Search the Community

Showing results for 'forklift and work on board'.

-

MOSIMTEC is looking for smart people to solve interesting problems for the world’s leading organizations. MOSIMTEC uses simulation modeling to help our clients understand the best ways to solve their most complex challenges. At MOSIMTEC, you will work on exciting projects covering a wide range of domains including material handling, mining, chemical processing, manufacturing, supply chains, maritime and port operations, and healthcare. You will be joining a diverse team of passionate individuals that can support your growth as a simulation consultant. Entry to early career positions will be located in Herndon, VA or Nashville, TN. Occasional travel to client locations or company-wide meetings will be required. Learn more & apply at: https://www.indeed.com/cmp/Mosimtec-1/jobs

-

Hello, I am trying to model a situation when a truck which comes for unloading and requires a worker or combination for worker to do the task. Basically I want to know how can I engage secondary resource (Worker or forklift) for loading, unloading or even for transit ( transit I require for cranes ). I am a novice in Simio and will be thankful for any kind of help.

-

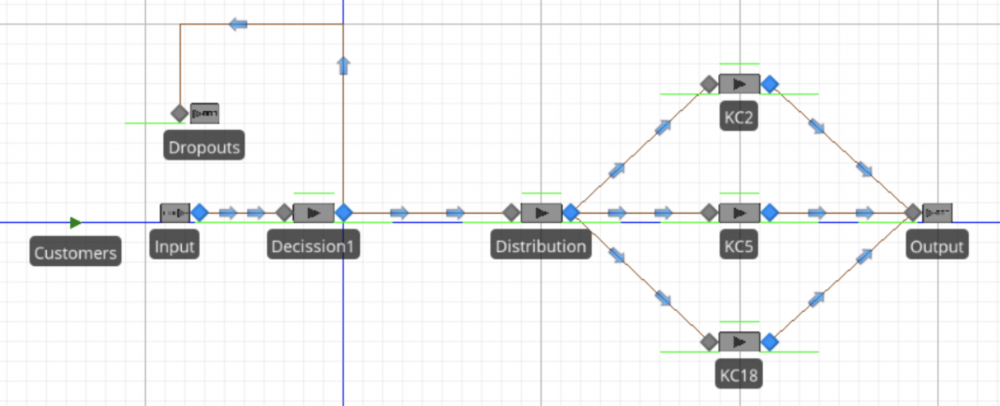

Hello - At the moment, my university group and I, are having troubles on simulating a basic telephone queue in SIMIO 10. We're in doubt on how to adjust each object, so that they can run on specific data we have received from a given source. And more likely on how to set this up? In the uploaded picture below, our basic model is shown. So please, if you have any advice on how to adjust this specific model to run as a basic telephone queue write a comment. All help is appreciated Best regards.

-

I was inspired by the VehicleX3 (vehicle with operator) that was shared on this forum. I would like to use this type of VehicleX3 with an operator who is a worker to simulate a process where the operator is required to take breaks after certain periods of activity. To implement this logic, I think it would be helpful to have Reliability Logic for the worker object in Simio. This doesn't seem to be part of the standard library so I tried to create my own subclass version of Worker with the Reliability Logic "copied" from the Resource object. My attempt to implement this custom object seems to work as long as the custom worker object doesn't "move". If the custom worker object moves, I get the Runtime error "Possible infinite loop detected in process logic". Any assistance in getting the logic working properly, or pointing me to an existing custom worker object that has Reliability Logic incorporated would be greatly appreciated. I'm attaching my small example model to illustrate the error when the worker (P1) is required to move to the Dest1 server as a required secondary resource for processing. WorkerWithFailuresExample.spfx

-

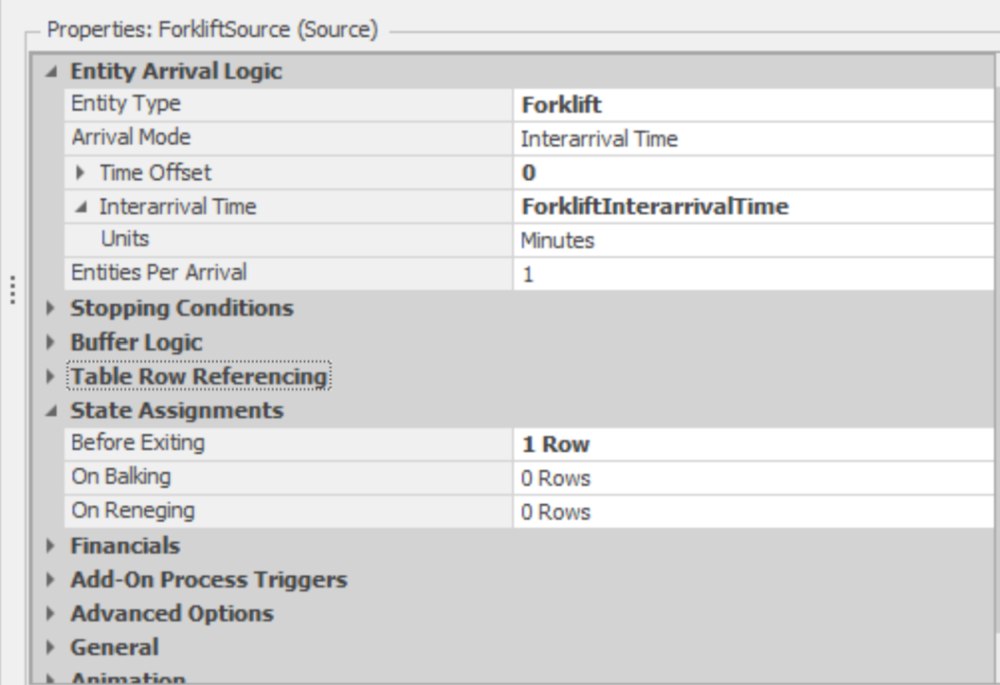

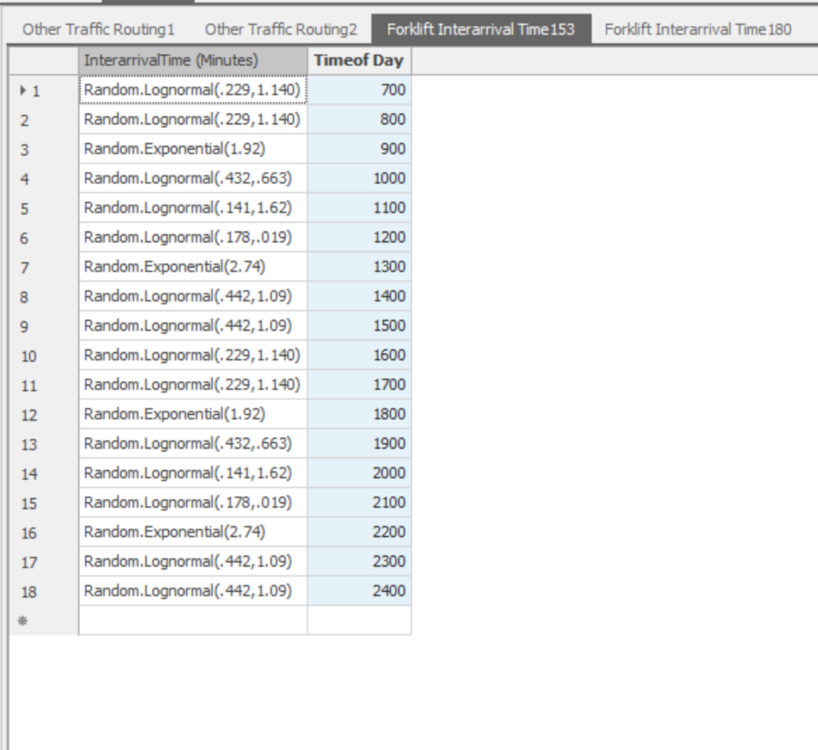

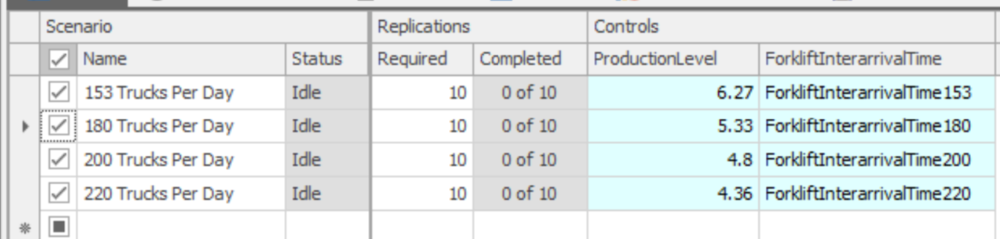

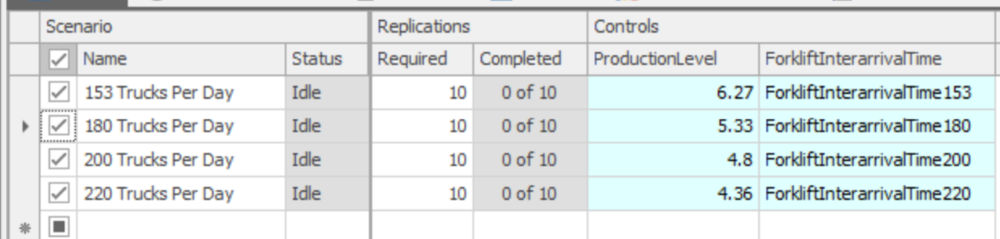

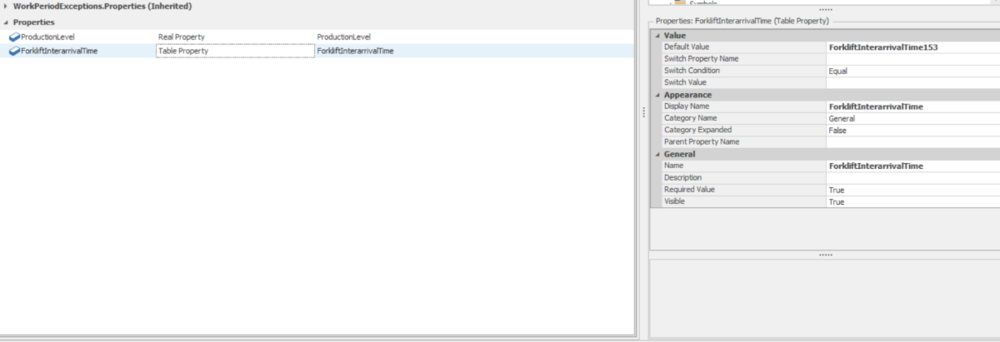

I have a source, called forklift source, that has a varying interarrival time based on the time of day. To do this, I created a time indexed table with the different interarrival times in different rows and the interval period set to one hour. This source also depends on the interarrival time of another source called Newtrucksource, but not on an hourly basis. I am trying to conduct an experiment where the interarrival time of newtrucksource changes with different experiments and a different time indexed interarrival table for source 1 is used for each of these different interarrival times. To do this, I created a real property for newtrucksource's interarrival time and a table property for forkliftsource's time indexed interarrival table. However, I can't get this to work because in the model, the interarrival time property for the forkliftsource must be a "number" and I am referencing a table which comes up as using "string". Trying to find a way to make this work.

-

People often want to model two or more vehicles or entities moving together. There are a few components to this: 1) Seizing the resource appropriately - can be done in processes, but often best done within the vehicle object to make the modeling easier. Here, a vehicle has 4 properties added to support use of an operator. 2) Animating them moving together - the picture below shows use of a second queue animated on the custom vehicle. 3) In some cases, you also need the "driver" to be shown moving. The Attached Animation Speed illustrated below, accomplishes that. I have attached a model that uses a custom vehicle object to model a wheelchair which is "driven" (pushed) by a person to pick up a patient. *********** FOR VERSION 190 AND EARLIER ************************************* VehicleWithDriver.spfx You could use the same approch, possibly with just animation changes, to model something like a truck or forklift that requires a driver. In fact, I just added a second model to that same project that illustrates use in manufacturing (e.g. a lift truck and driver).VehicleWithDriver.spfx VehicleWithDriver.spfx *********************************************************************************** ************** FOR VERSION 191 AND LATER *********************************** VehicleX3.spfx VehicleWithDriver_VehicleX3_Examples.spfx For more information on the update, see the post below. ***********************************************************************************

-

Hi, currently I am doing my internship at a logistics company. I am simulating the warehouse process, but due to the limitation in the number of symbols I have split the process in an inbound model and an outbound model. Now I came across a problem. There is a X number of employees which both work in the inbound and outbound model. Is there a way that both models can make use of one workers list? Or another way to solve this problem. Kind regards

-

Hi Everyone, I have 100s of different products in a warehouse and I want to get statistics for all of them such as distance travelled, number entered and exited. So I created the entity instances for each product automatically through data table. The entity.totaldistancetraveled function doesnt increase since the entity doesnt moveby itself but moved by forklift instead. So I have created a state variable called "distanceonforklift" and increased by the difference between the forklift total distance travelled value when entity exits and enters to forklift. I have also created a function called "distancefunction" on the entity and equated it to "distanceonforklift" state variable of the entity. For the return type of function I have chosen "number" and set the unit to "length". I validated that both distance state variable and function is calculated correctly in the facility window. However I cannot output the result of this state variable on the model results screen. I used the following expression under model outputstatistic but it didnt work. "ProductA.DistanceFunction". That expression gives me 0 value although there are some entities of this product which enters and exits the system. How can I see the average total distance travelled on forklift for the whole population of Product A?

-

Hello everyone, I have a simple production line of 15 servers, some combiners, nothing too complicated. I need to somehow setup the input buffer at each server to have 1 entity at the start of the simulation and then run it. Or having filled servers with 1 entity at each server. Could anyone please help me and show me how to set it up? I need to start counting the stats once all the workstations are filled, but warmup period does not seem to work for that case, because it destroys the enitities at the servers and starts over. The filled-input-buffer-way looked to me like the easiest solution. But if there is another way, please let me know. Thank you!

-

Hi, I have a bottleneck at the end of my assembly line. I cannot dupplicate that station as my total number of workers is already high. Before hiring, I would like to try and reallocate and have satellite employees. I want to allocate my workers to that station when the input buffer has exceeded one entity. Every worker has to finish the entity they are presently working on at the other stations and the first workers that are done need to go the bottleneck station. The rest of the time, the workers can be allocated based on the smallest distance to the work stations. The bottleneck station usually requests 4 workers. That information is already set up in a table. When there is two entities in queue in that buffer, I want workers to be able to go finish the work and hence increase the processing time by X. I have tried a lot of different things, and all my data is stored in relational tables. Thanks!

-

https://jobs.arup.com/jobs/aviation-analyst-9522 Arup is proud to be recognized by Fast Company in their third annual Best Workplaces for Innovators list, which honors businesses and organizations that demonstrate a deep commitment to encouraging innovation at all levels. We find solutions for some of the world’s most complex problems. From climate action to social value, we consider the broadest impacts of our work. We strive to build a more sustainable, resilient, and equitable future. This purpose shapes our culture and has made us leaders in sustainable development. You’d be joining our multi-disciplinary design teams focusing on technical excellence and innovative solutions that create a better future for people, places, and the planet. Start Here, Go Anywhere! Want to work for a company that invests in innovation and people who catalyze impact in the built environment? Arup is proud to be recognized by Fast Company in their third annual Best Workplaces for Innovators list, which honors businesses and organizations that demonstrate a deep commitment to encouraging innovation at all levels. We find solutions for some of the world’s most complex problems. From climate action to social value, we consider the broadest impacts of our work. We strive to build a more sustainable, resilient, and equitable future. This purpose shapes our culture and has made us leaders in sustainable development. You’d be joining our multi-disciplinary design teams focusing on technical excellence and innovative solutions that create a better future for people, places, and the planet. During your career at Arup, you’ll have the chance to engage in a fulfilling career and work with some of the most highly respected engineers and specialists in the world. You’ll also get the opportunity to work on exciting and significant projects, delivering quality work that has a positive and lasting influence on the community and the environment. Responsibilities of this specific role will include, but not be limited to the following: • Perform capacity/demand assessment for planning studies using various tools, methods and techniques • Conduct passenger and baggage flow simulation modelling, interpret results and identify solutions • Develop spatial requirements and program development for infrastructure and facilities planning • Undertake data driven analysis to gather insights including research-based projects • Assist with development of automation tools using programming languages • Assist with development and review of forecast demand • Collect and collate data from surveys, benchmark studies and other sources as needed in support of planning studies • Assist in preparation of reports, presentations and deliverables including illustrations, tables and drawings to communicate complex technical ideas through a graphical and visual approach for a wide range of clients • Generate and contribute to planning and operational reports and provide advice to planning and design teams, airports and airline clients • Project work includes many of the most significant complex airport developments globally • Some travel may be required in the longer term Qualifications Required: • Bachelor’s degree (Master’s degree preferred) in Civil/Industrial/Operations Research/Transport engineering or other relevant disciplines • 2-5 years of increasingly responsible experience in airport planning and analysis • Knowledge/experience of analytical techniques and tools applied in airport planning including spreadsheet, database and simulation software such as Simio, CAST or others • Python or R or similar programming skills preferred • Proficiency in Microsoft Office applications (Word and PowerPoint); advanced Excel user • Demonstrated strong numeric analytical competence and strategic thinking capability • Good written and verbal communication skills essential for team-based working • Excellent planning and organization skills and attention to detail for our fast-paced environment • Must be highly motivated, proactive and willing to take on new challenges Arup is the creative force at the heart of many of the world's most prominent projects across our industry. We offer a broad range of professional services to clients around the world that combine to make a real difference to our clients and the communities in which we work. Notable Projects: • Toronto Pearson International Airport • Montreal Trudeau International Airport • New York John F. Kennedy International Airport • Chicago O’Hare International Airport • Los Angeles International Airport • Istanbul International Airport • London Heathrow International Airport • Singapore Changi International Airport Benefits that Work - At Arup, we have a comprehensive and valuable benefits program that works for our employees and their families. These are 100% paid for by Arup expect for optional life insurance. These benefits provide health and welfare security for you as well as paid time off for rest and renewal. Our Global Profit Share Plan (paid bi-annually) provides an opportunity for you to share in the success of the Firm. As a valued employee of Arup, you can also choose to participate in our GRRSP 5% company match to help you save for your future. COVID-19 Vaccination Requirement - Arup requires all new employees to be vaccinated for COVID-19. Arup is an equal opportunity employer and consistent with federal, state, and local requirements, will consider requests for reasonable accommodation based on disability or sincerely held religious beliefs where it is able to do so without undue hardship to Arup. Flexible Working - We believe that flexible arrangements create a more inclusive way of working that supports our diversity and the wellbeing of our people. Options for alternative schedules and the ability to work outside of the office for a portion of your workweek are available. Arup is an Equal Opportunity Employer. We consider all qualified candidates regardless of national origin, veteran, disability, sixual orientation, gender, gender identity or other status protected by law. If you need any assistance or accommodations due to a disability, please contact us at americasbenefits@arup.com. For the fourth consecutive year, Arup has been named one of Greater Toronto’s top employers! Greater Toronto’s Top Employers for 2021 are recognized for exceptional human resources programs and forward-thinking workplace policies. Find out more about what makes our Toronto office an outstanding place to work here: https://bit.ly/2B3QYL8

-

Hello, a similar question from 2015 was not answered http://www.simio.com/forums/viewtopic.php?f=6&t=1936&p=6252&hilit=selection+condition#p6252. I have the same problem. I want to use a rather complex selection condition, but they don't work. For example: ((Server1.AttributeA == 1) == (Server2.AttributeB == 2)) or Math.If((Candidate.Node.AssociatedObject.Is.TypeA),something) I checked my conditions extensively and they should work, but they dont. It seems only "simple" selection onditions work. Does anyone know something about that?

-

I am trying to run an experiment for 7 days (with 2 day warm-up) and I was hoping to find out what impact Work Schedules have on this. So I have 8 hour shifts scheduled with various resources scheduled to go off shift at times specified in the work schedule. When running an experiment for 7 days, does SIMIO run during the off-shift period as well because my experiments seem to be extremely slow i.e. if my day shift is 9 am - 5 pm, does the experiment carry on working from 5 pm even though there is no activity at night and start again at 9 am on the Tuesday and so on till the end of the seven days? I now this may be a trivial question and would appreciate any help with this.

-

Leaving it as is should work for your purposes?

-

About the job Position: Industrial Simulation Services, Simulation Developer Location: Kitchener, Ontario Experience: 3-5 Years of relevant work experience Division: OTTO Motors Area of Study: Industrial/ Mechanical/ Mechatronics/ Systems Engineering NOTE: Must be able to travel to the U.S at time of application. About Clearpath Robotics Inc. Clearpath Robotics Inc. develops the future of robotics technology through development and sale of industry-leading self-driving technology, products, and services to over 500 of the world’s most innovative brands. Proprietary hardware, software, and services are delivered through the company’s research and industrial divisions: Clearpath Robotics and OTTO™ Motors. Clearpath Robotics Inc. is an award-winning company with recent awards including Robotics Business Review Top 50 Robotics Company, Edison Award for Innovation, Business Insider Top 40 under 40, and Canada’s Top 100 Employers. About Clearpath Robotics Research Solutions Clearpath Robotics’ research solutions group is a global leader in unmanned vehicle robotics for research and development, and provides hardware, software, and services to enable self-driving vehicle development, deployment, and operation. Clearpath Robotics works with over 500 of the world’s most innovative brands in over 40 countries, serving markets that span mining, military, agriculture, aerospace, and academia. Visit Clearpath Robotics atwww.clearpathrobotics.com. About OTTO™ Motors OTTO™ Motors is making material handling in industrial settings safer, easier, and more efficient through development of hardware and software that automates movement of goods in busy factories and warehouses. The company’s industry-leading self driving technology provides automated and on-demand material handling in the most demanding industrial environments, spanning automotive, medical device, aerospace, logistics, and more. Customers trusting their mission-critical material handling needs to OTTO Motors include Fortune 100 brands GE, Toyota, and Caterpillar. For more information visitwww.ottomotors.com. About the Job Having 10’s of robots run around our offices is great, but having hundreds of robots running around inside our computers is even better. Rich simulation environments offer a wide range of benefits to many aspects of our business: fast research, development and validation, sharp marketing tools and strong customer experience / support. We're looking for a Simulation Developer to create and run simulations that will help us optimize our robot fleets and system solutions. As a part of the Industrial Simulation Services (ISS) team, you will act as a subject matter expert and lead modeling and simulation activities. The ISS team works closely with our Systems Engineering, Applications Engineering and Project Management team, to support overall solution design from initial concept all the way to full system design and deployment. You will be building material flow strategies (based on self-driving vehicles) for products already in our arsenal and ones that do not yet exist. Your goal is to develop accurate and robust simulations to evaluate design, lower risk, and enhance the elegance of our solutions to fuel our growth. Primary Responsibilities Creating discrete event simulations for real and hypothetical systems, estimating fleet sizes, identifying traffic bottlenecks, testing what-if scenarios to optimize performance of robot fleets Consulting with project leads, sales team members and customers to obtain understanding of the requirements and to collect the necessary inputs Advising on simulation based metrics to evaluate system risks and performance Analyzing results and making recommendations for facility and material flow design Presenting your simulation results to our team of engineers, our sales team, and to clients Validating models against real world data to maintain accuracy relative to product portfolio Growing and improving our simulation library and internal templates for functionality, accuracy, scalability and efficiency Drafting functional specifications, proposals and effort estimation Recommending product feature and improvement ideas to our Product and Engineering teams, that lead to greater system optimization in the real world Additional tasks may include: Interacting with our development team as necessary to assess impact of new feature or product Developing simulation models to assist Sales & Marketing in demonstrating Clearpath's products and capabilities Using your expertise to assist our engineering services group in developing the more complex system concepts About You You're excited about the role that robots will play in the future, and intrigued by the challenge of joining a young company in this high-growth market. You have skills and experience that you know can make a difference with the Clearpath team, whether we're looking for them or not. You are driven and view work as more than just a job. You are motivated by making an impact on your workplace and you thrive on challenging and rewarding problems. Most of all, you want to be on the right side during the coming robot revolution. The ideal candidate will have: Proven success using simulation solutions to evaluate feasibility of facility design or operational changes Experience with discrete event simulation tools like Simio, AutoMod, AnyLogic, FlexSim, Delmia, and understanding of its limitations Experience collaborating with cross-functional and external client teams to gather comprehensive data required for model development and/or analysis Fearless in questioning to ensure end users get the most value out of your work. You understand the importance of early goal alignment and scope definition Effectively communicate complex model functionality to the client or internal team for assurance of model results accuracy Customer-first mindset Avid self-learner Ability to work independently with minimal supervision and manage deadlines. Able to cope with sudden jarring changes in projects, priorities, and the local gravity field. Bonus Points for: Experience identifying traffic and material flow bottlenecks and mitigating risk Experience in manufacturing industry Understanding of different industry warehouses. You see block diagrams and flowcharts everywhere and speak the language. Experience with Object-Oriented programming Working knowledge of one or more of C#, Python, VB.NET Exposure to working with ROS, Gazebo Past participation in simulation challenges What’s in it for you: Flexible Hours, Health Benefits, Parental Leave, Vacation, Equity, Community Days (paid), Half-Day Birthdays, Passionate and Dedicated Teams Curious to know more about the culture at Clearpath & OTTO, check out: https://clearpathrobotics.com/blog/category/blog/culture/ Come join us if you feel like our values resonate with you, and if you are interested in being a part of making industrial workplaces safer and revolutionizing automation. At Clearpath, we are committed to building and supporting a culture of diversity, inclusion, and accessibility. We hire the best talent regardless of race, color, creed, national origin, ancestry, disability, marital status, age, veteran status, six, sixual orientation, gender identity, and expression. If you require special accommodation to complete any portion of the application or interview process, please contact 1-800-301-3863.

-

Dear Forum, I am trying to build reality into my model. I have 3 shifts (1st, 2nd, 3rd). 1st Shift works form 7AM-3PM, 2nd Shift works from 3PM to 11PM, then 3rd shift works from 11PM to 7AM of the following day. So, I tried to put in Day Patterns in my schedules and on my 3rd shift, it resulted in an error "Duration must not result in a Work Period that spans multiple days." Is there a way to model these 3 shifts as they actually exist in the factory or do I need to change the time frames to "dummy" time frames so that do not span over a 24 hour period? Thanks, Bill Industrial Enginer

-

I am making a model that simulates trucks coming in with a certain amount of pallets. These pallets are transported with the use of forklifts to a sink. The truck arrives at a seperator where the pallets and trucks are seperated. The idea is that multiple forklifts work on one truck when there is only one. But when a second truck arrives one forklift should switch to the new truck. In the current model they work on the same trucks and react when a new truck comes in they unload it but then continue transporting the pallets of the first truck instead of staying with the new truck. So as soon as a forklift unloads a truck I also want it to transport the pallets within it. I think this has to do with the reservation of the vehicle. I already tried a lot of different options but nothing seemed to be working. I uploaded my model as well and I really hope someone could help me with this issue. Thanks in advance! Model1.spfx

-

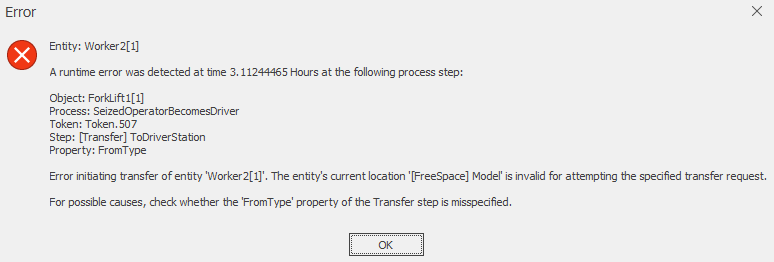

I am trying to model forklifts moving around that require a worker to operate. I found this example under SI Shared items and have tried to recreate as best I can. However, my model is complex in that I have multiple workers and forklifts. I want the forklift to choose an available worker. I can get it to work with 1 specific worker, but when I choose from list of operators I get this error: I have tried all the different Travel Mode options. Any ideas on how to correct this?

-

Senior Industrial Engineer - Simulation Req #: 67308BR York, Pennsylvania, United States Engineering & Technology Platforms & Services Posted on:03/29/2021 Job Summary Career Level Experienced Travel Percentage 10% Full-Time / Part-Time Full-Time Clearance Level - Must Currently Possess None Shift 1st Shift Relocation Available Yes ITAR: U.S Citizen or Green Card Required Yes Clearance Level - Must Be Able to Obtain None Job Description What motivates you? If the answer is a position where you can develop your skills and earn opportunities for advancement while being part of a forward looking team then this is what awaits you in a career at BAE Systems. Our employees work on the world’s most advanced combat vehicle systems. From the M109A7 Mobile Howitzer with its long range firepower to the Amphibious Combat Vehicle that transports America’s Marines from ship to shore, we are developing the technology of tomorrow while delivering the most cutting-edge equipment available today. Our flexible work environment provides every opportunity to positively impact the company without giving up your personal life and we welcome all those who understand the importance of improving production velocity, having big ideas, and craving innovation. We draw strength from our diversity and always put our customers first through an unwavering commitment to bring the warfighter home safe. Does this sound like a team you want to be a part of? If so, come build your career with BAE Systems. The Combat Vehicles line of business within the Platforms & Services (P&S) Sector of BAE Systems is looking for a self-motivated Senior Industrial Engineer to support the production scheduling of armored military vehicles. Working as a team member of a larger Industrial Engineering Group, this Engineer will be required to build and maintain simulations for varied fabrication, assembly, and testing processes. The candidate must also be comfortable with soliciting input through face to face interaction and, in general, must demonstrate that they possess strong analytical, problem-solving, and interpersonal skills that will support individual and team growth. A strong background in discrete event simulation, specifically with the use of SIMIO, is necessary. Specific responsibilities include: Day-to-Day · Complete simulation support activities such as time studies, production line balancing and production metric development · Evaluate complex Technical Data Packages (Drawings, Bills of Material) and be able to understand how a component or vehicle is assembled · Utilize a strong understanding of integration activities like implementation of standard work, material kitting, metric tracking, and process improvement to advance manufacturing methods. · Work on the manufacturing floor with other Engineering disciplines, production supervisors, and employees that directly interact with the components or vehicles being produced. Internal and External Customer Relationships · Engage in regular communications with production support, planning, logistics, quality, manufacturing supervisors, and direct labor workforce to assess operations performance. · Summarize and present findings to internal customers to gain buy-in for improvement efforts · Discuss the status of metrics and key performance indicators with appropriate decision makers Development · Work with Industrial Engineering leadership to understand the expectations of new Engineer within the organization and company · Share responsibility of self-development with immediate supervisor · Maintain a safe work environment and ensure compliance with safety objectives and policies. Required Education, Experience, & Skills - 4+ years of simulation experience within SIMIO - BS degree from an accredited university Preferred Education, Experience, & Skills Demonstrated capability with the use and application of SIMIO discrete event simulation software. About BAE Systems Platforms & Services BAE Systems, Inc. is the U.S. subsidiary of BAE Systems plc, an international defense, aerospace and security company which delivers a full range of products and services for air, land and naval forces, as well as advanced electronics, security, information technology solutions and customer support services. Improving the future and protecting lives is an ambitious mission, but it’s what we do at BAE Systems. Working here means using your passion and ingenuity where it counts – defending national security with breakthrough technology, superior products, and intelligence solutions. As you develop the latest technology and defend national security, you will continually hone your skills on a team—making a big impact on a global scale. At BAE Systems, you’ll find a rewarding career that truly makes a difference. The Platforms & Services (P&S) sector under BAE Systems, Inc does the big stuff: the armored combat vehicles, naval guns, missile launchers, and naval ship repair…just to name a few. Our employees take pride in the work they do and why they do it. They are on the front lines every day, building our products to protect the lives of those who serve. We may be biased, but we think P&S does some of the coolest work around, and we think you will too. At BAE Systems, we celebrate the array of skills, experiences, and perspectives our employees bring to the table. For us, differences are a source of strength. We’re laser-focused on high performance, and we work hard every day to nurture an inclusive culture where all employees can innovate and thrive. Here, you will not only build your career, but you will also enjoy work-life balance, uncover new experiences, and collaborate with passionate colleagues. https://jobs.baesystems.com/global/en/job/67308BR/Senior-Industrial-Engineer-Simulation Thanks, Jenny Ridings, PHR Principal Talent Acquisition Specialist BAE Systems My pronouns are she / her M: +1 904 570 2489 | E: jenny.ridings@baesystems.com https://jobs.baesystems.com Connect with BAE Systems: Join our talent community!

-

Hello, a Server block has a property named "Off Shift Rule" This is normally set to "Suspend Processing", i.e. the server signs off at the end of the shift and abandons all the waiting work. If you want to finish the waiting work, choose the other option, "Finish Work Already Started" I suppose that's what you want.

-

Hi All,

How do I add Efficiency to a server, so that it runs with set Eff, in capacity type I have work schedule and I do not want to use failure equations.

Thanks,

Unmesh

-

Record Statistics Per Entity Throughout Simulation

Emiliano posted a topic in SI General Discussions

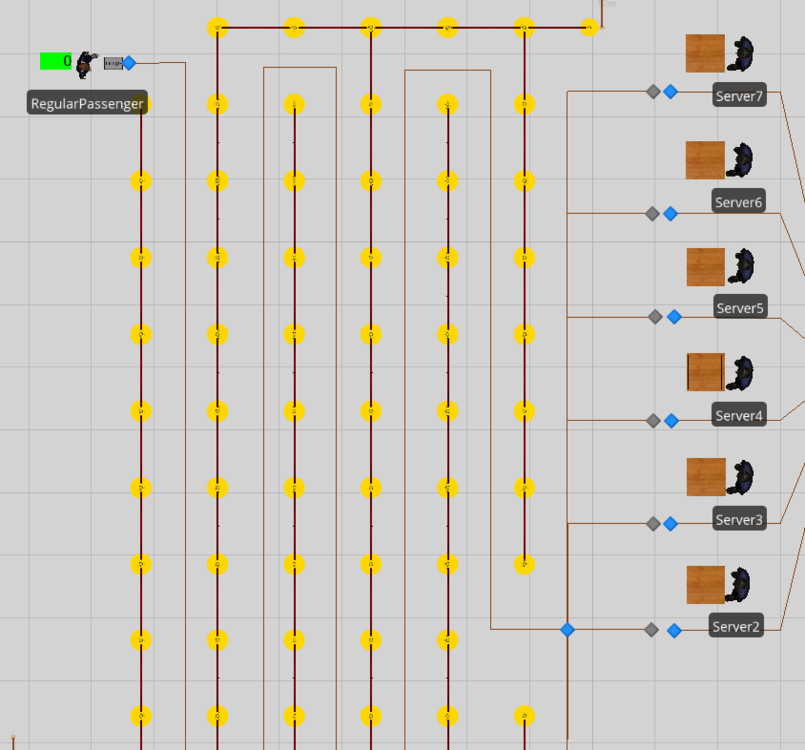

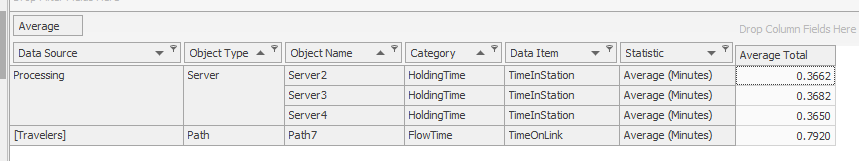

Hi! I have been using SIMIO for quite some time now, but I have barely come across this need. I need to record the time spent per entity at any given path/server in the simulation, rather than obtaining the average time for all entities at the end of the simulation. Take the image below as an example. I need to record the time spent in the link (TimeOnLink) per entity generated. The path corresponds to that connecting the source to servers 2-7. Then, I need to record the time spent per entity on servers 2-7 (TimeInStation). I can display the unique ID number for each entity by Entity.ID, now I need to match the statistics. I figure the best way to model is trough ExcelWrite, but I can't manage to make it work. Any hints? The plan is to get the following information per entity, rather than a summary of all entities.- 1 reply

-

- excelwrite

- entity

-

(and 1 more)

Tagged with:

-

Hi All,

I have defined the input buffer capacity and output buffer capacity for my servers, If the input buffer of destination server is full the vehicle still picks the entity(from output buffer of previous server) and moves to the destination(next) server and just waits with the entity unless input buffer capacity is available , how can I restrict the forklift from not picking up the entity or should only pick when the next server/destination has input buffer capacity available. any thoughts on this would be helpful.

-

Hi Gocken, Sorry for delayed reply. This is very interesting! I have been wondering how a search might work. Thank you so much for kindly taking the time to follow up with this answer. It is very helpful! I am particularly interested in the ability to search the entire population. Thank You! Beat Regards, Jim