Search the Community

Showing results for 'arrival table'.

-

Senior Industrial Engineer - Simulation Req #: 67308BR York, Pennsylvania, United States Engineering & Technology Platforms & Services Posted on:03/29/2021 Job Summary Career Level Experienced Travel Percentage 10% Full-Time / Part-Time Full-Time Clearance Level - Must Currently Possess None Shift 1st Shift Relocation Available Yes ITAR: U.S Citizen or Green Card Required Yes Clearance Level - Must Be Able to Obtain None Job Description What motivates you? If the answer is a position where you can develop your skills and earn opportunities for advancement while being part of a forward looking team then this is what awaits you in a career at BAE Systems. Our employees work on the world’s most advanced combat vehicle systems. From the M109A7 Mobile Howitzer with its long range firepower to the Amphibious Combat Vehicle that transports America’s Marines from ship to shore, we are developing the technology of tomorrow while delivering the most cutting-edge equipment available today. Our flexible work environment provides every opportunity to positively impact the company without giving up your personal life and we welcome all those who understand the importance of improving production velocity, having big ideas, and craving innovation. We draw strength from our diversity and always put our customers first through an unwavering commitment to bring the warfighter home safe. Does this sound like a team you want to be a part of? If so, come build your career with BAE Systems. The Combat Vehicles line of business within the Platforms & Services (P&S) Sector of BAE Systems is looking for a self-motivated Senior Industrial Engineer to support the production scheduling of armored military vehicles. Working as a team member of a larger Industrial Engineering Group, this Engineer will be required to build and maintain simulations for varied fabrication, assembly, and testing processes. The candidate must also be comfortable with soliciting input through face to face interaction and, in general, must demonstrate that they possess strong analytical, problem-solving, and interpersonal skills that will support individual and team growth. A strong background in discrete event simulation, specifically with the use of SIMIO, is necessary. Specific responsibilities include: Day-to-Day · Complete simulation support activities such as time studies, production line balancing and production metric development · Evaluate complex Technical Data Packages (Drawings, Bills of Material) and be able to understand how a component or vehicle is assembled · Utilize a strong understanding of integration activities like implementation of standard work, material kitting, metric tracking, and process improvement to advance manufacturing methods. · Work on the manufacturing floor with other Engineering disciplines, production supervisors, and employees that directly interact with the components or vehicles being produced. Internal and External Customer Relationships · Engage in regular communications with production support, planning, logistics, quality, manufacturing supervisors, and direct labor workforce to assess operations performance. · Summarize and present findings to internal customers to gain buy-in for improvement efforts · Discuss the status of metrics and key performance indicators with appropriate decision makers Development · Work with Industrial Engineering leadership to understand the expectations of new Engineer within the organization and company · Share responsibility of self-development with immediate supervisor · Maintain a safe work environment and ensure compliance with safety objectives and policies. Required Education, Experience, & Skills - 4+ years of simulation experience within SIMIO - BS degree from an accredited university Preferred Education, Experience, & Skills Demonstrated capability with the use and application of SIMIO discrete event simulation software. About BAE Systems Platforms & Services BAE Systems, Inc. is the U.S. subsidiary of BAE Systems plc, an international defense, aerospace and security company which delivers a full range of products and services for air, land and naval forces, as well as advanced electronics, security, information technology solutions and customer support services. Improving the future and protecting lives is an ambitious mission, but it’s what we do at BAE Systems. Working here means using your passion and ingenuity where it counts – defending national security with breakthrough technology, superior products, and intelligence solutions. As you develop the latest technology and defend national security, you will continually hone your skills on a team—making a big impact on a global scale. At BAE Systems, you’ll find a rewarding career that truly makes a difference. The Platforms & Services (P&S) sector under BAE Systems, Inc does the big stuff: the armored combat vehicles, naval guns, missile launchers, and naval ship repair…just to name a few. Our employees take pride in the work they do and why they do it. They are on the front lines every day, building our products to protect the lives of those who serve. We may be biased, but we think P&S does some of the coolest work around, and we think you will too. At BAE Systems, we celebrate the array of skills, experiences, and perspectives our employees bring to the table. For us, differences are a source of strength. We’re laser-focused on high performance, and we work hard every day to nurture an inclusive culture where all employees can innovate and thrive. Here, you will not only build your career, but you will also enjoy work-life balance, uncover new experiences, and collaborate with passionate colleagues. https://jobs.baesystems.com/global/en/job/67308BR/Senior-Industrial-Engineer-Simulation Thanks, Jenny Ridings, PHR Principal Talent Acquisition Specialist BAE Systems My pronouns are she / her M: +1 904 570 2489 | E: jenny.ridings@baesystems.com https://jobs.baesystems.com Connect with BAE Systems: Join our talent community!

-

Hi, I have 6 entities arriving at exactly 8am each day. Each of the 6 entities will create a certain number of entities on arrival from their respective distributions. How do I model in my source? I cannot have multiple sources as each entity has its own server processing times. Please can you help? Thank you

-

Hello, i want to model time varying arrival rates for my entities. If I choose rate tables I can't select random arrival rates. Is there any possibility to do so? Regards Nadine

-

Hi George, I know the normal ways, to create an entity from a table are: 1) Use a timer with the date/time table for a trigger for a own process or 2) A source with the arrival table option. If you want to create entities, maybe you can make a loop process like GFurtado with an Read-Step/Excel-Step and then you can use the Create-Step of Simio. Then you can check with an Decide-Step "TimeNow >= value" for example and create your Entity. With this option you can use FastForward too. With an lower delay time it is near the real time. Maybe this could be a solution for your problem. Because, then you dont need a third party tool to click on import. I checked the Simio API and I dont find something about a trigger for the Simio buttons or a button click event, what we can use for the problem. It would be nice, if there is an API to "use" the button click processes. For example, to import one or all tables again. Maybe a professional Simio API developer know more and can write here. Have a nice day! Best regards Pascal

-

Hi everyone! In my simulation model I created a sub-model and placed many on its facility. On the main model I have a table that only has 1 object column and I want to pass the table to the sub-model as a property. I've done this many times with processes: I create a process property on the object and on the main model I pass the process through its properties. However I can't do this with table property: *On the main model Simio accepts the name of the table I write -> Ok *On the sub-model at Controls I write the name of the table property and Simio returns an error... Why is this? Please, some help.. Thanks.

-

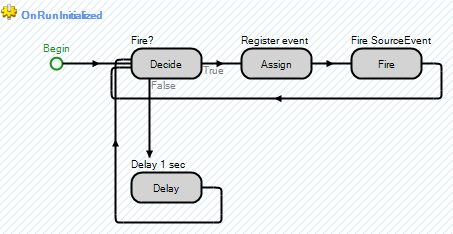

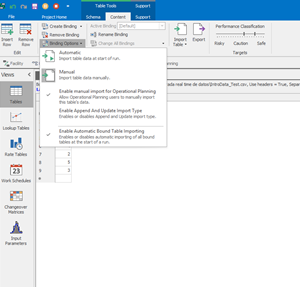

At some point I would start looking for a SCADA system, write it in Python or anything outside Simio. A Simio Engineer would be better suited to help you, but I still believe you could build this inside Simio (maybe through an API?). I manage to build a very ugly version of this that kinda works. It's not real real-time, because I still need to click on the manual import button (I don't know how to help you with this). I set my source's Arrival Mode to On Event; Create a process with a Decide step that checks if the table received a new value: If it received a new value, trigger SourceEvent; If it didn't, check again a second later. As I said, it's not very elegant, but I hope it inspires you to find the right solution.

-

Hi again! Ok! I must've missed it because I tried to use it as a time table (for arrival times) , but now I've tried what you told me before with it as a State and it does update both the table and the simulation! (It takes values at random, but it works! I'll try to find a way to make a time index!) So I'll update my question! Can arrival time tables be modified the same way? Because it didn't work for me using the method we both described! It changed the units and got a bit fuzzy with it, like taking values at random instead of following the order of the table! Referencing the pictures above, it would be like it started following the arrival table in order (3,3,3,4,8,9...) and after I update it it just goes full random and takes whatever value it wants(making it quite hard to check if it actually used the new ones which it usually doesn't for some reason) , is there a way to keep the arrival times following an order after I update the table? Or am I doing something terribly wrong? (Which being honest, is much more likely! haha) Thanks to everyone in advance, and so sorry for my mistake!

-

I would like to refer to a specific row in a date table for a specific property. I found the syntax for this as TableName[RowNumber].PropertyName. However, I want to use a model entity state variable that returns an integer for the row number. The model gives an error saying "invalid syntax". A model state variable works fine, but I can't use a modelentity variable. (TableName[ModelEntity.StateName].PropertyName). Are there any suggestions to solve this issue? Thank you.

-

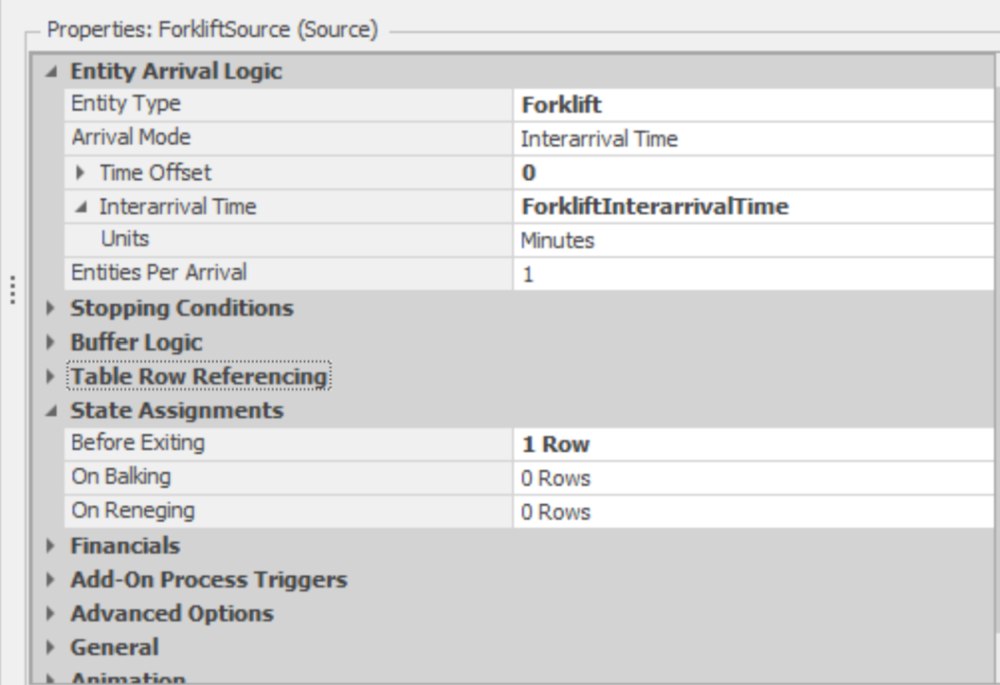

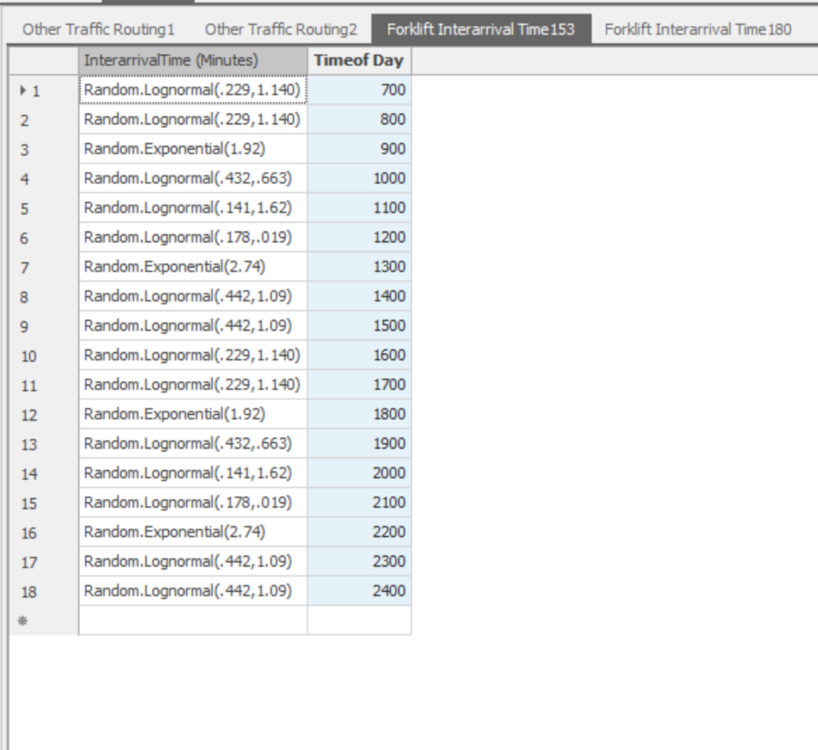

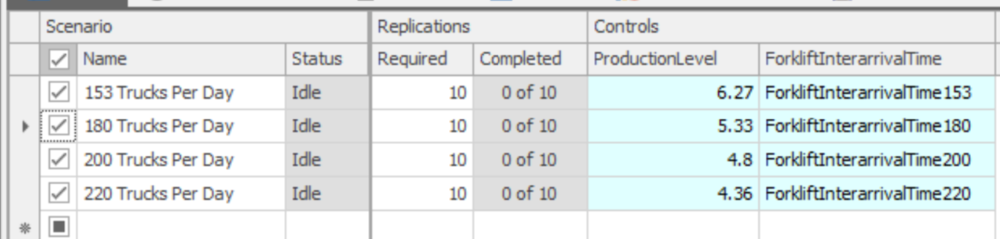

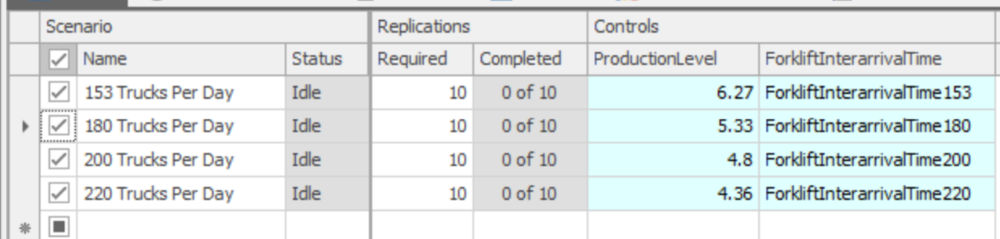

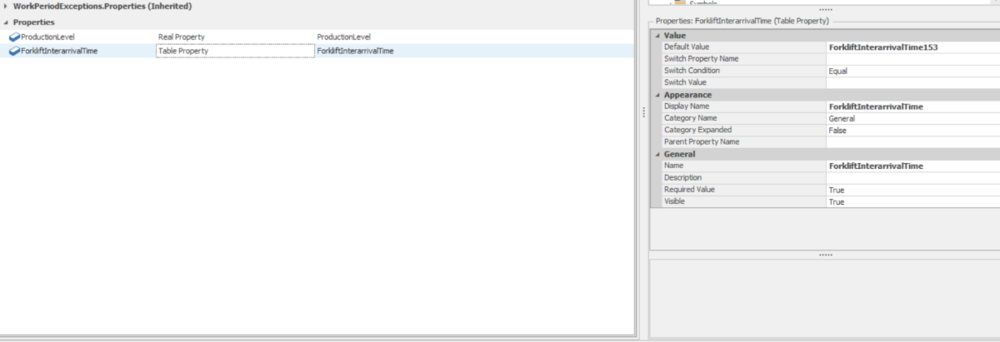

I have a source, called forklift source, that has a varying interarrival time based on the time of day. To do this, I created a time indexed table with the different interarrival times in different rows and the interval period set to one hour. This source also depends on the interarrival time of another source called Newtrucksource, but not on an hourly basis. I am trying to conduct an experiment where the interarrival time of newtrucksource changes with different experiments and a different time indexed interarrival table for source 1 is used for each of these different interarrival times. To do this, I created a real property for newtrucksource's interarrival time and a table property for forkliftsource's time indexed interarrival table. However, I can't get this to work because in the model, the interarrival time property for the forkliftsource must be a "number" and I am referencing a table which comes up as using "string". Trying to find a way to make this work.

-

Greetings, I am building a model which requires 20 entities to arrive at the first hour then four hours of break with no arrivals . Then repeat the same pattern of arrival of 20 for one hour and four hours break in between. I have been using the arrival schedule and use the rate of 20 in the first hour and 0 in the next four hours . However I am not getting 20 entities exactly with this arrival schedule and it is always less than 20. Is there away to force the exact number of entities arriving per hour? Thanks M Alseiari

-

I need to build a simulation of a train maintenance workshop. Each of the trains are entering and exiting the workshop with always the same daily schedule (day-hour-minute). I have set up two arrival tables (one for train arrival, the other for train departure) which trigger two timers, and it works well. My current problem is that the simulation should now run over 1 year (simulation time). The arrival table is expecting a time AND a date, and I am looking for a smart solution to avoid writing repeatedly the same schedule for the 365 days of the year in an Exel file. Thanks for your suggestions

-

Schedule for trains - ideas are welcome -

Kaminos replied to Kaminos's topic in SI General Discussions

Thanks Jzhou, UNfortunately setting this option to True did not behave as I expected. I am using the following Arrival Table: With the timer having "Repeat Arrival Pattern" set to True The simulation runs OK until 17:15, then it starts repeating the table pattern by adding 5:15 hours ---> hence a new trigger happens at 22:15, It looks like the "Repeat Arrival Pattern" option does not take into account the date itself, but rather the time slot duration between two events. -

Property of type Table - pretend Schema-Definition

jzhou replied to bennodual's topic in SI General Discussions

Hi bennodual You can create a table inside your customised object(say MyObject) and the column type match your properties, ie,he first of type datetime and the second of type real. and then convert it to a repeatgroup ,for example its name : tableA and on parent model you can instantiate your object and on the property panel, you will see the repeatgroup to assign. you can create a table directly via the schema dropdown list with the name MyObject, select MyObject.tableA and the table will be automatically created. the next step is refer to this table on the properties panel. -

Record Statistics Per Entity Throughout Simulation

lstretton replied to Emiliano's topic in SI General Discussions

Hi, See attached model that uses an output table to log information on each entity. You could just as easily you an ExcelWrite/Write Step to do the same thing. Cheers, Lucas. Data Table Entity Log.spfx- 1 reply

-

- excelwrite

- entity

-

(and 1 more)

Tagged with:

-

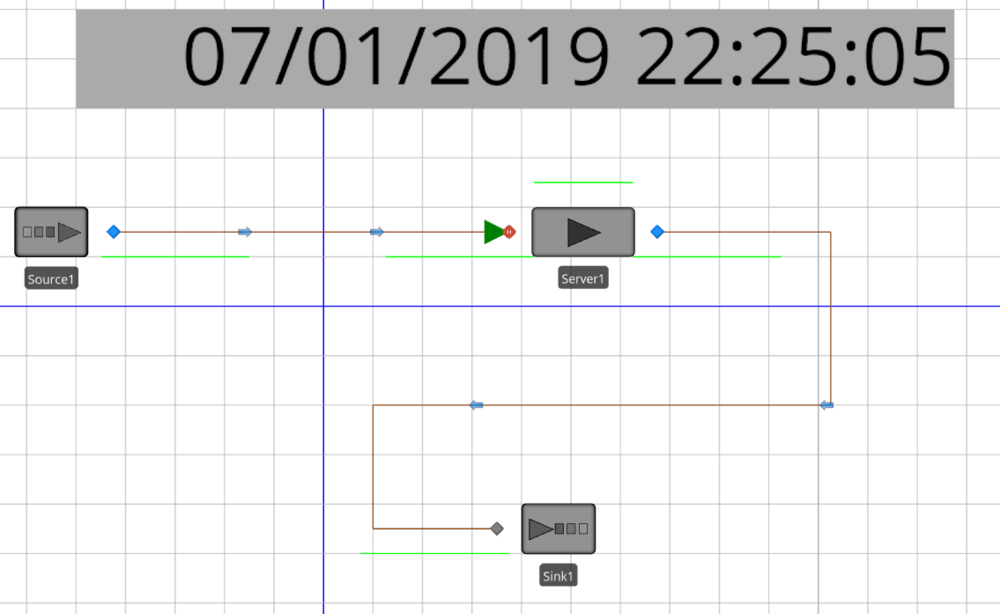

Hi, I have a problem when that I describe bellow in full detail. I have seen a simbit which is similar to my issue but do not know how to extend it. I have uploaded the model the description refers to. Your help is highly appreciated. Regards, Overview The idea is to allow the user choose the processing time for a server but not his entering the experssion himself, but by means of some intermmediate option. In particular, the user is have two options: ‘regular’ or ‘reduced’ for the processing time. According to the user’s pick, regular and reduced will lead to specific expresions contained in a table. The model There are three objects: • Source1 (default values from the estándar library) • Server1 (the processing time is to be chosen by the user) • Sink1 (default values from the estándar library) List There is a String List (named strUserOptions) containing the user can choose from, and contains two ítems: “Regular” and “Reduced”. Properties There is a List Reference Property rpUserOption, whose list is strUserOptions, so that the user can pick one of the above mentioned ítems. Its Display Name property is “Server Processing Time Speed” Table There is a Data Table (tabUserOptionInfo), with two columns: • Column 1 (name UserOption), List Property = strUserOptions • Column 2 (name ProcessingTime): Expression, Unit Type = Time, Default Units = Hours The table has two rows, as follows: Regular random.exponential(5) Reduced random.exponential(4.5) The objective My intention is that the user chooses either Regular or Reduced from the model property window and the corresponding value for the Server Processing Time is chosen for Server1 case_unsolved.spfx description.docx

-

Define incoming patients' admission to hospital dates as a "DateTime" Property in your table. And set "Arrival Mode" of Source object as "Arrival Table". Then, set arrival Time Property as "DateTime" property you defined. This will provide creating entities according to their admission to hospital times.

-

Hello, Storing this information in a Data Table and using a Search step might be the best approach. The Search expression will probably need to look for a specific Group and also check that the MaterialName is in stock. If the Table is listed in priority order, you will need to just Search forward until the criteria is met. You will either need to execute the Search step a few times and have a variable for the Group letter, or just have three separate Search steps specifying the exact group. Liz

-

Greetings. I need to model the operation plan for a new warehouse. The model must do the following tasks Receive great amount of bundles from production line (5 lines) Fill the storage cells based upon a strategy (this required an order to do the sloting. this orders must be satisfied by the vehicles). i have tried to do this by using sequence, but i need to repeat the sequence table rows until the cells capacity were completed. this is go to the same cell until its been filled and then change the destination cell (i can't achieve this). Do the prepicking task (again trough disptching rules). Load train or trucks in order to dispatch,. Any help or orientation willbe appreciated Best regards.

-

Hi Jim, May be there are many possible ways to follow to get the information you want. But, I suggest you to use a search step for searching a server's (or any other object's) processing queue to get such information. You can search not only the server's processing queue but also the whole "entity population" to get whole state variable's defined on them at any arbitrary time thoughout the simulation run. All you have to do is to define additional expressions on search step. In the example file attached a simple model is developed to get entities' state variables residing at server1's processing queue. Here note that, you have to click button at arbitrary times. Then, if 3 or more entities exist at server1.processing queue, the search step founds the first 3 of them (since a forward search is performedin this sample model) then later an excel write step writes entities created time (you can get many state variables of entities written on the same excel file). You can change search limit, queue state name, include a match condition etc. If you want to get such information at the beginning or at the end of the simulation run you should use this same logic at appropriate processes (onrunending, onruninitialized etc...). Also, you can get these information written on either a database or an output table as well. Hope this helps? getting a snaphot of Entity WIP via a button.spfx entities_processing.xlsx

-

Hi Gocken, Thank you for your kind and quick response! I really like this use of a button! Unfortunately, I was not clear enough. As entities move through the system they carry quite a lot of state information. Our desire is at end or replication or an arbitrary time like a button click which a neat idea, to take an inventory of all the entities AND their states. This would mean capturing all the entities in each processing queue and through a write step. writing them out, either to an output table or a CSV. This operation is a bit complex. It does not seem one can search a processing queue to sequentially write out its members properties. I believe it is possible to maintain the residence of servers by maintaining that in a special output table which is tedious to maintain and set up. I greatly appreciate your response! Best Regards, Jim

-

Hello. How can i get the row index where the max value of some data table column is stored? I need this because in my model i will seize workers based on this max value. edit: Using Maximize Expression will get me there?

-

Hey, I want to store information of each entity in a data table with tally statistics. I looked at the TallyStatisticsInTables-SimBit and implemented all steps in my model. My Tally Step stores the current NumberInSystem of my entities. So I created a data table with one column 'Entities_NumberInSystem' (Type Tally Statistics) and a TallyStatistic named 'EntitiesInSystem' which I referenced in the first row of my data table. The Tally Statistic Name in the Tally Step is set to 'Table1.Entities_NumberInSystem'. When I want to simulate my model I always get an error message: 'Error evaluating the value of property 'Tally Statistic Name'. Invalid data table reference Table 1.' Where is the problem? Could you please help me?

-

Entity Distance travelled on Transporter

ttarkan replied to ttarkan's topic in SI General Discussions

Hi again Liz. I found the problem but it wasn't easy to figure out with the RowForKey formula. I used the search function with tablerows as collection type. When I filtered the trace on the search and tally process, I found that the the table index of the found item and index of the search function was not the same in some cases especially for "small" type products. Further even the available row count of the products table was not returning the correct number rows in the table. The products table has 810 rows but it was finding 197 rows only in the search function. I had a separate "productsize" table which consists of "size" key string property and some other real type properties such as forklift capacity for each product size. I had used this productsize.size as foreign key in my main products table. I figured that the search function automatically filters to the products those matches the size of the product eventhough in search function match condition I only write ModelEntity.EntityType==Products.ProductName. When I removed the foreign key from the products table the problem was solved. Thanks for your help anyway. It was very useful and saved a ton of time from me. -

Hi Everyone, I have 100s of different products in a warehouse and I want to get statistics for all of them such as distance travelled, number entered and exited. So I created the entity instances for each product automatically through data table. The entity.totaldistancetraveled function doesnt increase since the entity doesnt moveby itself but moved by forklift instead. So I have created a state variable called "distanceonforklift" and increased by the difference between the forklift total distance travelled value when entity exits and enters to forklift. I have also created a function called "distancefunction" on the entity and equated it to "distanceonforklift" state variable of the entity. For the return type of function I have chosen "number" and set the unit to "length". I validated that both distance state variable and function is calculated correctly in the facility window. However I cannot output the result of this state variable on the model results screen. I used the following expression under model outputstatistic but it didnt work. "ProductA.DistanceFunction". That expression gives me 0 value although there are some entities of this product which enters and exits the system. How can I see the average total distance travelled on forklift for the whole population of Product A?