Search the Community

Showing results for 'how to use batch'.

-

Hello everybody, I'm trying to make this work but I cant Type/Conteiner BinBig BinMed BinSmall Product1 1 1 - Product2 - 1 1 Product3 1 - 1 Product4 1 1 1 I want to make a node where these entities (Products and Bins) are convined in one batch, I try to use a process based in decitions and search.. the file is attached if you wanna take a look on it.. (the product have to be the parent) OptimoContenedores2.spfx

-

Hi, You won't need batch logics of the definition. Just the combiner is enough. I made a simplified version of your model. Producto1 requires 1 med and 1 big, while Producto 2 requires 1 small and 1 big. Pay attention to the process that I created at TransferNode1, you'll need to adjust it for the Producto3 and 4. Watch the Combiner Object aswell. Hope it helps. ExampleSimplified.spfx

-

Hello Vinicius, thank you for you help but I still having problems with the model. I can understand the logic behind of the SimBit "CombineMultipleEntityTypeOntoPallets" but I have some doubts. I change the model adding a combiner, I creted a intergrer model entity state to identify the quantity of containers, and I have a real state to identify the container but I dont know how change the batch logic of the container to each product. In the definitios tab you can see the batch logics. I hope you can help me Best regards. OptimoContenedores3.spfx

-

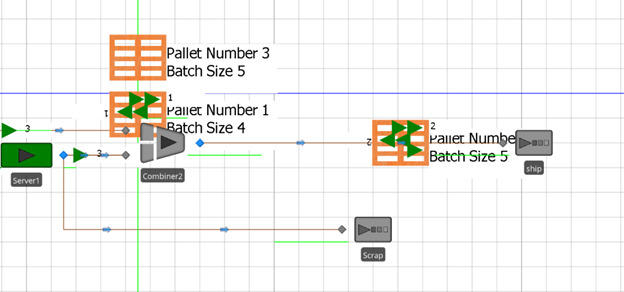

Got issues with a combiner. i have a server that processes the member parts but has a 0.1 probability of going to scrap, this means the batch size has changed. the parent part has a integer state that gets updated when this happens but doesn't update the combiner batch quantity property. I have attached an image showing this issue. you can see the pallet number displayed which is the way i match the parts with the correct pallet. the pallet(parent) also displays the batch size using the same integer state which i use in the combiner logic. Theres a pallet with 4 items on it and it shows the batch is 4 so why wont that process it? Also attached the whole model so you can look at it all Batch and Scrap.spfx

-

Hello, I'm working on a problem where at some point a worker will transport a specific amount of pallets. Whereafter these pallets are processed by a server and a server wil process them. Once processed, a different worker (or the same worker) will move the pallets to the next server. How do I save these entities as a batch and let workers know how much pallets they can process? At the moment I have two approaches. One where I create a 'batch' as an entity and assign to it the amount of pallets. The 'problem' in that case is that I do need to count the amount of pallets at a server, since it has a certain capacity. And sometimes an initial batch whitch comes from a truck needs to be split to fit the capacity of workers. But once this would be fixed, the worker will always transport the right amount of pallets. A second approach that I have tried is to create the pallet entities normally, and assign a 'PalletHistory' in the modelEntity properties, but I find that after processing I can't find this palletHistory for the workers to get a sign of how many pallets to transport. Do any of you guys have an idea how I can approach this? Greetings

-

I wonder if it is possible to pick one particular entity from the BatchMembersQeue and unbatch it. For example I have a pallet with 10 entities batched (9 red and 1 blue) and I want to remove only the blue one. I was able to find the entity with a search step, but I cannot transfer it or unbach it. Any ideas? TnksUnbatch one entity.spfx

-

The manufacturing line I am trying to simulate has two servers whose behavior I am having trouble modeling. First, these two servers are in parallel. Second, these servers process units in batches of 14. Third, I need both servers to not start a batch until at least 14 units are present in queue. Lastly, I need to pool the queue for both servers into a single queue. Any help would be appreciated. Thank you!

-

Hi , I have a system with a combiner, that combines different variations of batches. On exiting the combiner the crane picks the combined entity up and drops up at a server. Each of the different batches will have a different load and unload time. Is there a way to do this? Basically, does batch contain product ‘A’ if so crane time is ‘X Mins’ Does batch contain product ‘B’ if so crane time is ‘Y Mins’ Thanks for any help!

-

Hi, We have a model where we have multiple entity states. This creates interface challenges in defining and populating these states or changing many of them at a time. My question is, can the UI be bypassed in some way using some kind of batch operations? For example suppose I want to assign 150 entity states using string construction and naming conventions easily set up in a spreadsheet. Is there a way to define all those states and import them from a file rather than hand editing each one in the Definitions UI? Another example is I want to set large numbers of these states at appropriate points in processing. Is there any way to do so by just importing name value pairs from a file rather than hand editing each one and copy pasting from a spreadsheet built up accordingly. Thanks Very Much, Jim

- 2 replies

-

- state array

- repeat group

-

(and 4 more)

Tagged with:

-

-

I used to have a similar problem. My advice, avoid the pallet entering the combiner untill you have defined de @new@ batch size, elseway the batchsize wont be updated. In my case I put a scan step in a prevoious node, retaining the pallet ouside the combiner until I've re-defined the batchsize. Let me know if that works Rds

-

Generating new entinty in combiner

Khaled Khamis replied to xdabroar's topic in SI General Discussions

Hi, A combiner is able to combine 1 or more entities into a parent entity. The number of entities that are batched together is specified in the property Batch Quantity. I recommend looking at the SimBit "Combine Multiple Entity Types Onto Pallets" for an example. Best, Khaled -

New to Simio and learning as I go. The attached model includes a CombinerNode1 that batches entities in groups of 2 & 5 (random.discrete). I would like Server1 to use different processing times for the different batch sizes. For example, a batch of 2 entities should be processed in 5 seconds; Batches of 5 entities in 7 seconds, etc.. Eventually I will create batches of up to 6 entities. I have tried using Server1.Processing.Contents for Processing Time, but seems to return the value of 1 all times. Any help is appreciated! Thanks! Processing time based on BatchSize.spfx

-

In the batch that was created, I want to search the member entity with the lowest value for state variable "NumberOfRollContainers" and change its value to: <<TotalREQ" - 0.9 * "CapacityTrip">>, where "TotalREQ" and "CapacityTrip" are state variables of the parent entity. I am struggling with how to use the search step in this situation, so help is appreciated. Thanks in advance!

-

I want to assign a state variable to the batch members of a parent entity, is this possible? the reason for this: I have 2 types of entities (passengers and bags), they separate, then go through different processes and then are combined again. but since the passenger entities have to be combined with "their own" bags, a state (or something else) should be assigned which can be referenced as "match expression" in the combiner. is this the right way of modeling this type of process? or should i do this another way?

-

Tracking amount of pallets in a batch

MauricioBiolato replied to piedz's topic in SI General Discussions

Hope this helps Rds Search Batch example.spfx -

So I have tried doing this, but i can't quite get the workers to pick up the right trolleys. The capacity of the worker is too big and it will pick up more than the batch sometimes. In the logic i tried to use 'search', but can't quite seem to find the right expression. Any ideas?

-

I've ran into the following problem with a combiner: I'm using it to model a load zone where taxis arrive to the parent node, passengers arrive to the member node, and the number of passengers boarding each vehicle is set by a random.discrete distribution (so that for instance 50% of the taxis have 1 passenger, 30% over 2, and 20% have three). This all works great. But now, instead of having my passengers queue at the input node, I was hoping to make them queue at another upstream node, connected to the member input node by a path and every time a taxi arrives, I would like to send to the combiner only the number of passengers that will be batched with the taxi. I tried using Combiner.BatchQuantity but without success so far. From what I've seen by looking at a display showing Combiner.BatchQuantify, it seems it's continuously going through its possibilities, whether a taxi is at the parent input node or not. Then I thought that maybe the number picked to batch passengers with taxis, was selected from that continuously changing value when a taxi entered the parent node, so I tried using the event ParentInput@Combiner1.Exited (as well as ParentInput@Combiner1.Entered) to extract the batchquantify assigned to that taxi but the value did not match the actual batching. So I guess my question is: is there a way to access the value that is picked by the batching process to use it to send the right number of members to the combiner? Thank you very much for your help. Pascal

-

In my model, I have a combiner that batch 1 parent entity and 9 member entities together. I then need these 10 entities, when travelling out of the output node of the combiner, to go to 2 different paths. 5 of them should go on a path to node A and 5 of them should go to another path to node B. I tried using Combiner.BatchQuantity at Output_Combiner_Entered Add-on process but it doesn't work. May I have some suggestions? Note that the batch number is not fixed and will vary during the simulation run.

-

In my model, there is a combiner that generates a batch of 30 entities. After the combiner, I want to assign exactly 30% of the bach population (i.e: 9 members in a 30-member batch) to state "A" and the remaining 70% of the batch population (i.e: 21 members in a 30-member batch) to state "B". May I have some suggestions as to how to do so? Note that the number of members in a batch is varying for different batches Thank you!

-

I’m currently working on a project for my senior design course, in which my team is going to simulate the finishing stages of the grinding operations for the pulp and paper industry. The company we are working with has given us all the data needed to re-create their currently facility layout and production rates for each machine. The scope of the project is to model the current production system while simulating changes to the system in an effort to optimize throughput in a safer, more efficient, and more cost-effective manner. The simulation models will be used to compare different layouts while tracking changes in efficiency and output. Parts arrive in batches, and each batch contains segments that when put together form a circle. This batches can go from 12-16 segments. Depending on customer orders the batches will go through different machining operations until sent to shipping. Therefore, we have created a production schedule from previous customer orders that backtrack to over a year worth of data. The production schedule shows the customer order, the diameter of the circles, number of segments and the machining procedures needed. https://imgur.com/a/EICIy The table shows a sample on how the production schedule looks like (there 6 other columns containing other steps for each order). The problem we are currently facing is figuring out how to input the production schedule into Simio. We must treat each batch as discrete since they all vary in machining. The three-main operation are backing, facing and creep feed. Another issue we are encountering is that Creep Feed only machines one segments at a time in comparison to the other to main operation which can machine a full circle. Again, we don’t know how to tackle this problem. If any of you could advise me into how to go about inputting the work schedule into Simio and how to go about machining a full circle and then by segments. Thank you for taking the time to read. -Juan

-

Dear all, I am currently simulating a 3D printing facility in the frame of my Bachelorthesis and I have a specific problem which I cannot solve by myself. I have four Entity types with different lead times which are specified in a datatable as shown in one of the SimBit solutions. However, I need to batch the entities before they arrive in the workstation to simulate that several parts are processed within one 3D printing build job. The problem is that the workstation only calculates the leadtime of the parent entity and not of each individual member. Instead of calculating: 5hr + 4hr + 3hr + 2hr= 14hr for a batch of four entities, the machine only calculates 5hrs. Is there any solution with a search step to explain the workstation that it should define the batch members and then to add the lead time for each of them according to my datatable and to use the sum as processing time? I am really thankful for any help you can provide, so thank you very much in advance! Greetings from Hamburg, Armin R.

-

Hi All,

In my model, I have a transfer node and the entity could go to either of the next 2 serves as in the picture.

I have assigned product number(1,2,3...) to entities …., if product “1” moves from transfer node to S1 and the next product is also “1”, it should also move to S1 and if the product number changes its should change the server to S2. So the entire batch gets processed on one server.

After processing from S1 and S2 the entity should flow in batch so that at S3 I have batch production

Right now the entities go based on “By Link Weight” and randomly goes to the server which affects S1,S2,S3 servers setup time

Any thoughts how can that be achieved, I do not want to setup a sequence table.

-

Alright - I am going to try to phrase a previous question differently and see if anyone can help because I am still having difficulty with this... In the attached, simplified version of what I am attempting, I have a Parent Entity created. And for every Parent Entity, Math.Round((Random.Uniform(1,4)) number of Member Entities are created. Please help me if possible, to set an expression for the Batch Size that waits for each of the created members and batches them. I have the logic for how they match, but I can't seem to get the Batch Quantity to change based on how many of the Members were created each time. Any help appreciated! BatchingLogic.spfx

-

Hi! I want to model the loading of containers at a terminal. On each terminal there is a queue with containers. Each container has different properties, like the size in TEU (is equal to 1 or 2) and their destination. I want to batch a vehicle (parent entity) to a group of containers (member entities). When the capacity of the vehicle is for instance 10 TEUs, you have to batch an amount of containers to that vehicle. The problem is that I cannot express the Batch Quantity in containers, but only in TEUs. Per container the size in TEUs is known and the containers (member entities) must all have the same destination. What should be the expression for the Batch Quantity? It is the most optimal when the vehicle with a capacity of 10 TEUs will be loaded fully. So, when the first number of containers in the list that will be loaded on the vehicle has a common size of 9 TEUs, the last spot can only be occupied by a 1 TEU container. When the first container waiting is 2 TEUs, this one must wait, but the first 1 TEU container waiting in the queue can be taken by the vehicle. How to model this? Does someone has an idea to model this problem? Thanks!