write code. Attached is an example of the data file. Parts vs 1.xlsx

-

Yes, I saw the simbits, it wasn't helpful. I have 2 excel worksheet, one list 100 parts, another showing utilization of 50 vechicles for the next 120 months (life span of the vehicle). Each vehicle will have those 100 parts that requires some type of maintenance. Every so often maintenance must be performed based upon the frequency of those parts. How do you traverse the vechicle page both vertially hand horizontally. Plus I need to count up how many parts will be required (with cost) for given year and life span of the vehicle.

-

I'm very new to Simio. I'm trying to figure out the impact on maintenance schedule/work load. I have excel file with 300 pieces of equipment and forecasted operating hours for the next 5 years by month. The operating hours varies from month to month. As the item gains time, there are different maintenance action that takes place, up to 5 different maintenance actions. The next problem is over the 5 years the number of equipment will double. How do I read the excel file? Each row is piece of equipment, the columns are projected hours of operation for that month. How do I store operating time for each piece of equipment? Thanks

-

Hi, there. I'm very interested in Customizing objects. What I'm trying to customize is a vehicle which has more than one station. I have added some stations on the vehicle and tried an entity is stored in that new station when the vehicle picks up an entity. I know there is a ridestation in the standard vehicle. So, my plan is, first, entities are stored in ridestation then it goes to new stations I made, and when the vehicle arrives at destination node, the entities move to RideStation again , then drop off. are there any process logic to do that? Thank you for your help. Jay.

-

Hello Ahmed, You still have your vehicles set to Network only. But there aren't any paths/networks to follow at all for it. It can't travel from one place to the other without them. Therefore, distance traveled is 0. You could place two nodes at each end of the server and have your vehicles move back and forth between those in free space. You'd have to set your vehicles' initial travelmode to Freespace Only. Next, you have some issues with your logic. Entities are trying to seize the resources/vehicle. You have your tasks set to seize SomeProperty.HasValue. The .HasValue only checks to see if there is a value in the property. Which it does. But the check is more like a Boolean. 1 or 0. It is not a value or quantity. Then you have the number of units of capacity for each vehicle only set to 1 because work schedule. Which is fine. But even if you take the .HasValue off, you are trying to seize more units of capacity than one. Since your vehicles never have that capacity (remember ride capacity and resource capacity are different things) your order will never finish processing and will always be behind. I would worry about the logic of your model. I have modified your model to over simplify things. Which I recommend doing first. Then building upon that. Get an entity to travel from the start to finish before adding lots of other factors in. In the modified model (saved in10.165) , you can see that you have set a Target. The Scheduled finish date versus the actual finish date are tied together. As far as constraints, you will see that in the Planning tab, after running the Create Plan button, there is under the Tasks of Section1 where the Constraints are shown. See image. In this case, it's the resource arrival of a vehicle. I hope this information helps. Thank you, Judy Model 1 Modified.spfx

-

Attached are the files, code and an example of how to automatically run a schedule by dropping a file into a folder. See "SetupRunSchedule.docx" Updated 2017-10-29....Added the ability to add downtimes for Resources in the Event.csv. These will be read into the model prior to running Plan. Updated 2017-07-28....When the schedule is run, it now produces a file called "ExportSchedule.xml" that contains data from the resource usage log and target results. Updated 2019-05-21....Updated files to make is compatible with Simio 11. Updated 2019-09-18....Updated files to make is compatible with Simio 11.194. Updated 2019-11-08....Updated files to make is compatible with Simio 11.197. RunSimioScheduleFiles.zipSetupRunSimioSchedule.docxRunSimioSchedule.zip RunSimioScheduleCode.zip

-

Hi guys I'm doing a model of and evacuation plan for an airplane with 749 passengers. The passengers have to evacuate between the seconds I introduce in the table with the function random.uniform, in seconds and numbers between 0 and 5, that is the time a passenger needs to get up from their seats or walk to the door and jump the security slide. The problem that I have is that I introduce in the table some Random Uniform values to passengers, they must move by the model in that time (between 0 and 5) but, for some reason, passengers aren't taking those numbers, instead they turn in numbers under 0,00. That's a real problem because it's an airplane with 749 passengers evacuating in 5 seconds because of that, obviusly something impossible. Could anyone help me please? Thanks!

-

queuing at server1 when server2 is busy

YavuzKahraman replied to mmashaie's topic in SI General Discussions

HELLO, before asking my question ı want to make some explanations about the model. 1- the model is source- server 1, server2 - sink. server1 and server2 has no connection. source connceted with this two servers and two servers linked to the sink. each server has different processing times. 2- server1 is required 5 minutes in every 10 hours while server2 is required 6 minutes in every 8 hours. server1 cannot give service during the maintenance and maintenance cannot start if there are customers in queue. 3- when either server finishe serving a customer, server takes the next customer from the server's queue, if any, and if server's queue is empty but the other is not, server takes the first customer from the other queue. My question is how to build this model? could you please help me??? -

Hello, I am currently working on a SIMIO model simulating a maintenance workshop. The model is made of roughly a 1000 entities of various type, going through potentially different paths among 30 servers over the course of a year. I would like to be able to extract an excel file keeping the flow history of each entity, meaning at least the date, the server, and the ID of the entity and of the worker used, for each step of the simulation. I feel like this must be possible to achieve using Tally statistics, but even after reading some simbits solution, I can't figure out a way to do this. Thank you for your help, Clem

-

Restaurant Production Professional - (00006882) Description The Restaurant Production Professional is responsible for documenting, maintaining and communicating specifications for restaurant equipment and systems. This role is also responsible for maintaining the information management system for restaurant equipment. Works with key stakeholders to act as a subject matter expert on organizational projects and run the business deliverables. Act as resource and liaison within Restaurant Services. Works closely with the Maintenance Service Company and Real Estate regarding equipment specifications and equipment systems integration. Participates as team lead within the equipment development team. Researches and develops restaurant equipment and equipment systems as directed by key stakeholders. Participates in developing recommendations for the commercialization of equipment and technical support standards. Works with Real Estate and approved vendors on design integration and ergonomics to ensure effective and efficient use of space to meet operational and performance standards for execution in new and existing building designs. Develops research and testing procedures that support programs to sustain current equipment and maximize the equipment’s useful life cycle. Supports future equipment development for improving the system based on input from Operations, Real Estate, Maintenance Services, Risk, Supply Chain and the Quality Management team. Responsibilities Manages activities to organize and implement new equipment launches. Manages resources (time, people) that successfully execute project goals. Uses targeted and quantitative process for implementing equipment solutions Establishes release cycle for shipping deadlines and schedules. Communicates functional and technical standards to internal and external stakeholders. Directs activities for maintaining equipment within the Production Center (PC). Provides recommendations to key stakeholders regarding functional or technical methods to value engineer equipment to help manage initial and operational costs. Monitors progress of equipment rollouts and adheres to timelines. Presents status updates to key stakeholders. Partners with cross-functional team for issue resolution and, coordinates program and equipment development project activities. Works as integral participant in the technical and functional testing Works to improve the effectiveness and efficiency of the testing and monitoring processes Partners with key stakeholders to manage projects through any regulatory approval processes. Partners with the Innovation Team to ensure successful commercialization of equipment concepts. Stays current with technical regulatory and industry regulations and standards. Responsible for maintaining intellectual properties and the technical management systems where information is stored and accessed. Works with simulation and design software to maximize design opportunities Makes contingency plans for all equipment and program development projects, on a quarterly basis. Understand technical testing processes and able to utilize advanced techniques to provide leadership with recommendations Develops Production Planograms to support consistency within the various building design types and sales bands Oversees and completes New Unit Audits activities and action items needed to drive quality and consistency. Qualifications EDUCATION: (Minimum formal education the job requires) Bachelor’s degree or any equivalent combination of education and experience required EXPERIENCE: (Minimum experience the job requires) 2-5 years related experience, preferably in the restaurant industry Demonstrated basic/intermediate-level ability to communicate, influence and negotiate decisions while motivating assigned staff Demonstrated ability to work in a team environment Demonstrated working knowledge of employment laws relating to employee relations and personnel administration KNOWLEDGE: (Level of knowledge required to perform the job effectively) Proficiency in MS Office Word, Excel, Outlook and PowerPoint Working knowledge of WB Maintenance Services preferred Company Management and Operational Practices Preferred CAD experience a plus Simio Simulation Software a plus Revit design software knowledge a plus PROFESSIONAL CERTIFICATION: (Certificate requirement appropriate to position) Lean Six Sigma preferred Learn More: https://whataburger.taleo.net/careersection/exhomeoffice/jobdetail.ftl?job=00006882

-

Hi All, I have a question regarding a maintenance workshop that consist of 11 workers who are used as resources for 4 servers. The worker keeps on working while he is off shift. I tried the simbits; Worker Uses Work Schedule Interrupt Working Off Shift and Resource States When Off Shift. These work with one worker. However, i get the following error when I try to add more workers. Entity: Defaultentity.94 A runtime error was detected at time 11,0 hours at the following process step: Object: Model Process: Resourceoffshift1 Token: Mytoken1.46 Step: [Release] Release1 Property: ResourceReleases.NumberOfObjects Error releasing resources of type specific 'Worker1[1]' owned by object 'Defaultentity.94'. Unable to release '1' object(s) of the resource type because the number of individual resources owned and satisfying the specified release criteria is only '0'. Does anyone know how I can get my workers to stop working while they are of shift? I've added my model to this post. Thanks!! Roeland van Rijssel modelmaintworkshop.spfx

-

Hello, I have an entity traveling on a timepath between 2 nodes. While traveling on this timepath, I would like the entity to undergo a process. I assumed I would be able to invoke an Activity Element based on the mouse-over description, but I am unable to find info via SimBits or on the discussion forum on the Activity element and StartActivity and EndActivity steps which I think will be useful for me. I am running version 7.114.11717 and plan on upgrading shortly. Thanks in advance.